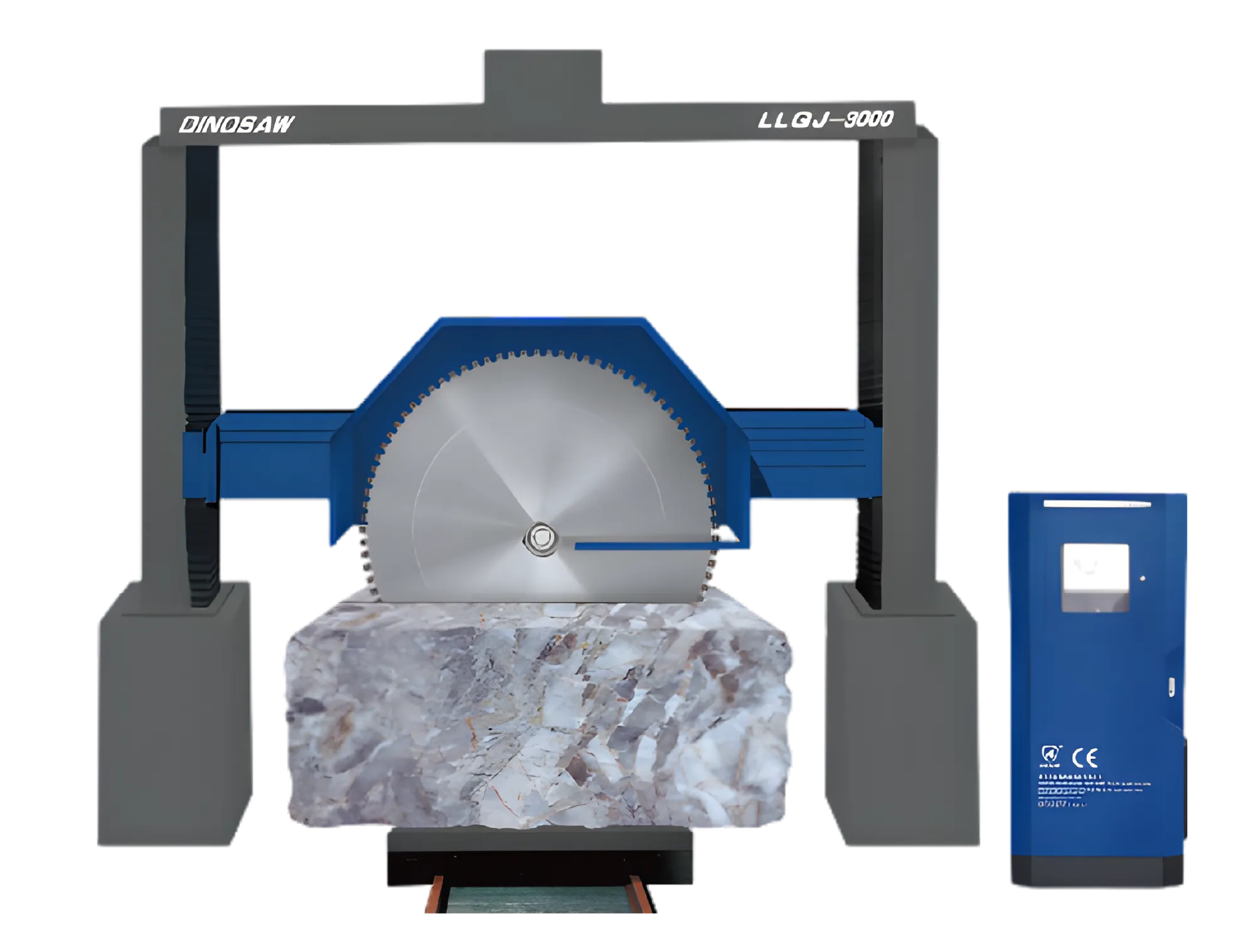

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover how our gantry cutting machine precisely processes tombstones, kerb stones, and standard slabs. Learn about its applications on various stones to boost your production efficiency.

TL;DR:Key Takeaways

- Versatile Material Processing: The gantry cutting machine handles a wide range of stones, from hard granite for tombstones to softer limestone for kerb stones, enabling you to serve diverse markets.

- Automated Precision: PLC automation ensures consistent slab thickness and dimensional accuracy, reducing material waste by up to 15% and minimizing costly manual errors.

- Efficient Block Slabbing:The gantry cutter is conventionally a single-blade machine for precise block slabbing. For true multi-blade simultaneous slab production, consider the Gantry Stone Cutting Machine.

- Actionable Next Step: Assess your primary materials and required block dimensions to determine the right machine model for your production needs.

What Can a Gantry Stone Cutter Do for Your Business?

What Materials Are Compatible with a Gantry Stone Block Cutter?

- Granite: A top choice for tombstones and high-end countertops, granite is known for its durability. According to industry resources, it scores between 6 and 7 on the Mohs hardness scale (source: Wikipedia), requiring a machine with a rigid structure and powerful motor to cut cleanly without causing micro-fractures.

- Marble: Valued for its elegant veining, marble is used in monuments and luxury architectural elements. It's softer than granite, but its delicate structure requires a stable, vibration-dampened cutting process to prevent chipping and preserve its aesthetic quality.

- Limestone & Bluestone: Commonly used for kerb stones, paving, and architectural details, these sedimentary rocks are relatively soft and easy to cut. A gantry machine excels at mass-producing standardized dimensions required for large-scale construction and infrastructure projects.

- Sandstone: Often used for standard slabs and cladding, sandstone's consistency makes it ideal for high-volume production. The machine's automated controls ensure every slab meets exact dimensional specifications.

- Travertine & Quartzite: Travertine's porous nature and quartzite's crystalline structure present unique cutting challenges. The machine's adjustable parameters, such as feed rate and water cooling flow, are crucial for processing these materials without causing damage.

Understanding the Processing Boundaries for the Gantry Block Cutting Saw

- LLQJ-2200: This model is ideal for small to medium-sized blocks, offering a maximum cutting height of 950 mm (approx. 37.4 inches). It's a great entry point for shops focusing on standard slabs or smaller memorial stones.

- LLQJ-2500: Offering a balanced capacity, this model increases the maximum cutting height to 1100 mm (approx. 43.3 inches), making it suitable for larger architectural elements and thicker monument blocks.

- LLQJ-3000: The largest in the series, this machine accommodates massive blocks with a maximum cutting height of 1350 mm (approx. 53.1 inches). It is designed for quarries and large-scale fabricators handling oversized blocks for major construction or monument projects.

How Do You Process Stone with the PLC-Controlled Gantry Saw?

- Preset Parameters with the PLC System: The brain of the operation is the Programmable Logic Controller (PLC). Before starting a job, you input the desired slab thickness, the number of cuts, and the total block height. The system then automates the cutting process, ensuring each slab is uniform without manual measurement.

- Select the Right Diamond Blades: Your choice of diamond blade is critical. The blade's segment composition must match the stone's hardness and abrasiveness. A blade designed for granite will perform differently on marble. Using the correct blade ensures a clean cut, minimizes chipping, and extends the life of your tooling.

- Ensure Adequate Water Cooling: Water is essential. It serves two purposes: cooling the blade to prevent overheating and warping, and suppressing hazardous crystalline silica dust. A consistent flow of water directed at the cutting point is non-negotiable for both cut quality and operator safety.

- Set Optimal Feed Rates: The feed rate—the speed at which the blade moves through the stone—must be adjusted based on the material. Cutting hard granite too quickly can cause excessive blade wear, while cutting soft limestone too slowly is inefficient. The machine's frequency converter allows for precise speed control to find the perfect balance.

Single-Blade Gantry Cutter vs. Traditional Methods

Scenario 1: High-Volume Slab Production

Scenario 2: Precision Monument Cutting

Mini Case Studies with the Gantry Slab Cutter: From Challenge to ROI

Case Study 1: Memorial Stone Manufacturer

- Initial Situation: A family-owned monument business was struggling to meet rising demand. Their manual cutting process was slow, resulted in approximately 20% material waste due to inconsistencies, and required highly skilled operators who were becoming difficult to find.

- Action: They invested in an LLQJ-2500 gantry cutting machine. They trained two existing employees to operate the PLC system, allowing them to preset cutting parameters for their most common tombstone dimensions.

- Quantified Result: Within six months, their production output increased by 40%. Material waste was reduced to under 5% thanks to the machine's precision. Labor costs per unit dropped by 30%, and they were able to reassign their skilled craftsman to higher-value engraving and finishing work.

- Replication Conditions: This success can be replicated by any business processing standard-sized blocks (up to 1100 mm high) and looking to automate the initial block-squaring and slabbing process.

Case Study 2: Standard Slab Wholesaler

- Initial Situation: A stone wholesaler supplied 2 cm and 3 cm sandstone slabs to construction companies. Their existing equipment produced slabs with inconsistent thickness, leading to frequent client complaints and installation difficulties on-site.

- Action: They installed an LLQJ-3000 with a multi-blade setup specifically for high-volume slab production. The PLC was programmed for their two primary thickness specifications, allowing for continuous, automated operation.

- Quantified Result: The company now produces over 500 standardized slabs per day with a thickness tolerance of less than ±0.5 mm. Client complaints dropped to zero, and they secured a 25% larger contract with a major developer due to their reputation for quality and reliability.

- Replication Conditions: Ideal for wholesalers or quarries focused on mass production of standardized slabs. Requires sufficient yard space for block staging and slab removal.

Case Study 3: Architectural Panel Supplier

- Initial Situation: A supplier of high-end architectural limestone panels was forced to turn down large projects because their CNC Bridge Saw was being tied up with basic block slabbing, a task it was not designed for. This created a significant bottleneck in their production workflow.

- Action: They integrated an LLQJ-2200 gantry cutter as the first step in their production line. The gantry machine is now dedicated to cutting raw limestone blocks into manageable, consistently thick slabs.

- Quantified Result: This freed up their CNC bridge saw for its intended purpose: precision cutting of complex shapes. The production bottleneck was eliminated, overall project lead times were reduced by an average of 5-7 days, and they were able to take on two major facade projects they previously would have declined.

- Replication Conditions: This two-stage workflow is highly effective for fabricators specializing in custom, high-value architectural work. It requires integrating the gantry machine into a larger, multi-equipment production line.

Risks and Prerequisites for Operating a Gantry Stone Cutter

Summary: A Versatile Asset for Growth

Frequently Asked Questions

How many slabs can a gantry machine cut at once?

- Context:The gantry cutter's strength lies in its flexibility to handle various block sizes and stone types with high precision using a single blade. For simultaneous cutting, a different machine is required.

- Risk:Confusing a gantry cutter with a multi-blade machine can lead to incorrect expectations about throughput. The gantry cutter offers precision and versatility, not mass simultaneous cutting.

- Next Step:If your primary need is high-volume simultaneous cutting, you should investigate a dedicated Gantry Block Cutting Saw Machine.

Do I need to change blades for cutting different types of stone?

- Context: Different stones have varying levels of hardness and abrasiveness. A blade's diamond concentration and bond are optimized for specific materials, such as hard granite versus softer sandstone.

- Risk: Using the wrong blade can lead to poor cut quality, premature tool wear, and even fractures in the stone, which increases operational costs and material waste.

- Next Step: As part of your operational planning after purchasing, create an inventory of material-specific blades. Consult with your blade supplier to match the correct blade to each type of stone you process.

Is this gantry block cutter suitable for a small workshop?

- Context: A key advantage is that it does not require a special concrete foundation for installation. This significantly reduces setup complexity and cost, which is a critical consideration during your initial assessment.

- Risk: Even for a small workshop, you must ensure you have adequate space not only for the machine's footprint but also for safely loading and unloading large stone blocks.

- Next Step: Review the specifications for the LLQJ-2200 model and measure your available workspace. Plan the logistics for material flow before making a final investment decision.

What is the typical learning curve for an operator?

- Context: The machine features a user-friendly PLC interface where basic operation involves inputting numerical values for thickness and cut dimensions. We provide comprehensive training during installation.

- Risk: Inadequate training can lead to operational errors, reduced efficiency, and potential safety hazards. Proficiency requires understanding both the machine's operation and its safety procedures.

- Next Step: When considering implementation and staffing post-purchase, identify key personnel for training and ensure they attend the full installation and commissioning process.

How does the machine handle imperfections in a stone block?

- Context: Human expertise remains vital in assessing raw material. An experienced operator will examine the block for visible cracks or fissures and plan the cuts to maximize yield around flawed sections.

- Risk: Cutting through a significant, undetected flaw can damage the blade, waste a large section of valuable material, or result in an unstable final product.

- Next Step: Implement a standard procedure for all operators to thoroughly inspect and mark up raw blocks before they are placed on the machine for cutting.

What's the advantage of a hydraulic lifting system?

- Context: This stability is crucial when making precise cuts in brittle materials like marble or granite, as it minimizes blade deflection and reduces the risk of micro-fractures in the stone.

- Risk: A less stable mechanical system can introduce vibrations that lead to an uneven finish, requiring more time and labor in subsequent polishing stages.

- Next Step: When evaluating different machine types, consider the hydraulic system a key technical feature for achieving superior surface quality and reducing downstream finishing costs.

Can I cut curved shapes with this machine?

- Context: For cutting curves, contours, or other complex shapes, a different type of machine is required, such as a CNC Bridge Saw or a CNC wire saw.

- Risk: Attempting to misuse the gantry cutter for non-linear cuts will not work and could potentially damage the machine's guide rails or drive system.

- Next Step: Clearly define your production needs. If your business requires cutting complex shapes, you must invest in the appropriate equipment in addition to a gantry cutter for primary slabbing.

How much maintenance does the machine require after purchase?

- Context: Maintenance involves a simple routine of daily, weekly, and monthly tasks. This includes cleaning slurry, checking blade condition, inspecting hydraulic fluid levels, and lubricating moving parts.

- Risk: Neglecting preventative maintenance can lead to unexpected downtime, costly repairs, and a reduction in the machine's operational lifespan and cutting accuracy.

- Next Step: Upon purchasing the machine, establish a formal maintenance schedule based on the user manual. Assign clear responsibilities to your operating team to ensure all tasks are completed consistently.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский