Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

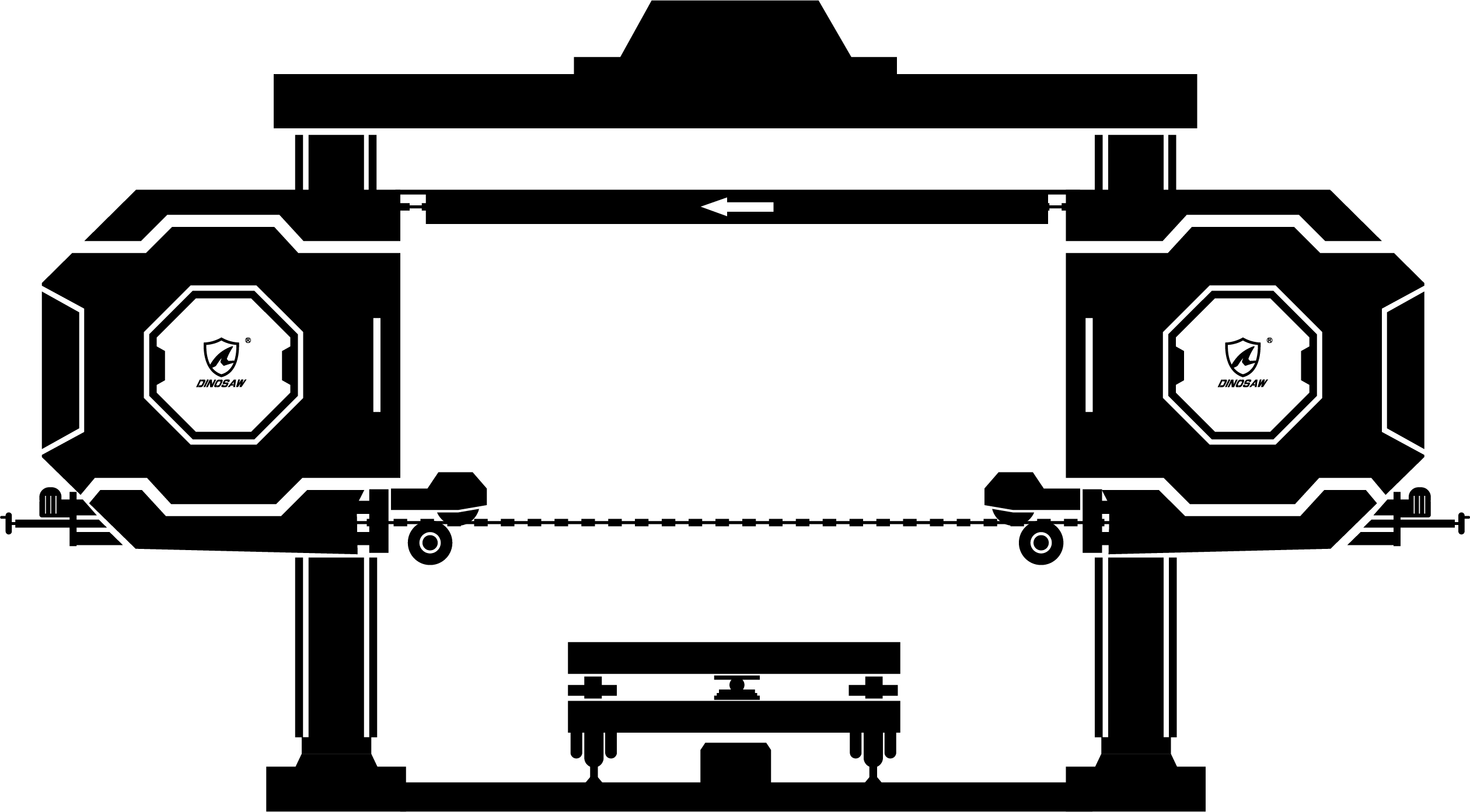

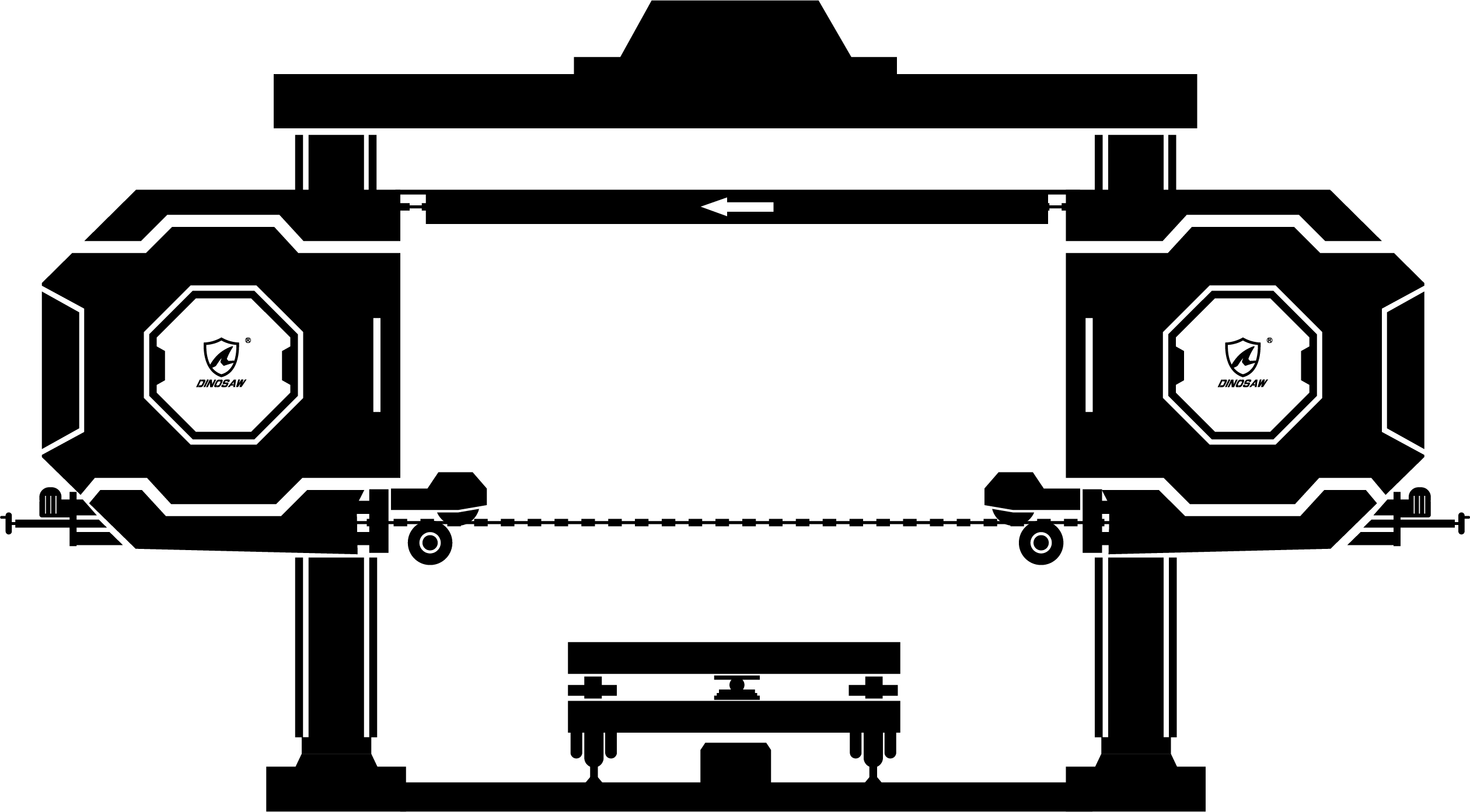

Quarry wire saw machine

Mar 10, 2024

Flagship Products 2025

Dinosaw Featured Machines

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Selection Criteria | Quarry Wire Saw | Quarry Chainsaw | Portable Trimming Saw | Sandstone Cutter |

|---|---|---|---|---|

Material Hardness | Excellent (Hard to Soft) | Good (Medium to Soft) | Excellent (All types) | Specific (Soft) |

Primary Goal | Large Block Extraction | Fast Block Separation | Block Squaring/Trimming | Direct-to-Size Blocks |

Site Conditions | Fixed Track, Large Quarry | Flexible, Ground-level | Highly Mobile, Any Location | Track-based, Rough Terrain |

Production Needs | High | Medium to High | Auxiliary | Very High (for specific products) |

Budget Range | High | Medium to High | Medium | High |

Motor Power (kW): Directly determines cutting capability. Higher power is needed for hard stone like granite. For example, the Sandstone Cutting Machine has a 75kW vertical motor to drive its large-diameter blade.Cutting Speed (m/min or m²/h): A key indicator of productivity. Note that the optimal speed depends on stone hardness. The Sandstone Cutting Machine has a travel speed of 10-45 m/min to adapt to various soft stones.Max Cutting Depth/Size (mm/m): Defines the block size the machine can handle. Ensure it meets the typical dimensions of your quarry's blocks. For instance, the Sandstone Cutting Machine has a max cutting depth of 520 mm.Mobility (Track/Rail): Rail-based systems (like the Quarry Wire Saw) offer high stability and precision for long-term, fixed operations. Track-based systems (like the Sandstone Cutter) provide excellent mobility for complex quarry terrains.Tensioning System (for Wire Saws): This is crucial for ensuring cut quality and extending diamond wire life. The Quarry Wire Saw Machine features an automatic constant tension system that adjusts in real-time for stable cutting.

For granite, the “best” machine depends on your cut type and site workflow:

Wire saw: best when you want efficient cutting with a narrow kerf and good material yield, especially for large blocks and controlled cutting paths.

Chainsaw: best when you need precise contour/shape cutting (profiling, special cuts, working near edges) where blade-based straight cutting is limited.

Double blade: best when your priority is fast, repeatable straight cuts and high throughput in a consistent setup.

If your quarry does multiple granite products, many teams choose one main cutting method (often wire saw or double blade) and keep a chainsaw for special/irregular tasks.

A quarry wire saw is typically used for primary quarry cutting tasks and larger blocks, while a portable trimming wire saw is designed for on-site edge trimming, correction cuts, and flexible positioning. If your workflow involves frequent block adjustments or finishing cuts on the quarry floor, portability can save time and crane movements.

Use your largest common block size as the baseline, then add a safety margin for setup, guide clearance, and real-world variation. If your blocks vary significantly, choose a machine based on the top 20% largest blocks you cut—otherwise you’ll constantly be constrained or forced into extra cuts.

Not always. A narrower kerf can improve yield (less waste), but overall cost also depends on cutting stability, tool wear, downtime, and how often you need rework. The best ROI comes from a machine that keeps stable cutting under load with predictable maintenance—not just the smallest kerf number.

To make a reliable recommendation without back-and-forth, provide:

stone type(s) and hardness (granite/basalt/marble/limestone/sandstone)

typical and max block size (L×W×H)

required cutting depth and whether you need contour/shape cutting

target output per day/week

available site power and working space

With these, we can shortlist models and propose a configuration that matches your quarry’s workflow.

CE/ISO are important baseline indicators, but safe production also depends on installation quality, operator training, routine inspection, and a clear maintenance schedule. A practical safety plan includes training + documented checks for tension systems, guarding, electrical components, and wear parts—especially in dusty quarry environments.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?