Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

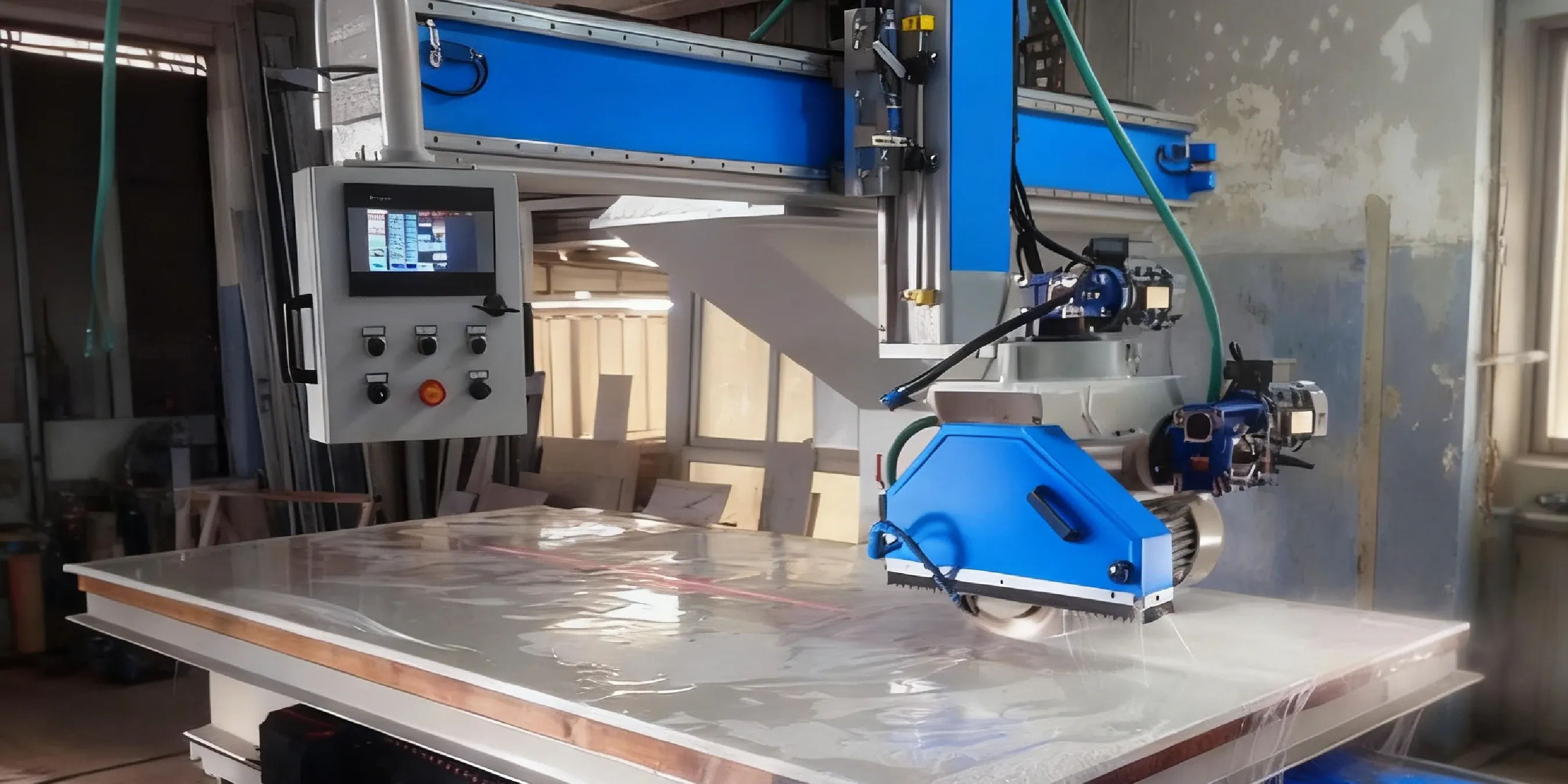

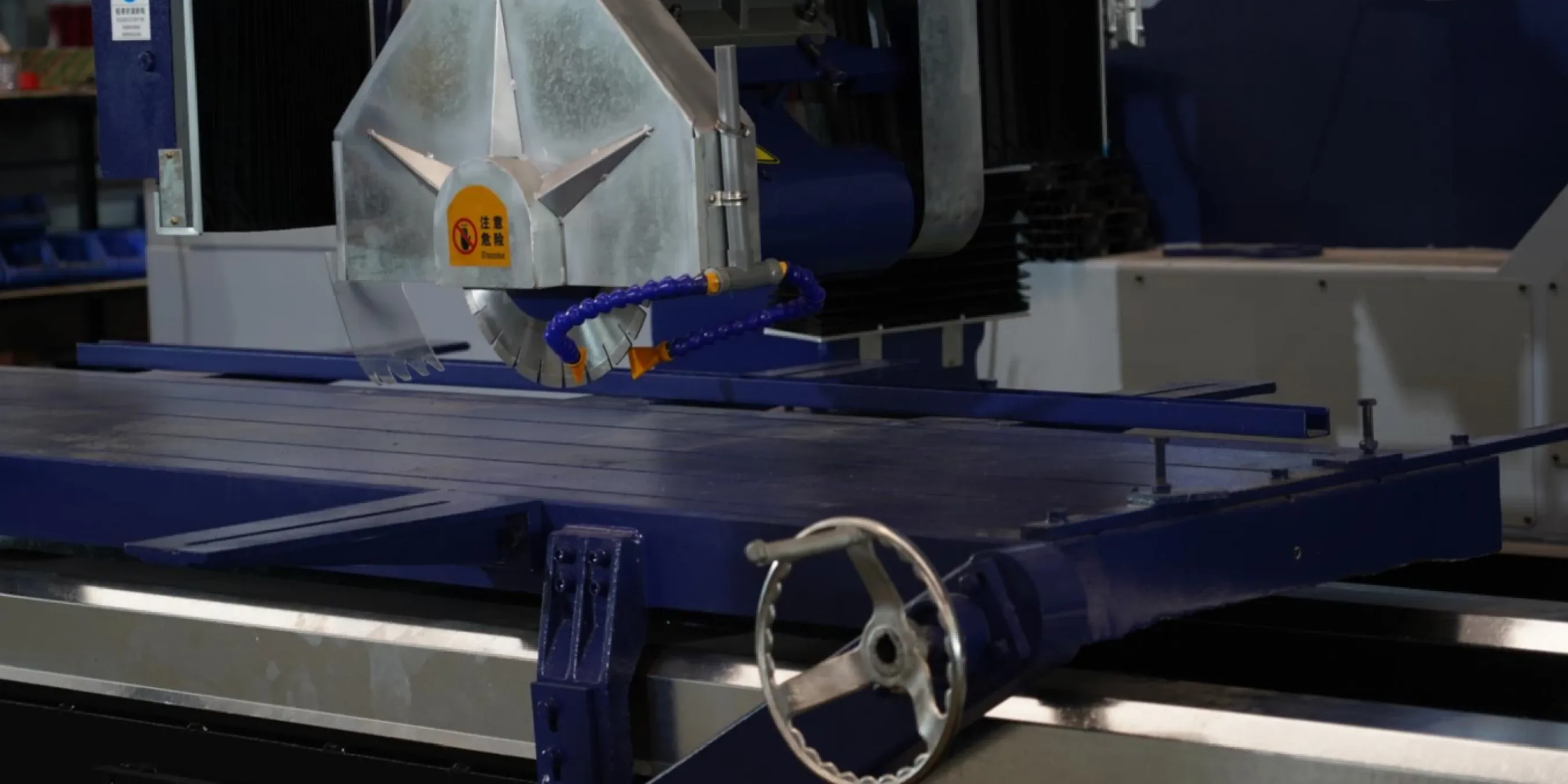

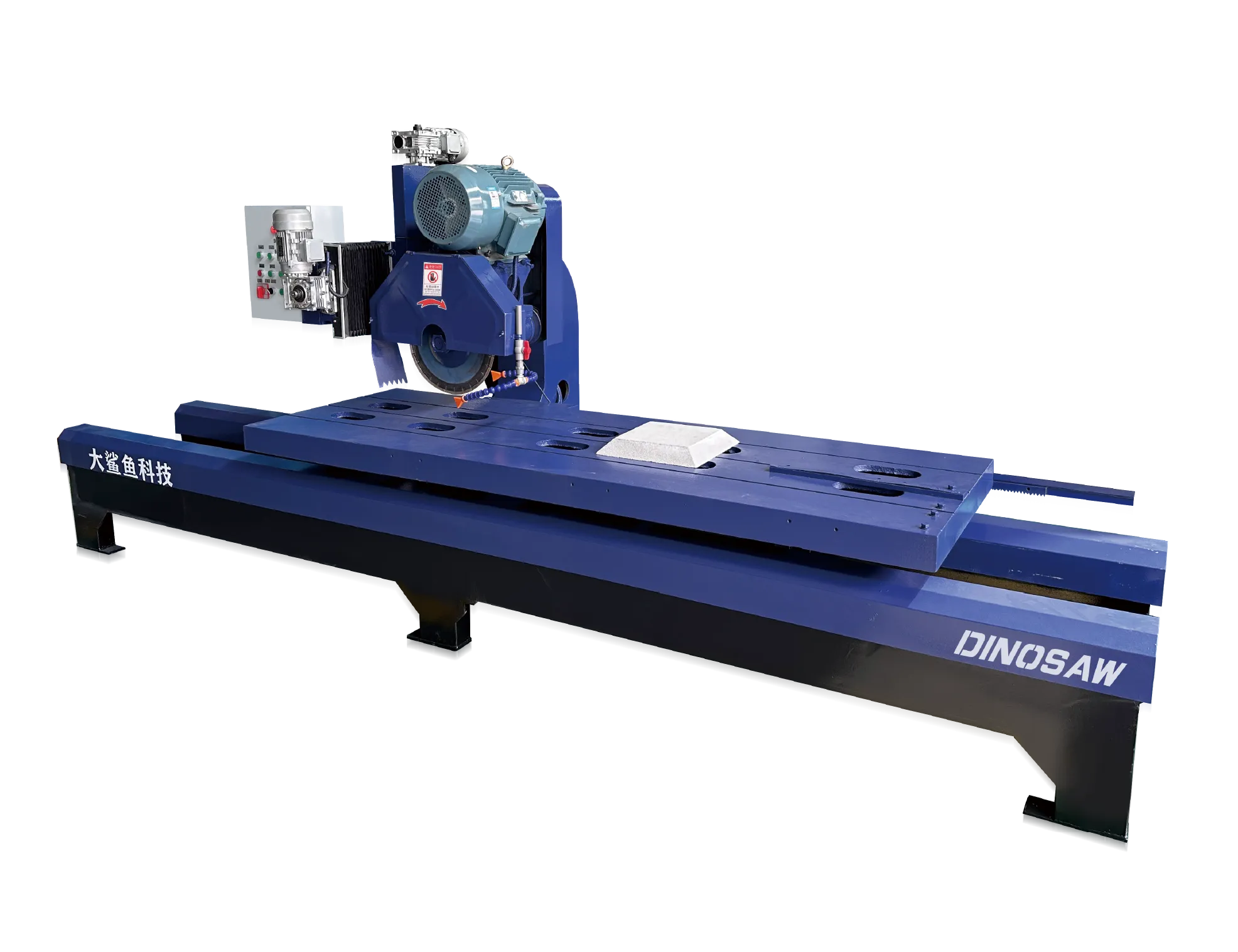

Process granite/marble/quartz edges with 45° chamfer. Best for small-batch straight cuts. Specs, PPE, & FAQs included.

TL;DR: Key Takeaways

- Best Use Case: Stone cutting machines are suitable for small-batch jobs requiring precise straight cuts and 45-degree chamfers on materials like granite, marble, and quartz.

- Cost-Effective Choice: Offers significant cost savings and faster deployment compared to CNC machines for standard cutting tasks, making it perfect for workshops prioritizing efficiency and budget.

- Core Capabilities: Excels at fabricating kitchen countertops, bathroom vanities, cabinet panels, curb stones, and splash guards with clean, professional finishes.

- Key Limitations: Not recommended for complex curves or free-form shapes. For intricate designs, a CNC or a dedicated Automatic Bridge Saw (CNC/PLC) is a better fit.

- Safety is Paramount: Proper operation requires strict adherence to safety protocols, including water for dust suppression and appropriate Personal Protective Equipment (PPE) to comply with standards like OSHA's.

Can Manual Industrial Stone Cutting Machine Handle Your Job?

What Can Manual Industrial Stone Cutting Machine Achieve?

- Precise Granite Edge Cutting: Achieve perfectly straight and clean edges on granite slabs, essential for high-end kitchen countertops and architectural elements.

- Marble Countertop Chamfering: Create elegant 45-degree bevels on marble countertops and vanities, delivering a premium look with minimal chipping.

- Custom Quartz Cabinet Panels: The machine’s accuracy is perfect for quartz cabinet panel fabrication, ensuring panels meet exact dimensions for a seamless fit.

- Uniform Curb Stones: Efficiently produce granite curb stones with consistent chamfering, ideal for landscaping and municipal projects requiring durability and aesthetic appeal.

- Perfectly-Sized Splash Guards: Cut thin backsplashes from granite or quartz with precision, ensuring a tight seal against walls and countertops to prevent water damage.

Manual Stone Cutting Machine vs. Automatic Bridge Saw (CNC/PLC)

From Theory to Practice: Three Mini Case Studies

Quartz Cabinet Panels

Initial Problem: A fabricator experienced edge chipping and a size error of ±2mm on quartz panels, leading to waste.

Action: They reduced the cutting speed and utilized the machine's oil-lubricated guide rails to ensure smooth, steady movement.

Result: Edge chipping was reduced by approximately 30%, and dimensional accuracy improved significantly.

Replication Conditions: Use a sharp blade designed for engineered stone, maintain a slow and consistent feed rate, and ensure guide rails are clean and lubricated.

Marble Countertop Edges

Granite Curb Stones

Risks and Prerequisites: Safety & Compliance First

Frequently Asked Questions (FAQ)

What materials can the Manual Industrial Stone Cutting Machine cut?

- Typical Path:

- Choose blade grit for the material (fine-grit for brittle, medium-coarse for hard).

- Set gentle feed; validate on a scrap; keep water 2–3 m³/h.

- Boundary: Not for complex free-form curves—use a CNC or a wire saw machine.

What is the maximum cutting size?

- Typical Path: Use appropriate blade diameter (Φ350–Φ600) and secure fixturing for large slabs.

- Boundary: Avoid single deep pass beyond thickness; use multi-pass strategy for thick stone.

When should I choose this manual cutter over an automatic bridge saw?

- Manual Wins On:Lower cost/TCO; fast setup for one-off jobs; operational flexibility.

- Automatic Saw Wins On:Complex geometry; high repeatability at volume; automated nesting to optimize material.

- Boundary:If more than half your work involves intricate shapes, automation is the better path.

How can I avoid edge chipping when cutting slate?

- Typical Path:

- Replace with sharp fine-grit diamond blade; reduce feed; test-cut.

- Verify table level; increase water coverage; clamp fully.

- Boundary:If chipping persists on thin panels, consider an automatic bridge saw.

What bevel accuracy can I expect for 45° cuts?

- Context:The rigid cast-iron frame and secure tilting head lock minimize deviation during cuts. Accuracy is dependent on a precise initial calibration using a digital protractor.

- Benefits:This level of accuracy ensures consistent, high-quality mitered edges for seamless joins in countertops and architectural elements, reducing rework.

What are the power requirements?

- Typical Path:Install by qualified electrician; verify breakers/grounding; inspect cables/terminals routinely.

- Boundary:Match motor power (7.5–18.5 kW) and local codes before commissioning. Your workshop's power infrastructure must support the required voltage, which is customizable.

How often does the machine need maintenance?

- Typical Path:

- Daily: check water and dust-proof covers.

- Weekly: clean/lubricate oil-immersed rails; remove debris.

- Monthly: inspect blade/belts/electrics; schedule yearly service.

What PPE is required to operate this machine safely?

- Boundary:Even with water cooling, you must comply with OSHA/NIOSH silica dust exposure limits.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский