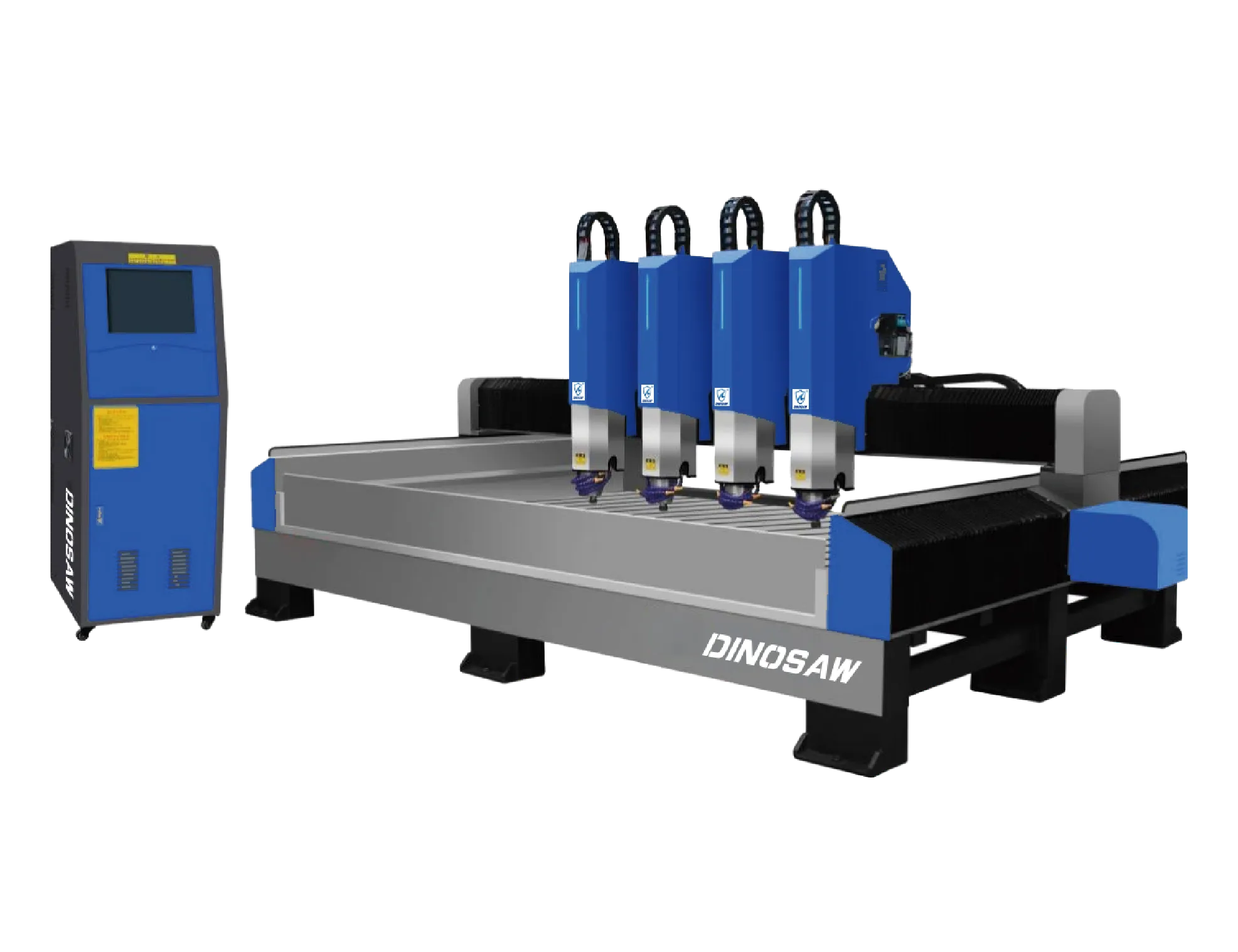

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

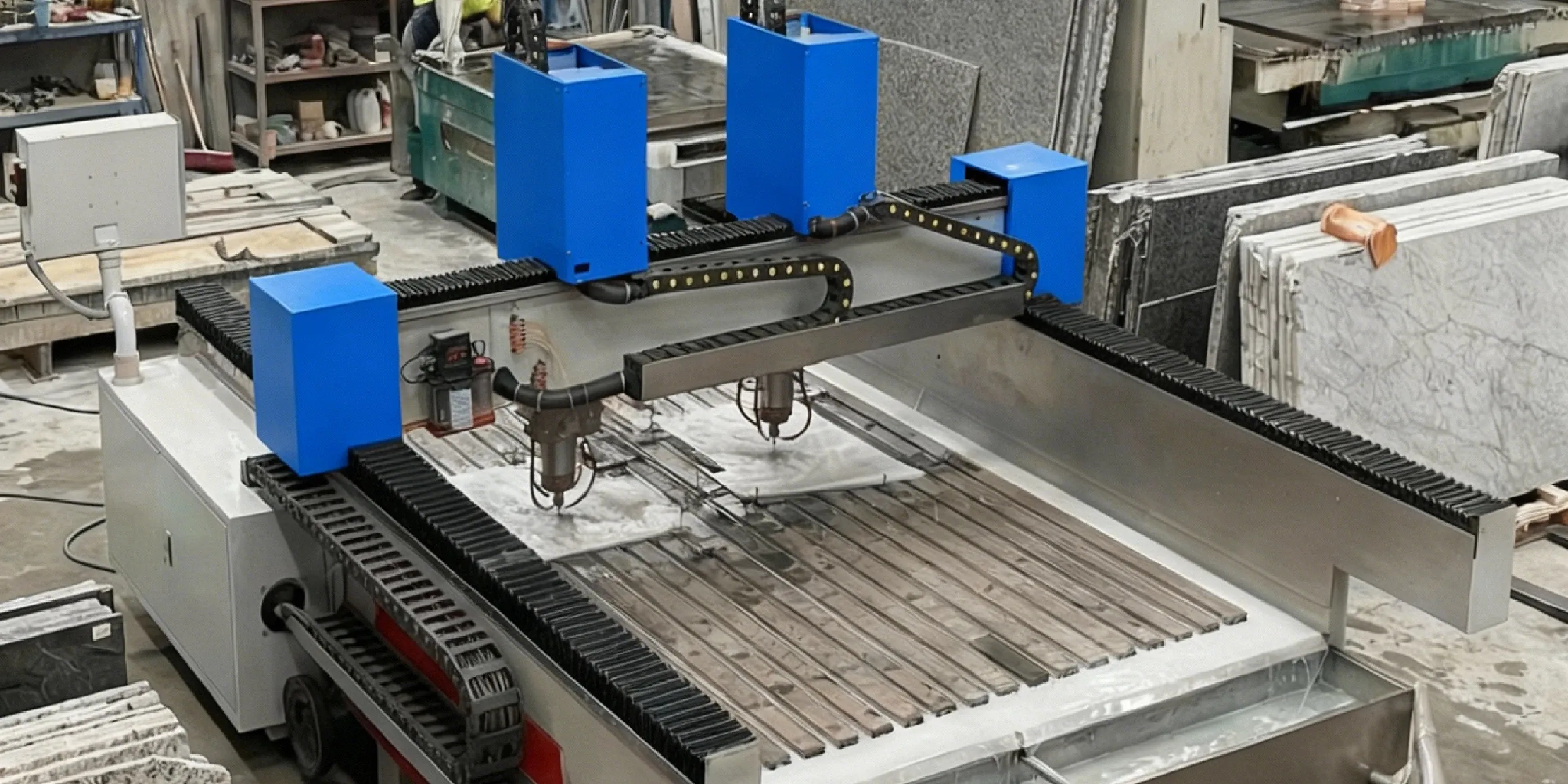

Maximize your stone engraving CNC machine's uptime with our guide. We cover daily maintenance checklists, troubleshooting, and operator safety best practices

TL;DR: The Operator's Cheat Sheet

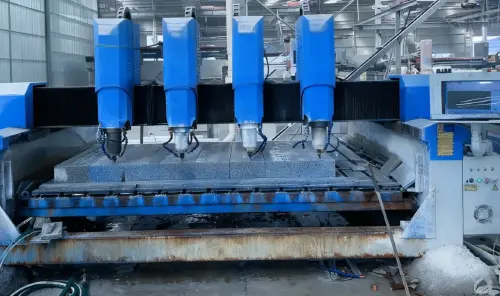

- Daily Checks are Non-Negotiable: Clean the stone engraving machine of dust/slurry and check coolant flow before every shift. This prevents 90% of common problems.

- Troubleshooting is Systematic: For poor quality, check the tool first, then speeds/feeds, then mechanical looseness. Don't guess.

- Safety First, Always: Wet cutting and NIOSH-approved respirators are mandatory to control hazardous silica dust.

- Lubrication is Key: Weekly lubrication of linear guides and ball screws is critical for maintaining accuracy and preventing premature wear.

Standard Operating Procedure (SOP) Checklist

Standard Operating Procedure (SOP) Checklist

- Startup: Power on machine, home all axes, check VFD for errors, ensure coolant pump is active.

- Tool Changeover: Clean spindle taper and collet, properly seat the new tool, and minimize stick-out.

- Calibration Check: Before critical jobs, touch off the tool to verify Z-height. Run a small test piece if unsure.

- Lubrication: Apply grease to linear guides and ball screws weekly or per the manufacturer's 40-hour schedule.

- Consumables Check: Inspect diamond tools for wear or chipping. Check coolant level and clarity.

- Safety Checks: Test the E-stop button. Ensure all safety guards are in place. Confirm dust/slurry collection is active.

How Do You Troubleshoot the Top 5 Common Problems?

Symptom | Diagnosis (Likely Cause) | Solution | Prevention |

|---|---|---|---|

Poor engraving quality | 1. Worn tool

2. Incorrect feeds/speeds

3. Loose workpiece | 1. Replace tool

2. Reduce feed rate/increase RPM

3. Re-clamp workpiece firmly | Regularly inspect tools. Standardize cutting parameters. |

Excessive tool wear | 1. Insufficient coolant

2. Wrong tool for material | 1. Check water pump/lines

2. Use correct tool grit/bond | Daily coolant system check. Use a tool chart for material matching. |

Machine losing position | 1. Loose motor coupling

2. Debris on guides | 1. Tighten coupling set screws

2. Clean and lubricate drive system | Weekly check of couplings. Keep machine clean. |

Spindle won't start or overheats | 1. VFD error

2. Blocked coolant flow | 1. Reset VFD, check error code

2. Clear blockage in cooling lines | Keep electronics cabinet clean. Clean water tank weekly. |

Excessive vibration | 1. Unbalanced tool

2. Machine not level

3. Worn spindle bearings | 1. Re-seat tool

2. Re-level machine frame

3. Contact support for replacement | Clean collet/holder during tool changes. Check level monthly. |

Parameter Calibration & Periodic Maintenance

Daily

- Clean dust/slurry from all surfaces.

- Check coolant flow and level.

- Inspect tool for visible wear/damage.

Weekly

- Lubricate linear guides and ball screws.

- Clean coolant tank and filter.

- Check drive belts for tension.

Monthly

- Check machine level and tram.

- Inspect all wiring for secure connections.

- Backup controller parameters.

Safety First: What PPE and Practices Are Required?

- Engineering Controls: Always use the machine's wet cutting system. This is your primary method for suppressing dust at the source. Source: NIOSH wet cutting guide.

- Respiratory Protection: Operators must wear a properly-fitted, NIOSH-approved respirator (e.g., N95 or higher) when working near or cleaning up stone dust.

- Other PPE: Safety glasses with side shields, waterproof boots, and hearing protection are also essential.

Frequently Asked Questions (FAQ)

How do I calibrate the machine for accuracy?

- Context: Tramming ensures the spindle is perfectly perpendicular to the worktable, which is critical for accuracy.

- Parameters: You can check for squareness using a dial indicator mounted to the spindle.

- Risk: If the machine is out of tram, do not attempt to adjust it yourself without experience, as incorrect adjustments can worsen accuracy.

- Next Step: Consult the machine manual or contact technical support for guidance. Our technical principles guide has more on this topic.

What is the best type of CNC tool for granite carving?

- Context: These tools have diamond particles fused into a durable metal matrix, which is necessary to withstand the abrasiveness of granite.

- Parameters: For detailed engraving, use a smaller diameter tool with a fine grit. For roughing or bulk material removal, use a larger, more aggressive tool with a coarse grit.

- Risk: Using the wrong tool type (e.g., a tool meant for wood or soft metal) will result in immediate tool destruction and poor results.

How often should I clean the water circulation tank?

- Context: During operation, abrasive stone slurry builds up in the tank. If not removed, this slurry gets recirculated through the system.

- Risk: Recirculated slurry can clog coolant lines (starving the tool of coolant) and cause premature wear and failure of the water pump, leading to costly downtime.

- Next Step: Integrate this task into your weekly maintenance schedule. The process involves draining the tank, removing the sediment, and refilling with clean water.

Do I need to update the machine's software?

- Machine Controller: You should not update the CNC controller's firmware unless specifically instructed by the manufacturer to fix a known bug. Unauthorized updates can cause serious compatibility issues.

- CAM Software: Your CAM software (e.g., Aspire, ArtCAM) should be kept up to date. Updates often provide new features, bug fixes, and more efficient toolpath strategies that can improve your workflow.

Can I operate the stone art machine unattended?

- Context: While the CNC automates the cutting process, unforeseen issues can occur. An operator should always remain in the vicinity of the machine.

- Risks: Potential issues include tool breakage, the workpiece shifting, or unexpected coolant flow problems. An attentive operator can stop the machine immediately, preventing damage to the workpiece, tool, or machine.

- Boundary: This is especially critical when running a new program for the first time or when working on a complex, high-value piece.

What are the signs that my spindle bearings are failing?

- Symptoms: Listen for a new grinding, rattling, or whining sound coming from the spindle during operation. You may also notice a sudden decline in the surface finish quality of your engravings or that the spindle housing is unusually hot to the touch.

- Risk: Continuing to operate a spindle with failing bearings can lead to catastrophic failure, which is far more expensive to repair than replacing the bearings early.

- Next Step: If you suspect bearing failure, stop using the machine immediately and contact our service department for diagnosis and to schedule a replacement.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский