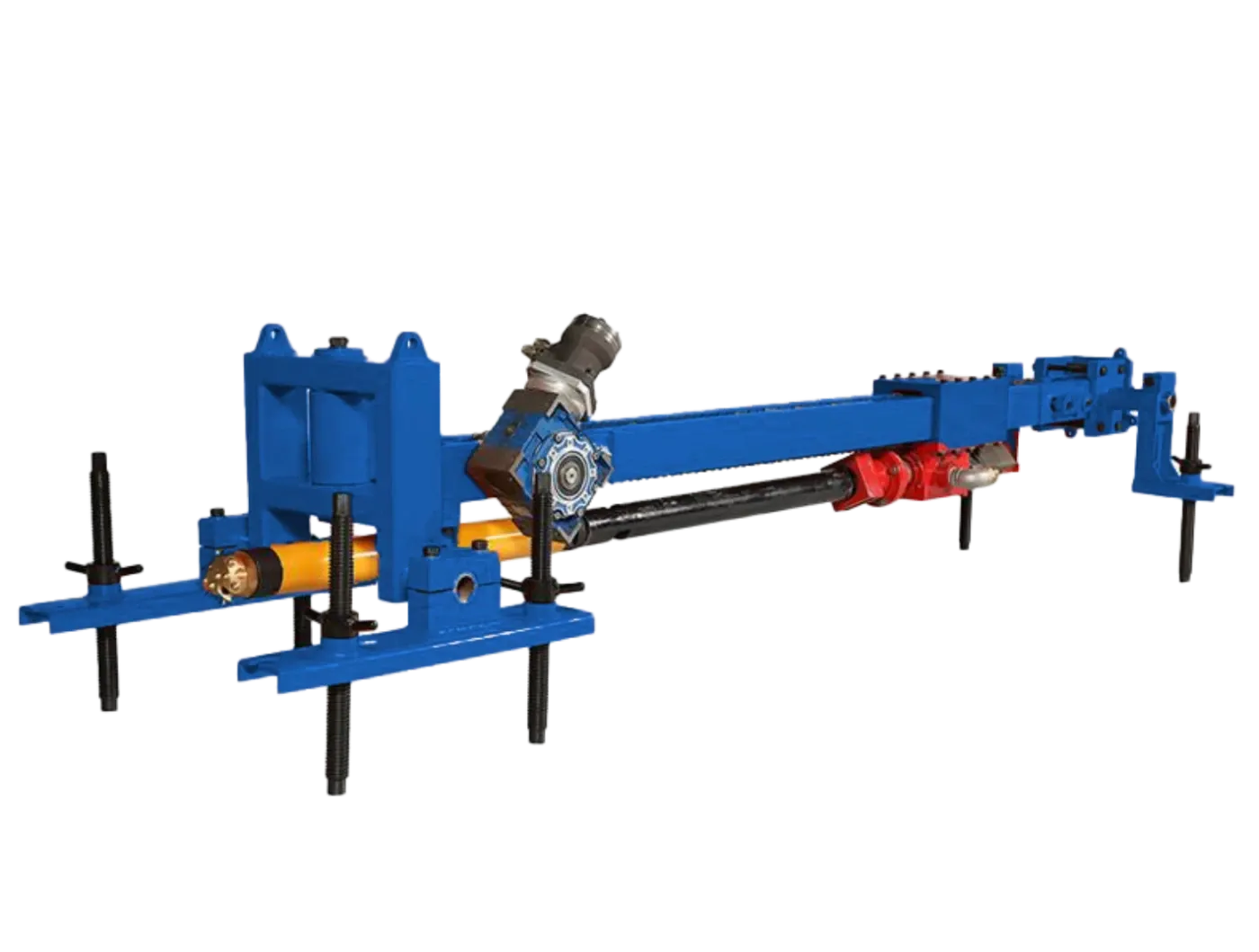

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Choose the right stone quarry drilling machine. Compare DTH vs. top-hammer and learn decision drivers like bench height, hole diameter, and compressor size.

TL;DR: How to Choose the Right DTH Rig

- Start with your rock:Hard, abrasive rock (granite, basalt) is the ideal use case for DTH technology.

- Match the machine to your scale:Consider bench height, required hole diameter (e.g., 76–152 mm), and mobility needs.

- It's a system:Your air compressor's capacity (CFM & pressure) is just as critical as the rig itself.

- Next Step:Use the If-Then selection tree in this guide to match your scenario to a recommended configuration.

Key Decision Drivers for Your Purchase

- Rock Type & Hardness:Is it hard and abrasive like granite, or medium-hard like limestone? DTH excels in hard rock, while other methods might be viable for softer formations.

- Bench Height & Hole Depth:What is your typical bench height? This dictates the required drilling depth per pass and influences the choice between DTH and top-hammer rigs.

- Required Hole Diameter:The hole diameter (commonly 76–152 mm) impacts blast design and explosive consumption. Your choice here determines the necessary DTH hammer and bit size.

- Air Compressor Capacity:This is not an afterthought. Your high-pressure air compressor must meet the CFM (cubic feet per minute) and pressure (bar/PSI) demands of the DTH hammer. An undersized compressor is the #1 cause of poor performance.

- Mobility and Automation:Do you need a highly mobile, crawler-mounted rig, or a simpler, skid-mounted unit? What level of automation and data integration (e.g., OPC UA) is required for your operation?

DTH vs. Alternatives: A Neutral Comparison

Feature | DTH (Down-The-Hole) Drilling | Top-Hammer Drilling |

|---|---|---|

Best For | Medium to very hard rock (e.g., granite, basalt); deeper holes (>15m); larger diameters (90-152mm). | Soft to medium-hard rock; fractured rock; shallower holes (<15m); smaller diameters. |

Energy Transfer | Excellent.Piston strikes bit directly in the hole. No energy loss through drill string. | Fair to Poor.Energy is lost at every rod connection, reducing efficiency with depth. |

Hole Straightness | Excellent.Stiff, large-diameter rods and in-hole hammer provide superior guidance. | Fair.More flexible drill string is prone to deviation, especially in deeper holes. |

Air Consumption | Higher. Requires a powerful, high-pressure compressor to both power the hammer and flush cuttings. | Lower. Air is primarily used for flushing cuttings, not powering the percussion. |

If-Then Selection Tree: Match Your Needs to a Solution

- If you run a high-volume granite quarry → prioritize a powerful DTH rig (e.g., 5-6" hammer class) paired with a high-pressure compressor (≥24 bar). Focus on rigs with robust crawlers for stability and an efficient rod-handling system to minimize downtime during bench drilling.

- If you quarry dimensional stone like marble → select a DTH rig known for precision and low hole deviation control. A smaller hammer (e.g., 3-4" class) is often sufficient. A wet drilling kit is non-negotiable to prevent micro-fractures and ensure a clean final product.

- If your main product is aggregate from limestone → a mid-range DTH machine (e.g., 4-5" hammer) offers a balance of speed and operational cost. High penetration rate is key, so ensure your air supply is more than adequate for the hammer's needs.

- If you operate in fractured or mixed geology → a DTH system is still viable but requires careful operation. A rig with precise feed control is crucial. Consider a DTH hammer with a check valve or foot valve to prevent debris from entering the hammer. A top-hammer might be a safer alternative if the ground is extremely broken.

- If your bench heights exceed 15 meters → DTH is the clear choice over top-hammer. The energy transfer efficiency of DTH ensures consistent performance at depth, where a top-hammer would struggle. Look for a machine with a carousel that holds enough drill rods for a single pass.

- If mobility and frequent rig repositioning are key → a crawler-mounted DTH rig with good tramming speed and a high degree of boom articulation is essential. This reduces setup time between holes and increases overall drilling hours per shift.

Procurement Checklist: What to Ask Your Supplier

- Total Ownership and Maintenance Plan:Ask for a breakdown of expected running costs, including fuel, lubricants, and major consumable parts (bits, hammers). What does the recommended maintenance schedule look like?

- Spare Parts Availability & Lead Time:Where are spare parts stocked? What is the typical lead time for critical components like a hammer rebuild kit or rotation motor?

- Training & Commissioning:Is on-site operator and maintenance training included with the purchase? Who performs the commissioning, and what is covered?

- Warranty & Service Support:What does the standard warranty cover, and for how long? What are the terms of the Service Level Agreement (SLA) for post-warranty support?

- Technical Documentation & Certifications:Will you receive comprehensive manuals for operation, maintenance, and parts? Does the machine meet all local safety and environmental certifications?

The DINOSAW Advantage: A Partner in Productivity

FAQs for Selecting a DTH Rig

What's the main difference between a DTH rig and a top-hammer rig?

- Context: The location of the hammer is the key distinction. DTH's in-hole hammer design ensures maximum energy transfer directly to the rock, making it highly efficient for deep and hard rock drilling.

- Next Step: To understand how this impacts your choice, review our DTH vs. Top-Hammer comparison table.

Why is DTH better for drilling in granite?

- Context: Granite's hard, crystalline structure requires immense, direct force. DTH technology avoids the energy loss that occurs in top-hammer systems, leading to higher penetration rates and less wear on the rig itself.

- Next Step: See the performance benefits for hard rock in our guide to DTH applications and materials.

Do I need a new compressor if I buy a DTH rig?

- Context: The compressor must provide enough air (CFM) at high pressure (17-24 bar) to both power the hammer and effectively flush cuttings from the hole. An undersized compressor is the most common cause of poor DTH performance.

- Next Step: Check the air consumption specs on the technical data sheet for our DTH hammers to ensure a proper match.

What is a realistic expectation for hole deviation with DTH?

- Context: The rigidity of the large-diameter drill string combined with the in-hole hammer provides excellent guidance, minimizing wander. This level of precision is critical for effective pre-splitting and predictable blast results.

- Next Step: Learn more about how precision impacts blasting outcomes in our guide to DTH applications.

How does bench height influence the top-hammer vs DTH comparison?

- Context: For benches taller than 15 meters, the energy dissipation through a top-hammer's drill string becomes a major bottleneck. DTH technology bypasses this issue entirely, making it the clear choice for deep-hole quarrying.

- Next Step: Use our If-Then selection tree to see how bench height affects the recommended DTH rig configuration.

Can one DTH rig handle both limestone and basalt hard rock drilling?

- Context: The machine itself is adaptable, but the consumable tooling is specific. A tough, wear-resistant button bit is needed for basalt, while a different bit design may provide faster penetration in medium-hard limestone.

- Next Step: Explore our material compatibility matrix to see how different rocks affect tooling choices.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский