Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

See what a monoblock bridge saw can produce: granite countertops, 45° miter edges, porcelain slabs, and sintered stone projects—capabilities, limits, and next steps.

TL;DR: Core Capabilities & Next Steps

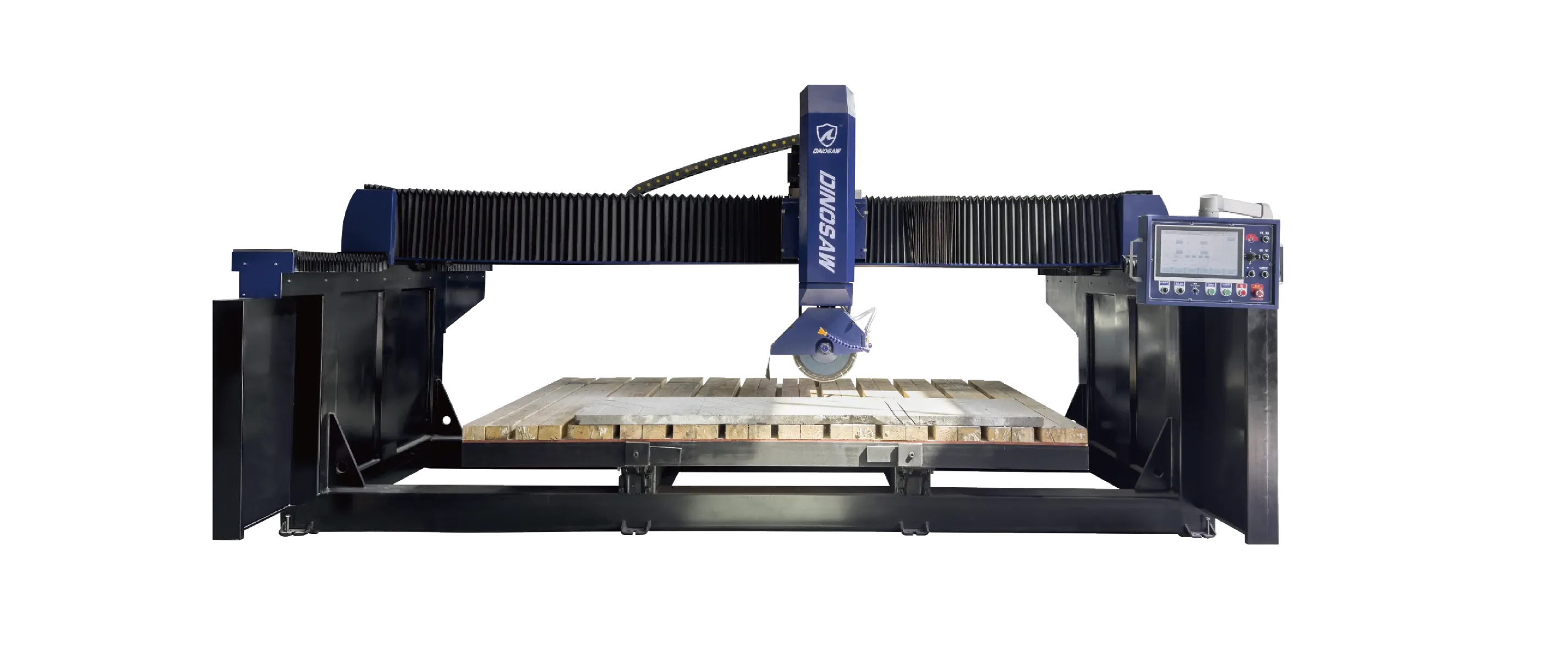

- A monoblock bridge saw is an all-in-one CNC solution for cutting natural stone (granite, marble), engineered stone (quartz), and hard ceramics (porcelain, sintered stone).

- It excels at high-value tasks like straight cuts for countertops, 45° mitered edges for waterfall designs, and complex curved shapes from DXF files.

- Next Step:Before purchasing, confirm your primary materials and job types. This guide helps you verify if the machine’s capabilities match your production needs.

What Materials Can This Bridge Saw Cut?

What Materials Can This Bridge Saw Cut?

How Does It Handle Natural Stone Like Granite?

- Example: Fabricating a seamless 3-meter granite island with a single, continuous cut.

- Example: Batch cutting 50 marble vanity tops for a hotel project with ±0.5mm consistency.

How Does It Cut Engineered Stone and Quartz?

- Example: Creating a waterfall countertop edge with a perfect 45-degree miter cut on a 20mm quartz slab.

- Example: Cutting a large-format sintered stone panel for exterior cladding without causing micro-fractures.

What Is the Process for Porcelain Slab Cutting?

- Example: Sizing a 3m x 1.5m porcelain slab for a seamless shower wall with exact dimensions.

- Example: Nesting multiple flooring tile cuts on a single large porcelain panel to maximize material yield.

What Kind of Jobs Can You Perform?

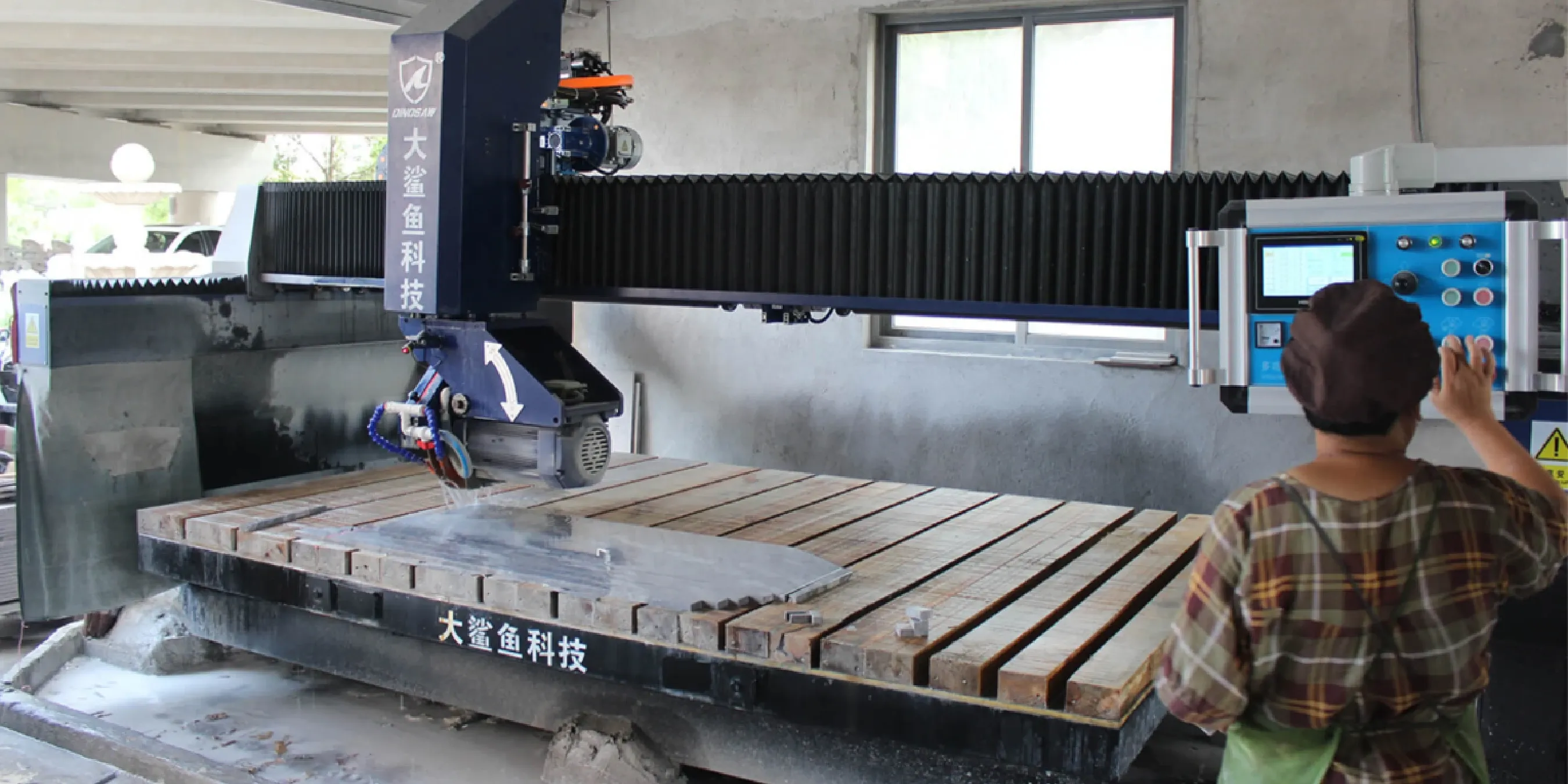

- Task: Fabricate Countertops. Program straight cuts, sink cutouts, and faucet holes using the CNC system. The rotating worktable allows for multiple cuts without moving the slab, drastically improving efficiency.

- Task: Create Mitered Edges. Utilize the 0-45° blade tilting capability to create perfect, clean miter joints for waterfall edges and thick-profile countertops. The CNC control ensures the angle is consistent along the entire length of the cut.

- Task: Cut Custom Shapes. Combine the rotating worktable with the CNC programming to cut arcs, curves, and other non-linear shapes for custom tabletops, reception desks, or landscape features.

3 Mini-Cases: How a CNC Bridge Saw Delivers ROI

- Problem: A mid-sized workshop using a manual saw, struggling with production bottlenecks and inconsistent quality on mitered edges.

- Solution: Upgraded to a YTQJ-600 monoblock bridge saw to automate cutting processes.

- Result: Reduced average production time per kitchen by 40% and eliminated rework on mitered joints, significantly boosting throughput.

- Problem: Outsourcing complex angled and curved cuts for custom headstones, leading to high costs and long lead times.

- Solution: Implemented a CNC saw with a tilting head to bring intricate cutting capabilities in-house.

- Result: Captured higher-margin business by producing complex designs internally and reduced project lead times by over 50%.

- Problem: Cutting architectural stone cladding on-site with manual tools, resulting in slow progress, safety risks, and high labor costs.

- Solution: Pre-fabricated all panels to precise specifications in a controlled workshop environment using a CNC bridge saw.

- Result: Accelerated project completion by an estimated 30%, improved installation quality, and reduced on-site labor costs.

What Are the Prerequisites for Installation and Safety?

Conclusion: Why Is It a Versatile Workhorse?

Frequently Asked Questions (FAQ) about this Granite Cutting Machine

What is a monoblock bridge saw used for?

- Context:The bridge and supports are built into a single, rigid frame, which holds the cutting blade.

- Benefits:This design eliminates the need for separate concrete foundation walls, making it easier and faster to install than traditional gantry saws.

- Next Step:Evaluate your workshop's floor space and power supply to confirm compatibility with a monoblock footprint.

How accurate is the cutting precision on a marble bridge saw?

- Context:This high precision results from the rigid monoblock frame minimizing vibration, combined with a closed-loop CNC system.

- Benefits:Servo motors and encoders constantly correct the blade's position, which is crucial for delicate materials like marble and ensures tight-fitting joints.

- Next Step:Request sample cuts or a live demonstration from the supplier to verify the claimed precision on your specific materials.

Can this CNC stone cutting machine cut curves?

- Context:The CNC system coordinates the movement of the X-axis (bridge), Y-axis (head), and C-axis (worktable rotation) simultaneously.

- Benefits:This enables the creation of custom tabletops, reception desks, and other complex designs automatically from a digital file.

- Next Step:Prepare a DXF file of a curved design and ask the supplier how to program and execute the cut on the machine's HMI.

Do I need a special foundation for installing this countertop fabrication machine?

- Context:The entire machine is a self-contained unit and can be installed on any solid, level concrete floor that supports its weight.

- Benefits:This saves significant time and money by avoiding the costly construction of permanent concrete walls, and allows for future relocation.

- Next Step:Verify your workshop's concrete floor thickness and levelness against the machine's installation requirements found in the technical manual.

What advanced cutting options are available?

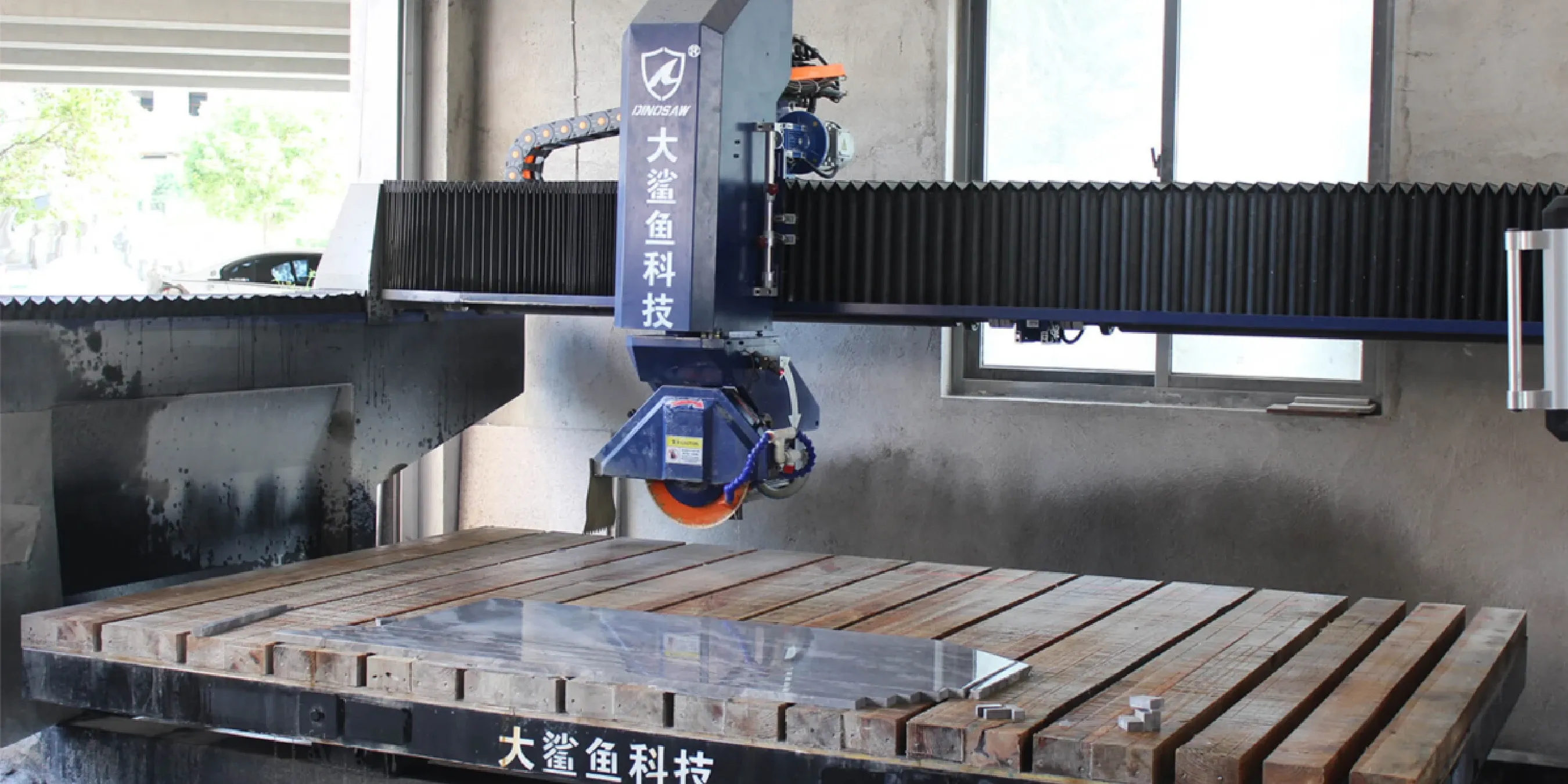

- Context:A basic machine moves in 3 axes (X, Y, Z). Advanced configurations add an A-axis for tilting the blade (miter cuts) and a C-axis for rotating the worktable.

- Benefits:This enables complex operations like 45-degree miter cutting for waterfall edges and shaping curved pieces without needing to manually move the slab.

- Next Step:Review your typical job requirements to determine if miter cuts and complex shapes are a significant part of your business, justifying the investment in these options.

Can I use this bridge saw for Dekton or Neolith cutting?

- Context:Success requires a rigid frame to prevent vibration, a powerful motor with variable speed, and a high-volume water cooling system.

- Benefits:The machine's stable structure and precise control minimize the risk of chipping or cracking these hard, brittle materials.

- Next Step:Ensure you use a diamond blade specifically designed for sintered stone and consult the manufacturer's recommended cutting parameters (speed and RPM).

How much does a monoblock bridge saw price?

- Context:A new monoblock saw from a reputable manufacturer is a mid-range investment, balancing capability and cost.

- Benefits:It offers a faster ROI due to lower installation costs compared to gantry systems, which require expensive foundations.

- Next Step:Contact the sales team directly to get a specific quote for the YTQJ-600 based on your configuration needs.

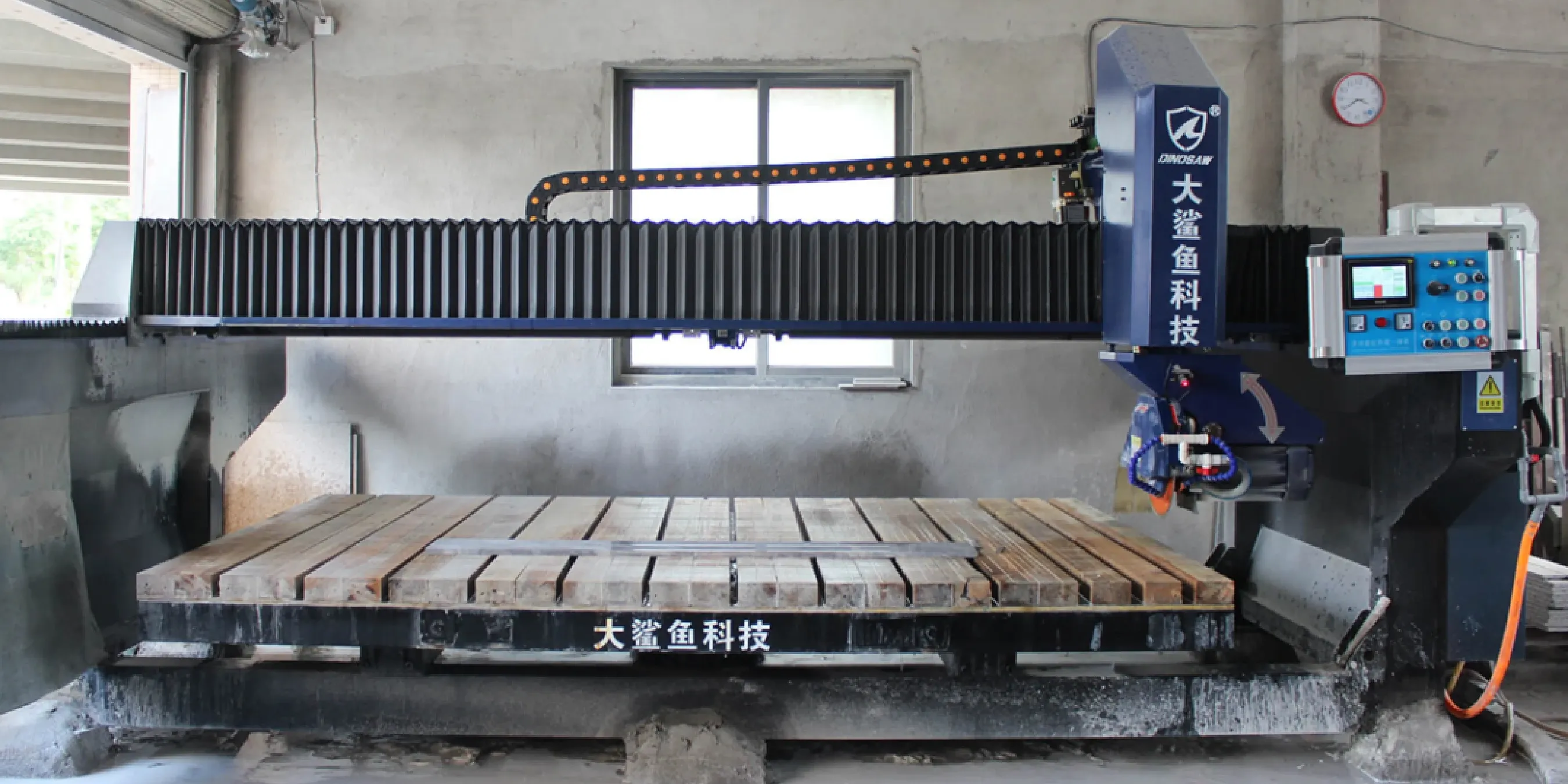

What are the space requirements for a monoblock bridge saw for sale?

- Context:You must account for clearance around the machine for loading/unloading slabs, operator access, and maintenance.

- Benefits:Planning for adequate space ensures a safe and efficient workflow, preventing accidents and making maintenance tasks easier to perform.

- Next Step:Plan for a safe operational area of around 8m x 6m and consult the machine's technical specification sheet for exact dimensions and required clearances.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский