Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

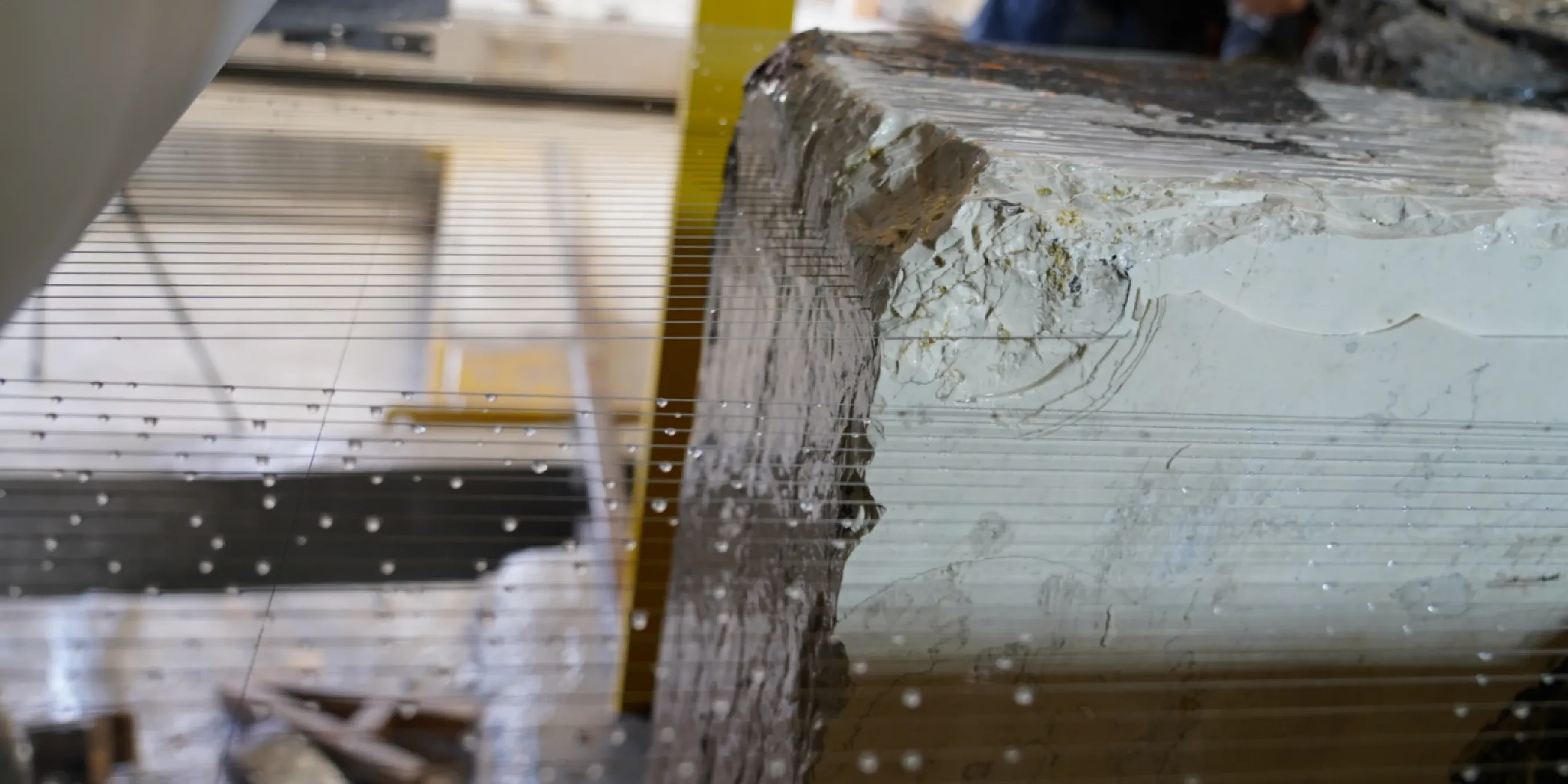

Discover how a CNC multi-wire saw enables precision cutting of marble, onyx, and granite slabs. Learn about material compatibility, 0.5mm kerf benefits, and processing boundaries.

TL;DR: What You Need to Know

- Can it cut thin slabs? Yes, this Multi-Wire Saw Machine excels at producing slabs as thin as 3mm from high-value materials like marble and onyx, maximizing your block's potential.

- How does it improve yield? With an ultra-thin 0.5mm kerf, it wastes significantly less material, increasing slab output by up to 30% compared to traditional gang saws.

- What's the next step? Define your material and thickness needs, then review the starting parameters in this guide to see how it fits your workflow.

Can This Multi-Wire Saw Machine Cut My Material? And How?

Can This Multi-Wire Saw Machine Cut My Material? And How?

What Can You Achieve with a Multi-Wire Saw?

Material & Processing Compatibility

Material & Processing Compatibility

- Premium Marbles: Includes varieties like Calacatta, Carrara, and Fendi White. Ideal for achieving consistent thinness without compromising the stone's delicate veining.

- Travertine & Onyx: Materials like Italian Silver Travertine and translucent Onyx can be cut into thin panels for backlit applications, thanks to the machine’s low-vibration system.

- Exotic & Luxury Stones: Successfully processes rare materials like Blue Bahia, Prada Green, and Bolivia Blue, where minimizing waste is paramount.

Parameter | Typical Range | Notes |

|---|---|---|

Typical Thickness | 3 mm – 12 mm | Harder materials like granite or dense onyx are best cut at ≥5mm. |

Surface Roughness | Ra ≈ 2.0 (manufacturer-reported) | Superior finish reduces subsequent polishing time and costs. |

Processing Boundaries: What to Cut and What to Avoid

Ideal For:

- High-value decorative stone blocks.

- Marble slabs with a target thickness of ≥3mm.

- Onyx and harder stones with a thickness of ≥5-6mm.

- Projects requiring consistent thickness tolerance of ±0.2mm.

Not Recommended For:

- Ultra-thin cutting of stone with large voids or pre-existing fractures.

- Oversized blocks that exceed the machine's processing dimensions and travel limits (refer to the product specification table).

- Materials that are extremely abrasive without specialized diamond wire.

How to Process: Key Starting Parameters

Wire Speed:Start with a moderate speed, allowing the CNC system to adapt. Perform a test cut on a small area first and adjust based on the material feedback.Feed Rate:Begin with a conservative rate within the 0-200 mm/h range, increasing incrementally based on the resulting surface quality and wire load.Diamond Wire Tension:Start in the mid-to-high range (e.g., 100–200 N for marble, moderately higher for harder stone) and let the closed-loop servo system auto-adjust for optimal, consistent tension (manufacturer-reported).

Scenario-Based Advantages vs. Traditional Methods

Feature | CNC Multi-Wire Saw | Traditional Gang Saw |

|---|---|---|

Material Utilization | 0.5mm kerf; 10-30% higher yield (manufacturer-reported) | 2-5mm kerf; significant material loss |

Surface Quality | Ra ≈ 2.0; minimal polishing needed (manufacturer-reported) | Ra ≈ 2.2; requires extensive secondary processing |

Noise Level | 60-80 dB; improved work environment (manufacturer-reported) | 110-130 dB; requires significant hearing protection |

Automation | Fully automated with adaptive cutting | Manual adjustments, labor-intensive |

Mini Case Studies: Real-World Results

Premium Jade

Italian Travertine

Luxury Onyx

Risks, Prerequisites, and Safety Compliance

- Dust & Water Management:Ensure the cooling and slurry removal systems are functioning correctly to manage silica dust, a known health hazard. Proper wastewater treatment is also essential for environmental compliance. According to occupational health guidelines, long-term exposure to silica dust can cause serious respiratory diseases.

- Noise Exposure: Although quieter than gang saws, the machine still operates at levels that require hearing protection (PPE). Adhere to local occupational noise exposure limits.

- Electrical & Mechanical Safety: Conduct daily checks of electrical cabinets, emergency stops, and safety guards. Ensure all moving parts are properly shielded before operation.

Summary: Is a Multi-Wire Saw Right for You?

Frequently Asked Questions (FAQ)

How thin can marble slabs be cut?

- Context:The CNC multi-wire saw can reliably cut marble down to 3mm, which is perfect for lightweight applications like wall cladding or furniture where weight reduction is a key design factor.

- Boundary:For harder or more fragile materials like dense onyx or granite, a minimum thickness of 5-6mm is recommended to ensure the slab maintains its structural integrity and avoids micro-fractures during handling.

- Next Step:Before planning a project, review the Multi-Wire Saw specs and consult with our material experts to confirm the optimal thickness for your specific stone.

What is the typical yield gain versus a gang saw?

- Context:You can expect a slab yield increase of 10-30% (manufacturer-reported). This gain comes from the ultra-thin 0.5mm cutting kerf, which turns far less of your valuable block into dust compared to a gang saw’s 2-5mm kerf.

- Boundary:The exact gain depends on the block size, slab thickness, and material type. The highest gains are seen with high-value materials where every millimeter of stone saved translates directly to increased profit.

- Next Step:To quantify the potential ROI for your business, contact us for a comparative analysis based on your current production metrics and material costs.

Can I cut slabs of different thicknesses in a single run?

- Context:The machine uses Variable Spacing Technology, which allows operators to program custom distances between each diamond wire. This means you can cut a mix of 5mm, 10mm, and 20mm slabs from the same block in one cycle.

- Boundary:While powerful, this capability should be used with care. Large differences in thickness between adjacent slabs can increase the risk of wire jumping or vibration. It is best suited for gradual variations in thickness.

- Next Step:For any mixed-thickness cutting jobs, we strongly recommend consulting our technical team for setup guidance to ensure a smooth, risk-free operation.

What are the recommended starting parameters for onyx?

- Context:We recommend a conservative start: a moderate wire speed and a slow feed rate (e.g., in the lower half of the 0-200 mm/h range). The diamond wire tension should start in the mid-to-high range and allow the machine’s adaptive system to take over.

- Boundary:These are starting points only. The machine’s real-time feedback sensors will analyze the stone's response and automatically optimize the parameters for the best balance of speed and quality.

- Next Step:Always perform a small test cut on a corner of the block to allow the CNC to calibrate its adaptive settings before commencing the full cut.

Is noise exposure lower with a multi-wire saw?

- Context:The multi-wire saw operates at 60-80 dB, which is comparable to a busy office. In stark contrast, traditional gang saws can generate 110-130 dB, a level that poses a serious risk to hearing.

- Boundary:While much quieter, the 60-80 dB level still requires hearing protection (PPE) for operators during prolonged exposure, in line with occupational health and safety standards.

- Next Step:Incorporate the reduced noise levels into your company's health and safety assessments, as it's a key benefit for both compliance and employee well-being.

How can I avoid wire breakage when cutting travertine?

- Context:The machine’s precision tension control is the best defense. It automatically senses changes in resistance as the wires pass through voids or dense sections and adjusts the tension in real-time to maintain a consistent force.

- Boundary:This automated system works best when paired with correct setup. Ensure the block is securely fixtured to prevent any movement, and start with a slightly reduced feed rate to give the system more time to react to material changes.

- Next Step:If you frequently process stone with high variability, consult our support team about specialized diamond wires designed for such conditions.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский