Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

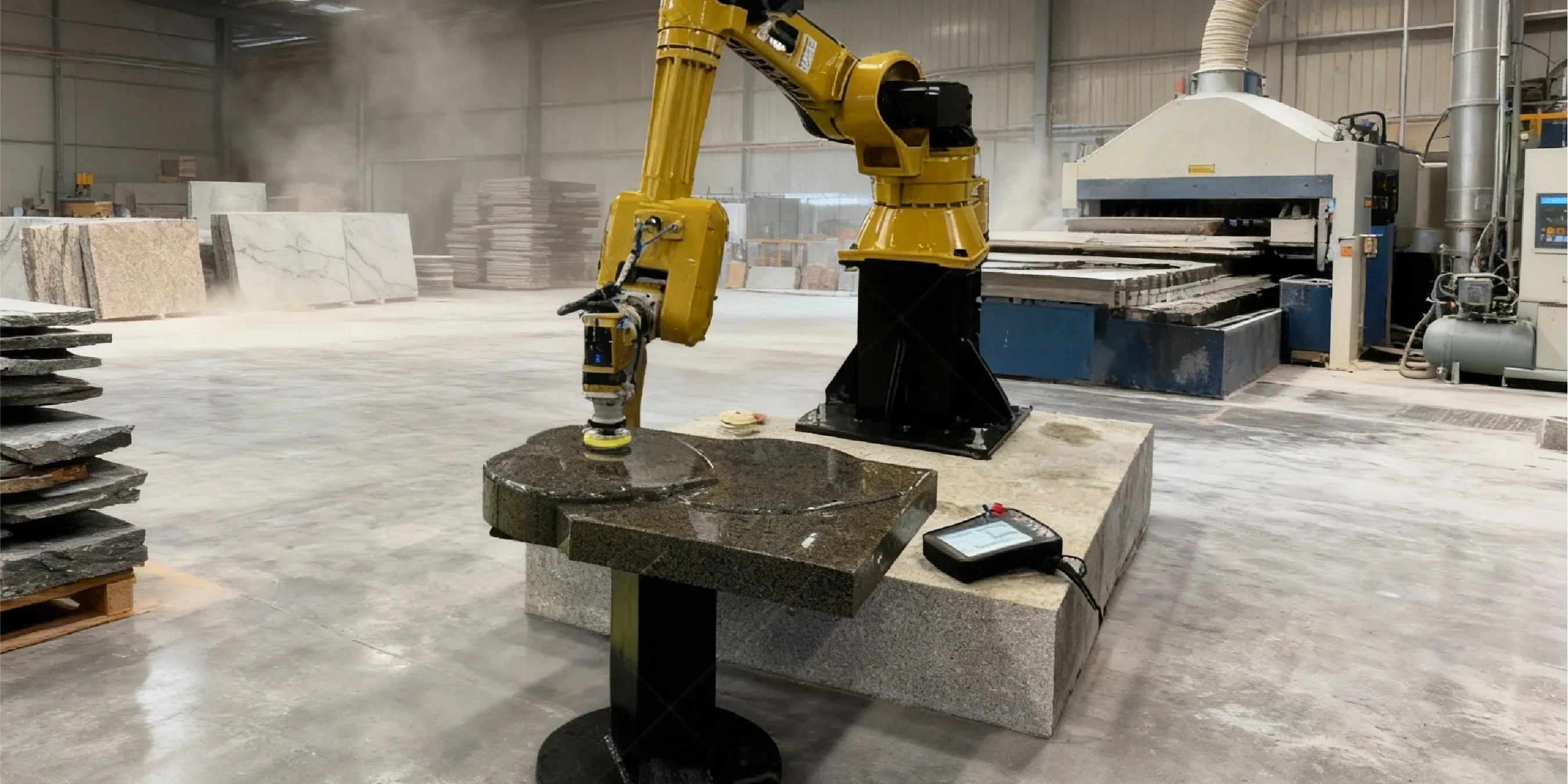

Polishing machine vs robot: which to choose? Our guide compares the robotic arm vs. CNC for stone polishing on flexibility, ROI, and TCO for your workshop automation.

TL;DR: How to Choose Your Polishing Machine

- For Complex 3D Shapes: A robot arm for stone polishing is unbeatable. It's designed for curved surfaces, sink bowls, statues, and intricate edge profiles.

- For Flat Slabs Only: A dedicated automatic polishing line or bridge polisher is far more efficient and cost-effective. A robot has no advantage here.

- The Deciding Factor is Flexibility: The choice in the polishing machine vs robot debate comes down to your product mix. A robot offers versatility for mixed production; a CNC offers speed for standardized production.

- Investment & Infrastructure: Both are serious investments. A robot requires significant upfront capital, a reinforced foundation, three-phase power, and a dedicated, safety-fenced work cell in a factory setting.

A 30-Second Guide to Choosing Your Polisher

A 30-Second Guide to Choosing Your Polisher

- If you primarily produce flat slabs (e.g., floor tiles, wall panels) → Your best choice is an automated line polisher for maximum throughput.

- If you fabricate countertops with sink cut-outs and complex edges → A stone edge polishing robot is superior for its ability to handle both flat surfaces and 3D contours in one setup.

- If you create 3D artistic pieces (statues, monuments, custom furniture) → A 6-axis stone polishing robot is essential. No other machine offers the required dexterity.

- If your factory space is limited → A single-head polisher or manual grinder has the smallest footprint, but at a high cost to labor and consistency.

- If your power supply is not three-phase industrial → You cannot operate a robotic grinding and polishing system or a large CNC line. This infrastructure must be in place first.

- If your budget is the primary constraint → Manual polishing has the lowest initial cost but the highest long-term labor cost and quality risk. An entry-level CNC is the next step up.

Head-to-Head: Robotic Arm vs. Alternative Polishers

Head-to-Head: Robotic Arm vs. Alternative Polishers

vs. CNC Bridge Polisher / Automated Line

vs. Single-Head Grinder

vs. Manual Polishing

Usage Thresholds & Programming Requirements

Usage Thresholds & Programming Requirements

Robotic Arm: Best for Repetitive Automation

CNC Polisher: Superior for High-Mix Production

Key Purchasing Factors Checklist

Key Purchasing Factors Checklist

- Total Cost of Ownership (TCO): Look beyond the initial robotic polishing machine price. Factor in installation, shipping, software licensing, training, energy consumption, and scheduled maintenance over 5 years.

- Spare Parts & Consumables: Does the supplier stock critical spare parts locally? What is the lead time? How proprietary are the polishing heads and pads? Availability is key to minimizing downtime.

- Maintenance Window & Support: What does the preventive maintenance schedule look like? Is remote diagnostic support included? Clarify the service level agreement (SLA) for on-site technician response times.

- Training Program: A comprehensive training program for both operators and maintenance staff is non-negotiable. It should cover programming, safety procedures, and basic troubleshooting.

- Warranty: Understand exactly what the warranty covers (parts, labor, travel) and for how long. Pay close attention to exclusions.

- Safety Certification & Compliance: Ensure the entire system (robot, controller, guarding) is certified to meet relevant safety standards, such as ISO 10218 and local electrical codes. The integrator is responsible for certifying the complete cell.

Scenario-Based Recommendations

Best For

A Viable Alternative For

Not Recommended For

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)

Is a robotic arm more expensive than a CNC polisher?

- Context: The upfront cost for a robotic system is often similar to a high-end 5-axis CNC. However, a robot's flexibility can eliminate the need for secondary machines or manual processes, potentially lowering the Total Cost of Ownership (TCO).

- Boundary: For pure flat-slab polishing, a dedicated Automated Polishing Line is cheaper and more efficient. The robot's value is in complex, high-mix production.

- Next Step: To make an informed decision, you must compare TCO, not just the purchase price. Contact us for a personalized cost-benefit analysis.

How much space does a robotic polishing cell need?

- Parameters: A typical cell requires a footprint of roughly 20x20 feet (6x6 meters), including the safety guarding. Vertical clearance is also critical and depends on the robot's reach.

- Boundary: This space must be a permanent, controlled-access area with a proper foundation. It cannot be placed in a temporary or high-traffic zone.

- Next Step: Provide our engineers with your factory layout, and they can design a cell that optimizes your floor space.

Can a robot arm be faster than a dedicated line polisher?

- Scenario 1 (Flat Slab): The line polisher is much faster.

- Scenario 2 (Finished Countertop): The robot is faster overall. It completes the flat surfaces, sink cutout, and complex edge profile in a single, automated handling. The slab on a line would require multiple machines and manual handling steps.

- Next Step: Analyze your product mix. The more handling steps a piece requires, the stronger the case for a robot.

What's the typical lead time for a robotic system?

- Parameters: A typical timeline is 4-6 months from purchase order to a fully operational system. This includes robot manufacturing, system integration and testing, shipping, on-site installation, and training.

- Risk: This timeline can be affected by global supply chain conditions. Confirm current lead times with your supplier before signing.

- Next Step: Begin the planning and consultation process early to align the delivery with your production schedule.

Do I need a robotics engineer to run this machine?

- Context: Modern polishing software is designed for machine operators, not robotics PhDs. A current CNC operator can typically learn to run the system with a few days of supplier-led training.

- Boundary (Programming): For high-mix production requiring new programs daily, you do need someone with programming aptitude on staff. For repetitive production, this is not a daily requirement.

- Next Step: Factor the cost of comprehensive training for at least two staff members (operator and maintenance) into your budget.

What is the best robotic arm for stone fabrication?

- Key Parameters:

- Payload: Must comfortably support the weight of the polishing head and tooling.

- Reach: Must be able to access all required surfaces of your largest workpiece.

- Context: Leading brands like FANUC, KUKA, or ABB are common, but the arm is just one component. The magic is in the integration—the software, force control head, and support provided by a specialist like DINOSAW.

- Next Step: Focus on the system integrator's expertise in stone polishing, not just the brand of the robot arm.

How does a robotic system improve stone polishing safety standards?

- Mechanism: The robot performs the wet, dusty, and repetitive work inside a locked, guarded cell. The operator works from a safe distance at the control panel.

- Compliance: This is a key engineering control for meeting modern health and safety regulations, such as the OSHA standard for respirable crystalline silica (1926.1153), and for reducing risks of repetitive strain injuries.

- Next Step: During purchase, ensure the integrator guarantees the cell will be certified to ISO 10218 standards.

Where can I learn more about different types of stone machines?

- Context: A polishing robot is just one piece of the puzzle. Knowing how it fits with CNC saws, waterjets, and edge polishers is key to building an efficient factory.

- Next Step: We've compiled a comprehensive guide that explains the 8 key types of machines every fabricator should know. You can read it here: CNC Stone Machines Explained.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский