Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Move beyond operational details. Learn how to implement diamond wire saw technology to enhance safety, expand capabilities, and build operational resilience.

TL;DR: The Strategic Case for Diamond Wire Saws

- Adopting this technology is a strategic move to de-risk operations, enabling projects that are impossible with conventional tools.

- It enhances your firm’s reputation by improving safety compliance (OSHA), reducing environmental impact, and delivering higher quality outcomes.

- Successful implementation hinges on a phased rollout: pilot project, targeted training, and scalable integration.

Beyond Operations: Viewing Diamond Wire Saws as a Strategic Asset

The Strategic Pillars of Diamond Wire Saw Adoption

Safety & Compliance

Capability Expansion

Quality & Reputation

Operational Resilience

A Complete Resource Hub

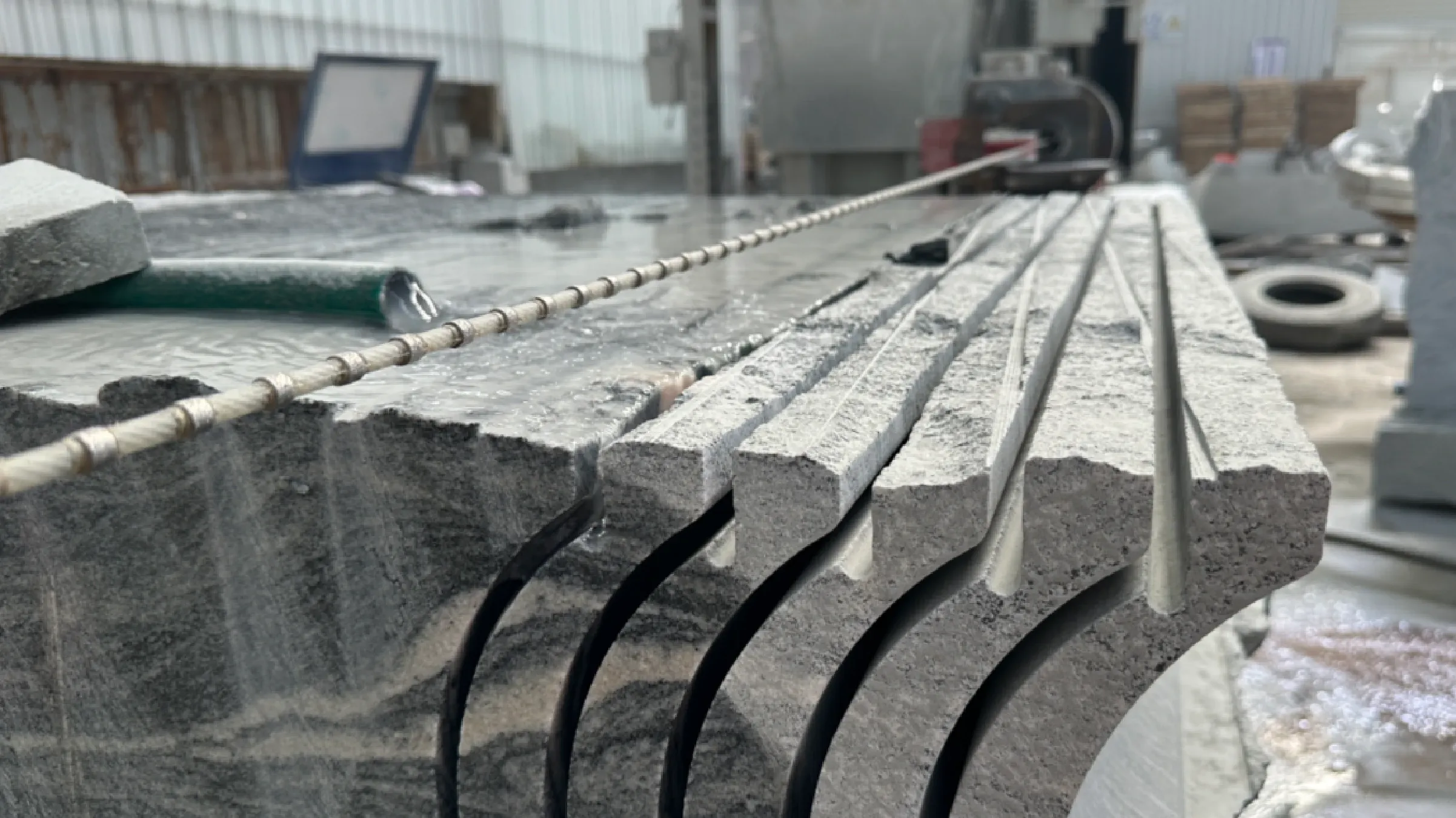

- Why does wire win where blades fail? See how this tool transforms demolition and quarrying projects in our applications and case studies guide.

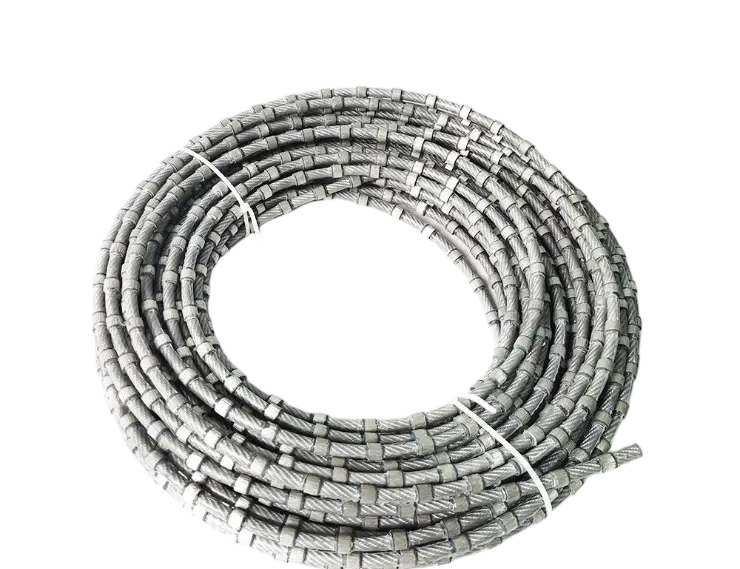

- Curious about the tech behind the cut? We break down the beads, tension, and pulleys to explain how diamond wire saws actually work.

- Sintered, brazed, or electroplated? Don't guess. Our buyer's guide lays out a clear decision framework for choosing the right wire.

- Are you rotating and cooling correctly? Learn to prevent breaks and achieve a smoother finish with our maintenance and troubleshooting checklist.

3-Step Implementation Roadmap for a Seamless Transition

- Select a small, measurable project to serve as a proof-of-concept.

- Work with DINOSAW experts to define clear KPIs (e.g., cutting speed, dust levels, setup time).

- Provide hands-on training from DINOSAW technicians for your core team.

- Document SOPs for machine operation, tool care, and safety protocols based on the pilot.

- Roll out the technology to other teams and projects based on the established best practices.

- Establish a maintenance and consumable supply plan to ensure operational continuity.

Managing Implementation Risks

- Technical Risk: A mismatched tool or poor maintenance can lead to wire breakage and downtime. Mitigation: Partner with a reputable supplier like DINOSAW for expert guidance on tool selection and a robust maintenance schedule.

- Operational Risk: Lack of proper training is the primary cause of accidents and inefficient use. Mitigation: Mandate comprehensive, hands-on training for all operators. Do not treat it as optional.

- Compliance Risk: Failure to manage dust and slurry can result in regulatory fines. Mitigation: Implement wet cutting as standard practice and adhere to local environmental regulations for slurry disposal.

What is the biggest barrier to successful implementation?

- Context:Operators accustomed to traditional methods may be hesitant to adopt a new process. A clear plan that demonstrates the benefits in safety and efficiency is needed to get them on board.

- Next Step:Start with the pilot project phase of our implementation roadmap to build confidence.

How does this impact our insurance and liability costs?

- Context:Replacing high-risk methods like blasting with a controlled, low-dust solution improves your safety record. This can lower workers' compensation premiums and reduce the risk of costly litigation from accidents or health issues like silicosis.

- Next Step:Discuss these safety advantages with your insurance provider, citing compliance with OSHA standards.

Can we lease the equipment before committing to a purchase?

- Context:This is an excellent way to build a business case for a full-scale investment by testing the equipment on a real-world project.

How does diamond wire cutting contribute to sustainability goals?

- Context:The technology benefits the environment by reducing noise, improving air quality via dust control, minimizing material waste due to high precision, and consuming less energy per cut compared to some traditional methods.

- Next Step:Showcase these benefits in your company's ESG (Environmental, Social, and Governance) reporting.

What kind of data can we get from modern wire saw systems?

- Context:PLC-controlled systems can output data on cutting speed, wire tension, amperage draw, and total cutting area. This data is key for monitoring productivity and managing consumables.

- Next Step:Integrate this data feed into your existing project management software to create performance dashboards.

How does this technology affect workforce development?

- Context:Training your staff on this technology enhances their skill set, improves retention, and attracts new talent interested in working with safer, more advanced tools.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский