Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Understand the engineering behind diamond wire saws. Explore core components like diamond beads, connection types (brazed, sintered), and wire tension systems that deliver precision cuts.

TL;DR: The Engineering Behind the Cut

- A diamond wire saw doesn't cut by force but by high-speed abrasion, using diamond-impregnated beads to micro-grind material.

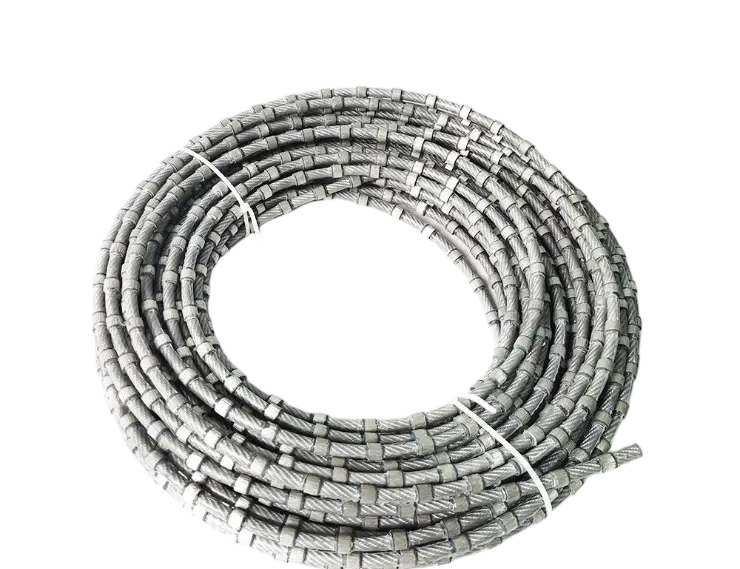

- Core components include the diamond beads, a high-strength steel wire, and specialized connectors (spring, rubber, or plastic) that match the application.

- Understanding these components helps you optimize performance, prevent failures, and maximize the return on your investment.

It’s Not Magic, It’s Engineering

The Core Principle: How Abrasion Beats Hardness

Why Abrasion Beats Blade Saws: Kerf Loss, Dust & More

Why Abrasion Beats Blade Saws: Kerf Loss, Dust & More

Factor | Diamond Wire Saw | Traditional Methods (Blade Saws/Blasting) |

|---|---|---|

Precision | High. Clean, smooth cuts with minimal kerf (2-3 mm loss). | Low. Rough surfaces, high material loss, and risk of micro-cracks. |

Noise & Vibration | Low. Minimal vibration and significantly lower noise levels. | Extremely high. Poses risks to operators and nearby structures. |

Safety | High. No sparks (cold cut), minimal dust with wet cutting. According to the OSHA respirable silica fact sheet, wet methods are key to safety. | Low. High risk of fly-rock (blasting) and hazardous dust. |

Flexibility | Virtually unlimited cutting depth and ability to make non-linear cuts. | Limited by blade diameter or blast pattern. |

Deconstructing the Wire: Core Components Explained

Diamond Beads: The Core of the Cutting Action

- Sintered Diamond Wire: Diamonds are mixed with a metal powder matrix and fused under high pressure/temperature. Best for durability on abrasive materials like granite.

- Brazed Diamond Wire: A single layer of diamonds is bonded to the bead surface. Offers aggressive, fast cutting, ideal for concrete with rebar and steel.

- Electroplated Diamond Wire: Diamonds are fixed with a layer of nickel. Best for precision on softer, valuable materials like marble and for creating complex shapes with a CNC diamond wire saw.

Steel Wire Core

Connection Types

- Rubber/Plastic: Provides excellent flexibility and water resistance, protecting the core from slurry abrasion. Standard for concrete, demolition, and general use.

- Springs: Offer high mechanical resistance between beads. Preferred for high-tension quarrying applications where the wire is under extreme stress.

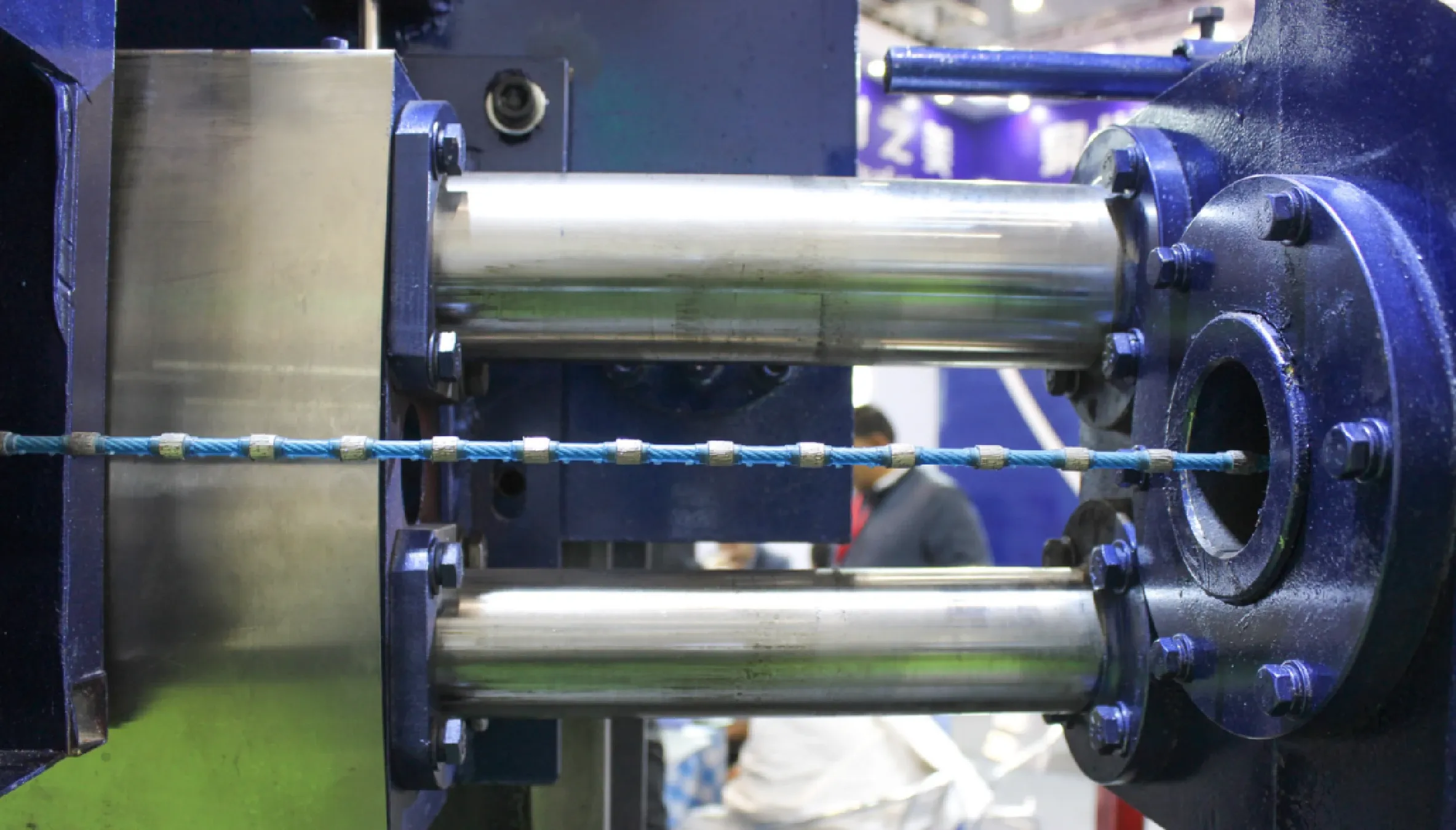

The Machine System (Drive, Tension, and Pulleys)

Common Wire Failures (Wire Splicing & Breakage)

- Wire Breakage: Often caused by excessive tension, sudden snags, or improper splicing. Mitigation: Use a calibrated tensioner, clear the cutting path, and follow proper splicing techniques as shown in our splicing tutorial video.

- Uneven Bead Wear: Caused by inconsistent material hardness or insufficient wire rotation. Mitigation: Rotate the wire periodically and ensure coolant flow is even across the entire cutting surface.

- Bead Loss: Can occur if the wire hits a sharp obstacle or if the bead bonding fails. Mitigation: Use high-quality wire and pre-scan the cutting area for obstructions.

Starting Guide for Cutting Parameters (Wire Speed & Feed)

Condition | Wire Speed | Feed Rate |

|---|---|---|

Hard Granite (Quarrying) | 22-28 m/s | Adjust per material hardness |

Reinforced Concrete w/ Rebar | 20-25 m/s | Adjust per rebar density |

Soft Marble (Slab Cutting) | 28-35 m/s | Adjust per desired finish |

Frequently Asked Questions (FAQs)

What’s the difference between sintered, brazed, and electroplated diamond wire?

- Context:Sintered beads have diamonds mixed throughout the matrix, offering a long life for abrasive stone. Brazed beads have a single exposed layer for fast cuts in concrete and metal. Electroplated is for fine finishes. The choice balances speed vs. tool life.

Why do some wires have springs instead of rubber?

- Context:Springs provide mechanical protection for the steel core under the extreme pulling forces of quarrying. Rubber is better for concrete and demolition because it's flexible and protects the core from alkaline slurry.

How important is the coolant?

- Context:Coolant (usually water) stops the diamond beads from degrading due to heat. It also clears the slurry from the kerf, ensuring a smooth process. Insufficient cooling is a primary cause of wire failure.

Can I use the same wire for granite and concrete?

- Context:Granite wires (sintered) are built for abrasion resistance, while concrete wires (brazed) must handle cutting steel rebar. Using the wrong one leads to poor performance and potential tool damage.

What does wire tension do?

- Context:Too little tension causes the wire to bow, creating an uneven cut. Too much tension stresses the wire core and motor, increasing the risk of snapping. It's a balance between rigidity and flexibility.

How does a diamond wire achieve a better finish than a blade saw?

- Context:A wire saw has a smaller contact area and its abrasive action is more like grinding. This results in a smoother, less-chipped surface that requires less subsequent polishing, which is vital for high-value stone.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский