Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Diamond Wire Saw - Premium Diamond Cutting Tools

Wire Saws for Stone, Concrete and more

Compatible Materials & Products

Specialized Cutting Wire Saw for Every Material Challenge

Diamond Wire Saw for Concrete

|

|---|

|

Reinforced concrete structures in bridges and buildings present unique challenges during renovation or demolition, requiring specialized wire saw for concrete that can handle embedded steel while maintaining structural safety and minimizing environmental impact.

DINOSAW diamond wire saws are engineered specifically for concrete applications with a robust brazed diamond bead composition that efficiently cuts through both concrete and embedded rebar. Our 10-12mm diameter wires feature specially designed bead spacing that prevents clogging with concrete debris, while the rubber connection type absorbs shock and reduces vibration when encountering steel reinforcement. For underwater applications, our specialized marine-grade diamond wires maintain cutting efficiency while withstanding harsh underwater environments.

Projects using DINOSAW wire saw for concrete cutting report up to 60% time savings compared to traditional methods, with significantly reduced noise and virtually no harmful dust production. The wire's ability to cut at any angle makes it ideal for complex demolition projects where structural integrity of surrounding elements must be maintained.

Diamond Wire Saw for Granite

|

|---|

|

|

Granite's exceptional durability and timeless appearance make it ideal for tombstones and memorial stones that must withstand generations of weathering. Creating these memorial pieces demands precision diamond wire cutting to achieve dignified designs while maximizing the use of premium stone blocks.

DINOSAW sintered diamond wire saws excel in granite processing through specialized diamond beads with optimized metal bond matrix for extreme hardness. Our 11mm diameter wires with 36/40 grit diamond concentration provide the aggressive cutting power needed for dense granite varieties. The spring connection type ensures flexibility and shock absorption when cutting through variable-density materials and natural fissures often found in granite blocks.

Memorial stone fabricators report 25% faster production cycles and significantly higher quality when using our diamond wire technology. The specialized bead spacing and diamond concentration ensure clean, precise cuts even through the hardest granite types, allowing for easier finishing and more intricate design capabilities in the memorial industry.

Diamond Wire Saw for Marble

|

|---|

|

|

Marble's natural beauty and elegant veining patterns make it the top choice for luxury countertops and decorative slabs. However, its delicate structure demands specialized wire saw stone cutting solutions to preserve unique patterns and prevent damage during processing.

DINOSAW diamond wire saws feature optimized bead composition specifically engineered for marble applications. Our electroplated diamond wires with 40/50 grit diamond particles deliver the ideal balance between cutting speed and surface quality, achieving 1.8-2.0㎡/h cutting efficiency with minimal kerf width. The plastic injection connection type provides the perfect stability for precision marble cutting while reducing vibration.

For premium marble varieties like Calacatta and Statuario, our fine-grit diamond wires with 60/80 diamond concentration produce exceptionally smooth surfaces that require minimal finishing. The result is flawless marble countertops and decorative slabs with up to 30% improvement in material yield compared to traditional cutting methods.

Diamond Wire Saw for Refractory

|

|---|

|

Refractory materials such as firebricks, ceramic blocks, and high-temperature insulation are critical components in industrial furnaces, kilns, and thermal equipment. The extreme hardness and temperature resistance of these materials present significant cutting challenges, requiring specialized diamond wire technology for precise fabrication and maintenance.

DINOSAW diamond wire saws for refractory applications feature brazed diamond beads with specialized formulations designed to withstand the abrasive nature of alumina, silica, and other refractory compounds. Our 8-10mm diameter wires with 40/50 grit diamond concentration provide the aggressive cutting power needed for these ultra-hard materials. The rubber connection type ensures stability while absorbing the vibration that occurs when cutting through the varied density and occasional crystalline structures in refractory products.

Industrial furnace manufacturers and maintenance contractors report up to 40% reduction in downtime when using our specialized refractory cutting solutions. The precise cutting capabilities allow for complex shapes and tight-fitting joints that significantly improve thermal efficiency and extend service life of industrial heating equipment. Even the most challenging materials like silicon carbide and zirconia can be effectively processed with minimal material waste.

Diamond Wire Saw for Metal

Industrial metal structures and components often require precise cutting during decommissioning, modification, or specialized manufacturing processes. Traditional thermal cutting methods introduce heat distortion and hazardous conditions, particularly in sensitive environments.

DINOSAW diamond wire saw for metal features specialized electroplated diamond beads with proprietary metal bond formulations designed specifically for ferrous and non-ferrous metals. Our 7-9mm diameter wires with 30/40 diamond concentration deliver efficient cold-cutting performance that eliminates heat-affected zones and prevents material distortion. The spring+rubber hybrid connection type provides both flexibility and stability required for metal cutting applications, especially when cutting through variable thickness sections.

Industrial applications benefit from the system's ability to make precise cuts through complex metal assemblies while maintaining structural integrity of surrounding components. With cutting speeds of 0.5-0.8㎡/h for steel, our wire saw for metal technology has proven particularly valuable in nuclear decommissioning projects, oil and gas facility modifications, and precision manufacturing environments where flame-free cutting is essential.

Bridge Construction & Demolition

Safe & Efficient Reinforced Concrete Cutting

DINOSAW brazed diamond wire cut through 1.5-meter thick reinforced concrete during a bridge renovation project. The cold-cutting process eliminated vibration and reduced dust by 85% compared to conventional methods. The project completed 12 days ahead of schedule.

Stone Quarry Operations

80% Increased Extraction Efficiency

An Italian quarry used DINOSAW diamond wires for marble extraction. With proper maintenance, they achieved wire longevity of 150 ㎡/m - 25% longer than industry average. The operation now extracts 35% more marketable blocks while reducing waste by 30%, significantly increasing profitability.

Underwater Metal Cutting

Precision Cutting in Challenging Environments

An offshore contractor used DINOSAW brazed diamond wire with marine-grade rubber connection for underwater steel structures. The diamond beads maintained cutting efficiency at 35m depth while resisting saltwater corrosion. Remote operation precisely cut metal assemblies, reducing operation time by 40%.

Specs and options

Specifications customizable upon request.

Diamond wire saws for different materials, manufacturing processes, and formulations vary significantly in performance and lifespan. If you're unsure about selecting the right diamond wire saw for your specific application, please contact our technical team for professional consultation.

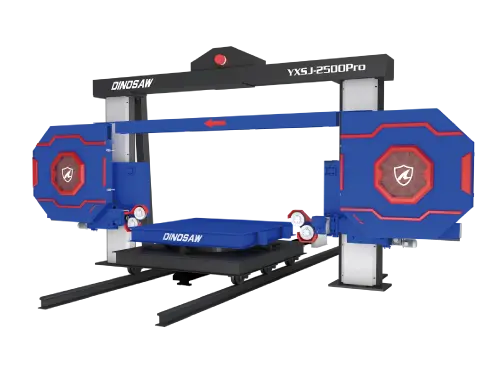

Product Series

Electroplated & Vacuum brazed diamond wire saw - Precision Cutting Series

Diamond wire saw for granite - Stone Quarrying Series

Diamond wire for reinforced concrete cutting - Concrete & Metal Series

Diamond wire saw for marble - Decorative Stone Series

Compatible with all wire saw machines on the market (Husqvarna, Well, Diamond Products, Pellegrini, CO.FI.PLAST, etc). Best performance achieved with DINOSAW machines due to our application data and engineering expertise.

Full range of accessories available: rubber spacers, springs, crimp connectors, wire connectioners, and steel wire cores for all applications.

Specialized diamond wire saws for concrete, metal, stone, and precision cutting

Advanced Diamond Wire Saw Technology for All Materials

Perfected Manufacturing Process

20+ years of R&D ensures optimal bead retention and minimal wire breakage

Universal Machine Compatibility

Compatible with all major brands including Hilti, Pellegrini, DINOSAW and more

Customization Services

Custom diamond concentration, bead spacing and wire specifications for unique cutting needs

FAQs

Common Questions About Diamond Wire Saws

What is a diamond wire saw?

Definition: Diamond wire saw is a highly efficient cutting tool composed of an internal steel wire core and beads embedded with diamond particles on the exterior. It cuts various hard materials through high-speed rotation. Its cutting characteristics include high efficiency and convenience (fast cutting speed, small equipment size), flexibility (able to cut various sizes and shapes), and producing precise, smooth cutting surfaces.

Main application materials:

- Construction materials: concrete, reinforced concrete, stone

- Decorative stone: marble, granite, quartz stone

- Industrial materials: metal, alloys, graphite, fiberglass, refractory bricks

- Precision materials: quartz glass, alumina ceramics, semiconductor materials

Manufacturing processes and specifications:

- Diamond mounting processes: electroplated (precision cutting), brazed (balanced performance), sintered (heavy-duty cutting)

- Connection methods: plastic injection , spring, rubber

- Diameter range: 0.35mm-12mm, selected according to application scenario

How does a diamond wire saw work?

Working principle: Diamond wire saws operate through a continuous cutting action where diamond-impregnated beads on a rotating wire abrade material through direct contact.

Setup & operation:

- Wire stretches between pulleys or guide wheels

- Rotates at optimized speeds

- Maintains proper tension throughout operation

Cutting mechanism:

- Diamond particles create micro-fractures in the material

- Material is gradually abraded as the wire moves

- Cooling fluids remove debris, reduce friction, and prevent overheating

Key advantages: The combination of diamond hardness, proper tension, speed control, and cooling enables efficient cutting of extremely hard materials that traditional cutting methods cannot effectively process.

What are the difference between diamond wire saws and band saws?

Different tools for different jobs. Diamond wire saws and band saws are not typically compared directly as they serve different purposes in stone processing industries.

Application differences:

Band saws:

- Primarily used for straight, parallel cutting of stone slabs and panels

- Ideal for mass production of marble slabs, granite panels, and composite boards

- Excel in standardized cutting where consistent thickness and flat surfaces are required

Diamond wire saws:

- Specialized for cutting complex shapes and irregular forms

- Perfect for sculptural elements, monuments, tombstones, furniture, and artistic pieces

- Essential for projects requiring 3D cutting capabilities and versatile angles

Performance considerations:

- Tool lifespan varies greatly depending on specific application, material properties, and operating conditions

- Band saws excel in rapid, high-volume production of uniform slabs

- Diamond wire saws provide unmatched flexibility for complex cutting paths and shapes

- Each technology has been optimized for its specific application niche

Selection guidance: Choose band saws for high-volume slab production and diamond wire saws for complex shapes, artistic pieces, and custom projects. The ideal tool depends on your specific cutting requirements rather than direct performance comparisons.

Do diamond wire saws cut through metal?

Yes, diamond wire saws efficiently cut through various metals including steel, aluminum, titanium, and metal alloys.

Key benefits: Clean, precise cuts without heat-affected zones or material distortion that traditional thermal cutting methods produce.

Cutting methods: Metal can be cut using either wet or dry cutting techniques:

Wet cutting - Traditional method using water for cooling and debris removal

Dry cutting - Can be performed with wire saw machines equipped with dust collection systems, significantly reducing pollution and environmental impact. See our Nuclear Decommissioning Gantry Dry Wire Saw for specialized applications.

How does a diamond wire saw work in mining?

Primary applications: In mining operations, diamond wire saws are primarily used for quarrying dimensional stone and mineral extraction.

Setup process:

- First, use down-the-hole (DTH) drills to create holes in the stone

- Thread the diamond wire through these pre-drilled holes

- Connect the wire ends to form a continuous loop

- Mount the wire on the wire saw machine

Two main applications in quarrying:

Primary cutting with high-power quarry wire saws

- Uses heavy-duty wire saw machines (typically 37kW or higher)

- Employs new, sharp and durable diamond wires

- For fast, precise cutting of stone blocks and separating blocks from the mountain face

- Critical for primary extraction of large stone blocks

Secondary trimming with lower-power wire saws

- Uses smaller wire saw machines (typically around 22kW)

- Often utilizes recycled older diamond wires to minimize costs

- For trimming and shaping the extracted blocks into transportable dimensionsFocuses on cost efficiency rather than cutting speed

Key advantages over traditional methods: This technology allows for extracting large, intact blocks with minimal waste, replacing traditional drilling and blasting methods with a cleaner, more precise extraction process.

How long does a diamond wire last?

Lifespan factors: Diamond wire lifespan varies based on material being cut, wire quality, and operating conditions.

Wire type comparison:

| Wire Type | Lifespan | Precision |

|---|---|---|

| Electroplated Wire Saw | Shortest | Superior |

| Brazed Wire Saw | Medium | Good |

| Sintered Wire Saw | Longest | Lower |

Maintenance impact: Proper maintenance significantly extends lifespan - regular cleaning, correct tension settings, and adequate cooling fluid flow can improve longevity by 20-30%.

What is the difference between spring-connected and non-spring-connected diamond wire saws?

Application scenarios: Spring-connected and non-spring-connected diamond wire saws are designed for different cutting applications based on material properties and cutting requirements.

- Marble quarrying: Spring-connected diamond wire saws are typically preferred for marble extraction in quarries due to their stability and protection benefits

- Granite cutting: Non-spring-connected diamond wire saws are generally used for granite extraction, where flexibility and ability to follow cutting grooves are essential

- Stone Profiling: For complex profile cutting in stone processing facilities, non-spring wires are typically preferred due to their enhanced flexibility for creating intricate shapes

Key functions of springs: Springs between diamond beads serve three critical purposes:

- Bead spacing maintenance - Springs fix the distance between diamond beads, preventing displacement and bead clustering that can cause uneven cutting

- Steel wire protection - Springs provide a protective buffer for the internal steel wire core, significantly extending wire lifespan (marble wire saws with springs can last 1-3 months of continuous use)

- Flexibility impact - Springs reduce wire flexibility, making the wire more resistant to bending. This is beneficial for straight cuts but becomes a disadvantage when the wire needs to follow curved cutting paths

Lifespan comparison:

- Spring-connected marble wire saws: Can remain operational for 1-3 months of continuous use due to the protective benefits of springs

- Non-spring granite wire saws: Typically have a much shorter lifespan of only 3-4 days in 24-hour operation due to the higher abrasiveness of granite and lack of spring protection

Operational considerations: During granite cutting, especially when using a combination of circular saw and wire saw mining techniques, the wire needs to be pressed into the cutting groove created by the circular saw. Spring-connected wires significantly increase operational difficulty in these scenarios due to their reduced flexibility.

How to use a diamond wire saw correctly?

Essential steps for proper diamond wire saw operation:

- Proper setup and wire loading

Start with correct wire loading - closed loop diamond wire can be directly loaded onto machines with closed loop structure, while non-closed loop wire requires splicing after loading. When splicing, ensure proper coiling and use appropriately sized crimping molds. Once loaded, ensure the wire is correctly threaded through guide wheels with appropriate tension according to manufacturer specifications. For detailed guidance, see our splicing tutorial video.

- Speed selection

Set the correct wire speed for your specific material

- Cooling system

Verify adequate cooling fluid flow before starting to prevent overheating

- Initial cutting

Begin with lower pressure/feed rate until a stable cutting channel is established

- Consistent monitoring

Watch for changes in sound, vibration, or cutting speed that might indicate problems

- Gradual feed rate

Maintain steady advancement without forcing the wire through the material

- Shutdown procedure

Reduce speed gradually before stopping and flush the cutting area with water

Safety & training considerations:

- Always follow machine-specific instructions

- Wear appropriate Personal Protective Equipment (PPE)

- Ensure operators receive proper training before operating wire saw equipment

Optimization tip: Regular practice with different materials will help operators develop the feel for optimal cutting parameters and troubleshooting skills.

How to properly maintain diamond wire saws?

Maintenance importance: Proper maintenance significantly extends diamond wire life and ensures optimal cutting performance.

7 Key maintenance practices:

- Material-based selection

Choose appropriate diamond wire saw based on specific materials and applications

- Proper storage

Store in dry, clean environments to prevent water and debris contamination

- Pre-use inspection

Check for damaged sections before use; remove damaged portions before splicing

- Proper splicing technique

Ensure proper coiling during splicing to prevent uneven wear

- Tension and speed management

Maintain appropriate tension and speed during cutting; remove wire from machine during extended non-use periods to prevent prolonged tension

- Cooling maintenance

Ensure consistent cooling during cutting operations

- Emergency handling

If wire gets stuck, don't force pull; instead, turn off power, release tension system, and manually assist in removing the stuck wire

Support services: DINOSAW provides detailed maintenance guidelines with each wire purchase and offers maintenance training for operators.

What causes diamond wire saw breakage and how to prevent it?

Diamond wire saw breakage is a common issue that can disrupt operations and increase costs. Understanding the causes and prevention measures is essential for efficient cutting operations.

- Major causes and prevention methods:Improper crimping and splicing issues

- Problem: Connection points are vulnerable to breakage due to poor crimping technique

- Prevention: Follow correct splicing procedures as shown in DINOSAW splicing tutorials

- Equipment needs: Use high-quality crimping molds with proper hardness (resistant to deformation) and high machining precision

- Wire quality and manufacturing issues

- Problem: Poor quality components, connectors, or manufacturing defects in injection molding

- Prevention: Specify cutting material requirements during procurement to ensure proper matching between wire manufacturing process and material hardness

- Supplier selection: Choose experienced, quality manufacturers with proven track records

- Operational errors

- Excessive speed: Reduce cutting speed when encountering resistant materials

- Corner handling: When detaching blocks from quarries, manually grind corner areas to create rounded transitions before accelerating cutting speed to prevent excessive tension at corners

- Wire jam response: Never force-pull jammed wire while machine is running; instead, shut down power, release tension system, and manually reposition the wire before resuming operation

- Pre-use inspection: Check for damage before use; if damaged sections are found, remove them and splice the wire properly before operation to prevent mid-operation breakage

Economic impact: Implementing these preventive measures can reduce wire breakage incidents by up to 70%, significantly improving operational efficiency and reducing downtime. For large-scale operations, this can translate to thousands of dollars in saved replacement costs and production time.

Certifications & Standards

Advanced Diamond Wire Saw Technology for All Materials

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Hard Material Cutting Efficiency?

Contact us today for a customized diamond wire solution with factory-direct pricing and global shipping

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Wire Saw Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский