Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Is a stone carving machine a smart investment? Our executive guide helps you build the business case by covering ROI, implementation, and key decision factors.

TL;DR: The 30-Second Executive Summary

- Value Proposition: This isn't an expense, it's an investment in efficiency and higher margins. It automates labor and unlocks high-value 3D carving services.

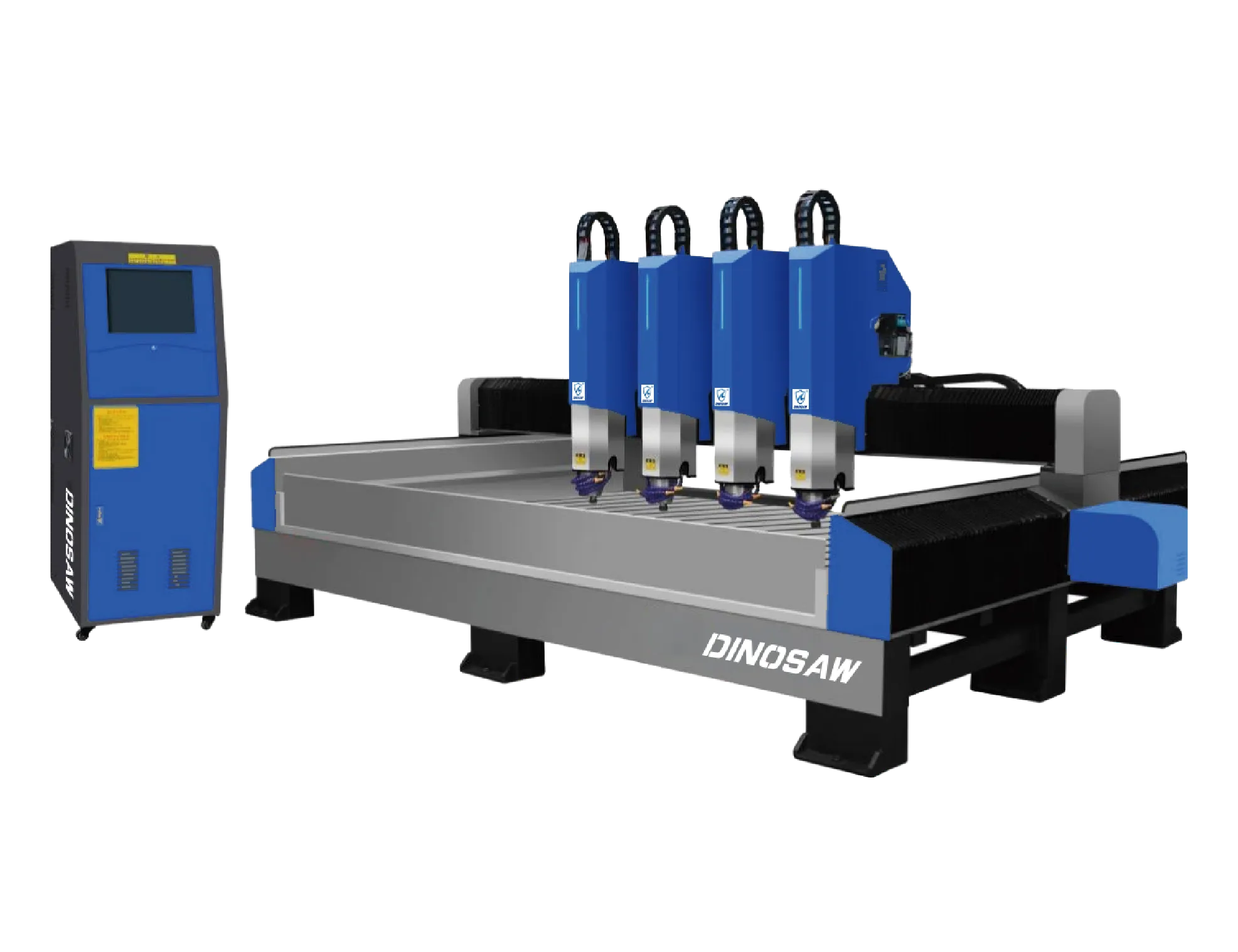

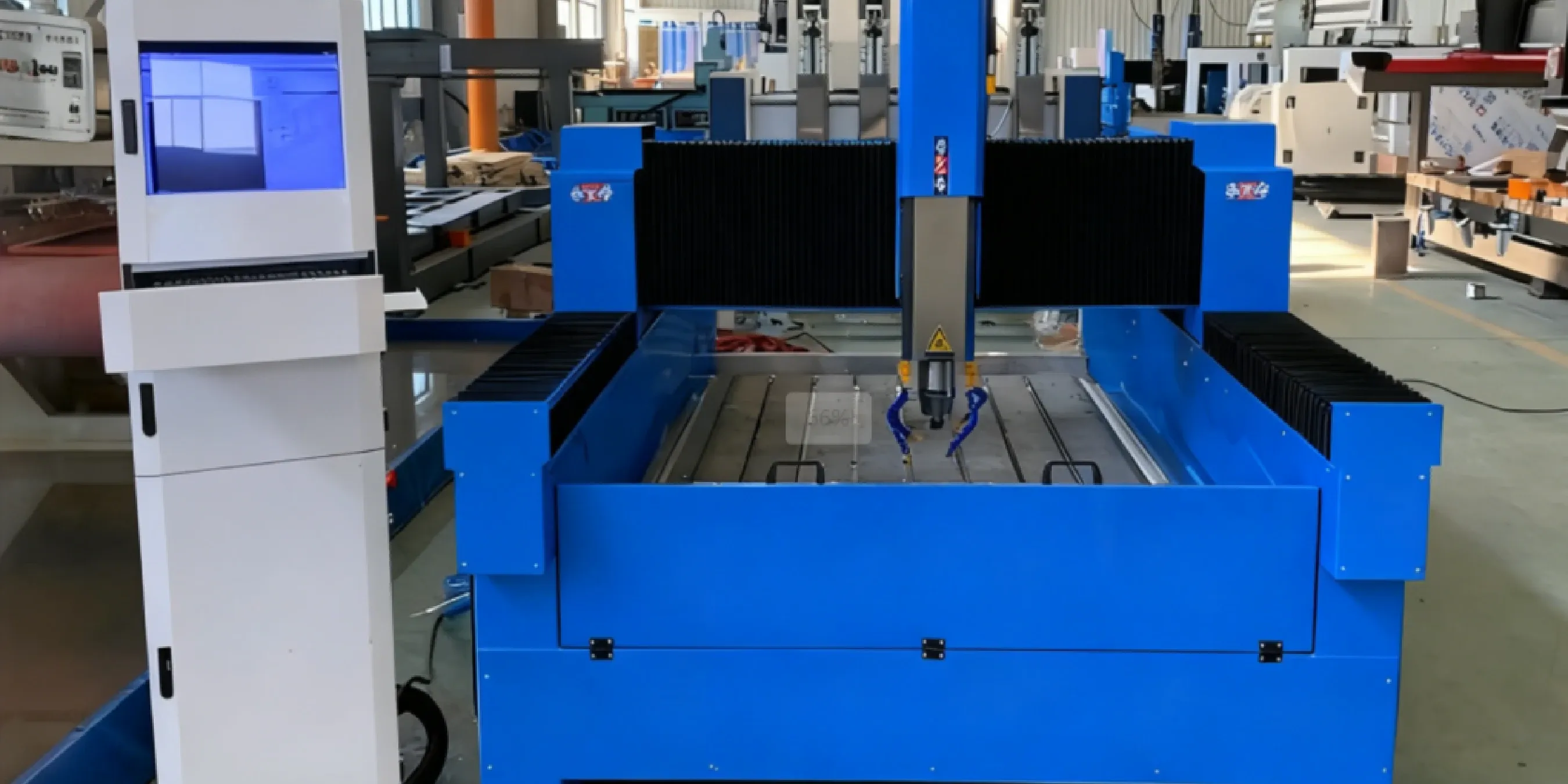

- Selection Cue: Match the stone engraving machine to your primary money-maker. Rigid 3-axis for monuments, 4/5-axis for complex architectural work. Don't overspend on capabilities you won't use.

- Implementation Path: A successful rollout is a phased process: facility prep, installation, training, then a pilot phase to standardize workflows.

- The Bottom Line (ROI): Calculate ROI based on labor savings, increased throughput, and new revenue streams—not just the initial machine price.

Quick Q&A for Procurement Stages

Quick Q&A for Procurement Stages

Awareness: "Why do I even need this?"

Evaluation: "What capabilities matter most?"

Purchase: "What's in the contract?"

After-Sales: "What happens after delivery?"

Your Requirements Definition Checklist

Your Requirements Definition Checklist

- Materials: What are your primary and secondary stone types? (e.g., Granite, Marble, Limestone)

- Geometry: What is the largest workpiece size (L×W×H)? Do you need 3D relief or full 3D sculpture capabilities?

- Precision: What is the required tolerance for your finished products? (e.g., ±0.1mm)

- Cycle Time: How many pieces do you need to produce per shift to meet demand?

- Facility: Do you have adequate space, three-phase power, and a solid foundation?

- Safety & Compliance: What are the local regulations for silica dust and machine safety you must meet?

Selection Overview: A Text-Based Comparison

For high-volume, flat engraving (e.g., headstones): A heavy-duty 3-axis machine is your workhorse. Its primary advantage is cost-effectiveness and simplicity. Its boundary is that it cannot produce complex 3D shapes. For complex artistic and architectural work: A 4 or 5-axis machine is required. Its advantage is unmatched geometric freedom, allowing for high-margin products. Its boundary is higher cost and a steeper operator learning curve.

Pilot & Acceptance: 5 Steps to Success

- Step 1: Install & Calibrate. Technician installs and validates machine accuracy. KPI Example: Positional accuracy verified at ≤±0.1mm.

- Step 2: Train Operators. Team receives comprehensive training on machine operation and CAM software. KPI Example: Operators can independently load, run, and troubleshoot a simple job.

- Step 3: Run Pilot Projects. Start with simple, low-risk jobs to build confidence and standardize parameters. KPI Example: Successfully complete 10 consecutive jobs with a <5% error rate.

- Step 4: Develop Workflow. Document best practices for tooling, speeds/feeds, and maintenance. KPI Example: A standard operating procedure (SOP) document is created.

- Step 5: Final Acceptance. Sign off on the installation once the machine meets all predefined performance criteria.

Decision Gates Checklist

- Technical Gate: Does the machine meet our defined requirements for size, power, and precision?

- Business Gate: Does the ROI projection meet our company's investment threshold?

- Legal Gate: Have we reviewed the purchase agreement, warranty, and liability terms?

- Compliance Gate: Does the machine and our planned workflow meet all safety and environmental regulations?

- Final Sign-off: Have all key stakeholders (production, finance, management) approved the investment?

Contract & Delivery Essentials

Implementation & Training

Implementation & Training

After-Sales & SLA

Your Complete Resource: A Summary of Our Guides

- Applications & Case Studies: Explore what the machine can *really* do and see how businesses like yours have boosted profits.

- Technical Principles: Get an engineer's look under the hood to understand the core components that guarantee precision.

- Selection & Comparison: A buyer's framework for choosing the right machine and looking beyond the sticker price to TCO.

- Operation & Maintenance: A practical guide for your operators to maximize uptime and ensure safety every day.

FAQ for Decision-Makers

FAQ for Decision-Makers

How do I justify the cost of a CNC stone machine to stakeholders?

- Context: A strong business case should present clear financial projections. This includes labor cost savings from automation, increased throughput (more jobs completed per shift), and new revenue streams from high-value services that were previously impossible.

- Next Step: Present this as an investment in efficiency, quality control, and competitive advantage. Our team can help you build a detailed ROI projection for your specific business.

What is a realistic implementation timeline?

- Parameters: This timeline can be broken down into phases:

- Installation & Calibration: 2–3 days

- Operator Training: 1–2 weeks

- Pilot Phase (workflow development): 2–4 weeks

- Risk: Rushing the training and pilot phases is a common mistake. This is where your team builds the confidence and develops the standard procedures needed to run the machine efficiently and safely.

How will this impact our existing workflow?

- Context: The focus moves from manual chiseling and polishing to digital design (CAD/CAM), machine setup, and operation. This change brings significant efficiency gains.

- Opportunity: This allows you to redeploy your highly skilled artisans to higher-value tasks that automation cannot replace, such as complex hand-finishing, final quality control, and developing new, creative product designs. This is a much better use of their valuable talent.

How do we future-proof this investment?

Machine Choice: Select a machine that is modular and can be upgraded. For example, start with a 3-axis machine but ensure the supplier can add a 4th-axis rotary device later as your business grows into new applications.

Supplier Choice: Partner with a supplier who has a strong reputation for long-term support and guaranteed spare parts availability. A machine is only as good as the support behind it.

What are the biggest hidden costs to watch out for with stone engraving CNC machines?

- Context: These are often overlooked in initial budgeting but are critical for successful implementation.

- Cost Areas:

- Facility Upgrades: A reinforced, level foundation and dedicated three-phase power can be significant expenses.

- Software & Training: A professional CAM software license and comprehensive operator training are essential for ROI.

- Tooling: High-quality diamond tooling is a significant and recurring operational expense.

- Next Step: Factor these items into your Total Cost of Ownership (TCO) calculation from day one.

What's the difference in profitability between flat engraving and 3D carving?

Context: While market dependent, 3D relief and sculptural work can often command profit margins that are 50% to 200% higher than simple lettering or 2D patterns.

Reason: This premium is driven by the higher perceived artistic value, complexity, and customization of the work.

Boundary: Unlocking this market requires a machine with true 3D capabilities, such as a 3d stone relief machine, and the CAM programming skills to create the designs.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский