Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

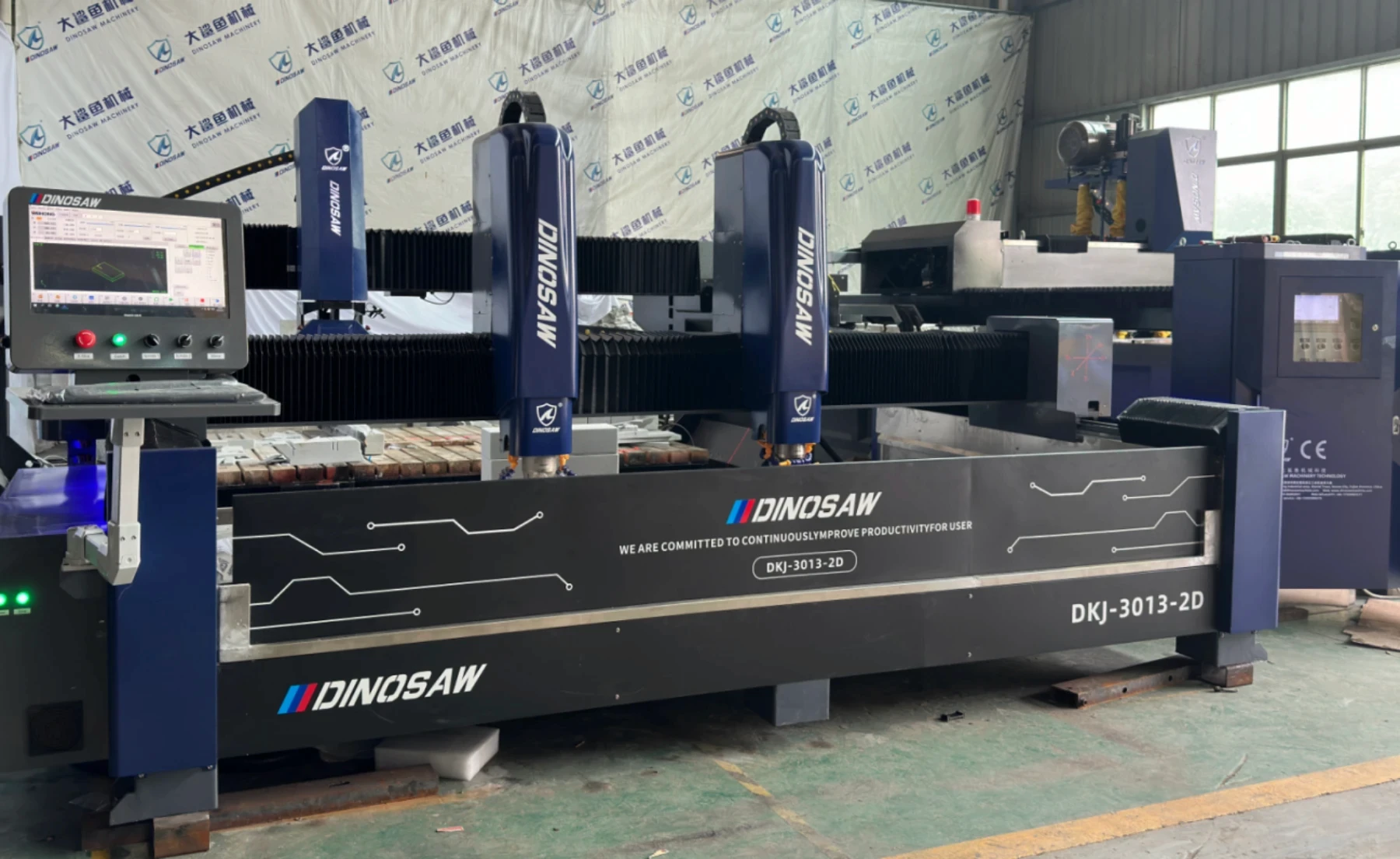

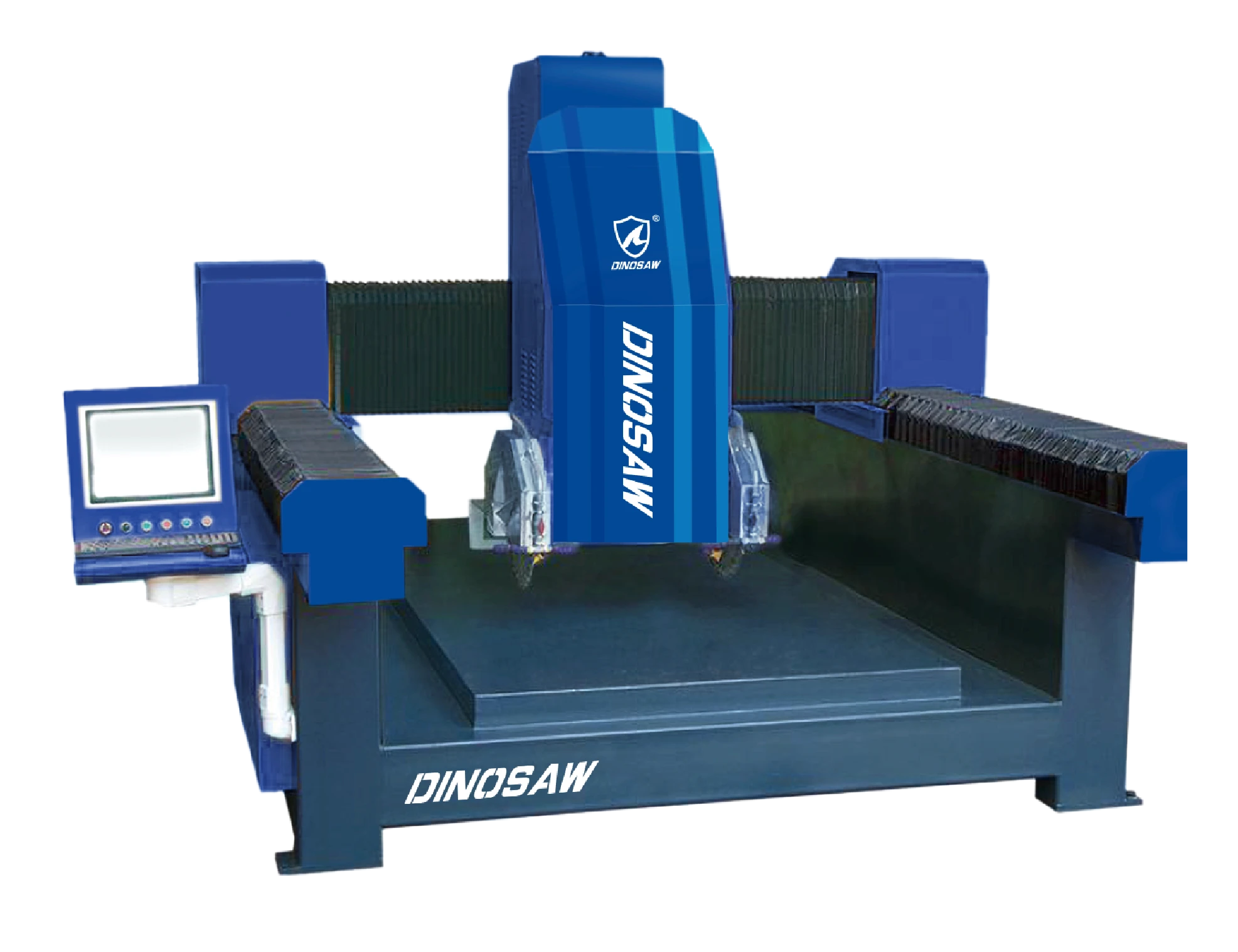

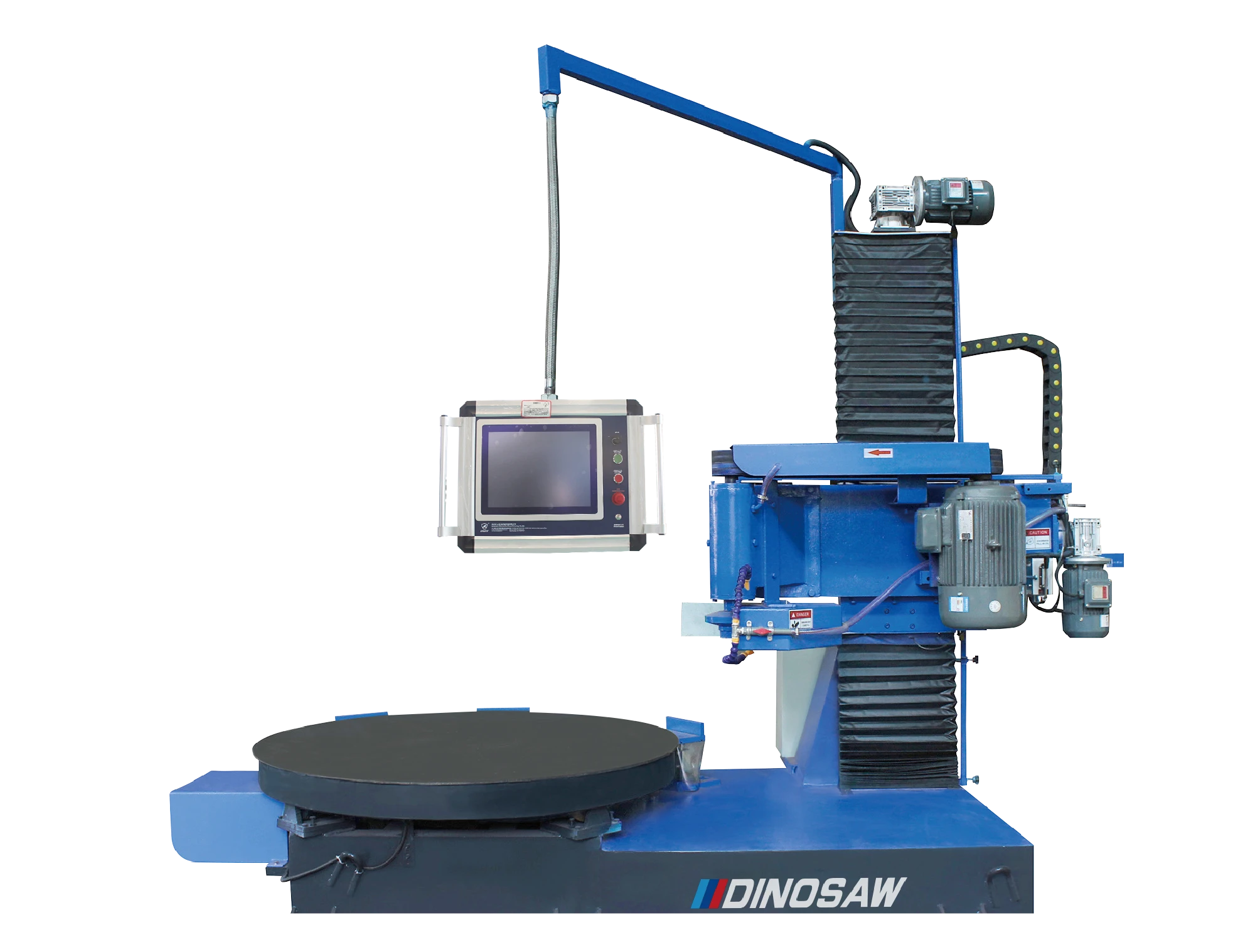

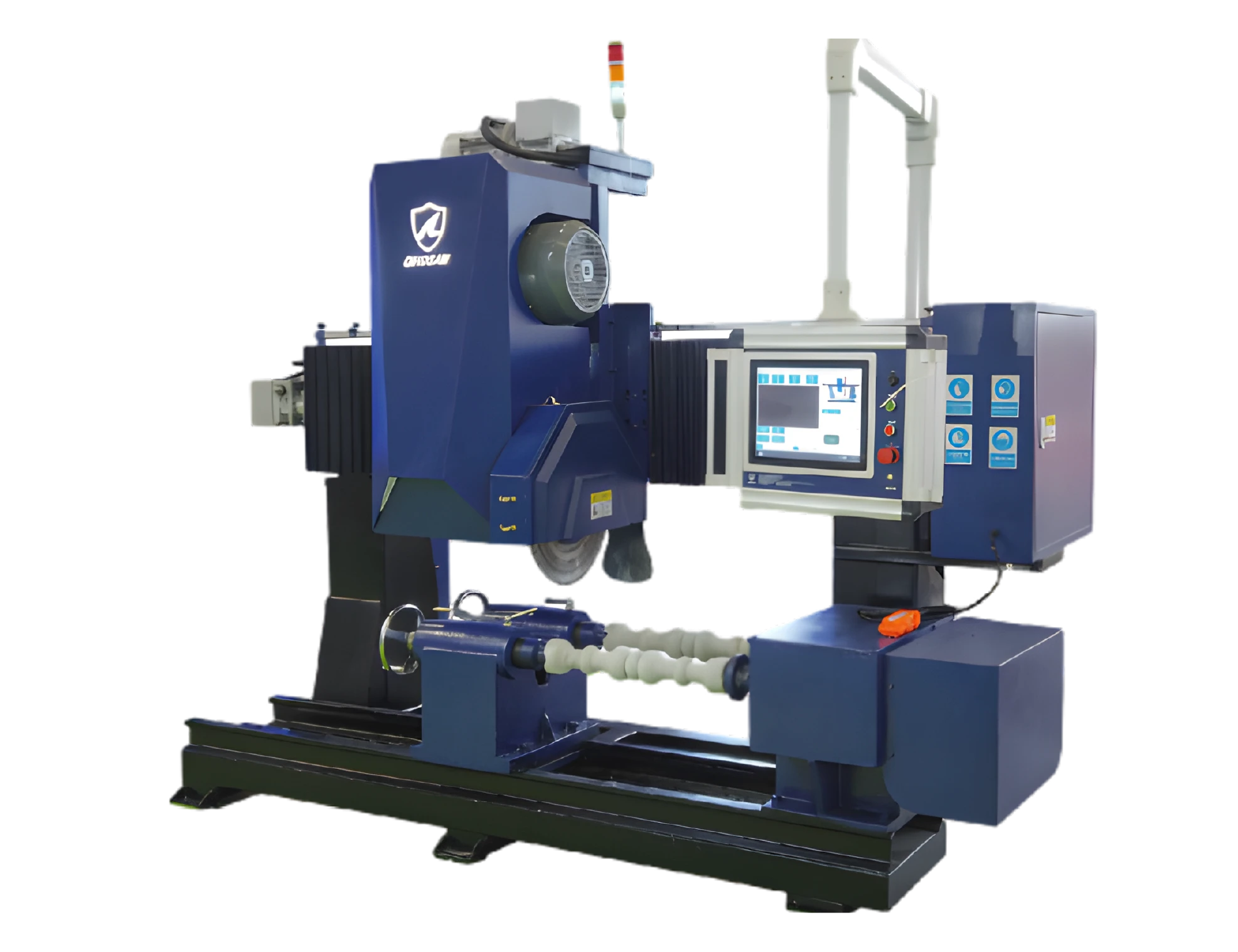

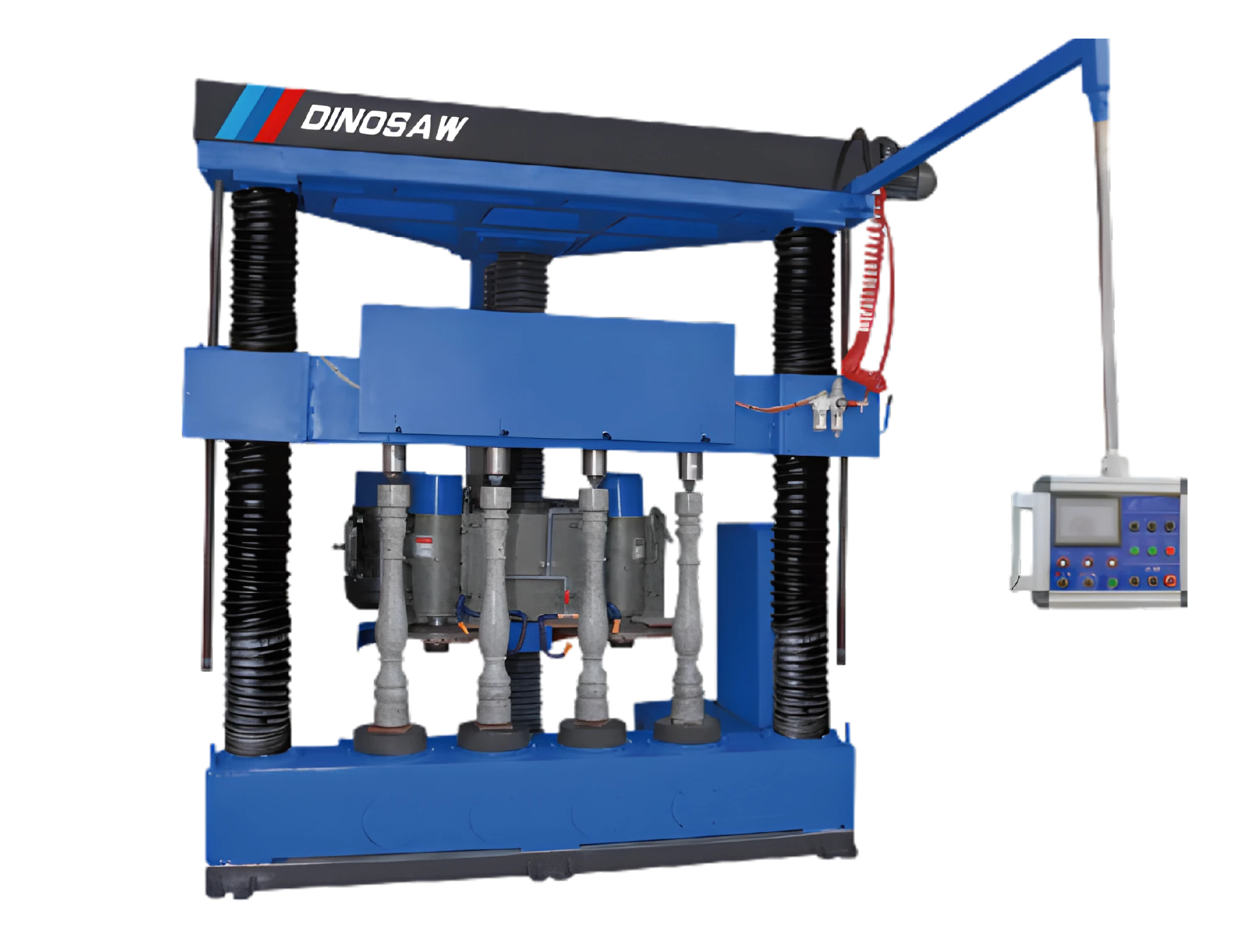

Profiling Machine

Discover Dinosaw’s versatile profiling machines, including bridge profiling machines, vertical models, and horizontal models. Designed for crafting Roman columns, balusters, decorative moldings, and more, these machines offer precision, efficiency, and advanced automation.

What is Profiling Machine?

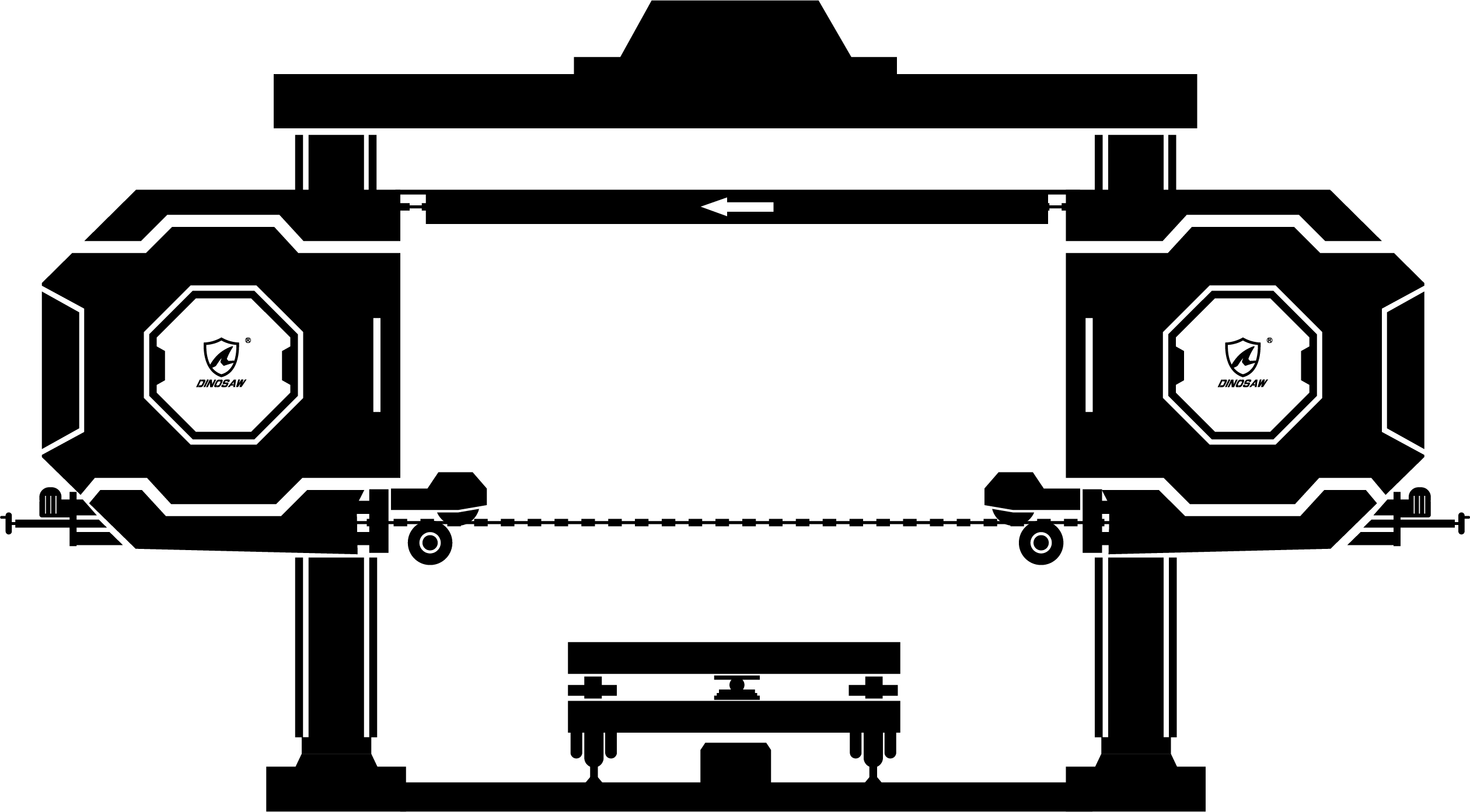

A stone profiling machine shapes architectural stone pieces by cutting or turning along a preset profile. Typical products include balusters, columns, bases/caps, spheres, and decorative profiles for marble and granite.

In English, it’s often described as a stone shaping machine. For round workpieces, buyers commonly search “CNC stone lathe.”

Main types

Lathe-type (turning): round balusters, columns, vases, spheres

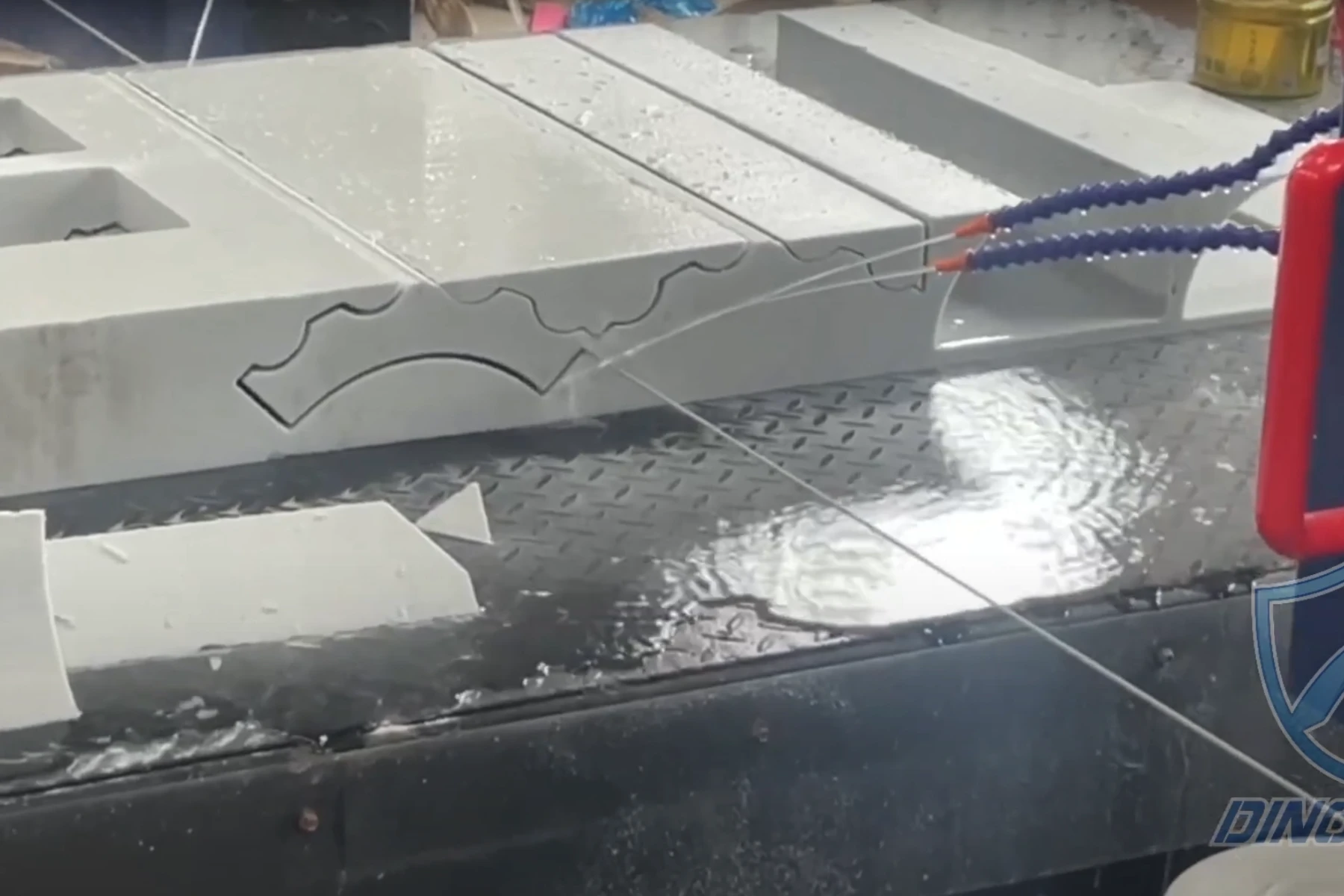

Saw-based / linear profiling: square profiles, caps & bases, structured decorative shapes

Selection tip: choose by your main product shape (round vs non-rotating)

Profiling Machine Project Cases

Custom Stone Shaping Results

Profiling Machine Operation Guide

How To Create Custom Shapes

Profiling Technology News

Stone Shaping Updates

How to Make Stone Balls Using CNC Stone Lathe ?

What Is a Stone Profiling Machine? A Fabricator's Guide

Best Stone CNC Machine 2025: A Buyer's Guide

Top 10 Stone CNC Machine Manufacturers (2026 Guide)

Which Stone Lathe to Choose: Vertical or Horizontal?

Is a CNC Stone Lathe Worth It? A Complete Cost-Benefit Analysis

Profiling Machine Buyer Guide: Choose the Right CNC Model for Architectural Stonework

Profiling Machine Buyer’s Guide (Balusters, Columns & Architectural Moldings)

In architectural stonework, a “profiling machine” usually means shaping by cutting or turning to produce repeatable decorative geometry—balusters, columns, caps/bases, and linear moldings. In English markets, you’ll also hear stone shaping machine. For round turning work, buyers often search CNC stone lathe.

1) Fast Model Match (Choose by Geometry First)

- Round / rotational parts (balusters, columns, vases): start with turning/lathe-type models.

- Large, heavy round elements (column caps & bases, oversized rounded details): prioritize load stability and vertical-lathe structure.

- Square / structured / linear profiles (square balusters, frames, straight moldings): use linear/saw-based profiling built for flat faces and corners.

Recommended lineup on this page: Vertical 4-Workpiece Baluster Profiling Machine, Column Cap & Base Profiling Machine, Integrated CNC Stone Profiling Machine, CNC Stone Lathe Machine.

2) What to Prepare (So the Recommendation & Quote Are Accurate)

Send these items and you’ll avoid the #1 mistake: choosing by a generic name instead of real production constraints.

- Product examples: photos + the target profile (one typical part is enough).

- Geometry range: max/min length; max/min diameter (round) or cross-section (square); any critical features (sharp corners, deep steps, thin necks).

- Material: marble / granite (and any others you actually run), plus thickness/blank condition.

- Output target: pieces per shift/day and whether jobs are repeat batches or custom mix.

- Quality definition: what “acceptable finish” means for your customer (installation-ready vs needs secondary finishing).

- Files (if available): DXF/DWG for profiles; STEP/IGES for complex 3D geometry.

3) Avoid These Common Buying Mistakes

- Mixing profiling with grinding. This page focuses on shaping by cutting/turning. If you need edge polishing or surface grooving by grinding, use Grinding & Polishing Machines.

- Over-optimizing for “speed.” For turning jobs, stability and repeatability usually reduce rework more than chasing maximum feed.

- Under-spec’ing the workpiece size range. The same “baluster” can mean very different diameters/lengths—always quote against your max size and max mass.

- Ignoring upstream/downstream workflow. Turning/linear shaping is one step; think about how blanks are prepared and how finishing is handled after shaping.

FAQs

What is a stone profiling machine called in English?

In many markets, it’s described as a stone shaping machine. If the profile is formed by rotating the workpiece, buyers commonly search CNC stone lathe or stone turning lathe. If the profile is formed on non-rotating parts (square/linear shapes), terms like linear profiling, profile shaping, or molding are also used depending on the process and the finished product.

Stone profiling machine vs CNC stone lathe—what’s the real difference?

The difference is the core forming method. A CNC stone lathe shapes by turning the workpiece—best for round, symmetrical parts (columns, round balusters, vases). A “profiling machine” category can include both turning models and linear/saw-based models. If your products must keep flat faces, corners, or square geometry, a linear/saw-based profiling model is usually the better fit than turning.

Which machine should I choose for round balusters, columns, vases, and railings?

If you run repeat batches of smaller round pieces and want higher throughput, start with the Vertical 4-Workpiece Baluster Profiling Machine. If you need one flexible turning solution for mixed round products (custom + standard), use the CNC Stone Lathe Machine.

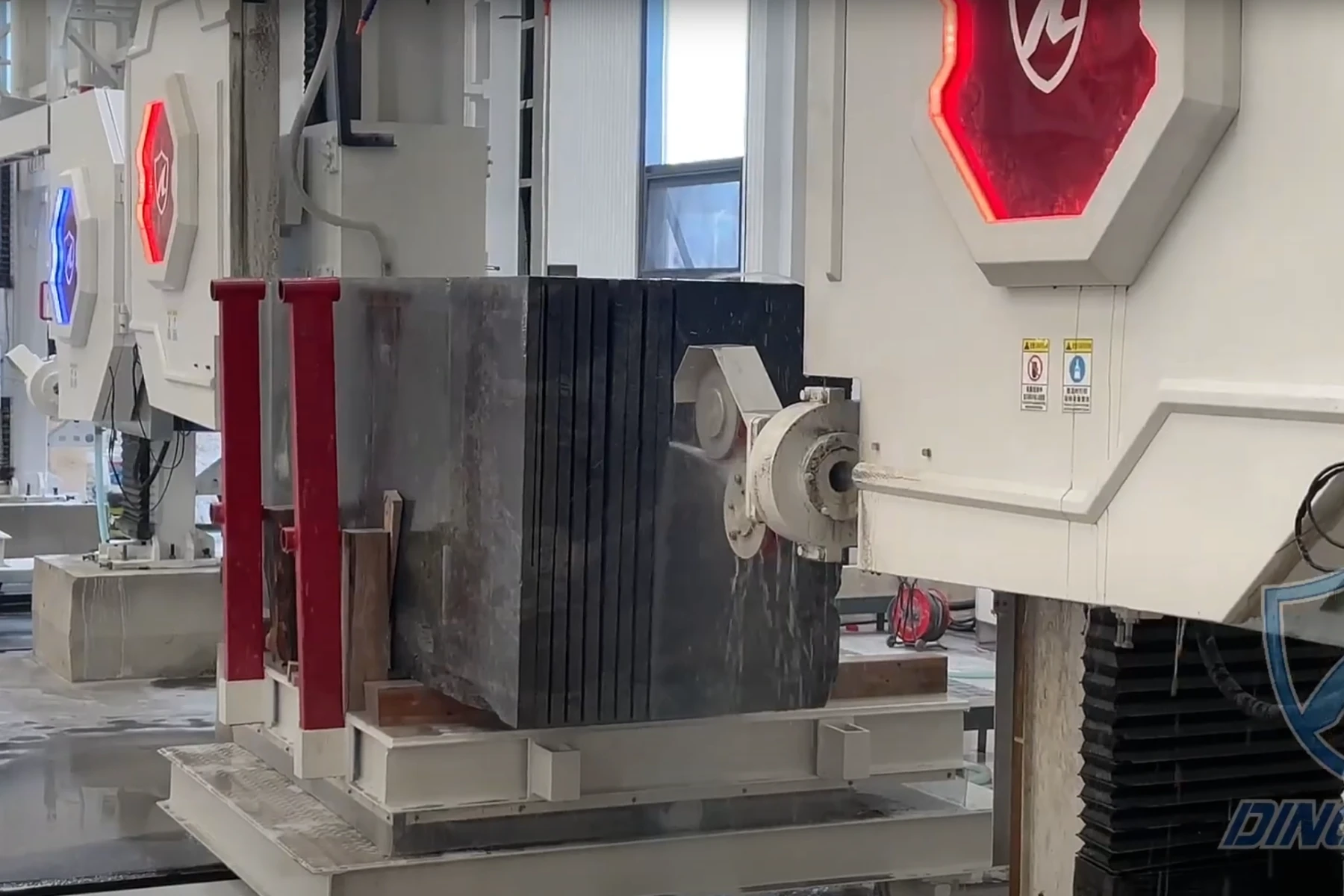

Which machine is best for large column caps & bases or heavy rounded architectural parts?

Choose a model designed around stability and vertical-lathe structure. The Column Cap & Base Profiling Machine is typically the right starting point when workpieces are heavier, larger, and require controlled 360° shaping.

Which machine is best for square balusters and decorative linear moldings?

Square/structured parts are usually better handled by linear/saw-based shaping that preserves faces and corners. Start with the Integrated CNC Stone Profiling Machine for consistent straight-line profiles and structured decorative geometry.

Can one machine cover both turning (round) and linear (square) profiling?

For occasional low-volume jobs, a single machine may cover part of the range—but for production, specialization is typically more efficient. Turning optimizes symmetry and repeatability on round parts; linear profiling optimizes corner definition and flat-face control on square/structured parts. If you produce both categories at scale, splitting equipment usually reduces setup time and rejects.

What information do you need to recommend the right model quickly?

Minimum: one product photo/drawing, material, max/min size range, and your output target. If you also tell us whether your parts are mainly round turning or square/linear, we can shortlist the best fit immediately and quote the right configuration.

Next Step: Get a Model Recommendation

Send your product photo/drawing + material + size range + output target. We’ll recommend the best-fit model and configuration for your workflow:

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский