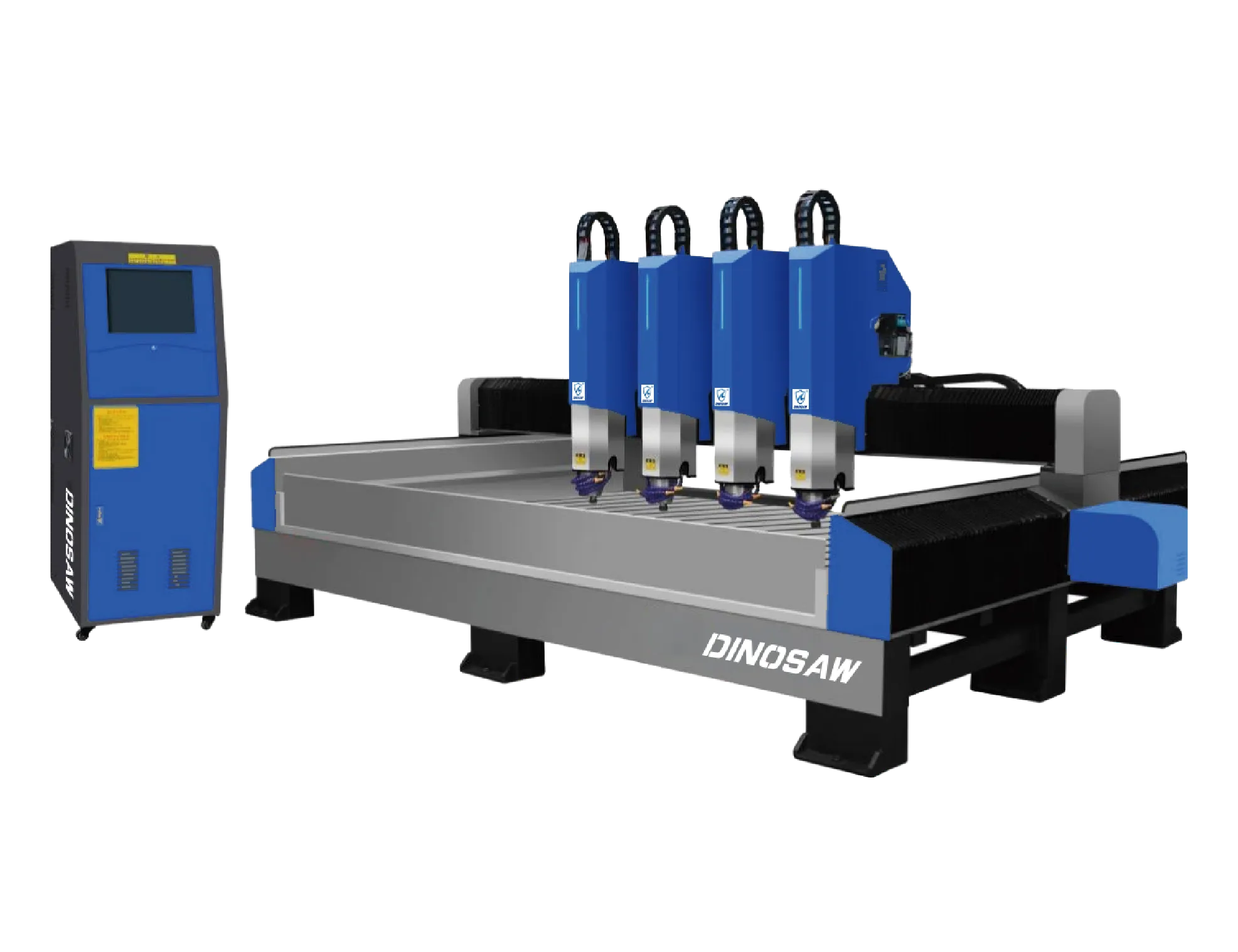

Merhaba, ben Lizzy, DINOSAW'dan (Robot Değil). Hangi Makineyi (model) istiyorsunuz? Lütfen şimdi WhatsApp üzerinden bize ulaşın

Curious what a CNC stone engraver machine can do for your shop? Explore our guide to see real-world case studies in granite carving and 3D stone relief.

TL;DR: What You Need to Know

- Can it handle granite? Yes. With a rigid frame, a high-torque spindle (5.5kW+), and diamond tooling, you can precisely engrave and carve even the hardest stones.

- How does it do 3D relief? It uses multi-axis control (X, Y, and Z) to move the tool, carving complex designs with depth and texture directly from a digital model.

- Is it better than manual carving? For commercial work, yes. This stone engraving equipment offers unmatched speed, repeatable precision (±0.05mm), and can produce complex designs not feasible by hand.

Can It Process My Material? A Direct Q&A

Can it engrave hard granite?

Can it carve 3D relief in marble?

Can it turn columns and balustrades?

Yes, this is a key application for architectural work.

How:While a standard 3 axis CNC machine excels at flat work, turning cylindrical shapes requires a 4th rotary axis. This device holds and rotates the stone column or baluster, allowing the spindle to carve it from all sides. For even more complex geometry, a full 5 axis bridge saw offers complete freedom.

Starting Parameters:For limestone, a good start is 14,000-18,000 RPM with a feed rate of 2,000-3,000 mm/min, using diamond profile tools.

Caution:The workpiece must be securely clamped at both the headstock and tailstock of the rotary axis to prevent any movement during carving.

Can it produce religious bas-relief panels?

Absolutely, this is a core strength of the technology.

How:This is a classic 3-axis bas-relief process. Using a fine-tipped ball-nose or V-groove bit, the machine carves shallow, intricate details from a digital model, perfect for creating scenes and figures on panels for altars, walls, or memorials.

Starting Parameters:For granite, use 18,000-22,000 RPM at 1,000-2,000 mm/min. For softer marble, you can be faster at 15,000-20,000 RPM and 2,000-4,000 mm/min. Caution:Fine details are fragile. Use small step-downs and a final, slow finishing pass with a small stepover to achieve a smooth, clean result and prevent chipping.

Can it produce tactile paving (blind path stones)?

Yes, this is an ideal application for ensuring public safety compliance.

How: The machine performs 3-axis bas-relief milling to create the required dots and lines. A ball-nose bit is used for the dots, and a V-groove bit is often used for the directional lines. The key is programming consistent patterns in your CAM software.

Starting Parameters: For granite or limestone, a good starting point is 16,000-22,000 RPM with a feed rate of 1,500-3,000 mm/min. A step-down of 1-2 mm per pass is recommended.

Caution: Depth consistency is critical (typically 3–5 mm). Ensure proper edge chamfering to prevent tripping hazards. Always use wet cutting and apply an anti-slip finish after processing.

Compatibility Matrix: Materials, Methods & Starting Points

Material | Method | Tooling | RPM/Feed (Start) | Notes |

|---|---|---|---|---|

Granite | Engraving, Bas-Relief | Sintered Diamond Tools | 18k-24k / 1-2 m/min | Requires high spindle torque and a very rigid machine. Water cooling is mandatory. |

Marble | 3D Relief, Lettering | PCD or Sintered Diamond | 15k-20k / 2-4 m/min | Prone to chipping; use sharp tools and consider a finishing pass. |

Sandstone | Deep Carving (CNC Sandstone Carving) | Coarse Grit Diamond | 12k-18k / 3-5 m/min | Very porous and abrasive. Effective dust collection (wet or vacuum) is critical. |

Slate | V-Carving, Signage | V-Groove Diamond Bit | 18k-22k / 2-3 m/min | Its layered structure can cause flaking. Plan toolpaths to cut with the grain if possible. |

Limestone | Balustrade turning (4-axis rotary) | Sintered Diamond / Profile Tooling | 14k–18k / 2–3 m/min | Softer; rotary axis improves throughput; clamp securely. |

Granite/Marble | Religious bas-relief panels | Fine-grit Diamond V/ball-nose | 18k–22k / 1–2 m/min (granite); 15k–20k / 2–4 m/min (marble) | Use light step-downs; finishing pass for clean edges. |

Granite/Limestone | Tactile paving dots/lines | Ball-nose/V-groove Diamond | 16k–22k / 1.5–3 m/min | Keep depth 3–5 mm, consistent spacing; apply anti-slip finish. |

Scenario Comparison: CNC vs. Traditional Methods

Factor | CNC Stone Engraver | Traditional (Manual) |

|---|---|---|

Repeatability | Extremely high (±0.05 mm), ensuring identical output every time. | Low. Dependent on artisan skill; variability is unavoidable. |

Speed | High. Automated process runs with minimal supervision, reducing labor hours. | Slow and labor-intensive. Not scalable for high-volume orders. |

Complexity | Easily produces intricate 3D reliefs and complex patterns from a digital file. | Limited by artisan skill and the time-consuming nature of complex work. |

Cost per Piece | Lower for production runs due to automation and speed. | Higher due to intensive skilled labor requirements. |

How Are Workshops Using Stone Engraving CNC Machines?

Case Study 1: Monument Engraving Workshop

- Initial Situation: A family-owned business specializing in headstones was struggling with turnaround times. Their traditional sandblasting was slow and limited design complexity.

- Action: They invested in a CNC stone engraver specifically designed as tombstone engraving equipment. They trained two operators on CAM software for design and toolpath generation.

- Result: Production time per standard headstone was reduced by 60%. They could now offer intricate, personalized designs, including custom monument shapes detailed in our diamond wire saw guide, increasing the average order value by 35%.

- Replicable Conditions: Standardized stone slab sizes; a library of pre-made digital design assets; CAM software training.

Case Study 2: Architectural Stone Fabricator

- Initial Situation: A firm producing custom limestone fireplace surrounds and columns relied on highly skilled (and expensive) artisans. Scaling production to meet commercial demand was impossible without compromising quality.

- Action: They adopted a 4-axis stone carving machine. The machine handled the roughing and semi-finishing work, leaving only the final touches for the artisans.

- Result: Overall project lead time dropped by 50%. The firm took on a large hotel lobby project that would have been previously unfeasible, increasing quarterly revenue by a significant margin. Their artisans could then shift focus to higher-value finishing and quality control.

- Replicable Conditions: Strong 3D modeling capability (CAD/CAM skills); a machine with a large work envelope; a hybrid workflow combining automation and hand-finishing.

Case Study 3: Custom Granite Countertop Business

- Initial Situation: A countertop installer wanted to differentiate from competitors by offering custom sink cutouts and decorative edge profiles beyond simple bevels. Their manual methods were imprecise and slow.

- Action: They acquired a 5 axis bridge saw with engraving capabilities. This allowed them to do precise cutting, shaping, and engraving in a single setup.

- Result: They became the local go-to for high-end custom kitchens. The ability to offer integrated, carved sinks and complex edge profiles led to a notable increase in profit margins on custom jobs, though this varies by design complexity.

- Replicable Conditions: Investment in a multi-function machine; operator training on 5-axis programming; marketing focused on unique, high-value customization.

Case Study 4: Religious Relief Workshop

- Initial Situation:A workshop creating marble relief panels for churches was reliant on manual chiseling, leading to long, inconsistent lead times and high skill dependency.

- Action:They adopted a 3 axis CNC machine and developed a library of CAM templates for common religious figures and patterns.

- Result:Project lead time was cut by 40%, and the defect rate from chipping and inconsistencies fell by over 60%. They could now take on more complex and larger-scale commissions.

- Replicable Conditions:A well-organized digital asset library, a clear Standard Operating Procedure (SOP) for finishing passes, and rigorous final quality checks.

Case Study 5: Municipal Tactile Paving Project

- Initial Situation: A city contractor was using manual templates to produce tactile paving stones, resulting in inconsistent dot/line spacing and depth, leading to failed inspections.

- Action: They implemented a CNC stone engraver with custom fixtures to hold batches of tiles. A standardized CAM pattern was created to ensure perfect consistency.

- Result: Dimensional variance was reduced by over 70%, eliminating failed inspections. Production throughput doubled due to batch processing.

- Replicable Conditions: A robust batch-clamping fixture set, a calibrated QC template for spot-checks, and a clear SOP for the anti-slip finishing process.

What Are the Risks and Boundaries?

- Space and Foundation: You need a solid, level concrete floor and adequate space for loading/unloading heavy materials.

- Power and Utilities: Ensure your workshop has three-phase power, compressed air, and a water supply for cooling.

- Digital Skills: Your team must be comfortable with CAD/CAM software to create designs and generate G-code. Learn more in our technical principles guide .

- Safety and Compliance: You must have a system to manage silica dust (wet or vacuum) to comply with OSHA guidelines .

Frequently Asked Questions (FAQ)

What is the price range for stone engraving machines?

- Context: Entry-level or small models can be found for under $10,000, while large industrial machines can exceed $100,000. Key cost drivers include the machine's size, spindle power, and axis configuration (3, 4, or 5-axis).

- Risk: A common mistake is focusing only on the initial purchase price. The true cost includes ongoing expenses.

- Next Step: Always budget for the Total Cost of Ownership (TCO), which includes tooling, software, training, and maintenance. Our Selection Guide provides a detailed TCO checklist.

How does a CNC stone engraver compare to traditional carving methods?

- Context: While manual carving has unique artisanal value, CNC technology excels in speed, precision, and complexity. It automates labor-intensive tasks, allowing skilled artisans to focus on higher-value finishing and design work.

- Parameters: A CNC offers verifiable repeatability (e.g., ±0.02mm), ensuring every piece of granite carving is identical, which is critical for product lines or architectural projects.

- Next Step: Review our Scenario Comparison for a direct, feature-by-feature analysis of CNC versus manual methods.

Can I use a standard wood CNC router for stone?

- Context: A dedicated stone engraver machine is engineered differently. It has a much heavier, more rigid frame to absorb the intense vibrations from cutting hard materials. A wood router's frame is too light and will result in tool chatter and poor accuracy.

- Risks: Using a wood router for stone will cause rapid wear, potential damage to the spindle and drive system, and lacks critical safety features like a robust water cooling system and proper sealing to protect components from abrasive dust.

- Next Step: Consult our Technical Principles guide to understand the specific components required for stone carving.

What materials can this machine engrave?

- Context: This includes hard stones like granite; softer stones like marble, limestone, and sandstone; and layered materials like bluestone and slate. It can also process engineered stone.

- Parameters: Success depends on matching the right parameters to the material. This involves selecting the correct diamond tooling, spindle speed (RPM), and feed rate based on the stone's specific hardness and composition.

- Next Step: Refer to our Compatibility Matrix for specific starting parameters for different stones and applications.

Where can I find a headstone engraving machine for sale?

- Boundary: The most crucial factor is not just buying the machine, but partnering with a supplier who provides a complete support package.

- Risk: Choosing a supplier without robust after-sales support can lead to extended downtime and a poor return on investment if problems arise.

- Next Step: Review the "Why Partner with DINOSAW?" section in our buyer's guide to understand the value of installation, training, and reliable support.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский