Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Diamond Router Bits for Stone, Concrete & Tiles

Sample, OEM/ODM & Agency Support

Compatible Materials & Products

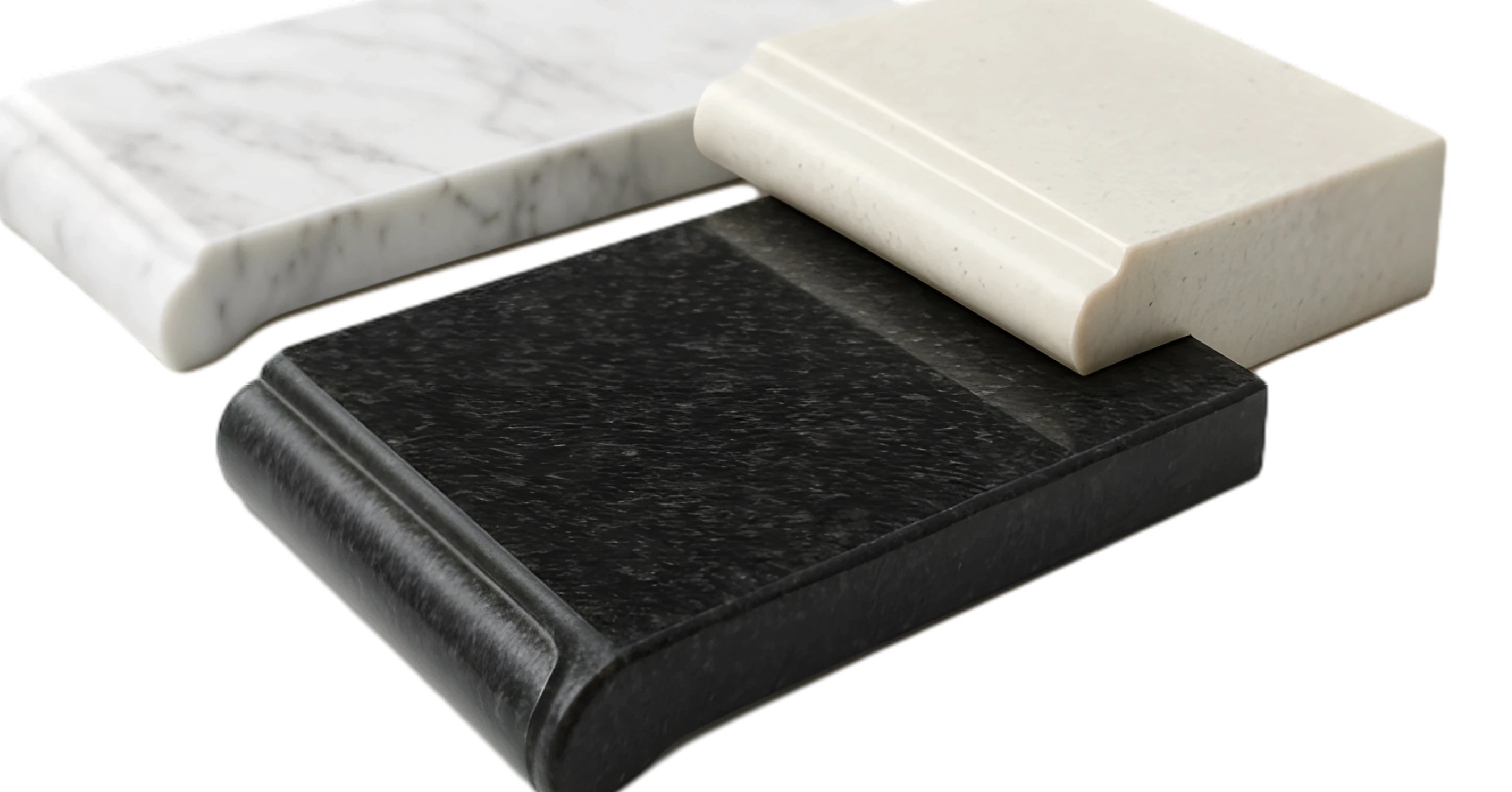

From Countertops to Monument Stones : Edges Shaping Tools

Granite > Countertops & Monuments

|

|---|

|

|

|

Granite's exceptional hardness and crystalline structure demands specialized cutting solutions for premium kitchen countertops and lasting memorial monuments. DINOSAW's sintered diamond router bits use chemical and mechanical bonding technology to create precise edge profiles, bevels, and decorative shapes without chipping granite's tough surface. The router bits cut through granite's quartz and feldspar crystals while maintaining dimensional accuracy for seamless seam matching in countertop installations.

Processing granite countertops requires edge profiling for bullnose, ogee, and bevel cuts plus sink cutouts and decorative details for monuments. DINOSAW's sintered bonding technology provides superior diamond retention under high cutting forces, enabling clean 90-degree edges and complex curves without material waste. The controlled cutting action prevents stress fractures that cause expensive callbacks and rework.

Fabricators achieve 60% reduction in finishing labor while eliminating costly edge repairs that damage shop reputation. Professional-grade cuts increase customer satisfaction and referral business, transforming challenging granite projects into profitable installations with consistent quality results.

Marble > Decorative Sculptures

Memorial and decorative marble requires delicate processing to preserve its natural beauty and soft crystalline structure for sculptures, headstones, and architectural elements. DINOSAW's vacuum brazed diamond router bits provide optimal diamond exposure for smooth marble cutting, creating intricate decorative profiles, lettering grooves, and sculptural details without surface damage. The superior bonding strength maintains cutting efficiency through marble's varying density layers while preventing tool deflection during detailed work.

Marble processing involves creating decorative edges for headstones, carved relief patterns for monuments, and ornamental details for architectural applications. The vacuum brazing process exposes more diamond cutting surface area, enabling gentle material removal that preserves marble's polished finish. Controlled cutting speeds prevent heat buildup that causes discoloration or micro-cracking in sensitive marble varieties.

Fabricators complete intricate memorial projects 40% faster while maintaining the emotional quality families expect. Smooth, professional finishes eliminate secondary polishing operations, reducing labor costs and ensuring lasting monuments that honor family memories with dignity and craftsmanship.

Quartz > Kitchen Surfaces

|

|---|

|

Engineered quartz surfaces demand precision cutting for seamless luxury kitchen installations, but their abrasive silica content rapidly dulls conventional tools. DINOSAW's specialized diamond router bits maintain exceptional sharpness through quartz's harsh cutting conditions, creating perfect edge profiles, sink cutouts, and seam joints for high-end kitchen projects. The advanced diamond bonding resists premature wear while delivering consistent dimensional accuracy essential for luxury installations.

Processing engineered quartz requires precise edge profiling for undermount sinks, decorative edges like ogee and bevel cuts, plus complex corner radiuses for island installations. DINOSAW's diamond cutting edges slice through quartz's polymer-bound silica particles without generating excessive heat that causes resin degradation. Controlled cutting parameters prevent delamination while maintaining tight tolerances for invisible seam matching.

Kitchen fabricators achieve perfect seam alignment that eliminates costly callbacks while completing projects 30% faster. Professional edges increase installation success rates and customer satisfaction, transforming challenging quartz projects into profitable repeat business with guaranteed results.

Ceramic > Precision Tiles

Precision ceramic tiles require controlled cutting to prevent cracking and maintain dimensional accuracy for high-end floor and wall installations. DINOSAW's resin bond diamond router bits provide exceptional flexibility for ceramic processing, creating clean edge cuts, precise notches for pipe penetrations, and custom shapes for complex tile layouts. The flexible resin bonding adapts to ceramic's brittle nature while preventing stress concentrations that cause micro-fractures.

Ceramic tile processing involves edge trimming for perfect fit installations, creating outlet cutouts and pipe notches, plus shaping decorative borders and custom patterns. DINOSAW's resin bond technology cushions cutting forces while maintaining sharp diamond exposure, enabling smooth cuts through ceramic's glazed surface without chipping. Temperature control prevents thermal shock that damages ceramic's crystalline structure during precision cutting operations.

Tile installers achieve flawless custom cuts that eliminate material waste while completing complex layouts 50% faster. Professional-quality edges ensure perfect fit installations that increase project value and customer satisfaction, transforming challenging ceramic work into profitable precision installations.

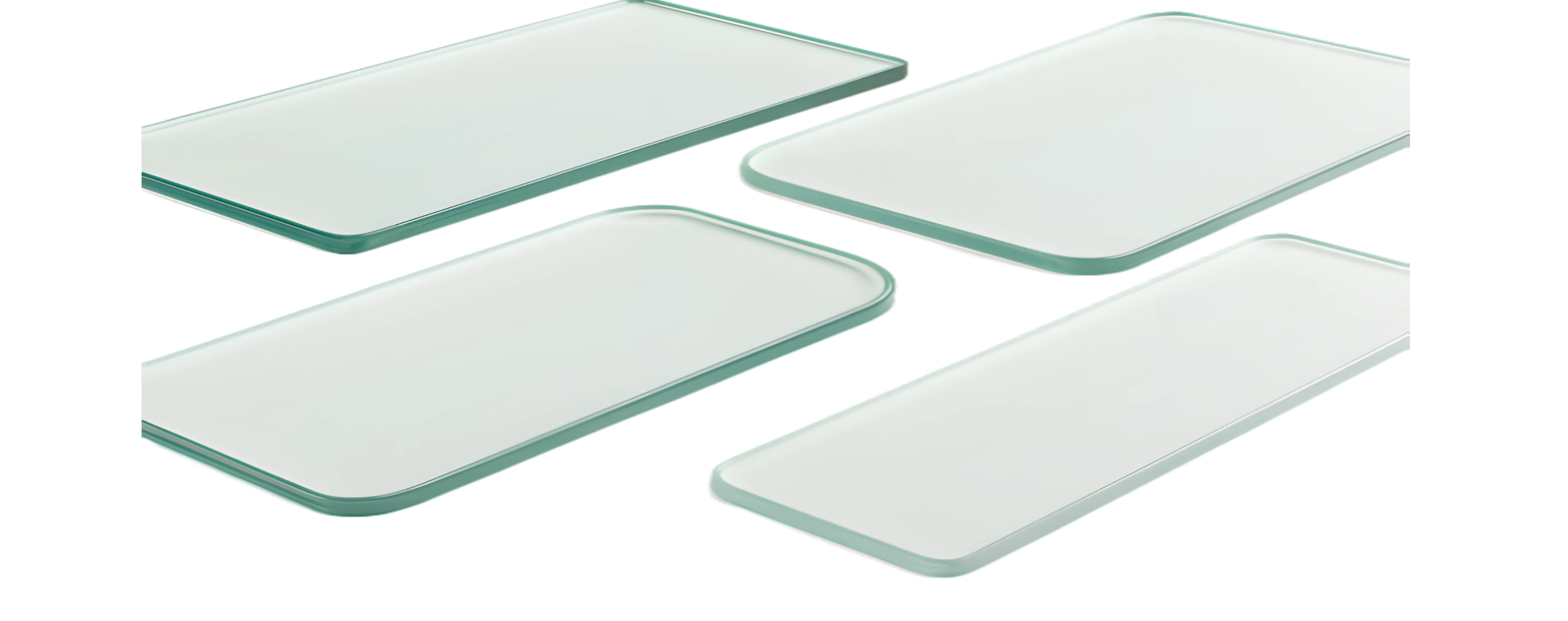

Glass > Shower Enclosure

|

|---|

|

Bathroom shower enclosures require precision glass cutting for safety, aesthetics, and watertight installations in residential and commercial applications. DINOSAW's fine-grit diamond router bits achieve exceptional surface quality on tempered glass panels, creating smooth polished edges, precise hinge cutouts, and handle mounting holes without stress concentrations. The specialized diamond bonding minimizes micro-chipping while maintaining optical clarity essential for premium shower installations.

Glass shower enclosure fabrication involves edge polishing for safety compliance, drilling precise holes for hinges and handles, plus creating notches for wall mounting brackets and seal channels. DINOSAW's controlled cutting action removes glass material gradually without generating heat buildup that causes thermal stress fractures. Fine diamond grits (120-220 mesh) deliver mirror-finish edges that eliminate secondary polishing operations while ensuring safety standards.

Glass fabricators achieve safety-compliant edges that pass building inspections while reducing processing time by 45%. Professional finishes eliminate costly rework and warranty claims, transforming complex shower enclosure projects into profitable installations with guaranteed safety and aesthetic quality.

Specs and options

Specifications customizable upon request.

Product Specifications

- Sintered Process - Granite, quartz, hard materials

- Brazed Process - Marble, limestone, medium hardness

- Resin Bond - Ceramics, glass, precision cutting

- Diamond Grit: 40-80 (coarse), 80-120 (medium), 120-220 (fine)

Technical Parameters

- Processing Thickness: 10-60mm• Interface: M8, M10, 5/8"-11, M14

- Compatible Equipment: Angle grinders, edge polishing machines, CNC routers

- Safety Guard: Required for angle grinder applications

Services & Support

- Custom sizing, grit specifications, and process types available

- Free technical consultation for process selection

- Professional installation guidance and safety training

- Lead time: 2-4 weeks for standard customizations

When standard bits fail, smart fabricators choose diamond

Cut Better. Last Longer. Profit More.

Custom Size Flexibility

Tailored dimensions and grit specifications for specific application requirements

Superior Tool Durability Performance

Enhanced diamond retention technology maintains cutting performance throughout extended operations

Multi-Material Compatibility

Effective across stone, glass, ceramics, and advanced composite materials

FAQs

Common Questions About Diamond Router Bits

Which diamond router bits work best for granite countertops?

For granite countertops, sintered diamond router bits provide the best results. They handle granite's hardness without chipping and last significantly longer than brazed alternatives. Choose coarser grits (60-80) for rough shaping and finer grits (120-150) for finishing edges.

How can I prevent chipping when cutting granite?

Use proper feed rates, maintain consistent pressure, and ensure adequate cooling. Diamond router bits perform best at 2000-3000 RPM for granite. Always use flood cooling or continuous mist systems to prevent overheating and extend tool life.

What's the difference between sintered and brazed diamond bits?

Sintered diamond tools use chemical and mechanical bonding for harder materials, while brazed tools offer higher diamond exposure for softer materials. Sintered bits excel with granite and engineered stone, providing longer life but slower cutting. Brazed bits cut faster in marble and limestone with superior surface finish.

Can diamond router bits be resharpened?

Professional diamond router bit resharpening services are available for sintered and some brazed types. However, the long lifespan often makes replacement more cost-effective than resharpening. Resin bond bits typically aren't resharpened due to their bonding structure, but their lower initial cost offsets this limitation.

How do I choose the right diamond grit for my application?

Diamond grit selection depends on your material and desired finish quality. Coarse grits (40-80 mesh) provide aggressive material removal for rough shaping, while fine grits (120-220 mesh) deliver smooth finishes. Medium grits (80-120 mesh) offer balanced performance for general-purpose applications across various stone materials.Optimal speeds range from 2000-4000 RPM depending on bit size and material. Smaller diameter bits can run at higher speeds, while larger bits require lower RPMs for proper cutting. Always use flood cooling or mist systems to prevent overheating and maximize tool life.

Are custom sizes available for special applications?

Yes, DINOSAW provides custom diamond router bits with tailored dimensions, grit sizes, and bonding types for specific applications. Custom profiles, shank sizes, and diamond concentrations can be manufactured to meet unique project requirements. Lead times vary based on complexity, typically 2-4 weeks for standard modifications.

How do I choose between sintered, brazed, and resin bond processes?

Process selection depends on your material hardness and application requirements. Sintered diamond bits excel with granite and engineered stone, providing maximum durability for production environments. Brazed bits offer superior surface finishes on marble and limestone with faster cutting speeds. Resin bond bits deliver precision control for delicate materials like ceramics and glass. DINOSAW provides free consultation to help determine the optimal process for your specific application.

Do I need special safety equipment for angle grinder use?

Yes, safety guard plates are mandatory when using diamond router bits with angle grinders. DINOSAW provides high-strength safety guards designed specifically for diamond router bit applications. These guards protect against debris and ensure compliance with industrial safety standards. Professional installation and proper training are recommended for safe operation.

Certifications & Standards

Cut Better. Last Longer. Profit More.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Solve Your Stone Edging Challenges?

Stop losing money on chipped edges and tool replacements. Get professional results.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Router Bits Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский