Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

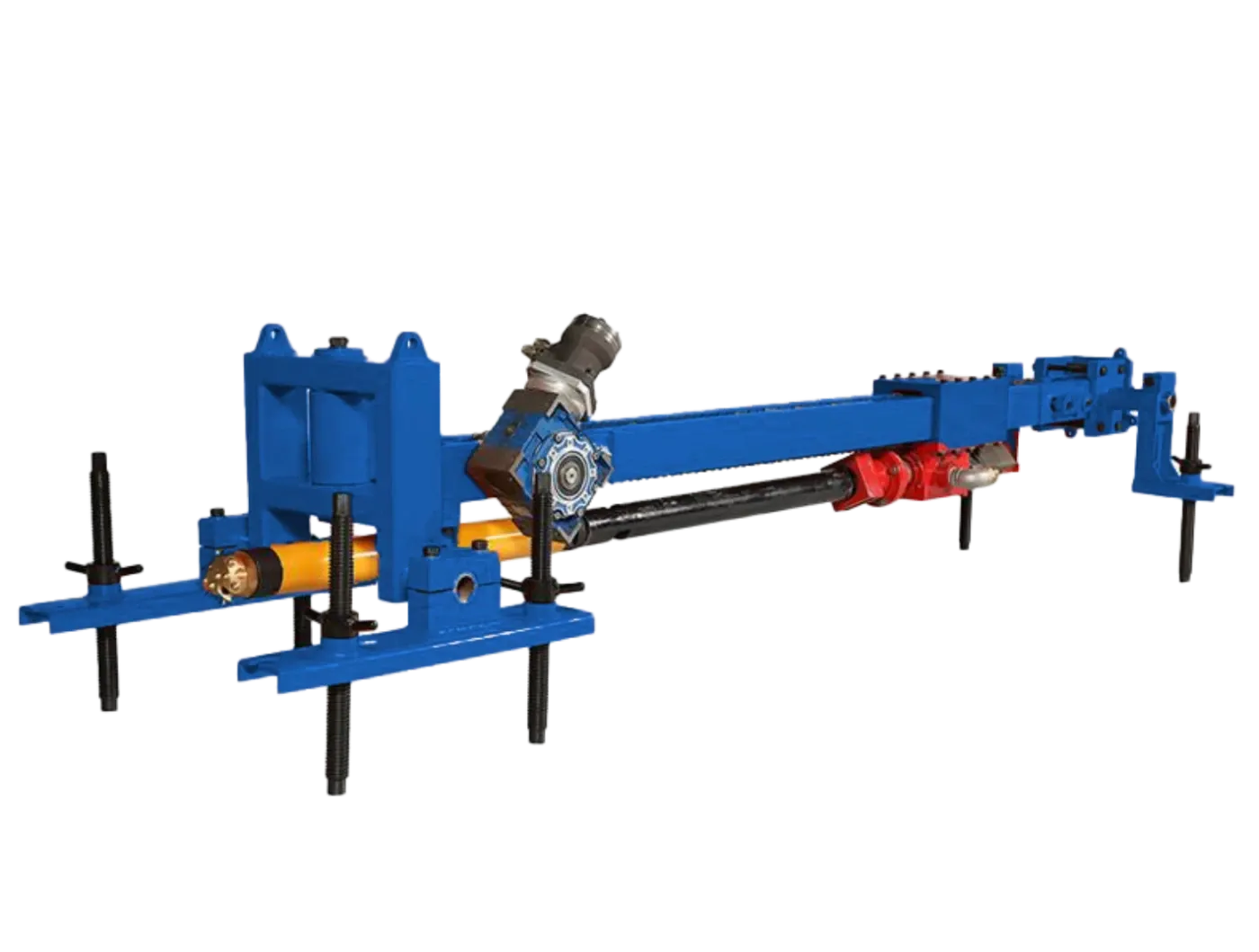

Keep your quarry drilling rig running. Follow our checklists for DTH hammer maintenance, lubrication, and troubleshooting common drilling issues.

TL;DR: Your Key to DTH Uptime & Performance

- Follow the schedule:Daily, weekly, and monthly checks are non-negotiable for preventing major failures.

- Lubrication is critical:Proper and timely lubrication of the DTH hammer is the single most important maintenance task.

- Troubleshoot systematically:Use the "Symptom → Cause → Solution" flow in this guide to diagnose drilling issues quickly.

- Next Step:Implement the preventive maintenance schedule provided below to extend your machine's life and improve quarry productivity.

Standard Operating Procedures (SOPs) for Daily Use

- Safety Checks:Confirm all safety guards are in place, emergency stops are functional, and the work area is clear. Ensure proper PPE for quarry drilling (hard hat, safety glasses, hearing protection, respirator) is in use.

- Lubrication Check:Verify the in-line lubricator (oiler) is full of rock drill oil. A DTH hammer running dry will fail rapidly.

- Consumables Check (Drill Bit & Rods):Inspect the button bit for excessive or uneven wear, broken buttons, or cracks. Check the drill rod coupling threads for damage or dirt.

- Hoses and Fittings Check:Look for any leaks, cracks, or abrasion on all air and hydraulic hoses. Tighten any loose fittings.

- Dust Suppression System Check:If using a wet drilling kit, ensure the water tank is full and the pump is operational. For dry collectors, check that the filters are clean and the vacuum is working.

Troubleshooting Common Drilling Issues

| Symptom | Likely Cause | Solution |

|---|---|---|

| Slow Drilling Penetration Rate | 1. Insufficient air from compressor. 2. Worn or incorrect button bit for granite/rock type. 3. Improper hammer lubrication. | 1. Verify compressor output (CFM & PSI) matches hammer specs. 2. Replace bit; ensure it's correct for the formation. 3. Check and refill the in-line oiler. |

| Stuck Drill String | 1. Poor flushing of cuttings. 2. Hole collapse in fractured ground. | 1. Ensure sufficient air volume. 2. Avoid over-drilling in unstable zones; use casing if necessary. |

| High Hole Deviation | 1. Improper collaring (starting the hole). 2. Excessive feed pressure. | 1. Start the hole with reduced rotation and feed. 2. Reduce feed pressure to match rock conditions. Proper hole deviation control is key. |

| Premature Hammer Failure | 1. Lack of lubrication. 2. Contaminants (water/dirt) in the airline. 3. "Dry firing" (running hammer without load against rock). | 1. Maintain a strict lubrication schedule. 2. Check air filters and drain water traps daily. 3. Engage the bit with the rock before applying full power. |

Preventive Maintenance Schedule

Daily Checks (Every 8 Hours)

- Check rock drill oil level in lubricator.

- Inspect drill bit for wear and damage.

- Clean and grease drill rod coupling threads.

- Drain water from air compressor tank and filters.

Weekly Checks (Every 40 Hours)

- Inspect all hydraulic and air hoses for wear.

- Check hydraulic oil level and filters.

- Clean dust collector filters.

- Check torque of all critical bolts and nuts.

Monthly Checks (Every 150 Hours)

- Disassemble and clean the DTH hammer.

- Inspect internal hammer components for wear.

- Change engine and compressor oil/filters.

Quarterly/Annual Checks

- Comprehensive inspection of the rig's structural components.

- Full hydraulic system service.

- Follow manufacturer-specific recommendations for major component service.

Safety & Compliance on Site

- Dust Suppression:Drilling generates silica dust, a known carcinogen. Engineering controls are the first line of defense. The U.S.Occupational Safety and Health Administration (OSHA)mandates the use of systems like wet drilling kits or certified dust collectors.

- Hearing Protection:DTH drilling noise levels can exceed safe limits. The CDC's NIOSH Mining Program provides extensive research on hearing loss prevention in mining. Always wear appropriate hearing protection.

- Lockout/Tagout (LOTO):Before performing any maintenance, always de-energize and lock out the machine according to established LOTO procedures to prevent accidental startup.

FAQs on DTH Maintenance

How much oil does a DTH hammer need?

- Context:The in-line lubricator creates an oil mist in the airline to constantly coat the hammer's internal piston and components, preventing metal-on-metal wear.

- Next Step:Check your hammer's specific manual for the recommended oil flow rate and fill the lubricator at the start of every shift.

When should I replace my rock drill bit?

- Next Step:Create a wear gauge or "no-go" template and check your bits daily. Consider investing in a bit sharpening system to extend life.

What's the first thing to check if my drilling speed drops?

- Context:An underpowered air supply is the most common cause of a sudden drop in drilling penetration rate. The hammer is literally starved for the energy it needs to operate.

- Next Step:Check the pressure gauge on the rig while drilling. If it's below the hammer's recommended operating pressure, check the compressor and air lines for issues.

How often should I do a full maintenance of the DTH hammer?

- Context:This allows you to catch wear on internal components like the piston, check valve, and wear sleeve before they fail, preventing a catastrophic and costly breakdown.

- Next Step:Order a service kit before you start the maintenance, and follow the disassembly/reassembly instructions in the service manual meticulously.

Is it okay to mix different brands of drill rods?

- Context:A drill string is a precision system. The drill rod coupling is designed to create a seamless transfer of energy and torque. Mismatched components compromise this system.

- Next Step:Always use high-quality rods from a single, reputable supplier that match your rig and hammer specifications.

What's the best way to clean drill rod threads?

- Context:Clean threads ensure proper make-up torque and prevent galling (thread damage) and air leaks, which rob the hammer of power.

- Next Step:Make this a mandatory part of your daily routine whenever adding or removing rods from the drill string.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский