Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover the technical principles of a PLC-controlled slab cutting machine. Learn how the dual-blade system on our granite and marble block cutter achieves precision.

TL;DR: Engineering Quick Facts

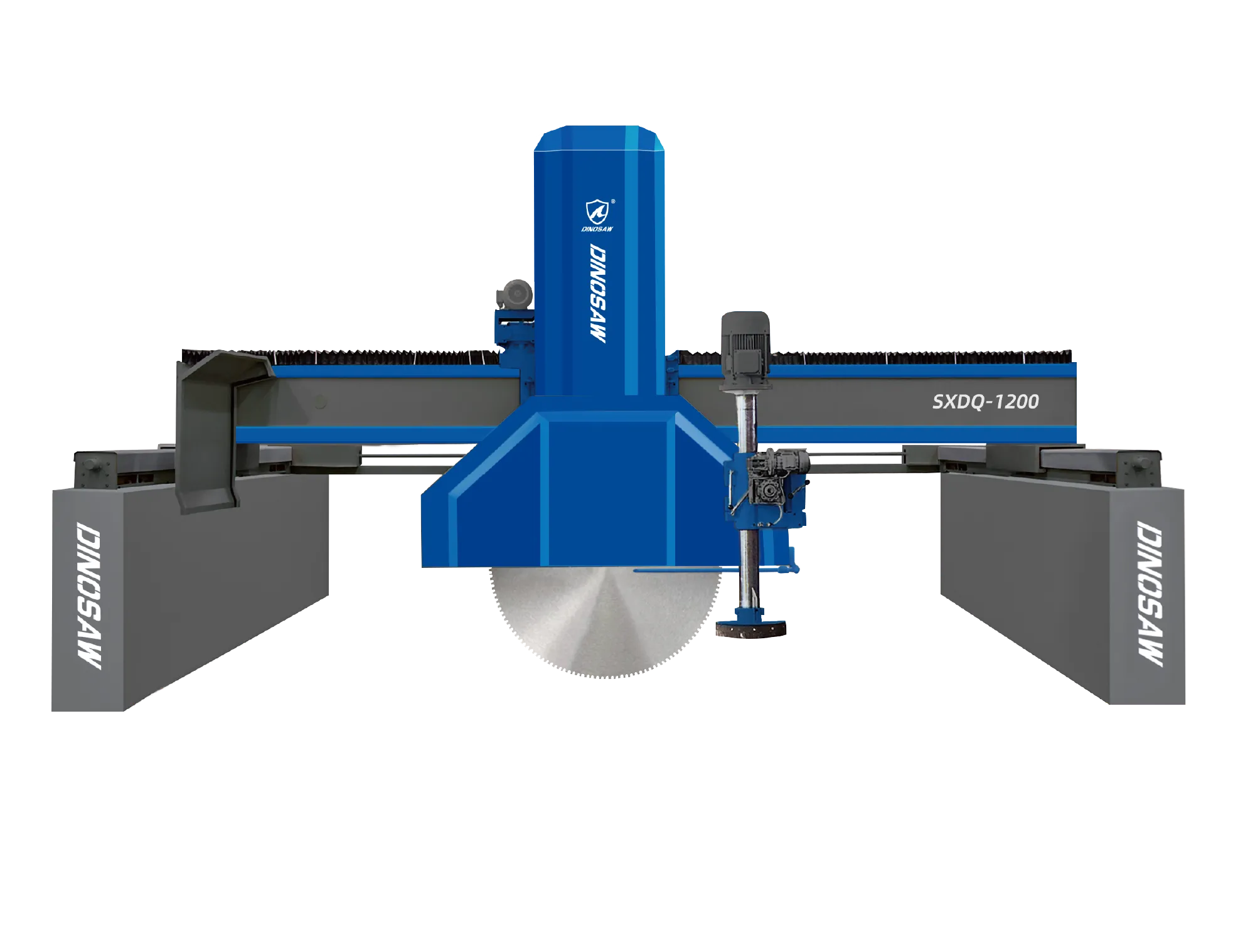

- Core Mechanism: On a Stone Block Cutter with Horizontal Blade, the system synchronizes a powerful vertical blade (Ø1200/1600mm) and a secondary horizontal blade (Ø400–600mm) to perform a complete cut‑and‑separate action in a single pass.

- Control System: The Stone Block Cutter with Horizontal Blade uses a centralized PLC to orchestrate motor speeds, feed rates, and cutting depths based on operator input, ensuring repeatable precision.

- Structural Integrity: The Stone Block Cutter with Horizontal Blade relies on a heavy‑duty bridge structure (approx. 9–9.5 tons) that provides the rigidity needed to handle high loads when cutting hard materials like granite, minimizing vibration and ensuring accuracy.

System Architecture for a Horizontal Blade Stone Block Cutter

Anatomy of an Automated Stone Block Cutting Machine

Vertical Blade Assembly

- Blade Diameter:Ø1200mm or Ø1600mm

- Main Motor Power:55kW or 75kW

- Max Vertical Travel:1350mm

Horizontal Blade Assembly

- Blade Diameter:Ø400mm - Ø600mm

- Motor Power:11kW

Bridge & Beam Structure

- Machine Weight:9,000 - 9,500 kg

- Overall Dimensions:7500×4350×6500 mm

PLC Control System

Trolley System

- Max Cutting Size:3800mm (L) x 2100mm (W)

Cooling System

- Water Consumption:Approx. 20 m³/h

Failure Modes and Engineered Mitigations

Potential Failure | Engineered Mitigation |

|---|---|

Blade Deflection or Vibration | The massive, reinforced bridge beam and guide rails provide extreme rigidity, minimizing flex under load. The PLC also monitors motor current to detect and prevent blade binding. |

Motor Overload | The PLC system uses current transformers to monitor the load on the main motor in real-time. If the load exceeds a preset threshold (e.g., due to a hard spot in the stone), it automatically slows the feed rate to prevent damage. |

Inconsistent Slab Thickness | High-precision encoders on the trolley and blade lift systems provide accurate positional feedback to the PLC. This ensures the trolley advances the exact programmed distance for each cut. |

Typical Working Parameters

Material | Feed Rate | Blade Speed | Cooling Strategy |

|---|---|---|---|

Hard Granite / Quartzite | Low | Lower RPM range to maximize torque | Maximum continuous flow |

Marble / Soft Limestone | Medium to High | Higher RPM range for a smoother finish | Ample, consistent flow |

Abrasive Sandstone | Medium | Moderate RPM to balance speed and tool life | Ensure full blade wetting to remove slurry |

Technical FAQ for Stone Block Cutting Machines

How does a PLC-controlled stone cutter synchronize the vertical and horizontal blades?

- Context:The horizontal blade must activate only after the vertical blade has reached the correct depth to avoid collision and ensure a clean cut for dimensional slab cutting.

- Benefits:The PLC program defines a strict sequence. It reads the vertical position from an encoder and will not send the 'start' command to the horizontal blade's motor until the pre-programmed depth is confirmed. This prevents machine damage and ensures process integrity.

- Next Step:To understand how this improves safety and efficiency, review the case studies in our Applications Guide.

What is the inverter's function in a modern slab cutting machine?

- Context:Different stone types (e.g., granite vs. marble) and blade diameters require different rotational speeds (RPM) for optimal cutting. A fixed-speed motor is inefficient.

- Benefits:The inverter (Variable Frequency Drive) allows the PLC to adjust the motor's speed dynamically. This enables soft starts to reduce electrical load, and allows the operator to fine-tune blade speed to match the stone's hardness, improving cut quality and extending blade life.

Why is weight important for a block trimming machine's precision?

- Context:Cutting hard stone like granite generates immense forces and vibrations that can cause a lighter machine frame to flex or chatter, leading to inaccurate cuts.

- Benefits:The heavy, cast-iron and steel construction acts as a stable platform, absorbing vibrations. This structural rigidity is essential for maintaining the blade's path and achieving consistent tolerances (e.g., ±2mm) for dimensional slab cutting.

Can the control system of a tombstone cutting machine integrate with factory ERP/MES?

- Context:For smart factories (Industry 4.0), production data like cycle times, material usage, and machine status needs to be shared with higher-level management systems.

- Benefits:The PLC can typically be configured to output data over standard industrial protocols (like OPC UA or Modbus TCP/IP). This allows for real-time production monitoring, automated order tracking, and better overall equipment effectiveness (OEE) analysis.

- Next Step:If you have specific integration requirements for your stone fabrication equipment, contact our technical team to discuss custom interface options.

What is the purpose of the hydraulic system in the machine?

- Context:Moving the heavy blade assembly up and down requires significant force, but it must be done smoothly to avoid jarring the stone or the machine.

- Benefits:Hydraulics are ideal for this application as they can generate high force in a compact space and provide very smooth, controllable motion. This is critical for gently lowering the blade into the cut and for maintaining consistent pressure, which improves cut quality, especially in fragile materials like marble.

How does the cooling system's water flow rate (20 m³/h) support cutting performance?

High water flow is critical for thermal management and slurry removal.

- Context:Cutting stone generates immense heat at the point of contact between the diamond segments and the material. It also creates a thick slurry of stone particles.

- Benefits:A high flow rate (1) effectively cools the blade, preventing the diamond segments from overheating and losing their cutting ability, and (2) powerfully flushes the cutting kerf, removing slurry that would otherwise increase friction and slow down the cut.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский