Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

See if Chinese CNC fits your shop—value vs quality, reliability and after‑sales support, plus a practical buying checklist. Read the guide.

TL;DR – Quick Decision Snapshot

Chinese CNC machines can be worth buying, but they are not the right choice for every buyer.

They tend to make sense for businesses that prioritize cost efficiency and capacity expansion, operate within reasonable tolerance requirements, and have access to technical support for commissioning and troubleshooting.

They are far less suitable for operations that demand ultra-tight tolerances, near-zero downtime, or immediate local service response, where the hidden costs of instability and delayed support can outweigh the initial savings.

If you are deciding whether Chinese CNC machines are worth buying, the key is not the country of origin, but whether the machine, support model, and risk profile align with your production reality.

Why Should You Consider Chinese CNC Machines in 2026?

Chinese CNC machines are no longer viewed solely as low-cost alternatives. Over the past decade, improvements in manufacturing capability, component sourcing, and quality control have made them viable options in many industrial applications.

That said, the real question is not simply whether Chinese CNC machines are “good” or “bad.” The decision depends on how well they align with your production requirements, risk tolerance, and support expectations.

In practice, most buying decisions come down to three factors:

- whether the machine can deliver consistent quality,

- whether the price advantage holds up over long-term operation,

- and whether after-sales support matches the realities of your business.

This article examines Chinese CNC machines through that decision lens—helping you determine not just what they offer, but when they are worth buying, and when they are not.

How Do Chinese CNC Machines Meet Quality Standards in 2026?

Continuous Innovation in Chinese Manufacturing

The perception of Chinese manufacturing has evolved dramatically. China has made substantial investments in industrial automation in recent years, transforming its capabilities from basic production to advanced precision engineering.

For CNC machines specifically, Chinese manufacturers have made remarkable strides in several key areas, including specialized equipment like CNC wire saw machines and other precision tools:

| 🔍 Precision Engineering | 🌟 Quality Control Systems |

|---|---|

| Modern Chinese CNC machines now achieve much improved tolerances, becoming increasingly comparable to high-end Western machines. The precision capabilities have shown remarkable improvement over the past decade. | Leading Chinese manufacturers now implement rigorous quality management systems, with many achieving ISO 9001, CE, and other international certifications. Multi-stage testing has become standard practice. |

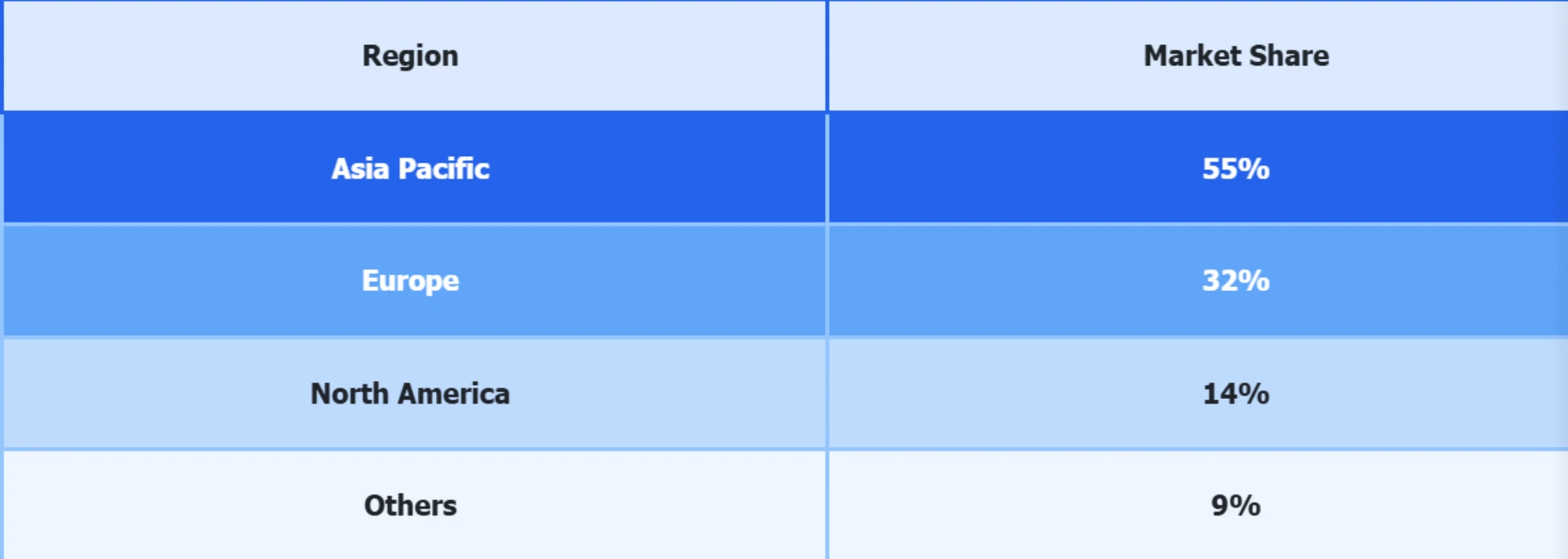

Quality Stratification in the Chinese Market

The Chinese CNC machine market is highly stratified, with significant quality variations across price points. Industry experts typically divide the market into three distinct tiers:

| Market Tier | Quality Level | Price Range (vs. Western) | Characteristics |

|---|---|---|---|

| High-end | Comparable to premium Western brands | 60-75% | Premium components, advanced control systems, comprehensive warranty, excellent after-sales support |

| Mid-range | Good quality, suitable for most applications | 40-60% | Quality components, reliable performance, standard warranty, decent after-sales support |

| Entry-level | Variable quality, requires careful selection | 25-40% | Basic components, functional performance, limited warranty, variable after-sales support |

The current market shows a significant shift toward mid-range and high-end machines as Chinese manufacturers upgrade their capabilities, particularly with specialized products like multi wire saw machines. Industry analysts note that the gap between top-tier Chinese CNC machines and Western counterparts has narrowed significantly, while price advantages remain substantial.

What Is the Price-Performance Ratio of Chinese CNC Machines?

Price-performance is not simply about getting the lowest purchase price. For CNC equipment, real value is determined by total cost of ownership—how stable the machine runs over time, how much tuning and downtime you can tolerate, and how much support you need after installation.

Chinese CNC machines often look attractive on paper because the hardware configuration can be strong for the price. The key is knowing when the cost advantage remains an advantage after commissioning, training, and long-term operation—and when it gets erased by hidden costs.

True Cost of Ownership Factors

However, purchase price is just one component of the total cost of ownership. For a comprehensive evaluation, consider these additional factors:

| ⚙️Maintenance Costs | Chinese machines might require more frequent maintenance, but parts are less expensive. Typical maintenance costs average 5-10% of machine purchase price annually, compared to 3-5% for premium Western machines. |

|---|---|

| ⏰Downtime Risk | Potential downtime risk is higher for lower-tier Chinese machines but comparable for mid-to-high-end models. Recent reliability data shows just 5-10% more downtime for equivalent Chinese machines versus premium Western brands. |

| 💼After-Sales Support | This remains an area where top Western brands still hold an advantage. However, leading Chinese manufacturers like Dinosaw now offer comprehensive warranty programs for their CNC wire saw products and have expanded their global service networks, with significantly improved response times. |

Key Takeaway on Value

For most manufacturing operations, particularly those with tight capital constraints, Chinese CNC machines in the mid-to-high range offer the most favorable value proposition in 2025. The initial savings combined with acceptable maintenance costs result in a compelling total cost of ownership for most applications.

When the Price-Performance Advantage Holds Up

Chinese CNC machines tend to offer the best price-performance when buyers have clear production requirements, realistic expectations, and enough technical capability to manage setup and process tuning. In these cases, the lower upfront cost can translate into faster ROI, especially for capacity expansion and general industrial applications.

When the Price-Performance Advantage Breaks Down

The value equation can change quickly if your operation depends on ultra-tight tolerances, requires near-zero downtime, or relies heavily on local on-site service. In these scenarios, additional costs—extended commissioning, repeated calibration, spare part lead times, or productivity loss—can reduce or even eliminate the initial savings.

A practical way to judge this is simple: if delays and variance cost you more than the machine saves, the price-performance ratio is no longer favorable.

How Do Chinese CNC Machines Perform in Real Manufacturing Environments?

In real manufacturing, performance is not judged by a spec sheet. It’s judged by repeatability, stability, and how quickly problems can be diagnosed and resolved.

This section focuses on what actually determines whether a Chinese CNC machine is worth buying in practice: consistent output over long runs, manageable downtime, and realistic after-sales support under production pressure.

Case Study 1: Stone Processing Industry

A mid-sized stone processing company in Barcelona switched from Italian stone cutting equipment to Dinosaw's 5 axis bridge saw in 2023.

According to their Production Manager: "The performance-to-price ratio exceeded our expectations. After initial skepticism, we've found the Dinosaw machine fully capable of meeting our quality standards while significantly reducing our capital investment."

Case Study 2: Custom Metal Fabrication

This Chicago-based metal fabrication shop incorporated two Chinese CNC milling centers alongside their existing American machines to handle increased production demand.

Operations Director: "While our American machines still hold a slight edge in precision and reliability, the Chinese mills deliver 95% of the performance at less than half the cost. For most of our production needs, they've proven more cost-effective."

Case Study 3: Wood Furniture Manufacturing

This high-end furniture manufacturer invested in a Chinese 5-axis CNC router for curved component production, replacing manual methods.

According to the CEO: "The capabilities of our Chinese CNC router have transformed our production capacity while maintaining our quality standards. The machine paid for itself within 10 months through increased efficiency and reduced labor costs."

What to Look for in Real-World Performance

When evaluating Chinese CNC machines in production settings, three signals matter most.

First is consistency: whether the machine can hold accuracy and surface quality across long cycles, not just during a short demo.

Second is stability: how often the machine requires recalibration, unexpected maintenance, or operator intervention to maintain output.

Third is support practicality: whether remote troubleshooting is effective, spare parts are available within acceptable lead times, and issues can be resolved without extended production delays.

If these three factors are within your operational tolerance, the lower upfront cost can translate into strong real-world value. If any of them repeatedly exceed your tolerance, the initial savings can be quickly offset.

Performance Patterns Across Industries

Analyzing data from manufacturing companies that integrated Chinese CNC machines between 2023-2025, including various types like marble CNC router and bridge saw systems, industry experts have identified these consistent patterns:

Performance Comparison: Chinese vs Western CNC Machines (2025)

| Performance Category | Chinese CNC(High-End) | Chinese CNC(Mid-Range) | Western CNC |

|---|---|---|---|

| Initial Cost | ★★★★★ | ★★★★★ | ★★ |

| Precision | ★★★★ | ★★★ | ★★★★★ |

| Reliability | ★★★★ | ★★★ | ★★★★★ |

| Software/Interface | ★★★★ | ★★★ | ★★★★★ |

| After-Sales Support | ★★★ | ★★ | ★★★★★ |

| ROI/Value | ★★★★★ | ★★★★ | ★★★ |

These real-world case studies demonstrate that while Chinese CNC machines may not match premium Western brands in every category, the gap has narrowed significantly. For many businesses, especially those prioritizing cost-efficiency without sacrificing essential quality, Chinese machines represent a viable alternative.

How Do You Choose the Right Chinese CNC Machine for Your Business?

Choosing the right Chinese CNC machine starts with a clear assumption: you are already considering Chinese suppliers as a viable option based on cost, application, and risk tolerance.

The goal at this stage is not to find a “perfect” machine, but to reduce uncertainty—by selecting configurations, suppliers, and support arrangements that match your operational reality.

With thousands of Chinese CNC machine manufacturers in the market, choosing the right equipment requires careful evaluation. This systematic approach will help you make an informed decision:

Step 1: Identify Reputable Manufacturers

Focus on established manufacturers with proven track records. According to Global Manufacturing Directory, top-tier Chinese CNC manufacturers typically share these characteristics:

| 🏭 Manufacturing Experience | 🏆 Certifications & Standards |

|---|---|

| Look for companies with at least 8-10 years of manufacturing history and international market presence. Companies like Dinosaw have been producing CNC machines export to over 50 countries. | Prioritize manufacturers with ISO 9001 quality management certification, CE marking for European compliance, and industry-specific certifications that indicate adherence to international standards. |

Step 2: Evaluate Machine Specifications Against Your Needs

Create a detailed requirements specification based on your production needs. Industry specialists recommend focusing on these critical parameters:

| Parameter Category | What to Evaluate | Considerations for Chinese Machines |

|---|---|---|

| Physical Dimensions | Work envelope, table size, machine footprint, weight capacity | Chinese machines often offer larger work envelopes at comparable price points, but verify measurement accuracy |

| Performance Specs | Spindle speed, axis travel speeds, positioning accuracy, repeatability | Request actual test data rather than relying only on marketing specifications |

| Control System | CNC controller type, software compatibility, interface language | Many Chinese machines now offer international controllers (Siemens, Fanuc) with English interfaces |

Step 3: Assess After-Sales Support

After-sales support remains one of the most critical factors. Based on industry experience, look for these support elements:

- Warranty Coverage: Minimum 12-month warranty, with options for extension

- Spare Parts Availability: Confirm that critical spare parts are stocked locally or can be shipped quickly

- Technical Support Channels: Verify availability of support via phone, email, and preferably remote diagnostics

- Response Times: Established SLAs for different support tiers (24/48/72 hours)

Step 4: Verify Before Purchasing

Before finalizing your purchase, take these verification steps to minimize risk:

- Request Video Demonstrations: Ask for live video demonstrations showing the machine performing operations similar to your requirements

- Sample Production: If possible, have the manufacturer produce sample parts based on your designs

- Third-party Inspection: Consider using an independent inspection service for pre-shipment verification

- Secure Payment Terms: Negotiate payment terms that provide protection, such as letters of credit or escrow services

By following this systematic approach, you can confidently select a Chinese CNC machine that meets your requirements while maximizing investment value. Industry experts emphasize that "The key to success isn't just finding the lowest price, but identifying the right manufacturer partner that provides the optimal balance of quality, performance, and support for your specific needs."

Where Quality Standards Still Vary in Practice

Meeting recognized quality standards does not always guarantee identical real-world outcomes.

While many Chinese CNC manufacturers comply with ISO certifications and established testing benchmarks, consistency can vary between suppliers, configurations, and even production batches. Factors such as component sourcing, assembly control, and calibration procedures often play a bigger role in long-term stability than the certification itself.

This is why evaluating Chinese CNC machines goes beyond asking whether they meet quality standards. The more important question is how much consistent performance those standards translate into for the price paid, which is where real buying decisions are made.

A practical rule of thumb is this: if a supplier cannot clearly explain configuration choices, commissioning steps, and support boundaries before the order, those uncertainties will not disappear after delivery.

By treating supplier selection as a risk-filtering process rather than a feature comparison, buyers are far more likely to achieve the price-performance balance discussed earlier in this guide.

What Are the Most Common Concerns About Chinese CNC Machines?

Potential buyers often have specific concerns about Chinese CNC machines. Here, we address the most common questions based on actual user experiences and industry data.

Are Chinese CNC machines worth buying compared to Western brands?

Chinese CNC machines can be worth buying, but only when the purchase decision is made around application fit, tolerance needs, and support reality—not country of origin. For many general industrial applications where cost efficiency and capacity expansion matter most, a well-selected Chinese CNC can deliver strong value. For operations that demand ultra-tight tolerances, near-zero downtime, or deep local service integration, premium Western systems often remain the safer long-term choice because you’re buying process stability, documentation depth, and predictable support.

How does the precision of Chinese CNC machines compare to Western brands?

Precision has improved significantly in the mid-to-high-end segment, and the gap is often small enough to be irrelevant for many industrial jobs. A practical way to interpret the difference is: Western premium brands tend to be stronger at holding the tightest tolerances with minimal drift over long production cycles, while top-tier Chinese machines can be very capable but may require more careful commissioning, calibration discipline, and process control to achieve the same repeatability.

What matters more than a single tolerance number is repeatability under real conditions: thermal stability, spindle condition over time, fixture rigidity, controller tuning, and operator/process consistency. If your work is repeat-critical or demands extremely stable tolerances across long runs, you should evaluate the machine based on long-cycle test results and process variance—not just a spec sheet.

Are Chinese CNC machines reliable enough for 24/7 production?

They can be, especially in the mid-to-high-end category, but reliability in 24/7 production depends on whether your operation can manage three realities: maintenance discipline, environment control, and response capability when something goes wrong. Even a capable machine becomes “unreliable” if downtime response is slow, spare parts are unavailable, or commissioning is incomplete.

For 24/7 use, buyers should focus on operational reliability indicators rather than marketing claims: stability across long cycles, frequency of recalibration, wear-part replacement intervals, spindle/drive behavior under load, and the supplier’s ability to troubleshoot remotely with clear escalation steps. If your line cannot tolerate pauses and you lack backup capacity, the risk profile is fundamentally different.

What are the biggest risks when buying a Chinese CNC machine?

The biggest risks are rarely basic functionality; they are usually consistency, commissioning effort, and support boundaries. Common risk patterns include: variation between suppliers and configurations, longer ramp-up time due to calibration and process tuning, spare part lead times that don’t match production urgency, and after-sales support that is remote-first rather than on-site.

A simple way to think about risk is: if the initial savings are smaller than the cost of delayed commissioning, repeated calibration, or production downtime, the price advantage is not real. The best mitigation is to define acceptance criteria, commissioning responsibility, and service response expectations before placing any order.

How reliable is after-sales service and spare parts support from Chinese suppliers?

It varies widely by manufacturer, and it’s one of the most important decision points. Some established suppliers provide structured remote support, clear troubleshooting workflows, and regional spare-part availability; others are reactive and inconsistent. You should assume support is not uniform and verify it like a technical requirement.

What to verify before purchase: response time commitments, communication channel (who exactly supports you), spare part list and lead times for critical components, whether remote diagnostics are supported, and what situations require paid on-site service. If your business requires immediate on-site response, you must confirm local coverage in your region—otherwise plan for a remote-first support model and keep critical spares.

Do Chinese CNC machines offer English interfaces and internationally recognized controllers?

Yes, most export-oriented machines provide English interfaces, and many suppliers offer internationally recognized controller options such as Siemens, Fanuc, or Mitsubishi. This can reduce the operator learning curve and improve workflow compatibility, especially when your team already has experience with those systems.

However, buyers should still verify controller version, post-processor compatibility, training materials, and whether the supplier can support software updates and troubleshooting over time. Interface language is only one part of usability; documentation quality and process guidance often matter more in daily operations.

Who should not buy a Chinese CNC machine?

Chinese CNC machines are generally not the best fit for operations where ultra-tight tolerances are non-negotiable, downtime tolerance is near zero, or immediate local on-site service is required as a standard expectation. They may also be a poor fit for first-time CNC buyers without in-house technical support, because commissioning and optimization often require more hands-on involvement than buyers anticipate.

If your operation depends on standardized documentation, plug-and-play integration, and predictable service coverage with minimal internal technical effort, premium Western brands can reduce risk even when the initial purchase price is higher.

Are Chinese CNC machines suitable for first-time CNC buyers?

They can be suitable if the buyer has a clear plan for commissioning, training, and ongoing troubleshooting. First-time buyers should prioritize suppliers who provide structured onboarding, clear manuals, practical parameter guidance, and reliable remote support—not just a machine shipment.

If you are new to CNC and lack technical staff, the biggest risk is not choosing the “wrong model,” but underestimating ramp-up time and process tuning. In that situation, either choose a supplier with proven support capacity and local assistance, or consider a solution where the service model is more mature and standardized.

Which industries are most successfully using Chinese CNC machines?

Chinese CNC machines are widely adopted in sectors where cost efficiency, flexibility, and production scaling are key priorities. Common successful applications include stone processing (marble, granite fabrication), furniture and woodworking, general metal fabrication, signage and engraving, educational institutions, and small-to-mid-sized job shops.

The pattern is consistent: industries with practical tolerance requirements and strong cost sensitivity tend to realize the most value—especially when buyers have technical capability to manage commissioning and maintain stable production processes.

Conclusion: Are Chinese CNC Machines Worth Buying?

Chinese CNC machines are neither a guaranteed bargain nor an automatic risk. Whether they are worth buying depends on how well they align with your operational priorities.

They are often worth buying if your business prioritizes cost efficiency and capacity expansion, operates in applications with reasonable tolerance margins, and has access to in-house technical capability or reliable remote support. In these scenarios, the price-performance advantage can translate into faster ROI and scalable production.

They are far less suitable if your operation depends on ultra-tight tolerances, requires near-zero downtime, or relies heavily on immediate local service coverage. In such cases, the hidden costs of instability, delayed support, or extended commissioning can outweigh the initial savings.

The most reliable way to decide is not by country of origin, but by fit. When expectations, application demands, and support realities are aligned, Chinese CNC machines can be a practical and competitive choice. When they are not, higher upfront investment elsewhere often proves cheaper in the long run.

Final Assessment

For most manufacturing applications, well-selected Chinese CNC machines offer excellent value. The decision ultimately depends on your specific requirements, budget constraints, and risk tolerance.

Ready to Explore Further?

Dinosaw offers comprehensive resources to help you evaluate our range of CNC machines for stone processing and other applications:

Detailed guide to stone CNC routers for granite and marble

Best Stone CNC Machine: Types and Buying Guide

Comprehensive guide to choosing stone cutting machines for factories

For personalized assistance in selecting the right CNC machine for your specific needs, our technical experts are available for consultation:Request Expert Consultation

Industry experts have concluded, "The decision to purchase Chinese CNC equipment is no longer primarily about cost savings—it's increasingly about finding the right technological fit at a competitive price point, with leading Chinese manufacturers now firmly established as mainstream options."

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский