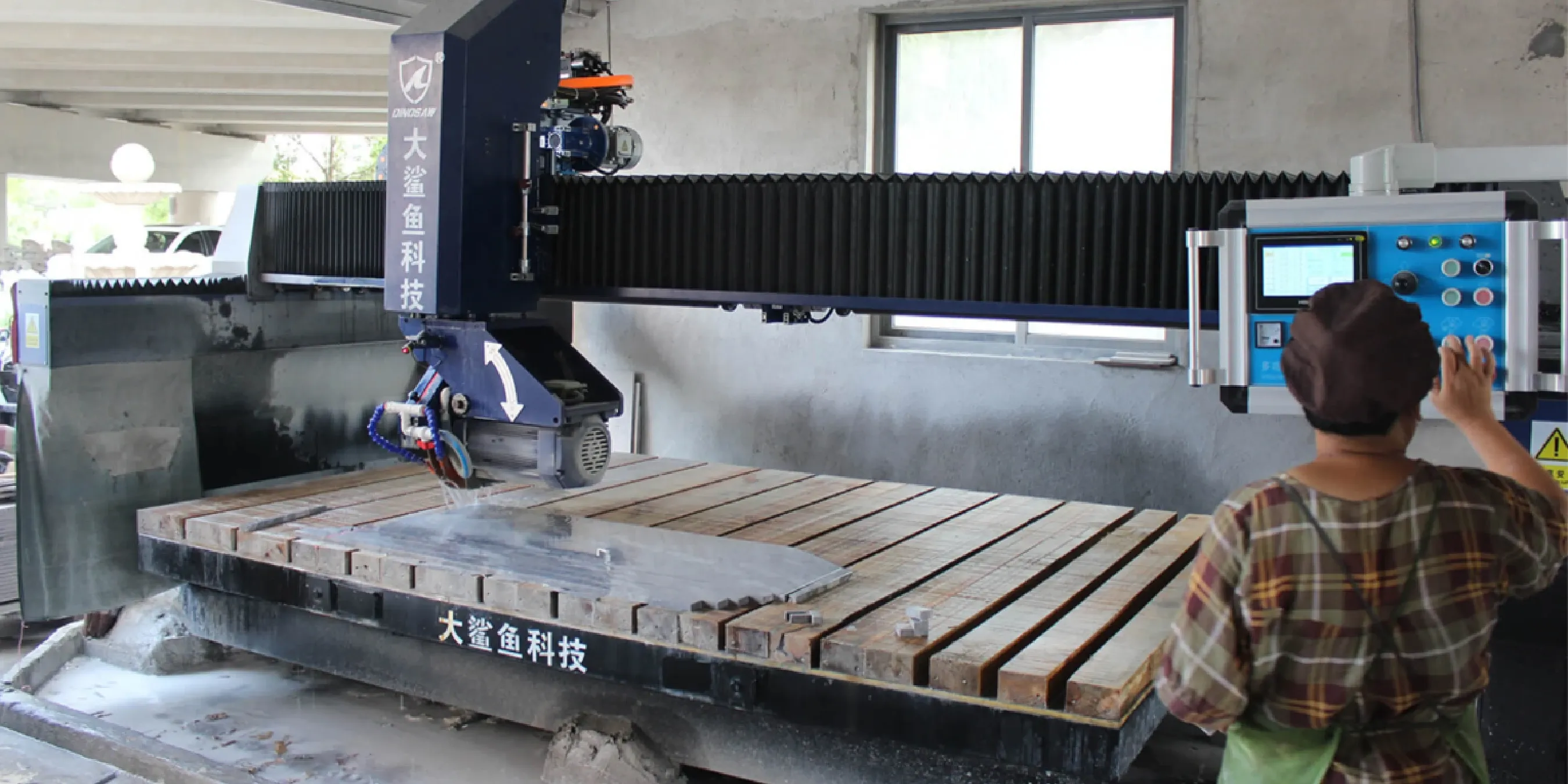

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Master your CNC stone cutting machine with this guide to bridge saw maintenance. Covers the daily SOP checklist, stone saw troubleshooting, preventive maintenance plan, and OSHA silica compliance, including lockout tagout (LOTO) procedures.

TL;DR: A Guide for Operators

- Daily Habits Matter: A 15-minute daily SOP checklist (cleaning, visual checks) prevents 80% of common issues and ensures cutting accuracy.

- Safety Is Non-Negotiable: Always use wet cutting to comply with OSHA silica dust regulations. Master lockout/tagout (LOTO) procedures before any maintenance.

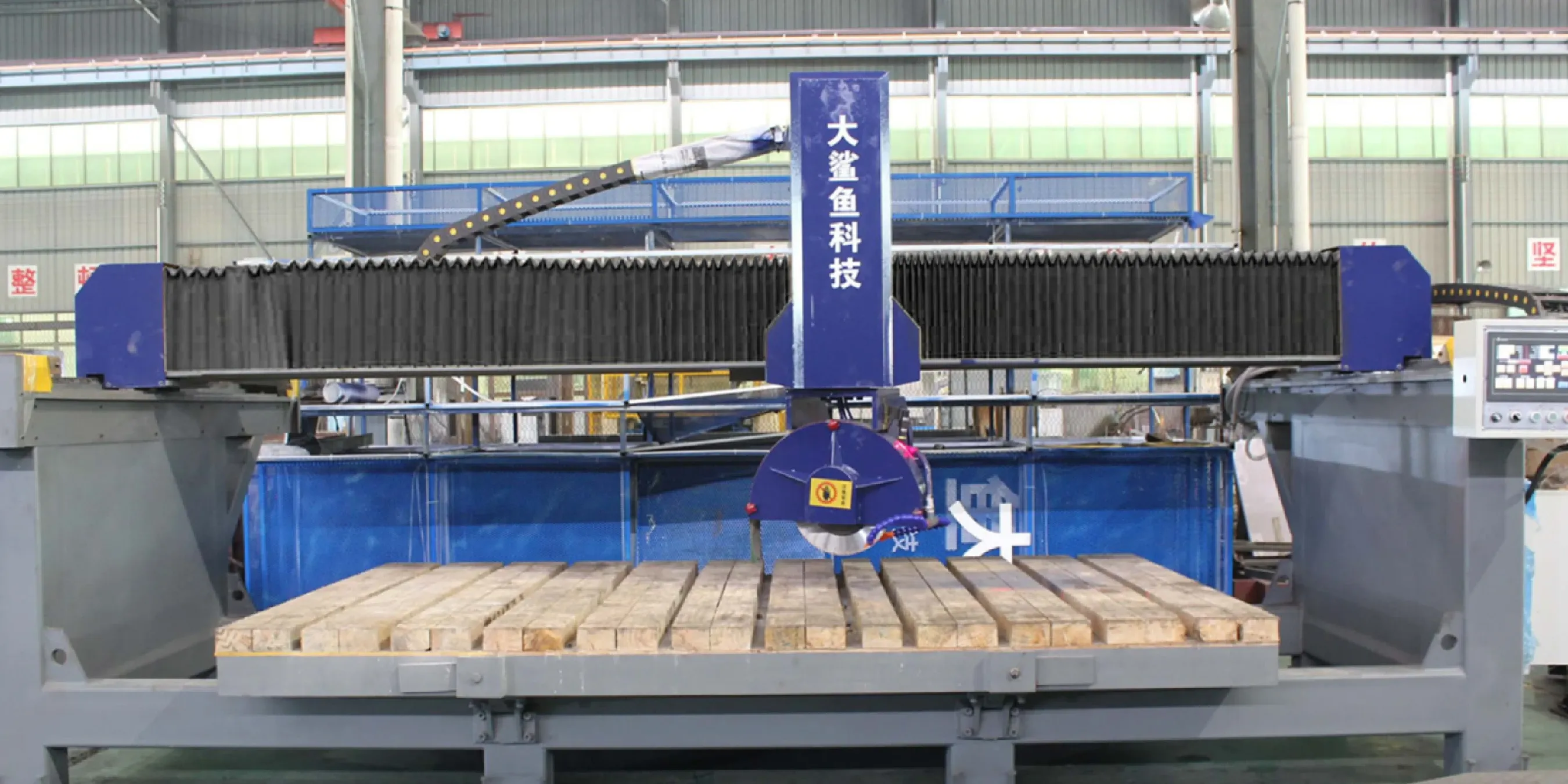

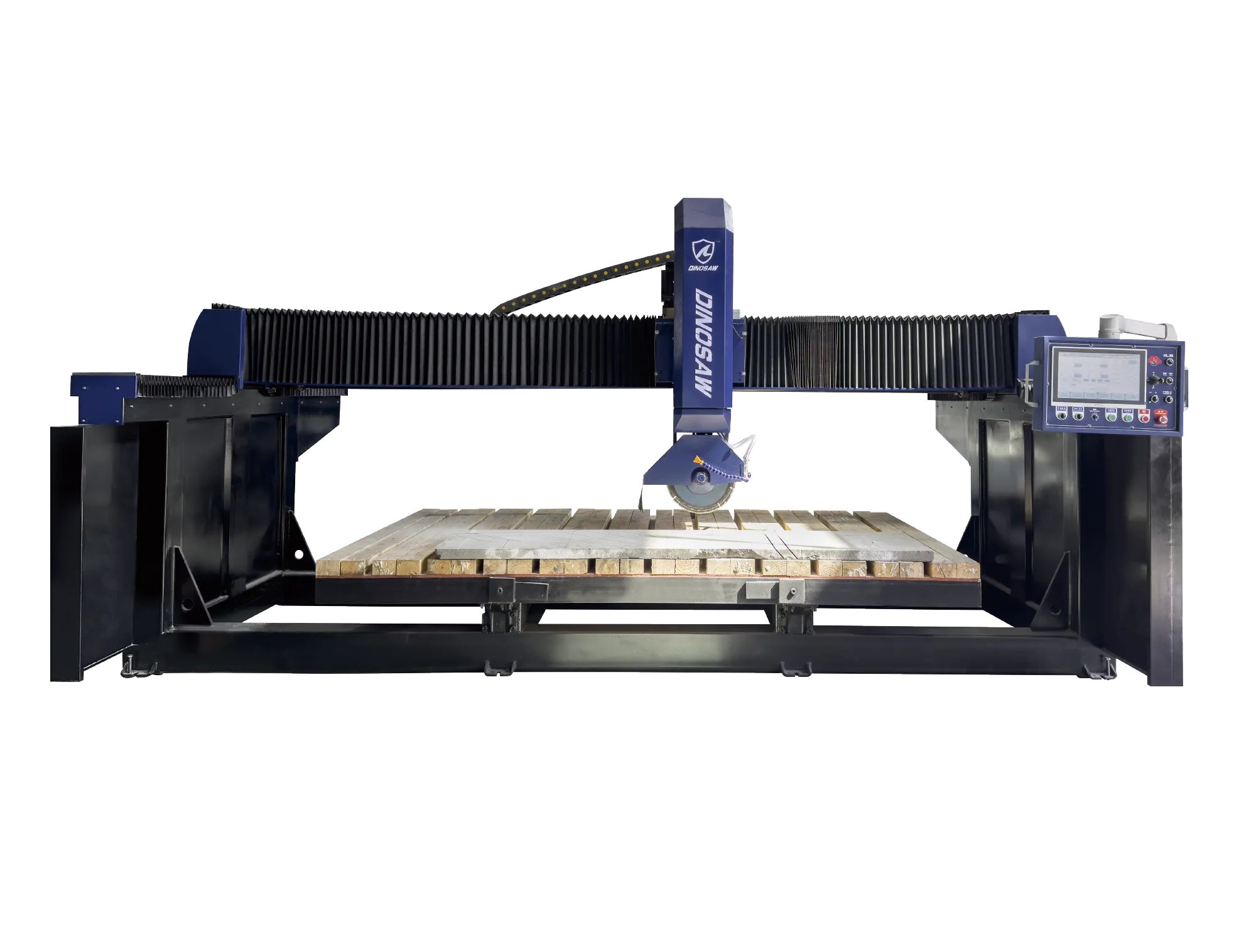

- Prevent, Don’t Just Repair: monoblock bridge saw Follow a simple weekly/monthly preventive maintenance plan focusing on lubrication and calibration checks to maximize machine life.

Daily Bridge Saw SOP Checklist

- Clean the Machine: Remove slurry and stone debris from the worktable, blade housing, and guide rails. Buildup can interfere with sensor accuracy and cause mechanical wear.

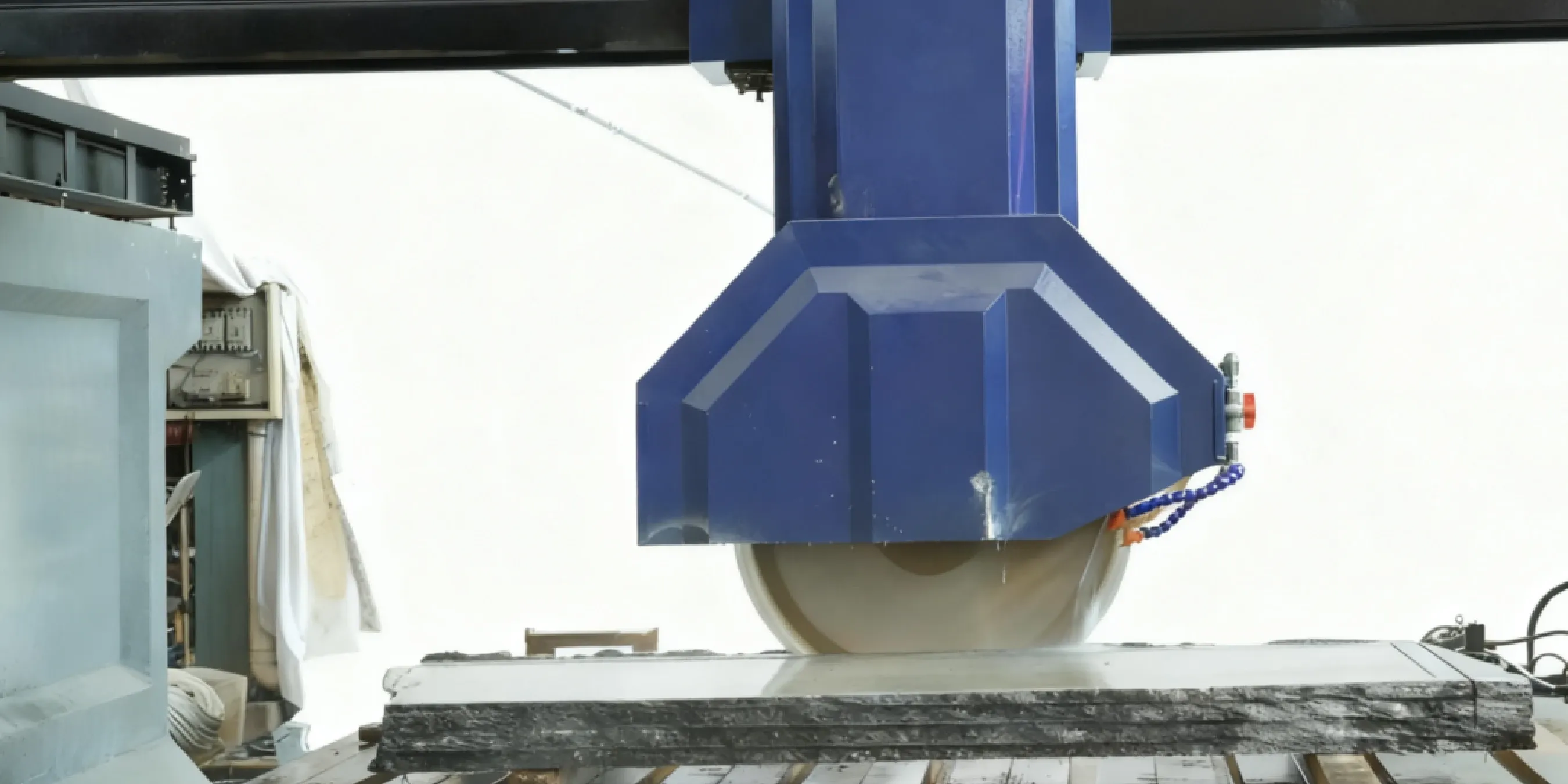

- Check Water Flow: Ensure the water nozzles are clear and providing ample coolant directly to both sides of the diamond blade. This is critical for blade life and OSHA compliance.

- Visual Inspection: Check for loose bolts, damaged cables, or leaks in the hydraulic/pneumatic lines. Early detection prevents major failures.

- Inspect the Diamond Blade: Look for signs of glazing, excessive wear, or missing segments. A damaged blade compromises cut quality and safety.

How to Troubleshoot Common Monoblock Bridge Saw Problems

Problem | Likely Cause | Solution |

|---|---|---|

Inaccurate Cuts | Debris on rails; machine out of calibration. | Clean rails; run calibration routine. |

Chipping on Material | Worn or incorrect blade; cutting too fast. | Replace blade; reduce cutting speed. |

Machine Stops Mid-Cut | Overload; sensor issue; emergency stop triggered. | Check for motor overload alarm; clean sensors. |

Blade Not Tilting | Hydraulic/pneumatic issue; limit switch fault. | Check pressure; inspect limit switches and wiring. |

Preventive Maintenance Plan for Your CNC Stone Cutter

- Weekly: Lubricate all linear slide guides and moving parts as specified in the manual. Check and tighten any loose electrical connections in the main cabinet (with power off).

- Monthly: Run the machine’s full calibration sequence. Check the tension of drive belts and chains. Clean all air filters for the electrical cabinet.

- Annually: Schedule a professional service with a certified technician for a comprehensive inspection, software updates, and alignment checks.

Essential Safety & OSHA Silica Compliance (HEPA, Wet Cutting)

Frequently Asked Questions (FAQ) on Maintenance and Safety

How can I extend the life of a diamond blade?

- Context: Pushing a blade too fast or using it on the wrong material generates excessive heat, which damages the diamond segments.

- Benefits: Proper use not only extends blade life but also ensures a cleaner, chip-free cut and reduces load on the main motor.

- Next Step: Create a chart with recommended speeds and feeds for your common materials and post it near the machine's control panel.

What are the main requirements for OSHA silica compliance (wet cutting, HEPA dust control)?

- Context: The OSHA standard requires engineering controls like wet cutting to keep dust levels below the Permissible Exposure Limit (PEL).

- Benefits: This protects workers from incurable diseases like silicosis and ensures your workshop avoids heavy fines and legal action.

- Next Step: Document your use of wet cutting in your company's written exposure control plan and ensure all operators are trained on its importance.

What is a lockout/tagout (LOTO) procedure and when should I use it?

- Context: Before any maintenance, the machine must be de-energized from its main power source, and a lock and tag are placed on the disconnect switch.

- Benefits: This prevents accidental startup, which could cause severe injury or death to the person working on the machine.

- Next Step: Develop a specific LOTO procedure for your bridge saw, train all authorized personnel, and conduct regular audits to ensure compliance.

What are signs a bridge saw diamond blade needs replacement?

- Context: Over time, the diamond segments on the blade wear down or become "glazed" (smooth), losing their cutting ability.

- Benefits: Replacing a worn blade improves cut quality, increases production speed, and reduces strain on the machine's motor.

- Next Step: Keep a log of blade usage to anticipate replacement needs and stock at least one spare blade to avoid downtime.

What’s the best way to clean a CNC bridge saw worktable and rails?

- Context: A high-pressure water hose can quickly remove most debris, followed by wiping down the rails with a clean cloth.

- Benefits: Cleanliness ensures smooth movement of the bridge and cutting head, maintains precision, and prevents premature wear of mechanical parts.

- Next Step: Make daily cleaning a mandatory part of the end-of-shift SOP for the machine operator.

How often does a bridge saw require alignment or encoder calibration?

- Context: Vibrations and normal wear can cause minor shifts in alignment over time. The CNC controller has built-in routines to recalibrate encoder positions.

- Benefits: Regular calibration ensures the machine maintains its cutting accuracy, preventing costly mistakes and wasted material.

- Next Step: Train operators on how to perform the monthly calibration check and schedule an annual service with a technician in advance.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский