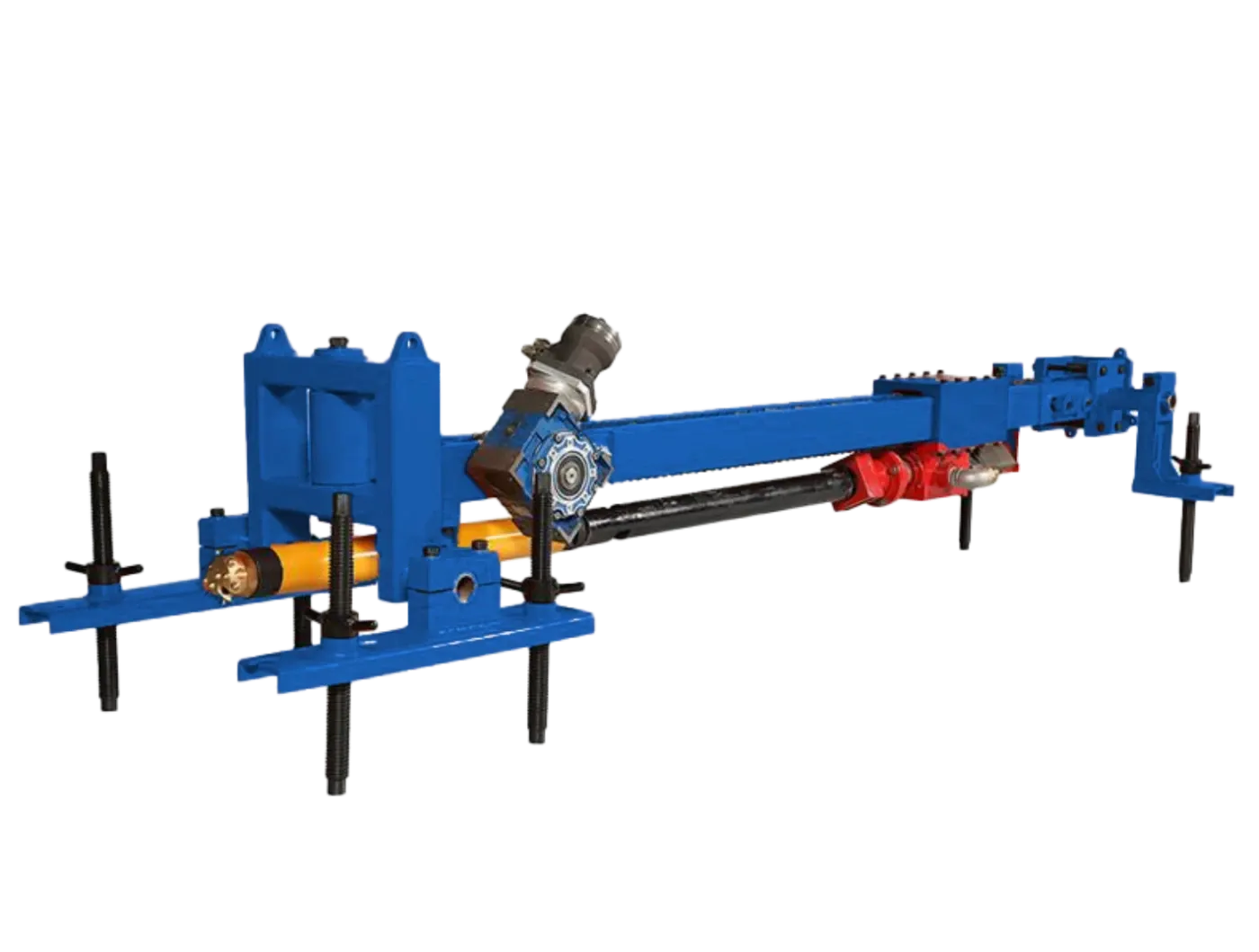

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Explore how DTH drilling boosts stone quarry productivity. Learn about granite, marble, and limestone applications, hole diameters, and pre-splitting techniques.

TL;DR: Your Quick Guide to DTH Drilling Applications

- DTH drilling excels at creating precise, straight holes in hard rock like granite and basalt for quarrying.

- Ideal for bench drilling, pre-splitting, and controlled blasting to maximize usable stone.

- Before you start, confirm your air compressor capacity and the specific rock type you're working with.

- Next Step: Review the material compatibility matrix in this guide to see if your stone is a match.

What Can You Achieve with a DTH Drilling Rig?

- Bench Drilling: Create uniform and accurately spaced holes for primary blasting. The low hole deviation of DTH drilling ensures an even blast, reduces oversized boulders, and improves fragmentation for easier loading.

- Pre-splitting: Generate a clean fracture plane to define the final wall of your quarry. DTH drills create closely-spaced, parallel holes that allow for a controlled split, minimizing damage to the final rock face and ensuring stability.

- Controlled Blasting: In sensitive areas or for dimensional stone quarrying, precision is paramount. DTH drilling allows for smaller, more precise blast patterns that maximize the yield of usable, high-value stone blocks.

- Plug-and-Feather (Split-and-Wedge): For non-explosive extraction, DTH machines can drill a series of holes where wedges and shims (feathers) are inserted to split the rock mechanically. This is common in marble and other decorative stone quarries.

Material & Processing Compatibility Matrix

Rock Category | Examples | DTH Suitability | Key Considerations |

|---|---|---|---|

Hard & Abrasive Rock | Granite, Basalt, Quartzite, Gneiss | Excellent | This is the ideal use case. DTH delivers high impact energy efficiently. Use button bits designed for hard formations to manage wear. |

Medium-Hard Rock | Limestone, Marble, Dolomite, Sandstone | Very Good | High penetration rates can be achieved. For dimensional stone like marble, precision is key. A wet drilling kit can help manage dust and cool the bit. |

Soft or Fractured Rock | Shale, Slate, Weathered/Broken Ground | Fair to Poor | Can be challenging. The high impact can cause hole collapse or blockages. Flushing can be difficult. A top-hammer rig may be more suitable in these conditions. |

What Are the DTH Drilling Machine's Boundaries ? (Can/Cannot)

- Hole Diameter: Most quarrying DTH rigs are optimized for hole diameters in the range of 76mm to 152mm (3" to 6"). Going significantly smaller or larger may require a different class of machine or drilling technology.

- Drilling Depth: While DTH can drill very deep holes, practical quarrying depths per pass are typically aligned with bench height, often up to 15-20 meters. Deeper holes face challenges with air pressure and flushing.

- Angle Drilling: While excellent for vertical holes, most rigs can be adjusted for angle drilling, which is essential for matching the geology of the rock face and optimizing blasts. However, extreme angles can increase stress on drill rods.

- Wet vs. Dry Drilling: Standard DTH is a dry drilling method, using air to flush cuttings. However, a wet drilling kit (water injection) is often necessary for dust suppression to meet environmental and safety regulations.

- Precision Tolerance: DTH is known for excellent hole straightness, with deviation typically under 2%. This level of hole deviation control is critical for pre-splitting and achieving predictable blast results.

How to Process? A Quick Start Guide

- Site Preparation & Positioning: Ensure the drilling area is stable and level. Accurately position the rig according to your blast plan.

- Collaring the Hole: Start drilling at a reduced feed pressure and rotation speed to create a clean entry point ("collar") for the hole. This prevents the bit from wandering.

- Full-Power Drilling: Once the collar is established, increase feed pressure and rotation to the recommended operating levels. Monitor air pressure and the flow of cuttings to ensure efficient flushing.

- Adding Drill Rods: As the hole deepens, add drill rods using the rig's rod handling system. Ensure threads are clean and properly lubricated to prevent seizing.

- Reaching Target Depth & Flushing: Upon reaching the target depth, lift the drill string slightly off the bottom and flush the hole with air for a few minutes to clear all remaining cuttings.

Example Starting Parameters (for Medium-Hard Granite)

- Air Pressure: 17-24 bar (250-350 PSI)

- Rotation Speed: 15-35 RPM

- Drilling Penetration Rate:value varies by geology, hammer size, and compressor capacity (measured in m/hour)

- High-Pressure Air Compressor CFM:Match compressor output to hammer specifications; ensure sufficient airflow (CFM/PSI/bar)

DTH Drilling Machine's Advantages Over Traditional Quarrying Methods

Higher Penetration Rate

Better Hole Straightness

3 Micro-Cases from the Field

Case 1: Granite Quarry

Case 2: Marble Quarry

Case 3: Limestone Quarry

Key Risks & Prerequisites

- Adequate Air Supply: The DTH hammer is air-powered. An undersized high-pressure air compressor (insufficient CFM or pressure) will starve the hammer, leading to a dramatic drop in penetration rate. Match the compressor to the hammer's specifications.

- Drill Bit Management: The rock drill bit is a consumable, but its life can be maximized. Using the wrong type of button bit for the rock, or continuing to use a worn bit, will slow drilling and can damage the hammer.

- Dust & Safety Compliance: Drilling creates significant silica dust, a major health hazard. According to the U.S. Occupational Safety and Health Administration (OSHA), engineering controls like dust suppression for drilling (e.g., a wet drilling kit) are essential. Proper PPE for quarry drilling, including respiratory and hearing protection, is non-negotiable.

FAQs about DTH Drilling Applications

What is the optimal hole diameter for DTH drilling in quarries?

- Context: This range offers a great balance between drilling speed and explosive-loading efficiency.

- Benefits: It's large enough for effective blasting but small enough to maintain high penetration rates and precision.

- Next Step: Your ideal diameter depends on your bench height and rock type; consult our team to confirm.

How does DTH compare to top-hammer for pre-splitting?

- Context: Pre-splitting requires a line of very straight, parallel holes to create a controlled fracture.

- Benefits: Straighter holes ensure the fracture follows the intended path, resulting in a smooth final wall and less damage to the rock mass.

- Next Step: If final wall quality is your priority, DTH is the recommended technology.

Can I use a DTH rig for horizontal drilling?

- Context: Horizontal holes are drilled at the base of a quarry bench to improve blasting outcomes.

- Benefits: A versatile rig that can perform bench drilling and horizontal drilling reduces the need for multiple machines on site.

- Next Step: Check the machine's specifications for its range of boom and feed articulation.

How much air do I need for a DTH drilling machine?

- Context: A 4-inch hammer requires significantly more air than a 3-inch hammer to function optimally.

- Benefits: Providing the correct air supply is the single most important factor for achieving the manufacturer-rated drilling penetration rate.

- Next Step: Always match your high-pressure air compressor's output to the hammer's requirements, not the other way around.

Is wet drilling always necessary?

- Context: Drilling in materials like granite and sandstone releases crystalline silica, a dangerous carcinogen.

- Benefits: A wet drilling kit injects a small amount of water into the air stream, effectively capturing dust at the source and protecting operators and the environment.

- Next Step: Budget for a water injection system or dust collector as a standard part of your DTH setup.

What kind of drill bit is best for hard rock like granite?

- Context: These tungsten carbide buttons are designed to crush the rock efficiently while resisting wear.

- Benefits: While more expensive upfront, they offer a lower overall cost per meter drilled due to their durability and sustained performance.

- Next Step: Consult with a supplier to choose the specific button shape and face design for your particular granite quarry drilling needs.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский