Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Can you dry-core granite? What's the best bit for marble countertops? Our guide covers applications, materials, and provides mini-cases for clean, fast drilling.

TL;DR: Your Guide to Diamond Core Bit Applications

- What They Do: These Diamond Core bits drill precise, clean holes in hard stone like granite, marble, slate, and concrete by grinding away material rather than cutting.

- Wet vs. Dry: Wet drilling is superior for hard, thick materials (granite, reinforced concrete), extending bit life and ensuring a clean finish. Dry drilling is for occasional, shallow holes where water isn't feasible, often with handheld drills.

- Key Materials: Excellent for granite, marble, engineered stone, and concrete. Performance varies based on the bit's bond hardness—soft bonds for hard materials, hard bonds for soft, abrasive materials.

- Critical Factor: Success isn't just about the bit; it's about matching the bit, RPM, feed pressure, and cooling method (wet or dry) to the specific material you're drilling.

What Can This Tool Actually Do for Your Shop?

- Drill Chip-Free Holes in Brittle Materials: This is the primary job. Materials like granite, marble, and porcelain tile are notoriously prone to chipping with the wrong tool. A diamond core bit grinds away an exact circle, leaving a smooth, factory-quality edge ready for faucets, sinks, or fixtures.

- Handle Reinforced Concrete: Need to core through a slab with rebar? A wet core bit designed for concrete can handle it. The diamonds grind the aggregate and the steel, allowing you to create clean passages without compromising structural integrity—a task impossible for standard drills.

- Speed Up Production: In a high-volume shop, manually cutting sink holes or other large openings is a bottleneck. A rig-mounted core drill can power through a 3 cm granite slab in minutes, freeing up operator time and increasing throughput. For even more efficiency, some shops use Automatic Drilling Machines (Gantry & Vertical) for repeatable, high-volume tasks.

- Extract Test Cores: For quality control or material analysis, you can use a core bit to extract a physical sample (the "core") from a slab or structure. This is essential in construction and geology for testing compressive strength and material composition.

- Integrate with Heavy-Duty Machinery: These bits serve as consumables for larger systems. They can be mounted on Automatic Drilling Machines (Gantry & Vertical) for automated production, or on DTH drilling machines for rock extraction in quarrying operations.

Which Materials Are Compatible for Granite Hole Drilling?

Material | Compatibility & Key Considerations |

|---|---|

Granite | Excellent. This is what they're made for. Use a wet bit with a soft bond. The hard granite wears away the soft bond, constantly exposing new, sharp diamonds for efficient grinding. |

Marble | Very Good. Marble is softer than granite. A medium-hard bond is often suitable. Wet drilling is highly recommended to prevent heat fractures and ensure a polished edge. |

Slate & Soapstone | Good. These are softer, layered stones. Use a medium-hard bond and lower RPM to avoid delamination (splitting along layers). A steady, light pressure is key. |

Sandstone | Good, with caution. Sandstone is highly abrasive. It will wear down bits quickly. Use a hard-bond bit designed for abrasive materials to prolong tool life. Wet drilling is mandatory to control dust and wear. |

Concrete & Overlays | Excellent. Specific bits are made for concrete, with designs to handle aggregate and rebar. Use a wet system for any serious concrete coring to manage heat and slurry. |

What are the Boundaries: Can vs. Cannot Do

Dry vs. Wet Drilling

Thin-Wall vs. Standard Bits

How Do You Start Processing with Stone Core Drill Bits?

- Hard Granite: Start with a low RPM and light, steady feed pressure. Let the diamonds do the work. If the bit stops cutting and just polishes the stone (glazing), it means the diamonds are not being exposed. You may need a softer bond bit or to "dress" the bit by running it through an abrasive material like a cinder block.

- Soft Marble: You can use a moderate RPM. The key is gentle, consistent feed pressure. Too much force can cause micro-fractures around the hole. Always use plenty of water for a clean, cool cut.

- Engineered Stone (Quartz): This material is tricky due to the resins. Strict, continuous cooling is critical to prevent the resin from melting and gumming up the diamond segments. Use moderate speed and pressure, and ensure water flows both inside and outside the bit.

What are the Advantages Over Other Tools?

- Cleaner Edges vs. Hole Saws: A standard bi-metal or carbide-tipped hole saw is designed for wood, plastic, or soft metals. On stone, it will chip, wander, and produce a rough opening that requires significant cleanup. A diamond core bit grinds a precise kerf, leaving a sharp, clean edge that often needs no further work.

- Speed and Lifespan in Hard Materials: While a carbide masonry bit can make a hole in concrete, it does so slowly and wears out extremely quickly on hard stone like granite. Our Industrial Granite Drill Bits: 3× Longer are designed to last, maintaining cutting efficiency over dozens or even hundreds of holes when used correctly. The long-term cost-per-hole is significantly lower.

Mini-Cases: Real-World Applications

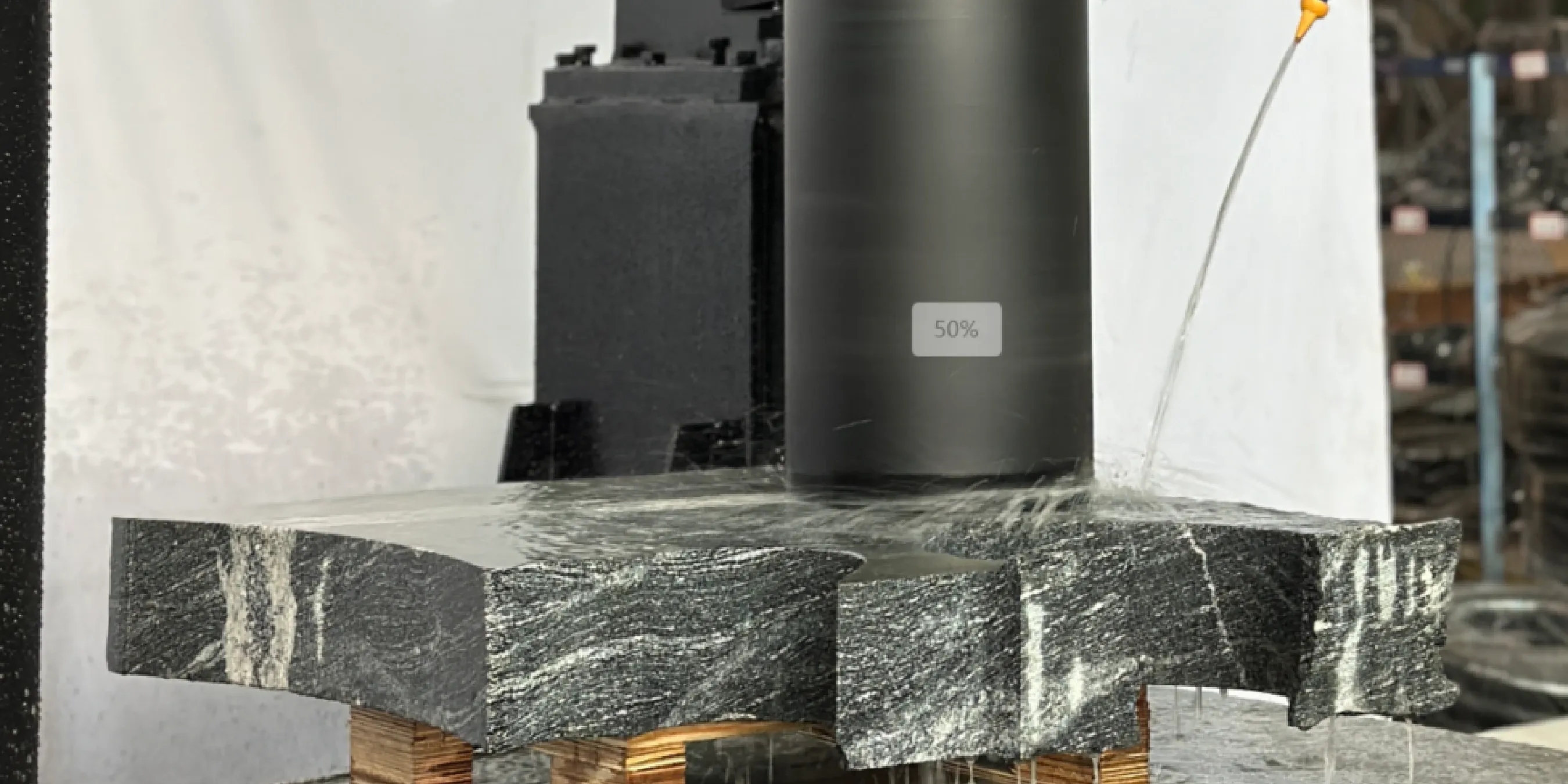

Case 1: The High-Volume Countertop Fabricator

- Problem: A high-volume kitchen countertop shop was experiencing significant chipping when drilling faucet holes (35mm diameter) in Ubatuba granite, leading to a 15% rework rate and delayed shipments.

- Solution: Switched to our wet-use diamond core bit with a soft bond, used on a rig-mounted drill at a manufacturer-reported optimal speed of 800 RPM. A stable drill stand and constant water flow were ensured.

- Result: Chipping was eliminated on over 98% of holes. The rework rate dropped to under 1%, and drilling time per hole was reduced by an average of 40 seconds.

Case 2: Construction Contractor

- Problem: A contractor needed to run 4-inch (102mm) plumbing lines through an existing 8-inch thick reinforced concrete wall. A hammer drill was too slow and caused excessive vibration, risking structural damage.

- Solution: Employed a heavy-duty, rig-mounted core drill with our specialized concrete core bit. A powerful, anchored drill rig and consistent water flow to flush debris and cool the Diamond Segment for Core Drill Bit were used.

- Result: Each hole was cored in under 25 minutes, including cutting through rebar, with minimal vibration and no structural damage.

Case 3: Tiling Specialist

- Problem: An installer was frequently cracking expensive, large-format porcelain tiles when drilling shower fixture holes with carbide bits on-site.

- Solution: Switched to a small-diameter (25mm) dry diamond core bit with a wax-filled core, used on a variable-speed angle grinder. Started drilling at a 45-degree angle to create a groove, then slowly brought the drill to 90 degrees with an oscillating motion.

- Result: Tile cracking was virtually eliminated. The installer reported being able to drill a clean hole in less than 60 seconds.

What are the Risks and Prerequisites?

Safety First: Dust and Water Management

Frequently Asked Questions (FAQ)

Can I use a wet core bit for dry drilling?

- Context: Wet bits are designed with segment bonds that rely on water for cooling. Using them dry causes extreme heat buildup. Dry bits, in contrast, have a different, more heat-resistant bond and features designed to withstand higher temperatures.

- Guidance: This heat buildup leads to premature segment loss, bit warping, and potential damage to the stone. It compromises the quality of your work and the integrity of the tool.

- Next Step: For safety and performance, always match the bit to the application. If water is not an option, invest in a dedicated dry core bit.

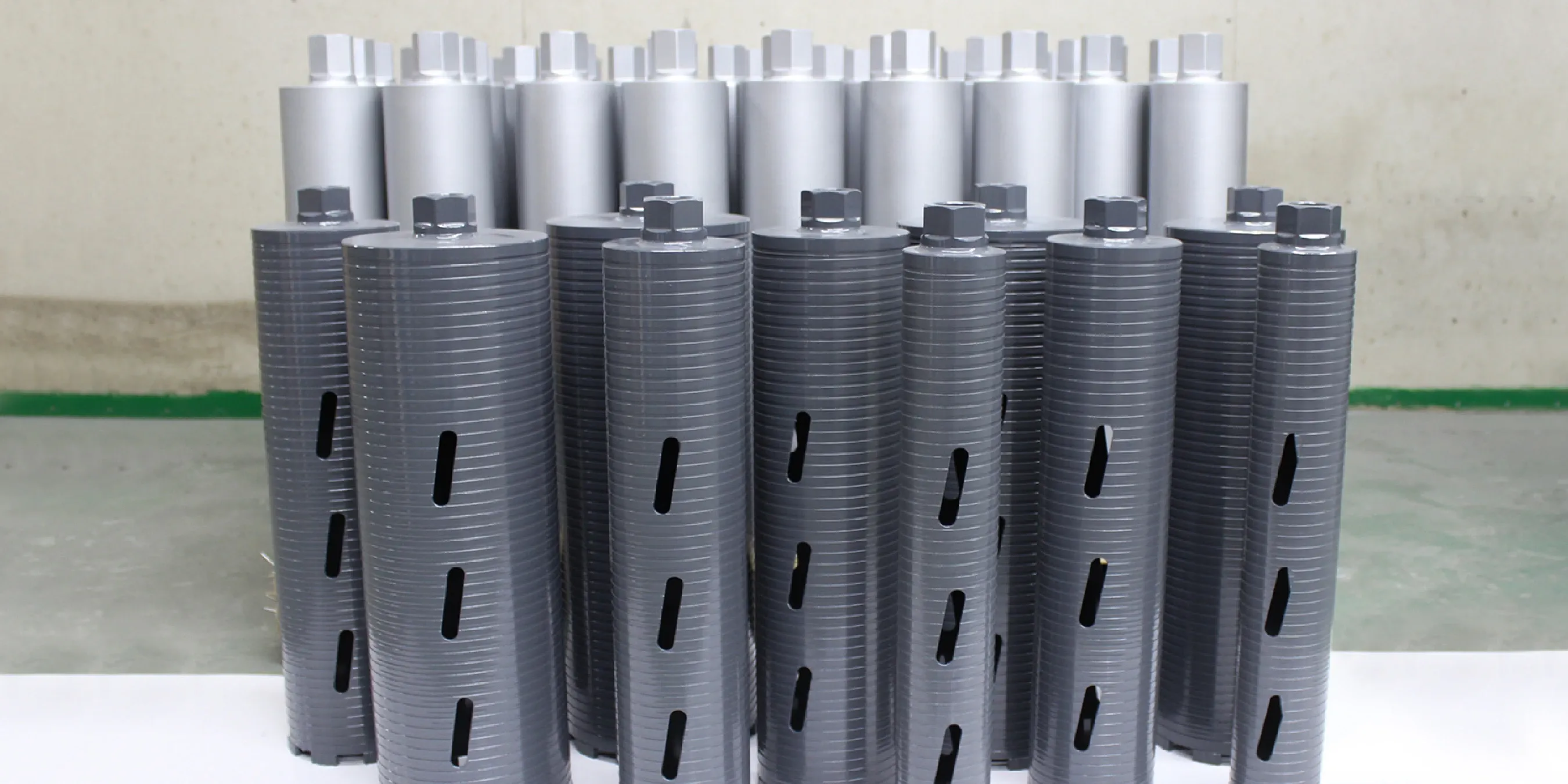

What is the best core bit for granite?

- Context: Granite is a very hard, dense stone. The soft bond is designed to wear away at a controlled rate, constantly exposing fresh, sharp diamond particles to grind the material efficiently.

- Guidance: A bit with too hard a bond will "glaze over"—the diamonds will get dull and the bit will polish the stone instead of cutting it. This significantly reduces efficiency and can damage the bit.

- Next Step: For high-volume granite drilling, explore our Diamond Core Bits for Stone and look for options with laser-welded segments and a thin-wall design for faster cutting speeds.

My core bit stopped cutting. What’s wrong?

- Context: This usually happens when the bond is too hard for the material, or the RPM is too high/feed pressure is too low. In either case, the dull diamonds are not being replaced by new, sharp ones from the bond.

- Guidance: The immediate fix is to "dress" the bit by running it through a highly abrasive material, like a concrete block or a specialized dressing stone, for a few seconds. This will strip away the bond and expose new diamonds.

- Next Step: If glazing keeps happening, you likely need a bit with a softer bond for your material. Contact our support team to verify the correct specification for your job.

How do I choose between a handheld drill and a rig-mounted one?

- Context: A handheld drill is for smaller diameter holes (typically under 3 inches / 76mm) in softer materials or for quick, occasional jobs. A rig-mounted drill is for larger, deeper holes or hard materials like reinforced concrete.

- Guidance: The rig provides stability, leverage, and consistent pressure, which are crucial for a straight, clean hole and for maximizing bit life. Handheld use requires more operator skill to avoid wandering or bit damage.

- Next Step: For professional countertop fabrication or construction coring, a rig-mounted system is the standard. If you only drill small holes intermittently, a handheld drill may suffice.

Can you drill through rebar with a diamond core bit?

- Context: Standard stone or concrete bits can struggle with rebar, often leading to segment damage. Bits for reinforced concrete have specialized segments that can effectively grind both hard aggregate and softer, tougher steel.

- Guidance: It's critical to maintain a lower RPM and steady feed pressure when you hit rebar to avoid snagging or damaging the bit. Constant water flow is mandatory to clear debris and prevent overheating.

- Next Step: Ensure you order a bit rated for rebar. Check our product specifications or contact sales to confirm you have the correct tool for your concrete application.

What does "reverse threaded core bit" mean and when do I need one?

- Context: A reverse-threaded bit has its threads machined in the opposite direction of a standard (clockwise) bit. This prevents the bit from loosening and potentially flying off during operation on a counter-clockwise drill.

- Guidance: Using the wrong thread type is a significant safety hazard. The bit will not tighten during use; it will loosen. This is common in some specialized CNC or line-drilling equipment.

- Next Step: Always check your drill motor's specifications. If it requires a reverse thread, you must use a compatible bit.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский