Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An executive summary for business leaders on CNC wire saw machines. Understand the value, how to evaluate, and the path to implementation for your facility.

30-Second Overview

What it is:A CNC diamond wire saw is a specialized tool that uses a diamond-impregnated wire to make complex, precise cuts in hard, brittle materials.

What it does for you:It enables your shop to produce high-value custom parts with intricate geometries, minimizing material waste and reducing manual labor.

Where it fits:Ideal for large blocks, complex 3D shapes, and materials like granite or composites.Where it doesn't:Not efficient for high-volume straight cuts or most metal cutting.

How to proceed:Start by using our evaluation checklist to assess your needs and compare supplier specifications.

This guide cuts through the jargon to deliver practical information for business owners, engineers, and procurement managers who need to make informed decisions about this powerful technology. We will cover what this machine does, when to use it, how to evaluate your options, and the steps for successful implementation, ensuring you can confidently assess the impact of CNC diamond wire saw technology on your operations.

What This CNC diamond wire saw Machine Does in Simple Terms

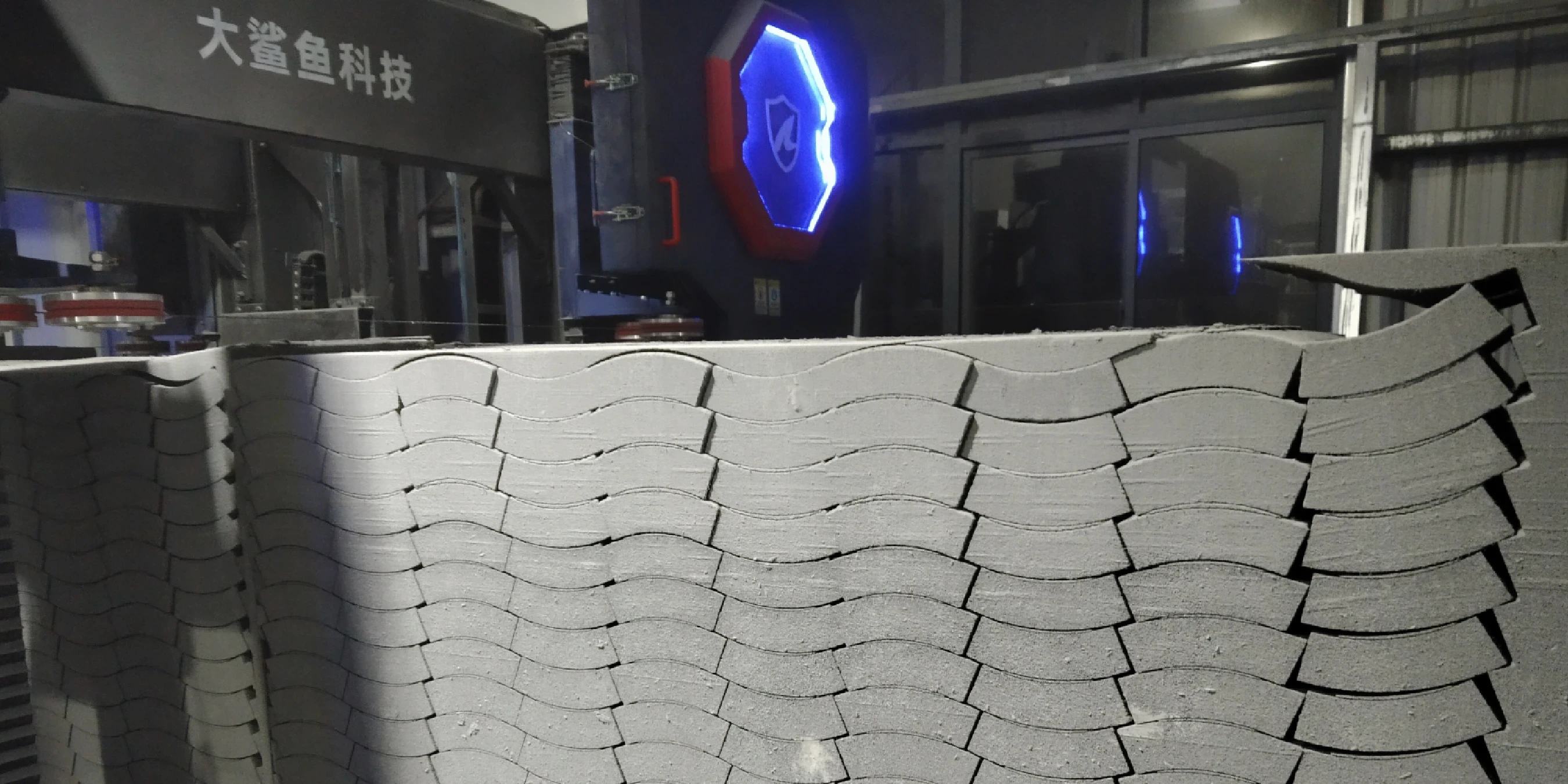

A CNC diamond cutting machine is a specialized tool that uses a continuous loop of diamond-impregnated wire to slice through hard, brittle, or large materials. Think of it as a highly precise, flexible "bandsaw" for stone, ceramics, or composites.

Instead of a rigid blade, the thin wire can follow complex paths programmed by a computer. This allows it to create curved, contoured, and intricate 3D shapes that are impossible for traditional saws.

The primary purpose of these wire sawing systems is to solve key challenges: cutting complex designs efficiently, minimizing material waste (thanks to the thin wire), and automating processes that would otherwise require intensive manual labor. This allows a workshop to produce high-value custom parts, not just standard slabs or blocks.

When to Use a CNC Wire Saw (and When Not To)

A CNC wire saw is a versatile tool, but it's not the right fit for every job. Here’s a quick guide to its ideal applications:

Use it for:

Complex 3D Shapes:Creating sculptures, custom architectural elements (like Roman columns), or artistic pieces.

Thick or Large Workpieces:Slicing large blocks of granite, marble, or other materials where blade saws are impractical.

Brittle or Abrasive Materials:Cutting foam ceramics, refractory bricks, quartz, or composites without causing fractures or delamination.

Minimizing Material Waste:When working with expensive materials, the thin kerf (cut width) of the wire saves significant material compared to thick blades.

Don't use it for:

High-Volume Cuts on Thin Slabs:A traditional bridge saw is much faster and more cost-effective for this task.

Most Metal Sheet Cutting:While specialized wires exist for some metal structure, blocks or pipes , a band saw or waterjet is generally the correct tool for cutting steel or aluminum sheet.

Evaluation Checklist for Procurement

When conducting a technical evaluation of a CNC wire saw, focus on these critical areas. This checklist will help you compare different suppliers and models effectively.

Frame Rigidity:A heavy, stress-relieved steel frame is non-negotiable. It absorbs vibrations and ensures long-term accuracy. Ask for the machine's total weight-heavier is often better.

Axis Configuration:Do you need three, four, or five axes? For complex 3D shapes, a 5-axis machine is essential. For 2D curves and simple profiles, a 3- or 4-axis machine may suffice.

Controller & Software:Is the CNC controller from a reputable brand? Does the software easily import standard file types like .dxf or .step? An intuitive interface reduces training time.

Tensioning System:This system keeps the wire taut. A reliable hydraulic or pneumatic system with automatic feedback control is crucial for preventing wire breakage and ensuring cut accuracy.

Guide Wheels:Inspect the quality of the guide wheels. They must be precisely aligned and made of durable materials to withstand constant abrasion. Poor quality wheels lead to frequent wire breaks.

Service & Support:What is the after-sales service plan? Confirm warranty terms, spare part availability, and the provider's technical support response time.

Procurement Q&A: Your Key Questions Answered

Beyond the sticker price, how should we model the Total Cost of Ownership ?

Total Cost of Ownership (TCO) provides a far more accurate financial picture than the initial purchase price alone. It’s critical to model all recurring operational costs to understand the machine’s true financial impact over its lifespan.

Your model should include key recurring expenses such as consumables (diamond wire, guide wheel linings), energy consumption, coolant, and waste slurry disposal costs. Also, be sure to budget for preventive maintenance parts, labor, and any necessary operator training.

These costs will vary based on machine usage and local utility rates. Contact DINOSAW for detailed modeling guidance.

What accuracy and throughput can we plan for with common materials?

For planning purposes, you can expect a typical cutting accuracy of ±1 mm from a well-calibrated machine. This precision is a key advantage for projects with tight tolerances.

As a baseline for throughput, you can plan for approximately 1.2–1.5 m²/h when cutting granite and 1.5–2 m²/h for marble under standard operating parameters.

Keep in mind that final results will always vary based on the specific material hardness, cutting geometry, and diamond wire specification. It is crucial to validate these figures with a test cut on your own material before final machine acceptance.

Do we need a 22 kW motor, or is the standard 15 kW enough?

A 15 kW motor is the standard for most models and is adequate for the majority of stone and composite cutting workloads. An upgrade to a 22 kW motor is generally recommended only if you consistently process very hard substrates or need to perform heavy, aggressive cuts.

The decision should not be made in isolation. You should pair your motor choice with the machine’s tensioning capacity and frame rigidity to avoid creating a bottleneck, which can lead to slow cycle times and excess wire stress.

Always confirm your power requirements with DINOSAW before finalizing the order to ensure the configuration matches your intended use case.

What training and change management steps reduce ramp‑up time?

Effective training and change management are crucial for minimizing downtime and accelerating your team's proficiency. Request a comprehensive package that includes on-site installation and hands-on operator training.

This training should cover software, machine setup, daily maintenance routines, and all safety protocols. Support this by providing your team with clear standard operating procedures (SOPs), a one-page startup checklist, and a named technical support contact with defined response targets.

Summary and Next Steps

Investing in a CNC diamond wire saw is a strategic decision that can unlock new capabilities and revenue streams. By following a structured evaluation process, focusing on key technical components, and planning for a phased implementation, you can ensure a successful outcome.

This technology empowers your workshop to tackle more complex, higher-margin work, moving your business up the value chain.

Ready to take the first step? Contact our team to begin your personalized needs assessment and discover how a CNC wire saw can transform your fabrication facility.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский