Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

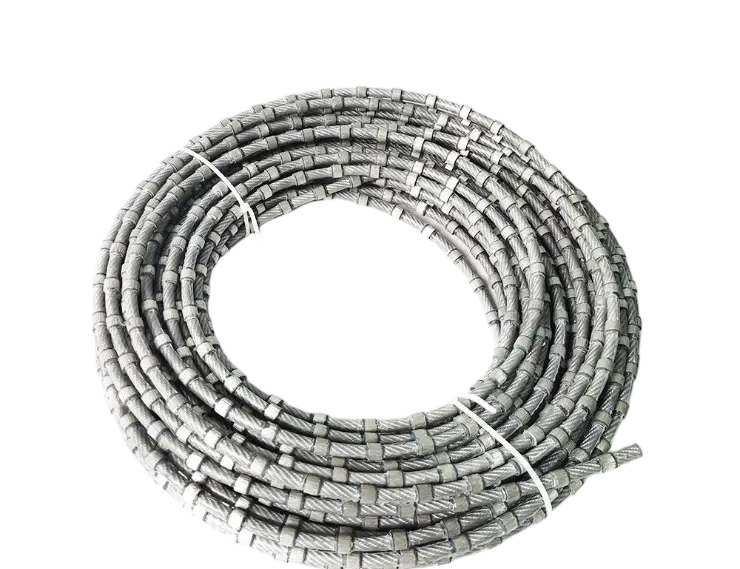

Maximize your diamond wire's lifespan. Our guide covers daily checks for tool care, troubleshooting wire splicing, and a complete maintenance schedule.

TL;DR: The Operator's Cheat Sheet

- Proper daily diamond wire saw maintenance prevents over 70% of common failures like wire breakage and extends equipment lifespan.

- This guide provides a practical checklist for daily, weekly, and monthly tasks, plus a troubleshooting flow for the top 5 issues.

- Adhering to safety protocols for dust control and electrical checks is non-negotiable for operator safety and regulatory compliance.

Your Wire Saw Is a High-Performance Asset. Protect It.

Tool Care and Storage Checklist

- Pre-use Inspection: Check bead condition for wear or damage. Verify the integrity of the core wire and connectors.

- Wire Threading & Route Check: Ensure the wire is correctly routed through all pulleys without twists.

- Tensioning: Use a calibrated gauge to set wire tension according to the manufacturer’s specifications for the material being cut.

- Coolant Verification: Confirm adequate water flow is directed onto the kerf (cutting point).

- Wire Rotation Practice: Periodically rotate the wire at its joint to promote even bead wear and extend its lifespan.

- Post-Use Cleaning: After cutting, thoroughly clean slurry and debris from the wire and wipe it down.

- Replacement Criteria: Retire the wire when beads are flat or glazed, have excessive wear, or the splice count exceeds recommendations (typically 2-3 repairs).

Top Wire Issues & How to Fix Them

Symptom | Cause & Fix |

|---|---|

Frequent Wire Breakage | Cause: Improper tension, hitting an obstruction, or a poor splice. Fix: Recalibrate tension. Inspect the cutting path for rebar or obstacles. Ensure splices are made with a professional hydraulic press and correct sleeves. |

Curved or Uneven Cut | Cause: Insufficient wire tension, worn pulley linings, or uneven bead wear. Fix: Increase tension to specified levels. Inspect and replace worn pulley linings. Rotate the wire to ensure even wear. |

Slow Cutting Speed | Cause: Beads are glazed (polished smooth), incorrect wire for the material, or insufficient machine power. Fix: Briefly cut an abrasive material (like a sandstone block) to re-dress the diamonds. Verify you are using the correct wire. Check machine motor amperage. |

Bead Loss or Wire Twist | Cause: Wire was pinched or hit a sharp edge. The machine’s pulleys may be misaligned. Fix: Inspect pulley alignment. Avoid sharp bends in the wire path. Retire wires that have lost multiple beads. |

Wire Overheating | Cause: Insufficient coolant flow. Fix: Immediately stop the cut. Check for blocked water nozzles, increase water pressure (target 20–40 L/min), and ensure flow is directly on the kerf. |

Preventative Maintenance Schedule

- Visual inspection of the wire for damage.

- Check coolant flow and nozzles.

- Inspect guide pulleys for free rotation.

- Clean and lubricate pulley bearings.

- Measure wire diameter to track bead wear.

- Check hydraulic fluid levels and hoses (for hydraulic machines).

- Inspect pulley linings for grooves or wear.

- Verify tensioner calibration.

- Check electrical connections for corrosion or damage.

Frequently Asked Questions (FAQs)

How often should I rotate the diamond wire?

- Context:Rotating the wire by giving it a half-twist at the joint is a crucial practice. This ensures all sides of the diamond beads are utilized, which maintains cutting efficiency and extends the tool's life.

What are the signs that a wire should be retired?

- Context:Continuing to use a worn-out wire is unsafe and inefficient. Also, a wire that has been spliced more than 2-3 times should be retired as each splice is a potential weak point.

- Next Step:Establish clear retirement criteria in your SOPs for all operators.

Can I use any water for cooling?

- Context:Highly acidic or alkaline water can corrode the steel wire, especially if the protective coating is damaged. Also, ensure the water is free of debris that could clog the coolant nozzles.

- Next Step:Include a water pH test in your monthly maintenance checks.

What is the most critical safety check?

- Context:Before starting, you must clear the area of non-essential personnel and verify the cutting path is free of obstructions. This prevents accidents from wire snags or breakages.

What is the most critical safety check?

- Context:Before starting, you must clear the area of non-essential personnel and verify the cutting path is free of obstructions. This prevents accidents from wire snags or breakages.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский