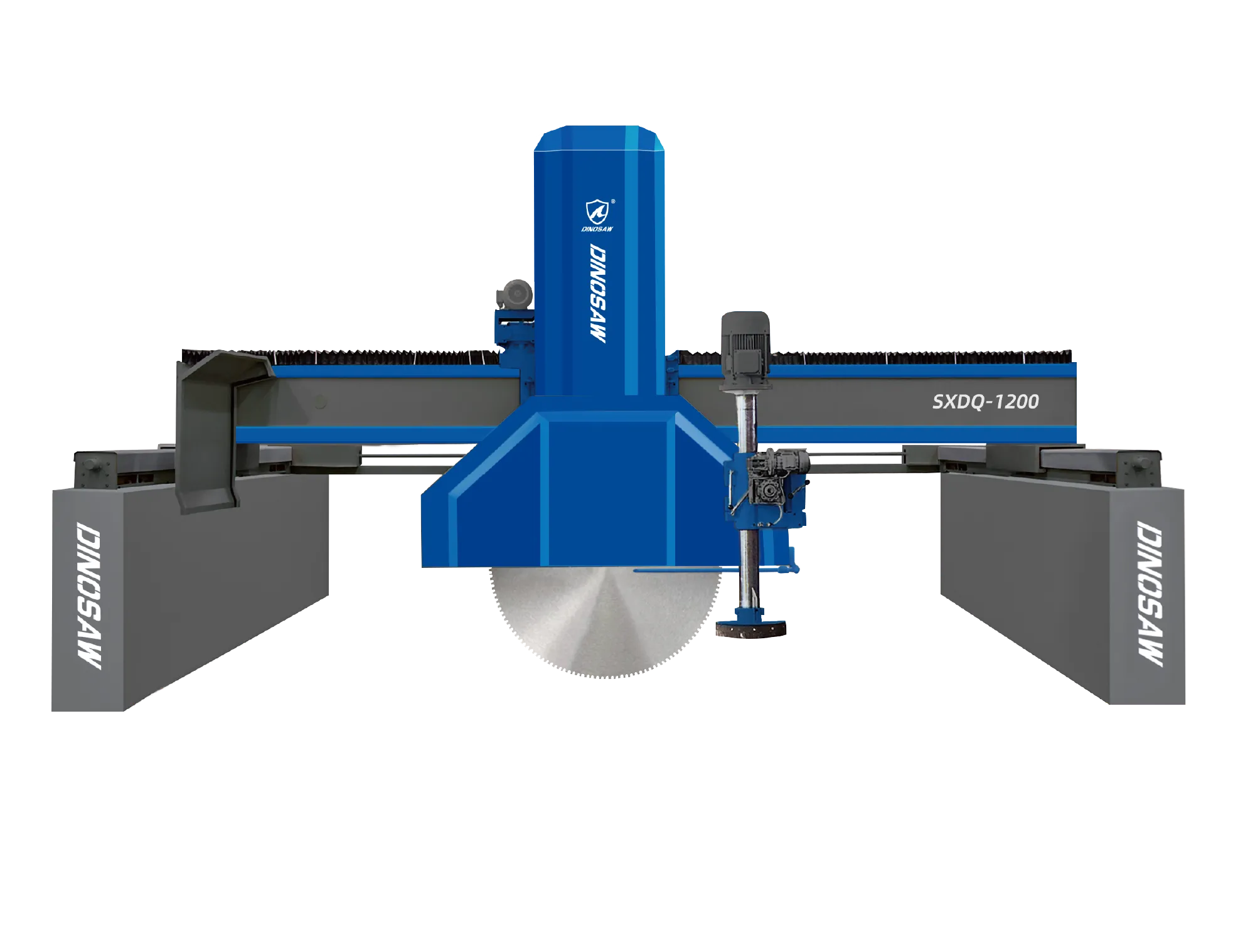

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Learn essential maintenance and safe operation for your dual-blade stone block cutting machine. Includes daily checklists, troubleshooting, and blade replacement guides.

TL;DR: The Core Maintenance Philosophy

- Proactive, Not Reactive: A consistent schedule of daily cleaning, weekly lubrication, and monthly inspections prevents most major breakdowns Ensure optimal performance of the stone block cutting machine.

- Safety is Paramount: Always follow Lockout/Tagout (LOTO) procedures before any maintenance. Never bypass safety sensors or guards.

- Use Genuine Parts: Using OEM-specified spare parts and lubricants is critical for maintaining machine integrity, performance, and warranty.

Preventive Maintenance Overview

Daily Checks

- Clean slurry and debris from blades, trolley, and rails.

- Inspect water nozzles for clogs.

- Verify safety guards and E-stops are functional.

Weekly Checks

- Lubricate all guide rails and moving parts.

- Check blade tension and look for signs of wear.

- Inspect hydraulic oil levels and check for leaks.

Monthly Inspections

- Inspect electrical cabinet for loose connections.

- Check trolley wheels and bearings for wear.

- Verify calibration of PLC sensors.

Key Maintenance Procedures

Key Maintenance Procedures

- Perform Lockout/Tagout (LOTO) procedure.

- Release blade tension and remove the retaining flange.

- Carefully replace the old blade with a new one, ensuring correct orientation.

- Re-secure the flange and tension the blade to manufacturer specifications.

Basic Troubleshooting Guide

Basic Troubleshooting Guide

Problem | Potential Cause | Solution |

|---|---|---|

Crooked Cut | Improper blade tension or excessive feed rate. | Check and adjust blade tension. Reduce the feed rate. |

Chipped Edges | Feed rate too high or insufficient cooling. | Reduce feed rate. Check water nozzles for blockages. |

Unexpected Stop | Safety sensor triggered or PLC alarm. | Check for obstructions. Review PLC alarm log on HMI. |

Safety Protocols: Non-Negotiable Rules

- Lockout/Tagout (LOTO): Always de-energize and lock out the machine before any maintenance, cleaning, or blade changes.

- Guarding: Never operate the machine with safety guards removed or sensors bypassed.

- Wet Cutting for Silica Control: Always ensure the water cooling system is fully operational. According to OSHA standard 1926.1153, wet cutting is a required engineering control to limit worker exposure to respirable crystalline silica.

Operations & Maintenance FAQ

Operations & Maintenance FAQ

How often should I replace the hydraulic oil?

- Context: Hydraulic oil degrades over time, losing its lubricating properties and accumulating contaminants that can damage pumps and valves.

- Procedure: During the weekly check, inspect the oil's color and clarity. If it appears milky (water contamination) or dark and gritty, it needs to be replaced sooner. An annual replacement is a good baseline.

- Next Step: Incorporate a weekly visual inspection into your logbook and schedule an annual oil change with your maintenance team.

What is Lockout/Tagout (LOTO) and when do I use it?

- Context: Unexpected machine startup is a leading cause of serious injury in industrial settings. LOTO provides a physical barrier to prevent accidental re-energization.

- Procedure: It involves turning off the machine, isolating it from its power source, locking the isolation device, and placing a tag on the lock identifying the worker performing the maintenance. It must be used before any task that involves placing hands or tools near moving parts.

- Next Step: Ensure all operators and maintenance staff are fully trained on your company's specific LOTO policy. Make it a mandatory step in your Standard Operating Procedures (SOPs) for all maintenance tasks.

My kerb stone edges look chipped — what should I adjust?

- Context: When cutting materials like limestone for kerb stones, the blade is trying to remove material faster than it can be cleanly fractured, causing the edges to break away instead of being cut smoothly.

- Procedure: First, reduce the feed rate by 10-15% and run a test cut. If chipping persists, inspect the blade segments for excessive wear or glazing. Finally, ensure the cooling nozzles are clear and providing ample water directly to both sides of the cut.

- Next Step: Document the optimal feed rate for this material in your SOPs to ensure all operators use the correct parameters.

How do I safely inspect and tension the main blade?

- Always follow LOTO and use the manufacturer’s tensioning steps to prevent vibration and poor cut quality.

- Context: Incorrect tension causes wobble and crooked cuts; over-tension can damage the blade hub.

- Procedure: De-energize (LOTO), remove guards, check tension with the specified gauge; adjust to the recommended band; spin by hand to confirm even runout; re-install guards.

- Next Step: Add a monthly blade tension check to your SOP and logbook.

What routine checks prevent trolley misalignment over time?

- Small alignment drift accumulates; a simple weekly audit keeps the trolley moving parallel to the blade path.

- Context: Side-to-side play introduces taper and inconsistent thickness.

- Procedure: Inspect guide wheels and rails; tighten fasteners; verify encoder readings match programmed travel; run a test cut and measure opposite edges with a straightedge.

- Next Step: Schedule a quarterly precision audit with maintenance to re-square the trolley.

When should I switch diamond segment types for different stones?

- Match bond hardness to material abrasiveness to avoid glazing or premature wear.

- Context: Hard granite needs softer bonds to expose fresh diamonds; abrasive sandstone needs harder bonds to resist rapid wear.

- Procedure: Monitor cut feel and edge appearance; if glaze appears or speed falls, change to a softer bond; if segments wear too fast on soft stones, select a harder bond.

- Next Step: Maintain a labeled blade inventory and presets for granite, marble, limestone, sandstone.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский