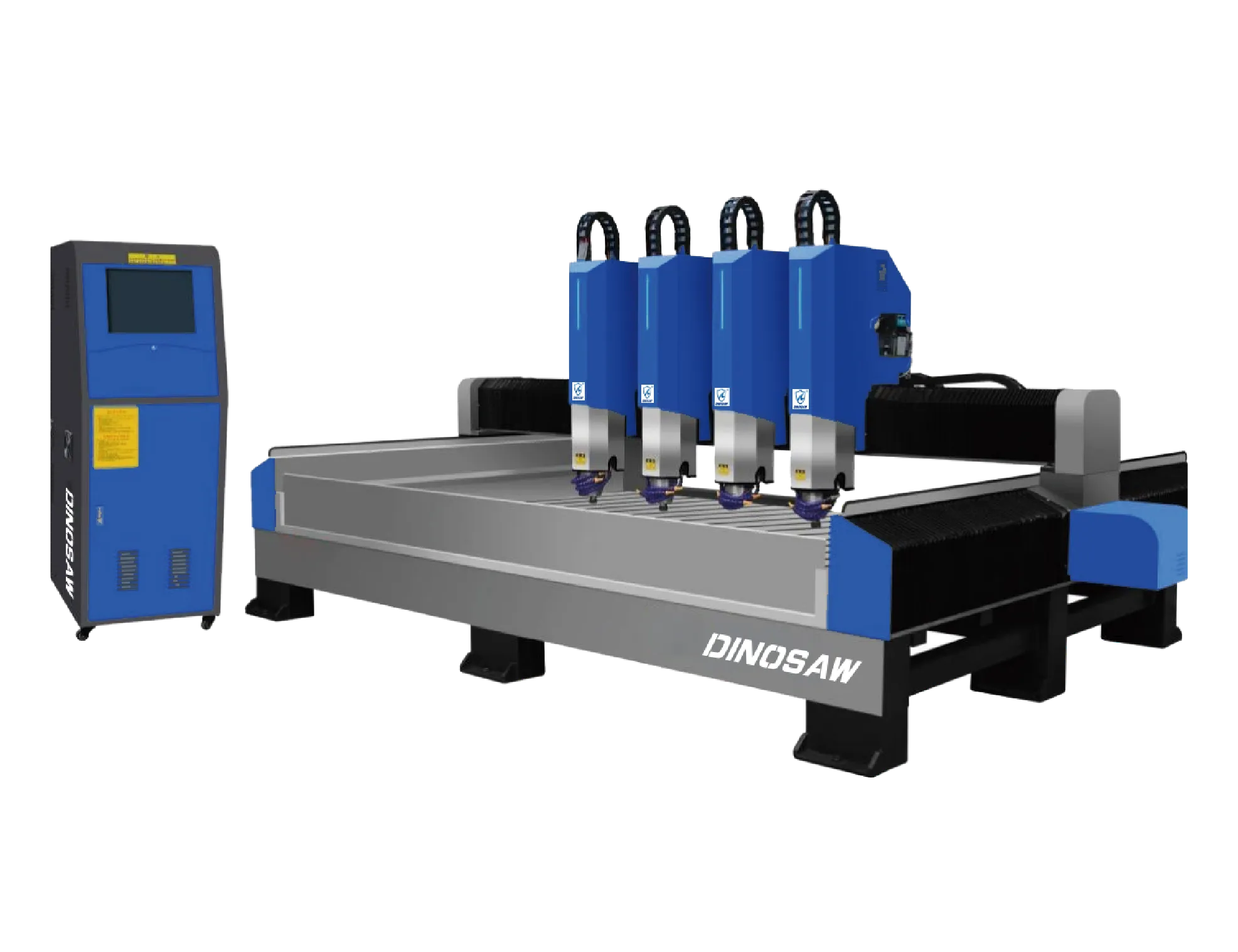

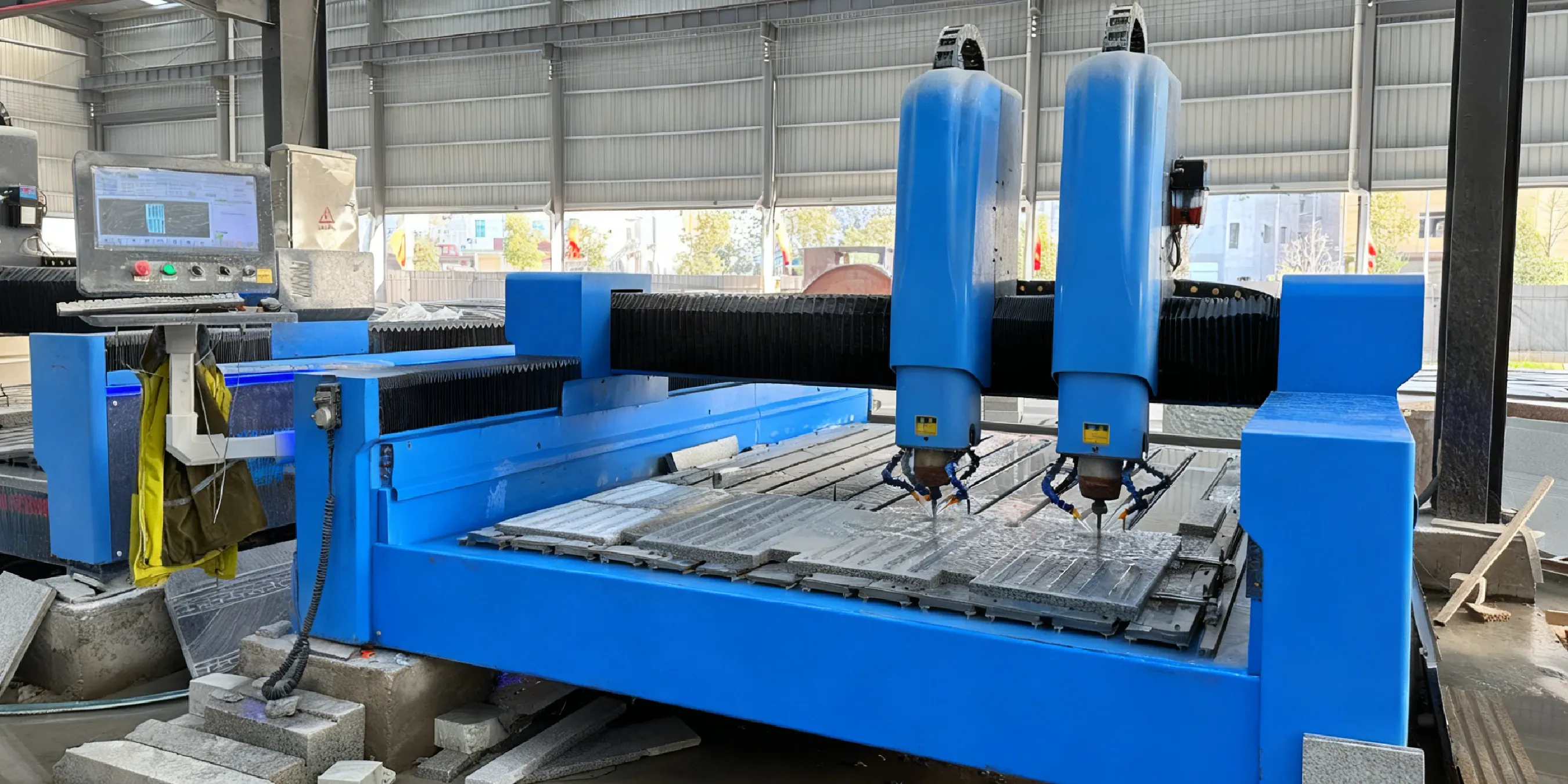

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Looking for a stone engraver for sale? Compare prices, features, and TCO to choose the right stone engraving equipment for granite, marble, and more.

L;DR: The Buyer's Shortlist

30-Second Decision Guide: An If-Then Guide For Your Application

30-Second Decision Guide: An If-Then Guide For Your Application

- IF you primarily engrave letters on headstones, THEN a rigid 3-axis machine with a high-torque spindle is your most cost-effective solution.

- IF your work includes 3D portraits or bas-relief, THEN prioritize a machine with a precise ball screw drive and a controller with excellent 3D processing.

- IF you fabricate architectural elements like columns, THEN a 4-axis machine with a rotary attachment is essential.

- IF you produce complex sculptures or custom countertops, THEN you need the multi-angle capabilities of a 5-axis machine, as explained in our guide to cutting custom shapes.

- IF your workshop handles both granite and marble, THEN ensure the machine has variable spindle speed control. Refer to our guide on stone identification .

- IF you are a small shop with limited space, THEN consider a smaller format machine but do not compromise on frame weight, as rigidity is critical for quality.

Scenario Comparison: Manual vs. CNC Stone Engravers

Scenario Comparison: Manual vs. CNC Stone Engravers

Feature | CNC Stone Engraver | Manual Methods |

|---|---|---|

Cost-Effectiveness | Higher initial investment, but lower cost per piece on production runs due to automation and reduced labor. | Lower initial cost (tools are cheaper), but very high labor cost per piece, making it less scalable. |

Automation & Speed | Fully automated. A job that takes days by hand can be completed in hours. | Fully manual. Speed is limited by artisan skill and endurance. |

Accuracy & Precision | Repeatability of ±0.02mm is standard. Every piece is identical. | Depends entirely on the artisan's skill. Variation between pieces is unavoidable. |

Your Buying Checklist for Stone Engraving Equipment

- Total Cost of Ownership (TCO): Look beyond the sticker price. Factor in tooling, software, maintenance, and energy costs. A cheaper machine can be more expensive long-term.

- Spare Parts & Consumables: Does the supplier stock critical spare parts (like spindles, drivers) for quick shipment? What is the cost and availability of recommended tooling?

- Maintenance & Support: What is the recommended maintenance schedule? Does the supplier offer remote diagnostics and on-site service? Check their standard service-level agreement (SLA).

- Training: Is comprehensive training on both the machine and software included? Poor training is a direct cause of low ROI.

- Warranty & Certifications: What does the warranty cover and for how long? Does the machine have relevant certifications (e.g., CE, UL) for your region?

Why Partner with DINOSAW?

- Expert Consultation: Our engineers work with you to configure the perfect machine for your needs, ensuring you don't over- or under-invest.

- Reliable Lead Times: We provide transparent and reliable delivery schedules to help you plan your facility upgrades and workflow transitions.

- Responsive Support (SLA): We offer clear service-level agreements for technical support, ensuring you get help when you need it to minimize downtime.

- Proven Case Studies: We have a portfolio of successful implementations across various stone-working sectors, from monument shops to architectural firms.

Frequently Asked Questions (FAQ)

What is the expected ROI for a stone carving machine for sale?

- Context: ROI is driven by three key factors: increased production speed (which lowers labor costs per piece), the ability to offer new high-margin services (like 3D carving), and reduced material waste due to fewer manual errors.

- Boundary: This timeline assumes the machine is fully leveraged and not sitting idle. A successful ROI requires a steady stream of work that utilizes the machine's capabilities.

- Next Step: Contact our team to help build a custom ROI calculation based on your current operational costs and potential new revenue.

Are financing or leasing options available?

- Context: These options are typically provided through third-party financial partners. Leasing can be an effective strategy to conserve capital, as it often requires a lower initial outlay and may offer tax advantages depending on your region.

- Next Step: It's always best to discuss these options with your supplier's sales team to determine which financial instrument best suits your company's budget and long-term strategy.

What kind of warranty and support should I expect?

- Parameters: A standard warranty is typically one year on parts. However, a strong support package is more critical for minimizing downtime.

- Boundaries: Before buying, verify that the supplier offers responsive remote support (via phone/email), has technicians available for on-site service, and maintains a stock of critical spare parts for quick shipment.

- Next Step: Ask for the supplier's Service Level Agreement (SLA) to get their support commitments in writing.

How much training is required to operate the machine?

- Parameters: An operator can typically learn basic machine functions (loading, homing, running a file) in just a few days. However, becoming truly proficient with CAM software to create complex and efficient toolpaths can take several weeks or more.

- Risk: The learning curve is highly dependent on the user's technical background. Insufficient training is a direct cause of low ROI and underutilization of the machine.

- Next Step: Ensure comprehensive training from the supplier is included in your purchase package.

Can the machine be customized for my specific needs?

- Context: Customizations are made to fit your specific workflow and product requirements.

- Examples: Common requests include modifying the table size, increasing the Z-axis height (for taller workpieces), and upgrading the spindle power. You can also add features like an Automatic Tool Changer (ATC) or a 4th rotary axis.

- Next Step: It's best to explore custom CNC router options directly with the manufacturer to discuss your needs.

What is the difference between a CNC stone engraver and a laser engraver for stone?

- Context: A CNC engraver uses a physical cutting tool (a bit) to physically carve into the stone, creating real depth and 3D relief. A laser engraver uses a focused beam of light to heat and vaporize the surface, creating a shallow mark or etching.

- Boundary: While a laser may be faster for surface marking, it cannot achieve the significant depth, textured finish, or sculptural effects of a CNC router, especially on hard materials like granite.

How does a waterjet compare to a CNC stone engraver?

- Context: A waterjet uses a high-pressure stream of water mixed with an abrasive to cut cleanly through very thick stone slabs without creating a heat-affected zone. It excels at creating intricate 2D shapes and cutouts.

- Boundary: A waterjet is generally more expensive to operate and is not efficient for 3D carving, surface engraving, or creating relief textures. These applications are where a CNC router shines.

Should I buy a new or used stone CNC machine?

- Context: A new machine provides a full warranty, the latest technology, comprehensive training, and complete support from the supplier. This ensures peace of mind and long-term reliability.

- Risks (Used): A used machine may offer initial cost savings, but it comes with significant risks: no warranty, potentially outdated technology, an unknown maintenance history, and a lack of supplier support. These factors can lead to higher long-term costs.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский