Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

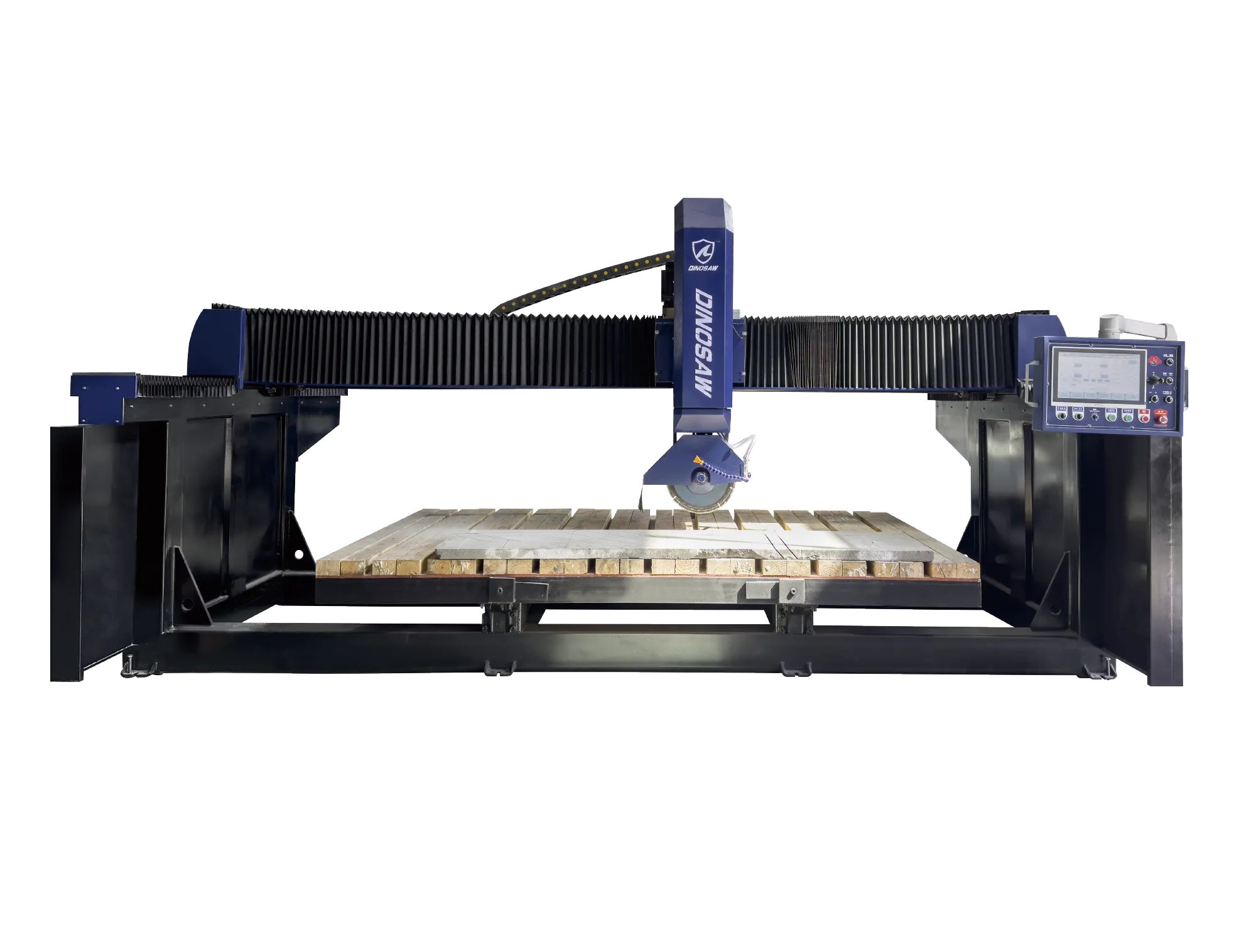

Making the right choice between a monoblock bridge saw and a gantry saw. Understand the key decision drivers like footprint, installation, precision, and the bridge saw price to select the ideal stone fabrication equipment.

TL;DR: Key Takeaways

- Choose a monoblock bridge saw for its compact footprint, foundation-free installation, and high precision, making it ideal for small to mid-sized shops with flexible layout needs.

- Opt for a traditional gantry saw only for large-scale industrial facilities where cutting oversized quarry blocks is the primary task and a permanent concrete foundation is feasible.

- Your key decision drivers are production volume, available floor space, need for advanced capabilities (like miter cutting), and total budget including installation.

Choosing the Right Bridge Saw for Your Fabrication Shop

If-Then Quick-Select Guide (Your 30-Second Decision)

- If your shop has limited floor space and you need to be operational quickly, then a monoblock saw is your best fit due to its compact footprint and foundation-free installation.

- If you operate a large-scale industrial facility and your primary job is cutting oversized or very thick quarry blocks, then a gantry saw's wider span and heavier build may be necessary.

- If you need high-precision capabilities for mitered edges and complex shapes but want to avoid major construction, then the YTQJ-600 monoblock is the ideal solution.

- If your workflow is primarily focused on standard countertop slabs and architectural panels, then a monoblock's 3200x2000mm worktable is perfectly sized and more cost-effective.

Monoblock vs. Gantry Saw: A Neutral Comparison

Factor | Monoblock Bridge Saw | Gantry Saw |

|---|---|---|

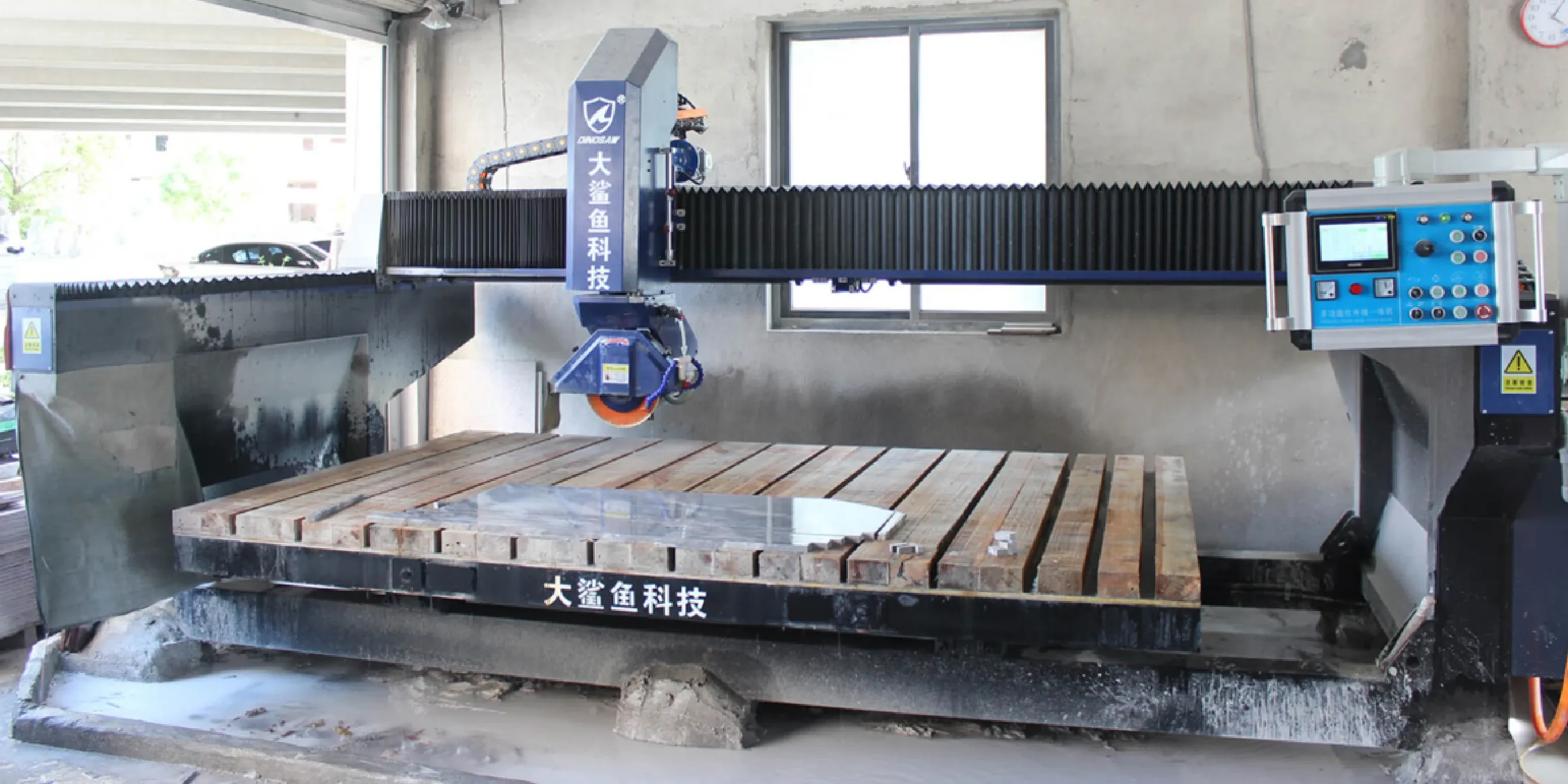

Footprint & Foundation | Compact, self-contained. No special foundation needed; can be placed on a solid, level concrete floor. | Large footprint. Requires costly and permanent reinforced concrete foundation walls to be built. |

Installation & Relocation | Fast installation (typically 1-3 days). Can be relocated in the future if the workshop layout changes. | Slow installation (weeks). Permanent and cannot be easily relocated. |

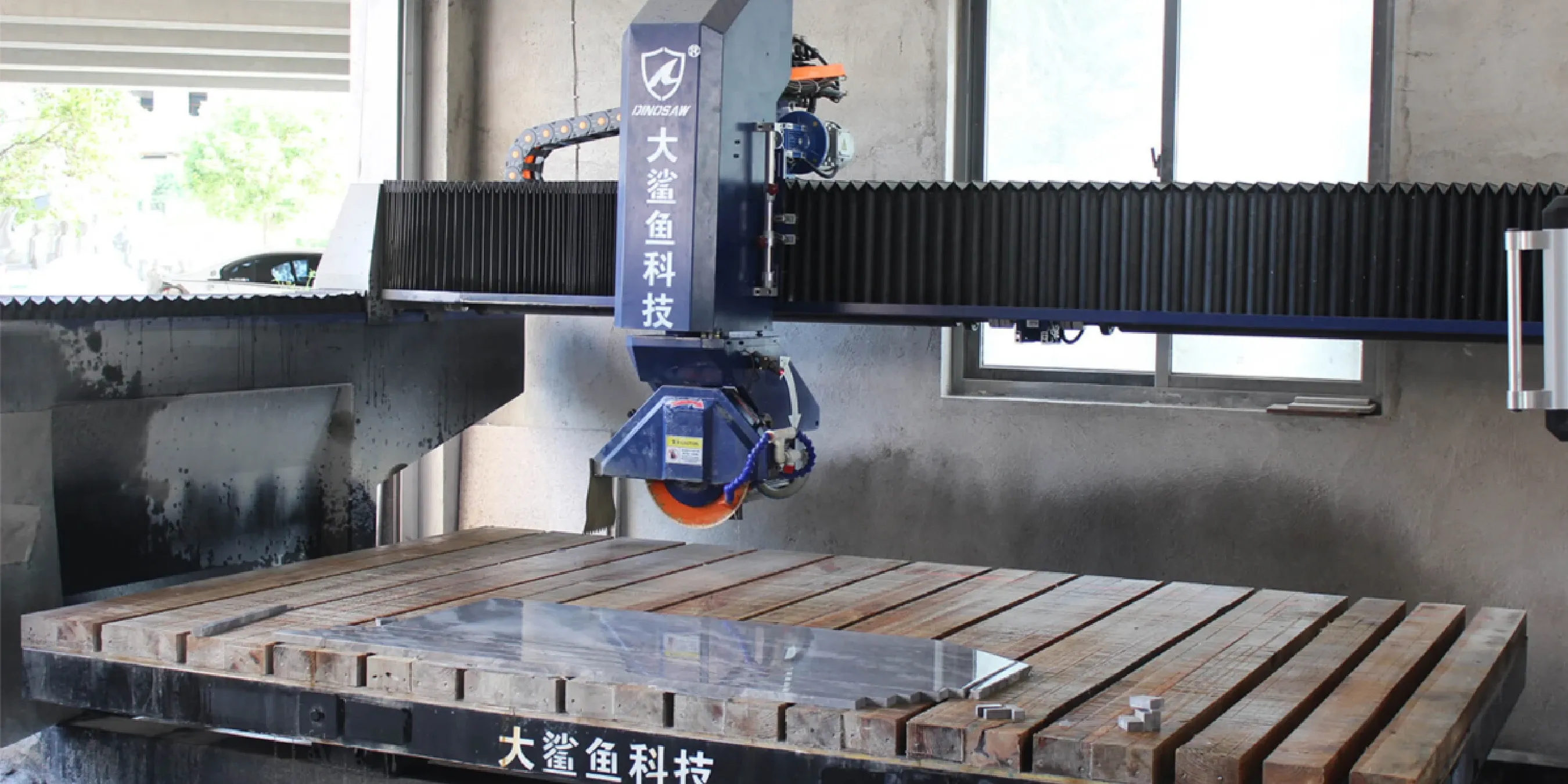

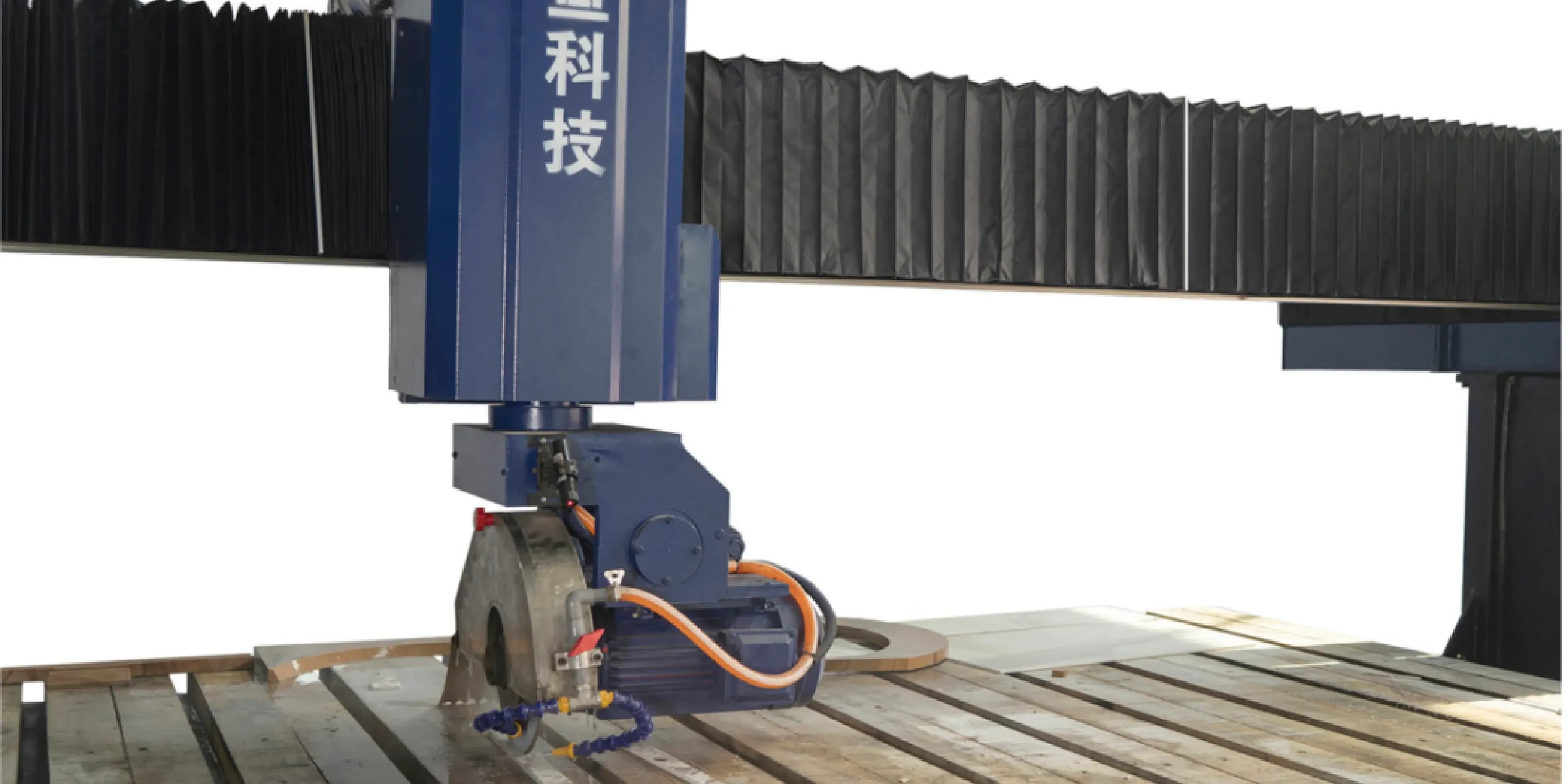

Precision & Rigidity | Excellent rigidity from the integrated steel frame minimizes vibration, enabling high-precision cuts (±0.5mm). | Extremely rigid due to massive concrete foundations, but precision depends heavily on the quality of initial setup. |

Cost (Total Investment) | Lower total cost of ownership. The initial bridge saw price is competitive, and foundation costs are eliminated. | Higher total cost of ownership due to the high price of the machine plus significant foundation construction expenses. |

Ideal Use Case | Small to mid-sized fabrication shops handling standard slabs for countertops, vanities, and architectural work. | Large-scale industrial facilities processing oversized quarry blocks or requiring extremely wide cutting spans. |

Why Does the Monoblock Design Dominate Modern Workshops?

Frequently Asked Questions (FAQ) on Choosing a Saw

What is the main difference between a monoblock vs. gantry bridge saw?

- Context: A monoblock saw has its bridge and supports integrated into a single frame, allowing it to be placed on a level floor.

- Benefits: This leads to drastically lower installation costs and time, and provides the flexibility to move the machine later.

- Next Step: Evaluate your long-term workshop layout plans. If flexibility is a priority, the monoblock is the superior choice.

Is a gantry saw more accurate than a monoblock bridge saw?

- Context: Precision comes from the rigidity of the frame and the quality of the motion control system (servo motors, encoders, linear guides).

- Benefits: A well-engineered monoblock saw like the YTQJ-600 provides a rigid, vibration-dampening structure that ensures high precision (±0.5mm) without needing massive foundations.

- Next Step: When comparing machines, focus on the specifications of the motion system and frame construction, not just the architectural type.

How often does a bridge saw require alignment or encoder calibration?

- Context: Vibrations and normal wear can cause minor shifts in alignment over time. The CNC controller has built-in routines to recalibrate encoder positions.

- Benefits: Regular calibration ensures the machine maintains its cutting accuracy, preventing costly mistakes and wasted material.

- Next Step: Train operators on how to perform the monthly calibration check and schedule an annual service with a technician in advance.

What is the typical bridge saw price difference?

- Context: Foundation work for a gantry saw can add tens of thousands of dollars and weeks of construction to a project.

- Benefits: A monoblock saw eliminates this cost, making it a more accessible investment with a faster return on investment (ROI).

- Next Step: Request a total cost of ownership (TCO) analysis, including machine price, shipping, installation, and foundation work, to make a true comparison.

Who should buy a gantry stone saw?

- Context: This includes quarries or large distributors that need to cut oversized quarry blocks or require exceptionally wide cutting spans that exceed a monoblock's capacity.

- Benefits: For these niche applications, a gantry saw provides the necessary scale and heavy-duty capability.

- Next Step: If your business is focused on standard slab fabrication, a gantry saw is likely an unnecessary and overly expensive investment.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский