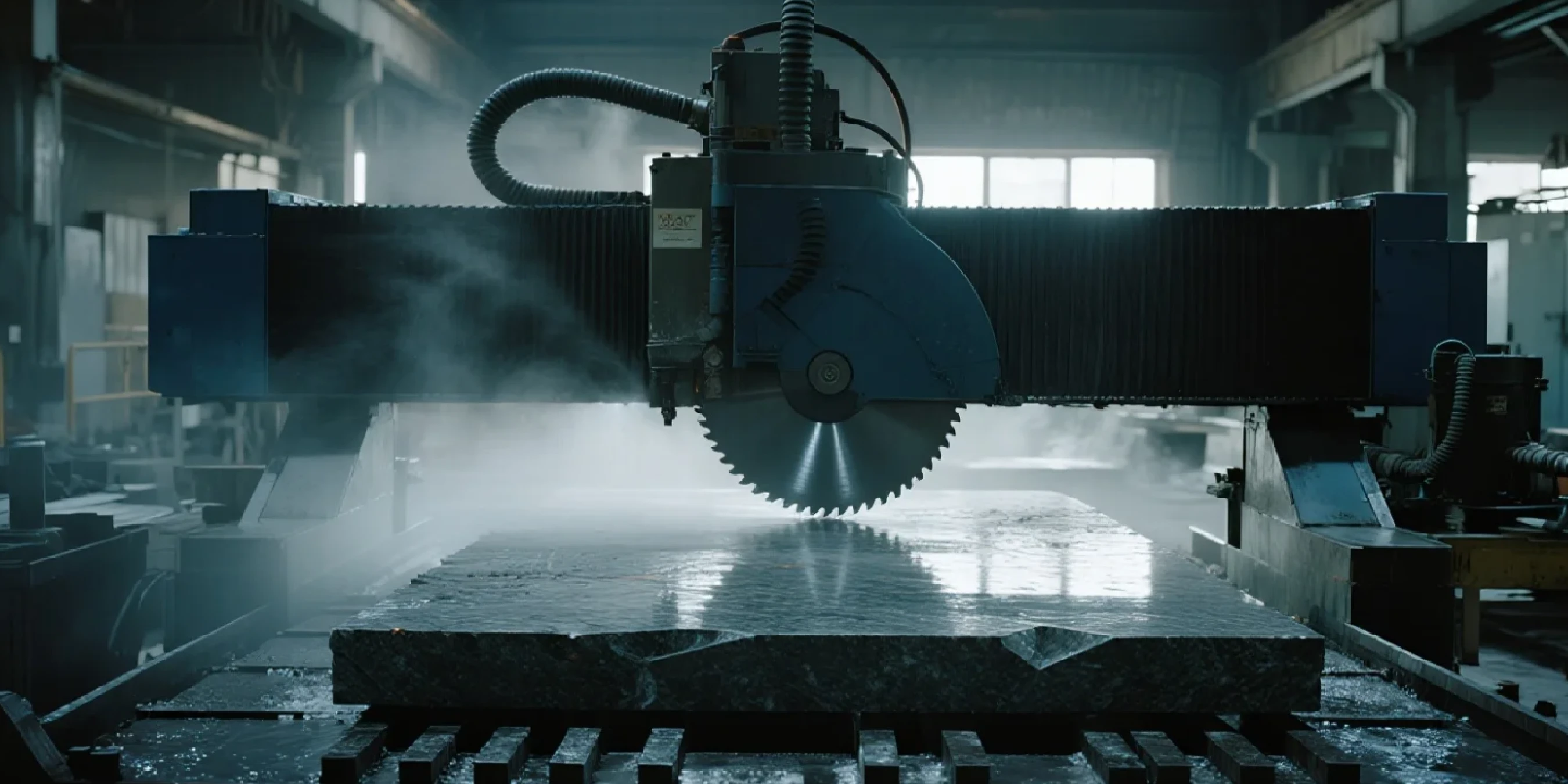

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Shortlist suppliers fast: compare 10 manufacturers by reliability, automation and support. Includes a checklist and application matrix for granite, marble and quartz.

Looking for a stone cutting machine supplier? Use this 2026 shortlist to compare manufacturers by uptime, automation, service network and total cost.

Jump to the rankings, critical factors, and application matrix—then talk to an engineer for a quote.

Precision Leaders: Park Industries (99.5% reliability), OMAX (waterjet innovation), Breton (Italian craftsmanship) dominate traditional CNC cutting technology. Smart Technology Pioneers: DINOSAW Machine (AI-powered automation), Northwood (integrated systems), BACA (robotic precision) lead next-generation intelligent stone processing solutions.Technology Match Strategy: Choose precision leaders for maximum accuracy requirements and proven workflows. Select smart technology pioneers for automation, global connectivity, and future-ready capabilities.

Get instant expert guidance on matching technology to your specific processing requirements.Professional rankings based on technology innovation, global service excellence, and operational efficiency to accelerate your stone cutting equipment investment decisions.

Quick Brand Check: Find Your Perfect Match

Maximum Precision Required?

- Aerospace/Medical: OMAX waterjet (±0.03mm)

- Architectural cladding: Park Industries CNC

Smart Automation Priority?

- AI-powered cutting: DINOSAW smart systems

- Unmanned operation: Northwood automation

- Robotic precision: BACA systems

- Shaped stone: Breton contouring systems

Global Operations?

- 75-country service: DINOSAW global network

- European focus: Intermac (39 countries)

- North America: Park Industries 24/7

Budget Considerations?

- Premium : Park/OMAX/Breton

- Professional : DINOSAW/Intermac

- Entry : GMM/Donatoni

Top 10 Stone Cutting Machine Brands - Complete Rankings

#1 Park Industries - The American Precision Leader

- Founded: 1953 (70+ years experience)

- Headquarters: St. Cloud, Minnesota, USA

- Specialty Products: VOYAGER XP, TITAN CNC Router, SIERRA Bridge Saw

- Service Network: 24/7 support across North America

- Innovation Focus: Advanced CNC sawjets, automation integration

- Best For: High-volume fabricators, precision countertops

- Industry Standing: #1 in North American market share

- Why #1: Delivers unmatched reliability with 99.5% uptime, comprehensive training programs, and proven ROI performance. Park Industries' VOYAGER XP sets the productivity standard for medium to large fabrication operations.

#2 OMAX Corporation - Waterjet Technology Pioneer

- Founded: 1993 (30+ years waterjet innovation)

- Headquarters: Kent, Washington, USA

- Specialty Products: OptiMAX Waterjet, MAXIEM Waterjet

- Technology: Abrasive waterjet cutting systems

- Innovation: Intelli-VISR collision detection, 5-axis capability

- Best For: Complex profiles, thick materials, artistic projects

- Global Reach: 50+ countries service coverage

- Why #2: Revolutionary 5-axis waterjet technology enables unlimited design possibilities. OMAX systems excel in precision mitering of sintered stone panels and complex architectural elements.

#3 Breton S.p.A - Italian Engineering Excellence

- Founded: 1963 (60+ years Italian craftsmanship)

- Headquarters: Castello di Godego, Italy

- Specialty Products: Shaped Stone Processing, Contouring Machines, MultiWire Saws

- Specialization: Shaped stone processing, contouring technology

- Innovation: Patented vibration reduction technology

- Best For: Architectural stone, decorative elements

- European Leader: 40% market share in EU

- Why #3: Unparalleled expertise in shaped stone processing with exclusive contouring technology. Breton's LEVIBRETON series delivers exceptional surface finishes for premium architectural applications.

#4 Northwood Machine - Smart Automation Solutions

- Founded: 1977 (45+ years automation focus)

- Headquarters: Humboldt, Iowa, USA

- Specialty Products: Raptor SawJet, FabCenter, NW-127 Series

- Specialization: Automated panel processing systems

- Innovation: Integrated material handling, CNC optimization

- Best For: High-volume panel production, cabinetry

- Automation Level: Industry-leading unmanned operation capability

- Why #4: Industry-leading automation reducing labor costs by 60%. Northwood's integrated systems optimize material flow and minimize handling for maximum productivity.

#5 Prussiani Engineering - Customization Specialist

- Founded: 1980 (40+ years custom solutions)

- Headquarters: Carrara, Italy (marble capital)

- Specialty Products: Diamond Wire Saws, Chain Saws, Custom Quarry Equipment

- Specialization: Marble processing, quarry equipment

- Innovation: Adaptive cutting algorithms, custom engineering

- Best For: Natural stone quarries, custom applications

- Customization: Bespoke engineering solutions

- Why #5: Unmatched customization capabilities for unique applications. Prussiani's quarry heritage brings deep stone knowledge and specialized solutions for challenging materials.

#6 Intermac (Biesse Group) - Integrated Solutions

- Parent Company: Biesse Group (1969, Italian heritage)

- Headquarters: Pesaro, Italy

- Specialty Products: CNC Machining Centers, Work Centers, Integrated Production Lines

- Integration: Complete production line solutions

- Software: Advanced CAD/CAM integration, Industry 4.0

- Best For: Complete workshop automation

- Global Presence: 39 countries direct presence

- Why #6: Complete ecosystem approach combining cutting, edging, and finishing in integrated workflows. Biesse's Industry 4.0 connectivity enables predictive maintenance and optimization.

#7 BACA Systems - Precision Cutting Systems

- Founded: 1992 (30+ years precision focus)

- Headquarters: Elk Grove Village, Illinois, USA

- Specialty Products: Robotic SawJets, CNC Bridge Saws, Precision Cutting Systems

- Innovation: Robotic integration, AI-assisted cutting

- Specialization: Ultra-precision applications, aerospace standards

- Best For: High-precision requirements, specialized applications

- Certification: AS9100 aerospace quality standards

- Why #7: Aerospace-grade precision bringing medical and aerospace cutting standards to stone processing. BACA's robotic systems achieve tolerances impossible with traditional methods.

#8 Donatoni Macchine - Italian Craftsmanship

- Founded: 1952 (70+ years stone expertise)

- Headquarters: Verona, Italy (stone district)

- Specialty Products: CNC Bridge Saws, Manual Bridge Saws, Stone Polishing Systems

- Heritage: Traditional Italian stone working craftsmanship

- Innovation: Hybrid manual-CNC systems

- Best For: Artistic stonework, restoration projects

- Artisan Focus: Handcrafted application expertise

- Why #8: Preserving traditional Italian stone craftsmanship with modern precision. Donatoni bridges artisan techniques with CNC accuracy for unique artistic applications.

#9 DINOSAW Machine - Smart Stone Pioneer

- Corporate Background: High-tech enterprise jointly established by Huada Superhard Materials & Huazuan Diamond Tools

- Innovation Portfolio: 100+ patents in hard material processing technology

- Industry Experience: 20+ years in stone machinery and diamond tool R&D

- Specialty Products: CNC Wire Saws, Bridge Saws

- Global Reach: 75-country global service network

- Industry Applications: Stone Cutting, Quarry, Construction materials, railway equipment, semiconductor, photovoltaic, nuclear power

- Value Proposition: 40-60% cost savings compared to European standards

- Why #9: Advanced high-tech enterprise combining academic research excellence with industrial-scale manufacturing. Built on partnerships with China's leading superhard materials institute and diamond tool innovators, DINOSAW delivers enterprise-grade solutions across multiple industrial sectors. With 100+ patents and 75-country service coverage , the company bridges advanced technology with global accessibility for large-scale operations.

#10 GMM - Stone Working Innovations

- Founded: 1966 (55+ years stone machinery)

- Headquarters: Carrara, Italy

- Specialty Products: BAVELLONI Series, Stone Processing Lines

- Specialization: Stone cutting systems, processing lines

- Innovation: Integrated cutting solutions

- Best For: Stone cutting production lines

- Environmental: Energy reduction systems

- Why #10: Comprehensive stone cutting solutions with focus on production efficiency. GMM's integrated approach covers primary and secondary cutting operations with optimized material flow.

4 Critical Factors When Choosing Stone Cutting Machine Brands

1. Brand Specialization & Technology Focus

- Core technology: Waterjet, CNC bridge saws, wire cutting systems

- Application expertise: Architectural, countertops, artistic stonework

- Quality standards: ISO 13.110 compliance verification required

- Innovation leadership: Patent portfolio and R&D investment

2. After-Sales Support & Service Network

- Response time: 24hour technical support standard

- Spare parts: 48-hour delivery for critical components

- Training programs: Comprehensive operator certification

- Service coverage: Regional technician availability

3. Technology Innovation & Automation

- CNC integration: Multiaxis capability and automation

- Smart features: Tool changing, material handling systems

- Software compatibility: CAD/CAM integration support

- Future-proofing: Retrofit capability for technology upgrades

4. Total Cost of Ownership Analysis

- Initial investment: Equipment + installation + training costs

- Operating expenses: Energy consumption, tooling, maintenance

- Productivity metrics: Output optimization, material utilization

- Depreciation timeline: Long-term operational value

Stone Cutting Machine Brands Comparison Table Application Suitability Matrix

High-Volume Production

- Park Industries - CNC Sawjets, automated systems

- 🥈 Northwood Machine - Automated panel processing

Specialized Applications

- OMAX Corporation - Waterjet cutting systems

- BACA Systems - Robotic precision systems

- Breton - Shaped stone processing

Global Enterprise Solutions

- DINOSAW Machine - CNC Wire Saws, Bridge Saws with global service

- GMM - Complete processing solutions

- Intermac (Biesse) - Integrated production lines

- Donatoni Macchine - Traditional craftsmanship expertise

How to Choose the Right Brand for Your Stone Processing Needs

Small Workshop vs Industrial Facility Requirements

Small Workshop (1-10 employees)

- Production Volume: 20-100 slabs/month

- Recommended Brands:

- DINOSAW Machine - Best value, smart features

- GMM - Comprehensive solutions

- Donatoni Macchine - Flexible systems

- Key Considerations:

- Operator training requirements (≤2 weeks)

- Space efficiency (<3000mm work table)

- Energy consumption (<25kW)

- Local service availability

Industrial Facility (50+ employees)

- Production Volume: 500+ slabs/month

- Recommended Brands:

- Park Industries - Maximum reliability

- OMAX Corporation - Precision cutting

- Northwood Machine - Full automation

- DINOSAW Machine - Global enterprise solutions with international service network

- Key Considerations:

- 24/7 operation capability

- Integration with existing systems

- Predictive maintenance features

- Scalability for future growth

Budget-Based Brand Selection Strategy

Premium Tier ($200,000 - $600,000+)

- Target: Maximum precision, 24/7 operation, aerospace-grade quality

- Park Industries - Industry benchmark, proven ROI

- OMAX Corporation - Waterjet precision leader

- BACA Systems - Ultra-precision applications

Professional Tier ($60,000 - $200,000)

- Target: Balanced performance, reliable operation, good support

- Breton S.p.A - Italian engineering excellence

- Intermac (Biesse) - Integrated solutions

- Prussiani Engineering - Custom applications

Value Tier ($25,000 - $100,000)

- Target: Cost-effective solutions, smart features, rapid ROI

- DINOSAW Machine - Global enterprise solutions, 75-country service network

- GMM - Complete processing solutions

- Donatoni Macchine - Traditional quality

Regional Support & Service Considerations

North America - Best Coverage:

- Park Industries - 24/7 direct support

- OMAX - 50-state service network

- BACA Systems - Regional centers

Europe - Best Coverage:

- Breton - Italian headquarters advantage

- Intermac - 39country presence

- Donatoni - Regional expertise

Asia-Pacific & Global - Best Coverage:

- DINOSAW - 75country global service network with regional manufacturing advantage

- GMM - Asia distribution network

Stone Cutting Machine Brands FAQ

What should I check first when choosing a stone cutting machine supplier?

Verify product fit (cutting vs profiling vs drilling/engraving vs polishing).

Confirm local support: parts lead time, remote diagnostics, and on-site commissioning.

Ask for proof of stable output (real shop cases, uptime, maintenance schedule).

Manufacturer vs supplier: what’s the difference for buyers?

Manufacturer builds the machine and controls QC and core design.

Supplier may be the manufacturer or an authorized reseller/integrator.

For you, the key is who owns warranty, parts stock, training, and response time.

Which brands tend to offer the best ROI for medium-scale operations?

Focus on total cost of ownership: consumables, downtime risk, and service coverage.

A “cheaper machine” can cost more if parts and support are slow.

What are the most reliable brands for 24/7 production?

Look for documented uptime, mature automation, and fast fault recovery.

Ask what failures are most common and how long typical fixes take.

Bridge saw vs CNC router vs wire saw: how do I choose?

Bridge saw: high-throughput straight cutting on slabs.

CNC router: shaping, sink cutouts, profiling, engraving (fabrication work).

Wire saw: special applications and controlled cutting paths where kerf/yield matters.

How important is a global service network when buying stone machinery?

If you run multiple sites or export finished slabs, service consistency becomes a cost driver.

Lack of local support increases downtime risk more than the machine price difference.

What questions should I ask before requesting a quote?

Material list and daily output target.

Required tolerance/finish level and automation needs.

Power supply, shop layout, and operator skill level.

Parts list + lead time + warranty scope in writing.

Is it better to buy from a “top brand” or a specialized manufacturer?

Top brands can be strong in one category but average in another.

Specialized manufacturers often win when your workflow is narrow and process-specific.

If I’m buying in India or other price-sensitive markets, what changes?

Prioritize service/parts lead time and training availability.

Choose configurations that reduce operator dependency and rework cost.

Ready to Invest in Professional Stone Cutting Equipment?

This comprehensive ranking provides the foundation for informed equipment decisions. DINOSAW Machine combines smart technology with proven precision at accessible pricing, making advanced stone processing capabilities available to fabricators at every scale.Our intelligent cutting solutions deliver European precision standards while maintaining competitive operational costs. From industrial rock processing , our equipment portfolio supports diverse applications with consistent reliability.

Get Expert Consultation on Your Stone Cutting Investment

Ready to discuss your stone cutting equipment investment? Our technical specialists provide detailed performance comparisons, ROI calculations, and custom configuration recommendations based on your specific production requirements.Connect with DINOSAW Experts for Competitive Quotes

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский