Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Explore how a dual-blade stone block cutter boosts efficiency for granite, marble, and kerb stones. See real-world case studies and production data.

TL;DR: Key Takeaways

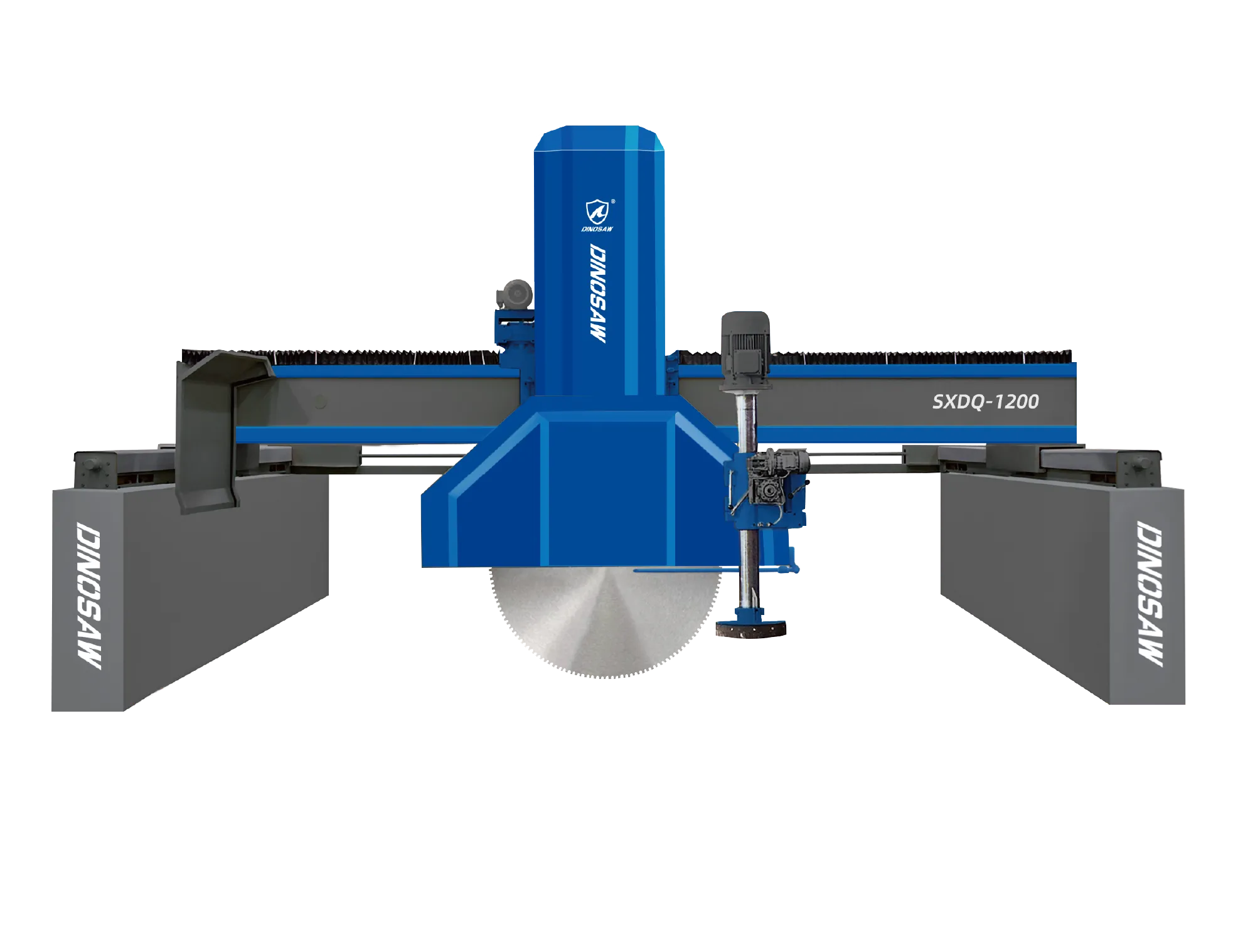

- What it does: This Stone Block Cutter with machine automates the process of cutting large stone blocks into multiple slabs of uniform thickness in a single pass, using synchronized vertical and horizontal blades.

- Primary Applications: Ideal for high-volume production of granite and marble slabs, limestone kerb stones, sandstone panels, and tombstone/monument bases.

- Key Benefit: Dramatically increases throughput and precision by cutting and separating slabs in a single pass (no flipping, no extra bottom cut), reducing labor and material waste compared to single-blade saws.

Disambiguation: This Model Includes a Horizontal Blade

- A built-in horizontal blade works in sync with the vertical blade.

- It separates the slab in the same pass — no extra bottom cut is needed.

- There is no need to flip the heavy block for cross-cutting, making the process safer and faster.

- This makes it ideal for producing strips, kerb stones, and slabs.

What Can a Stone Block Cutter with Horizontal Blade Do For Your Business?

From Raw Blocks to Finished Goods: Key Use-Cases

- High-Volume Slab Production: For fabricating granite and marble slabs for countertops, flooring, and wall panels. The machine turns entire blocks into a stack of uniform slabs in one continuous cycle, dramatically increasing inventory turnover.

- Kerb Stone & Paver Manufacturing: Ideal for producing standardized limestone or granite kerb stones for municipal and infrastructure projects. Its high speed and repeatability ensure you can meet large order demands on tight deadlines.

- Architectural Panels & Cladding: For cutting sandstone and other materials into dimensional panels for building facades. The high dimensional accuracy ensures a perfect fit during installation, reducing on-site adjustments and labor.

- Tombstone & Monument Bases: Efficiently produces thick, rectangular bases for monuments. Automating this initial sizing step frees up skilled labor and more versatile CNC machines for the detailed, high-value carving work.

Performance Highlights (Qualitative)

- Consistent Precision: The machine's robust build and PLC control system deliver consistently tight and uniform tolerances, reducing waste and the need for downstream processing.

- Increased Throughput: By eliminating the block-flipping time required by single-blade saws, the dual-blade system achieves a significant boost in output for products like granite slabs.

- Predictable Output: The automated cutting cycle enables a steady and predictable output of standardized products, such as kerb stones, helping to meet demanding production schedules.

Material & Processing Compatibility Guide

Material | Typical Application | Key Benefit |

|---|---|---|

Granite | Slabs for countertops, flooring, monuments | High power handles hardness; consistent thickness. |

Marble | Slabs for architectural panels, tiles, tombstones | Smooth cutting action minimizes fractures. |

Limestone | Kerb stones, building blocks, pavers | High-speed, repeatable cuts for standardized products. |

Sandstone | Wall panels, cladding, dimensional stone | Precise dimensional control with minimal chipping. |

Quartzite | Blocks for further processing into slabs | Handles extreme hardness without blade stalling. |

What Are Its Processing Limits? (Can vs. Cannot)

What It Can Do

- Cut large blocks up to 3800mm long and 2100mm wide.

- Produce slabs with thicknesses from 10mm to 80mm.

- Perform automated, repeated rectangular cuts.

What It Cannot Do

- Perform curved or profiled cuts (requires a CNC profiler).

- Polish or finish surfaces (requires a separate polishing line).

- Cut extremely thin veneers below 10mm.

How Does a Stone Block Cutter Machine Work? A Quick Process Overview

- Block Loading: The raw stone block is placed on the machine's trolley.

- PLC Programming: The operator inputs the desired slab thickness and number of cuts into the PLC control panel.

- Automated Cutting: The machine begins the cycle. The large vertical blade makes the main cut, immediately followed by the horizontal blade, which separates the slab from the main block.

- Slab Removal: The finished slab is removed, and the trolley automatically advances for the next cut.

How Does It Compare to Traditional Methods?

Metric | Dual-Blade Cutter | Manual Splitting | Single-Blade Saw |

|---|---|---|---|

Efficiency | High | Very Low | Medium |

Labor Required | 1 operator | Multiple workers | 1-2 operators |

Safety | High (Automated, enclosed) | Low (High risk of injury) | Medium (Requires block flipping) |

Material Waste | Low (high precision) | High (Inconsistent breaks) | Medium |

3 Mini-Case Studies from the Field

- Problem: Manually sizing heavy granite blocks for tombstones was a slow, hazardous process that created a production bottleneck and tied up skilled labor.

- Solution: Replaced two single-blade saws with one dual-blade cutter to automate the initial block sizing, eliminating the need to flip heavy blocks.

- Result: Daily output increased significantly, material handling injuries were eliminated, and artisans were freed for high-value carving work.

- Problem: Meeting high-volume municipal orders for limestone kerb stones required a significant boost in production speed without sacrificing dimensional accuracy.

- Solution: Automated the production line with a dual-blade cutter, leveraging its high-speed, repeatable cutting capabilities for standardized products.

- Result: Achieved a clear efficiency boost, delivering a steady, predictable output with consistent tolerances that met strict contract specifications.

- Problem: An order for 800+ identical sandstone panels for a building facade required near-perfect consistency to avoid costly on-site rework and project delays.

- Solution: The project was assigned to the dual-blade cutter to ensure every panel was cut to the exact same specifications from the start.

- Result: Achieved a minimal rework rate. The machine's consistent cutting performance ensured all panels maintained consistent tolerances, keeping the project on schedule and on budget.

Application-Driven Blade & Segment Selection

- For Hard Stones (Granite, Quartzite): Use segments with a softer metal bond. The bond wears away faster, exposing new diamond particles to effectively cut the hard material.

- For Soft/Abrasive Stones (Marble, Sandstone): Use segments with a harder metal bond. This prevents the diamonds from being stripped away too quickly by the abrasive material, prolonging blade life.

Optimizing for Edge Quality & Tolerance

- Manage Feed Rate: Pushing the machine too fast can cause blade deflection and chipping. Start with the recommended parameters and adjust based on the cut quality.

- Ensure Ample Cooling: Insufficient water flow causes overheating, which can warp the blade and damage segments, leading to poor cuts. Always check that water is coating both sides of the blade evenly.

- Regularly Check Blade Tension: A loose blade will vibrate and produce a rough, inaccurate cut. Follow the maintenance schedule for checking and tensioning blades.

Material-Specific Starting Parameters (Guidelines)

Material | Feed Rate | Blade Speed | Cooling Flow | Expected Tolerance |

|---|---|---|---|---|

Granite | Low to Medium | Match to material hardness | Continuous high flow | Tight and consistent |

Marble | Medium to High | Adjust for smooth finish | Continuous, ample flow | High precision |

Limestone | High | Optimized for speed | System capacity (20 m³/h) | Consistent |

Sandstone | Medium | Adjust to minimize chipping | Ensure full blade wetting | Consistent |

Quartzite | Low | High torque configuration | Continuous high flow | Tight and consistent |

Integrating the Stone Block Cutter with Horizontal Blade into Your Production Line

Sizing and Custom Cuts

Surface Finishing

Measuring Success: Qualitative Pilot Metrics

- Quality of Cut: Are the cut surfaces and edges consistently clean and within acceptable visual standards? (Document with photos).

- Operational Readiness: Are operators fully trained and following standard operating procedures (SOPs)? Is a preventive maintenance schedule in place?

- Safety Compliance: Is the team consistently following all safety protocols, including Lockout/Tagout (LOTO) for maintenance?

- Process Continuity: Does the machine operate smoothly without frequent unplanned stops or manual interventions?

- Site Prerequisites: Ensure a solid, level concrete foundation and adequate space for loading/unloading blocks and slabs.

- Power & Water Supply: Verify that the electrical supply matches the machine's requirements (e.g., 75kW main motor for a large model) and that a sufficient water supply is available for blade cooling.

- Dust & Water Management: Effective dust suppression is not just a best practice; it is a critical safety requirement. According to OSHA's standard 1926.1153, employers must use engineering controls like wet cutting to limit worker exposure to respirable crystalline silica. The U.S. National Institute for Occupational Safety and Health (NIOSH) also strongly recommends water spray systems to control dust. Implement a closed-loop water recycling and slurry management system to conserve water and manage waste responsibly.

- Operator Training: While automated, operators must be trained on PLC operation, safety procedures, and basic maintenance. We provide comprehensive training to ensure your team is fully prepared.

Frequently Asked Questions (FAQ)

What is a horizontal blade on a stone cutter used for?

- Context: It works in tandem with the vertical blade during the cutting cycle. The vertical blade cuts down, and the horizontal blade immediately cuts across the bottom to separate the slab.

- Benefits: This eliminates the need for manual splitting or flipping heavy blocks, which prevents a major production bottleneck, reduces labor, and significantly improves operator safety.

Can this machine cut hard materials like quartzite blocks?

- Context: When processing extremely hard stones like quartzite or dense granite, where other machines might stall or vibrate excessively.

- Benefits: The machine's rigid bridge structure and high-power motor (e.g., 75kW) provide the necessary torque and stability to cut through these materials smoothly and efficiently.

- Next Step: If you work with hard materials, contact our experts to discuss the right configuration for your needs.

For producing standard slabs, is a dual-blade cutter more efficient than a bridge saw?

- Context: A bridge saw is a versatile tool for making custom, angled, or secondary cuts on a single slab. A dual-blade block cutter is a specialized production machine for turning entire blocks into multiple slabs.

- Benefits: The block cutter operates in a continuous, automated cycle, processing the entire block with minimal downtime. A bridge saw requires more setup and handling for each individual cut, making it slower for bulk production.

- Next Step: Evaluate if your workflow is primarily bulk production or custom jobs to determine the right machine. Learn more about the specialized block cutter here.

How much can this machine increase daily throughput for kerb stone production?

- Context: In the production of standardized items like kerb stones, speed and repeatability are key. This machine is designed for continuous, automated cutting.

- Benefits: By eliminating the need to stop and flip the block between cuts, the machine maximizes uptime and can produce a significantly higher volume per shift compared to traditional methods.

- Next Step: To calculate the potential ROI for your specific output needs,request a consultation with our production experts.

What cutting tolerance can be expected when processing large granite blocks?

- Context: For applications like architectural panels or high-end countertops, dimensional accuracy is critical to ensure a perfect fit and finish.

- Benefits: This level of accuracy minimizes material waste from out-of-spec cuts and reduces the need for secondary grinding or calibration, saving both labor time and material costs.

Can I cut slabs of different thicknesses in the same batch?

- Context: When a single block needs to be processed into products with varying specifications, such as a mix of 2cm and 3cm slabs for a project.

- Benefits: You can program a sequence (e.g., five 20mm cuts followed by three 30mm cuts) into the PLC. The machine will execute the entire batch automatically without needing operator intervention between thickness changes, maximizing efficiency.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский