Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A technical dive into down-the-hole drilling. Understand the hammer, drill bit, and air flow that deliver superior energy transfer and penetration rates in hard rock.

TL;DR: The Core Tech of DTH Drilling

- How it works:A pneumatic hammer strikes the bit directly *down the hole*, minimizing energy loss and maximizing impact on the rock.

- Why it's better for hard rock: DTH Drilling delivers high-frequency, high-impact energy for faster penetration with significantly less hole deviation than other methods.

- Key components:The system's performance relies on the synergy between the DTH hammer, a specialized drill bit, and a powerful air compressor.

- Next Step:Dive into the anatomy of the five key components to understand the mechanics behind its power.

What is Down-The-Hole (DTH) Drilling?

What is Down-The-Hole (DTH) Drilling?

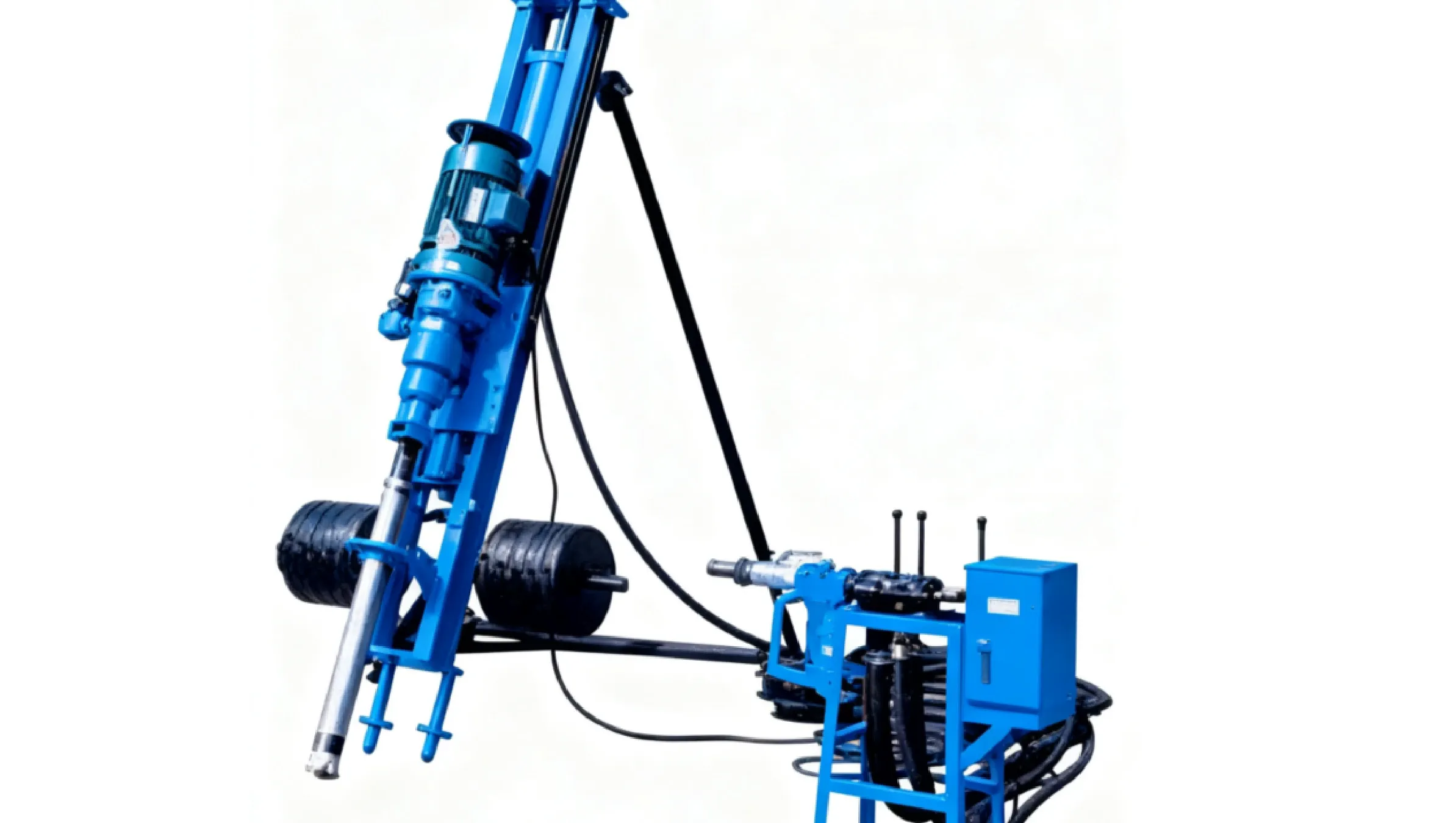

System Architecture: How the Components Work Together

- The rig's air compressor generates high-pressure air.

- Air travels through the rotation unit and down the hollow drill rods.

- It enters the DTH hammer, where it drives a piston to strike the back of the drill bit at high frequency.

- The drill bit crushes the rock, while the rotation unit slowly turns the drill string to ensure the entire hole face is worked.

- Exhaust air from the hammer powerfully flushes the rock chips up the annulus between the drill rods and the hole wall.

Anatomy of a DTH System: 5 Key Components

Component | Function & Mechanism | Typical Parameter Ranges & Notes |

|---|---|---|

DTH Hammer | The heart of the system. It converts pneumatic energy into kinetic impact energy via an internal reciprocating piston. | Models are designated by size (e.g., 3", 4", 5" class). Choice depends on hole diameter and required impact energy. |

Drill Bit | The consumable tool that makes contact with the rock. Features tungsten carbide buttons to crush and fracture the material. | Types include flat face, concave, and convex designs with spherical or ballistic buttons. A button bit for granite is designed for wear resistance in abrasive rock. |

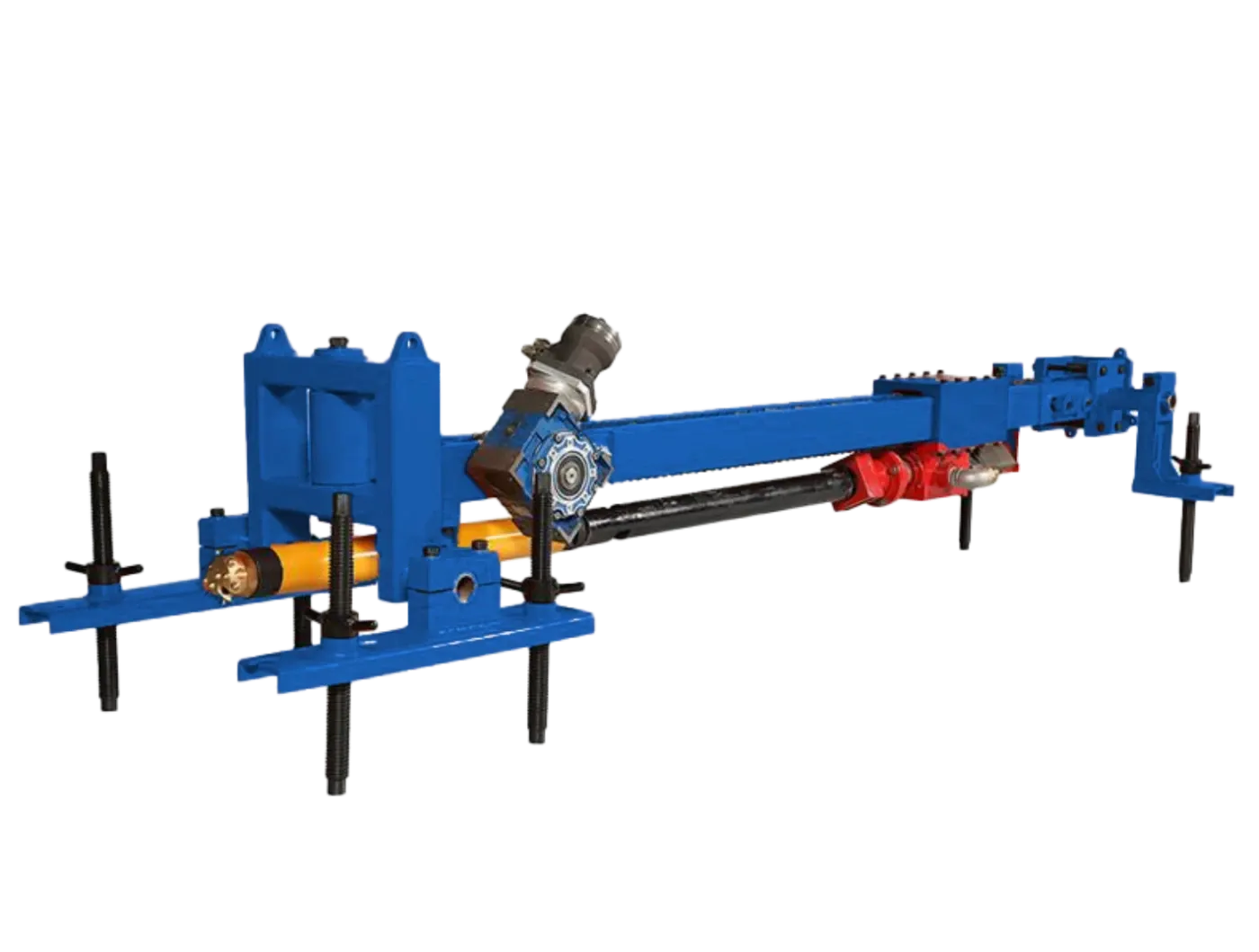

Drill Rods | Hollow, thick-walled pipes that transmit rotation and feed force to the hammer, while also serving as a conduit for compressed air. | Proper drill rod coupling and thread maintenance are critical to prevent energy loss and component failure. |

Rotation Unit | A hydraulic or pneumatic motor on the rig that provides slow, high-torque rotation to the drill string. | Rotation speed is typically low (e.g., 15-75 RPM). It doesn't cut the rock, but indexes the bit to strike a fresh surface with each blow. |

Air Compressor | The power source. It must supply sufficient air volume (CFM) at high pressure (PSI/bar) to power the hammer and flush the hole. | This is a critical system match. Insufficient high-pressure air compressor CFM is the most common cause of poor drilling performance. |

Why DTH Outperforms Top-Hammer in Hard Rock

DTH Drilling Advantage

Top-Hammer Limitation

Common Failures and How to Mitigate Them

Issue / Symptom | Primary Cause(s) | Mitigation & Solution |

|---|---|---|

Reduced Penetration Rate | Insufficient air pressure/volume; worn drill bit; improper hammer lubrication. | Verify compressor output matches hammer specs. Inspect and replace worn bits. Follow the lubrication schedule for the hammer for hard rock. |

Excessive Hole Deviation | Improper collaring technique; incorrect feed pressure; unstable ground. | Start holes at reduced power. Adjust feed pressure to match rock conditions. Ensure the rig is on a level, stable platform. |

Stuck Drill String | Poor flushing of cuttings; hole collapse in fractured ground; sudden loss of air. | Ensure adequate air volume for flushing. Avoid drilling in highly fractured zones where possible. Regularly check air lines for leaks. |

Premature Hammer Failure | Lack of lubrication; ingress of water/debris; running the hammer without load. | Adhere strictly to the maintenance of DTH hammer procedures, especially lubrication. Ensure filters are clean. Avoid "dry firing." |

System Compatibility: Integrating with Your Setup

FAQs on DTH Drilling Technology

What is the main reason DTH has better energy transfer efficiency?

- Context:In top-hammer systems, energy dissipates at every rod joint, weakening the impact force, especially in deep holes.

- Benefits:This direct impact results in a much higher percentage of the rig's power being converted into rock-breaking work, increasing the drilling penetration rate.

- Next Step:When evaluating rigs, compare the specified energy output of the hammer, not just the engine power.

How does the hammer for hard rock differ from one for soft rock?

- Context:Hard, competent rock like basalt requires immense force to fracture, whereas softer rock can be broken with less energy.

- Benefits:Using a matched hammer prevents underperformance (too weak) or excessive wear and tool damage (too strong for the rock).

- Next Step:Specify your primary rock type (e.g., basalt hard rock drilling) when consulting with our engineers to ensure the correct hammer selection.

Why is drill rod coupling maintenance so important?

- Context:Damaged or improperly lubricated threads can leak air, seize up, or even break, leading to a lost drill string in the hole.

- Benefits:Proper maintenance ensures full air pressure reaches the hammer and prevents costly downtime from fishing a lost string.

- Next Step:Implement a daily routine of cleaning and greasing drill rod threads as part of your pre-operation checklist.

Can I use any high-pressure air compressor?

- Context:An undersized compressor is the single most common cause of poor drilling performance, as it starves the hammer of power.

- Benefits:A correctly sized compressor ensures the hammer operates at its designed frequency and impact, maximizing your drilling speed.

- Next Step:Always refer to the hammer's technical data sheet for its air consumption requirements before pairing it with a compressor.

What is the role of the rotation unit if the hammer does the work?

- Context:Without rotation, the bit would simply pulverize the same spot. This process, called indexing, is crucial for advancing the hole.

- Benefits:Correct rotation speed ensures even bit wear and efficient fracturing of the entire hole face.

- Next Step:Adjust rotation speed based on rock conditions—slower for harder rock, slightly faster for softer rock.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский