Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A decision-driven guide comparing wet vs. dry core bits for stone. Use our checklist to select the right bit based on material, thickness, and your drill setup to optimize TCO.

TL;DR: Your 30-Second Selection Guide

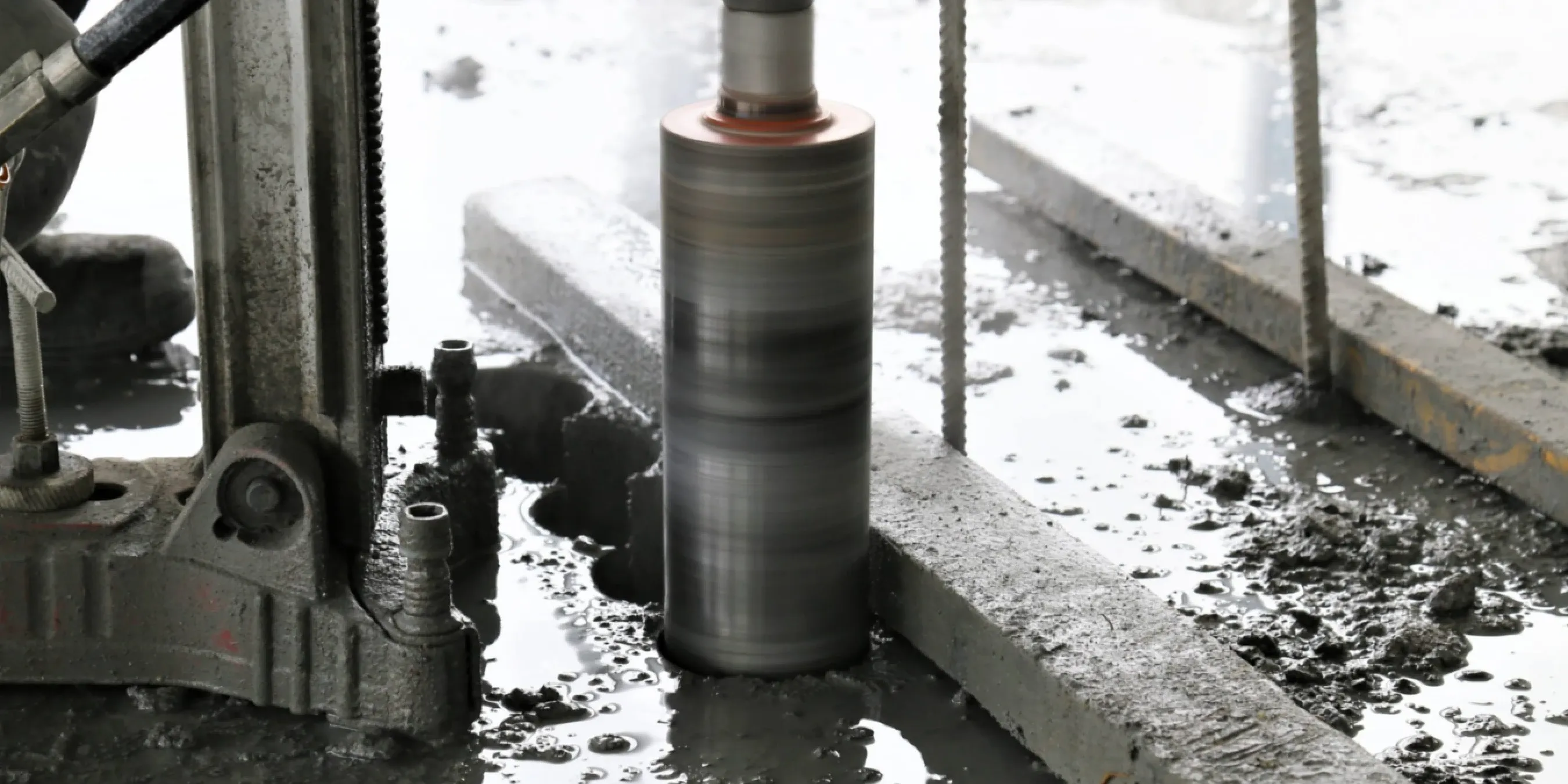

- Wet Bits for Production: For hard, thick stone like granite countertops or reinforced concrete, wet drilling is non-negotiable. It ensures tool longevity and a clean finish.

- Dry Bits for Convenience: For on-site, occasional jobs like drilling thin tile or shallow holes where water is impractical, a dedicated dry bit is the right tool.

- Match Bond to Material: Use a soft-bond bit for hard materials (granite) and a hard-bond bit for soft, abrasive materials (sandstone). This is the key to performance.

What Key Factors Drive Your Granite Core Drill Bit Purchase Decision?

- Material Hardness & Abrasiveness: Is it hard, dense granite or soft, abrasive sandstone? This determines the required bond hardness.

- Drilling Environment (Wet vs. Dry): Is water readily available? Is dust control a primary concern? This is the fundamental choice between wet and dry bits.

- Hole Diameter & Depth: Are you drilling small anchor holes or large passages for plumbing? This impacts the required drill rig and bit construction.

- Equipment Used: Are you using a high-power, stable rig-mounted drill or a handheld angle grinder? This affects the choice between standard and thin-wall bits.

Your If-Then Selection Tree for Wet vs. Dry Diamond Core Drill Bits

- IF drilling hard granite (>1 inch / 25mm thick) in a workshop, THEN use a wet bit with a soft bond. Start at a low RPM (manufacturer-reported 600-900 RPM for 2" bits) with steady pressure. Risk Note: Using a dry bit will cause rapid failure.

- IF drilling reinforced concrete (>4 inches / 100mm deep), THEN use a wet bit rated for rebar with a medium-hard bond on a securely anchored rig. Maintain high water flow. Risk Note: A standard stone bit may fail upon hitting rebar.

- IF drilling soft, abrasive sandstone on-site, THEN use a wet bit with a very hard bond to resist premature wear. Risk Note: A soft-bond bit will be destroyed very quickly by the abrasive material.

- IF drilling shallow holes in porcelain tile on-site with a handheld grinder, THEN use a dry bit with a wax-filled core for cooling. Start at an angle to prevent wandering. Risk Note: Do not apply excessive pressure; let the bit's speed do the work.

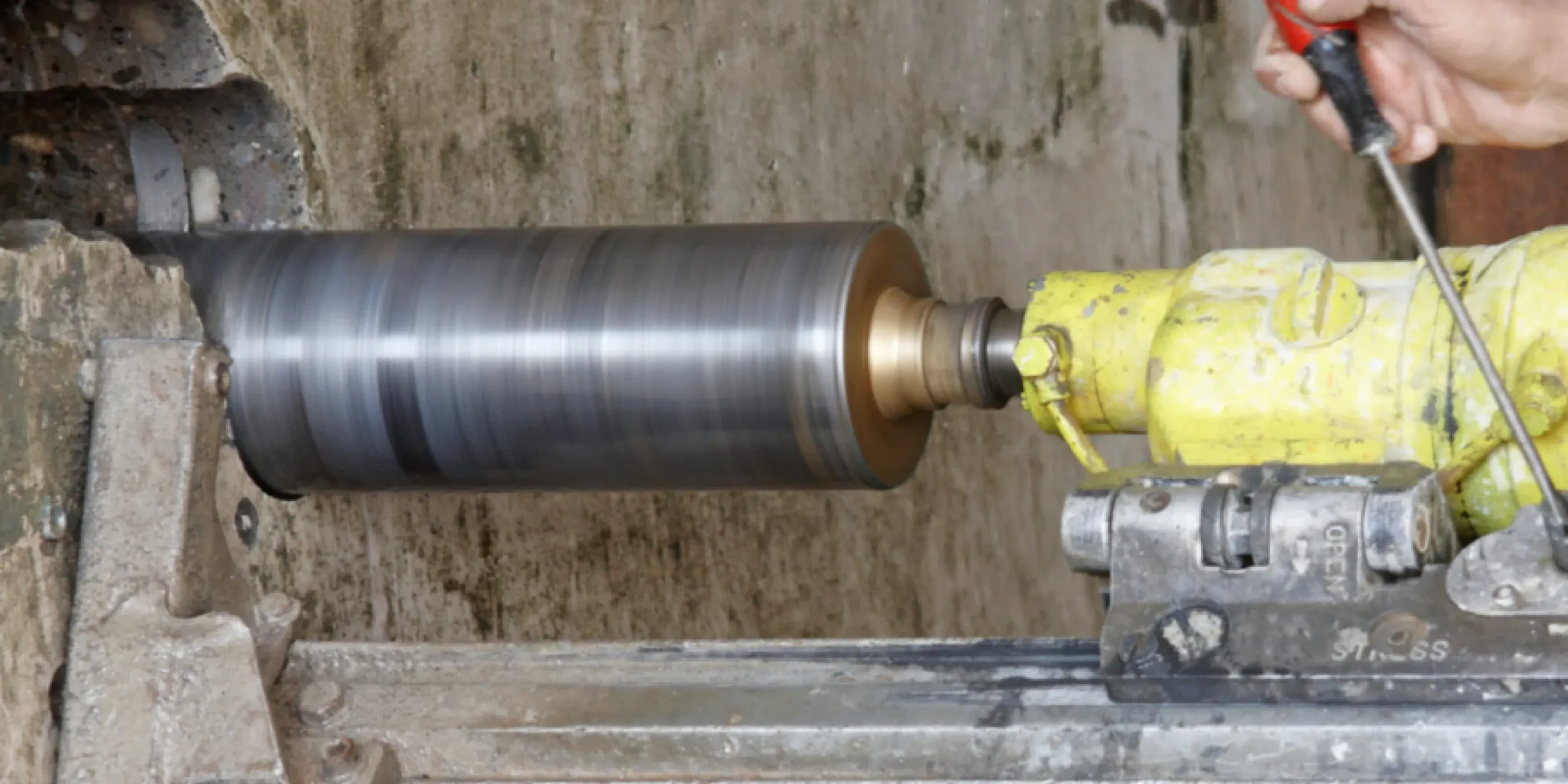

- IF performing high-volume, repetitive drilling on a CNC machine, THEN use a thin-wall wet bit to maximize speed. Ensure your Automatic Drilling Machines (Gantry & Vertical) provides robust cooling. Risk Note: Thin-wall bits are less forgiving of misalignment.

- IF drilling marble or other delicate stones, THEN use a wet bit with a medium bond and crown-style Diamond Segment for Core Drill Bit for a finer finish and reduced chipping. Risk Note: Excessive pressure can easily cause micro-fractures.

What Are the Key Decision Drivers?

Decision Driver | Wet Core Bit Advantage | Dry Core Bit Advantage |

|---|---|---|

Tool Lifespan & TCO | Significantly longer life due to constant cooling. Lowers the long-term cost-per-hole, making it the superior choice for production environments. | Shorter lifespan due to heat stress. Higher cost-per-hole but avoids setup time for water management, making it viable for quick, one-off jobs. |

Finish Quality | Superior. Water flushes debris, resulting in a cleaner, chip-free hole that rarely requires secondary finishing. | Acceptable for rough work. Can leave a slightly rougher edge and burn marks, especially if pressure is too high. |

Operator Safety (Dust) | Excellent. Turns hazardous silica dust into a manageable slurry. According to OSHA's silica standard, wet methods are a primary engineering control. | Requires strict controls. A high-efficiency vacuum dust collection system (VDCS) is mandatory to comply with safety regulations. |

Operational Speed | Faster cutting in hard, thick materials due to efficient cooling and debris removal. Overall project time may be longer due to water setup/cleanup. | Slower penetration rate. However, total time for a single hole can be faster due to zero setup for water. |

Your Procurement & Lifecycle Checklist for Stone Core Drilling Machine Adoption

- Total Cost of Ownership (TCO): Don't just look at the upfront price. Calculate cost-per-hole by factoring in the expected lifespan. A premium Industrial Granite Drill Bits: 3× Longer bit may have a higher initial cost but a lower TCO.

- Spare Parts & Retipping: Can the bits be retipped? Is there a reliable supply of replacement segments? This extends the life of the steel barrel, reducing long-term costs.

- Maintenance Window: Choose laser-welded segments for dry or high-heat applications, as they are far more resistant to heat-related failure than brazed segments.

- Training & Support: Does the supplier provide clear operational guidelines? Access to technical support can prevent costly errors.

- Warranty & Certifications: Check for manufacturing defect warranties. Ensure the supplier complies with quality standards like ISO 9001.

Frequently Asked Questions (FAQ)

For a countertop business, should I stock both wet and dry bits?

- Context: Most of your work (cutting sink/faucet holes in granite) will be done in the workshop where wet drilling is optimal. However, on-site adjustments or installations may require a dry bit for convenience.

- Guidance: Stock wet bits in your most-used diameters (e.g., 1-3/8" for faucets) for production. Keep a small set of versatile dry bits for your installation crews.

- Next Step: Review your job history to identify the 80/20 rule for diameters and purchase your primary stock of wet bits accordingly.

What does 'TCO' mean for a disposable tool like a core bit?

- Context: A cheap bit that drills 50 holes costs more in the long run than a premium bit that drills 300 holes. TCO includes the initial price, lifespan (number of holes), and associated labor/time costs.

- Guidance: A bit that cuts faster and lasts longer reduces operator downtime and increases throughput, directly impacting profitability. Factor in the cost of potential rework from a low-quality bit.

- Next Step: Ask for manufacturer-reported data on expected lifespan for your specific material to calculate a rough TCO before purchasing.

Is a 'thin wall' core bit better?

- Context: Thin-wall bits remove less material, reducing friction and allowing for faster penetration. This makes them ideal for high-speed CNC machines.

- Guidance: Their lower rigidity makes them less suitable for less stable handheld drilling, where a standard, thicker-walled bit is more robust and forgiving.

- Next Step: Choose thin-wall bits for stable, rig-mounted, or CNC operations where cycle time is critical. Stick with standard bits for general-purpose or handheld use.

Which bond hardness should I choose for sandstone vs granite?

- Context: Granite is hard but not very abrasive. Sandstone is soft but extremely abrasive. The bond must be chosen to counteract the material's properties.

- Guidance: Use a soft bond for hard granite, allowing the bond to wear away and expose new diamonds. Use a hard bond for soft, abrasive sandstone to resist being worn down too quickly.

- Next Step: Consult the supplier's bond hardness chart. When in doubt, describe your material to the supplier to get a precise recommendation.

Which diameters should I stock for faucet and sink holes?

- Context: Most plumbing fixtures have standard sizing, allowing fabricators to stock a limited, high-use inventory.

- Guidance: A typical faucet hole requires a 1-3/8" (≈35 mm) bit. Other common accessory holes for soap dispensers or sink clips may require 2" (≈50 mm) or 3" (≈76 mm) bits.

- Next Step: Audit your last 50 jobs to identify the most common diameters you drill. Standardize your inventory around these 2–3 core sizes to optimize stock levels.

How do I stay compliant with silica dust regulations?

- Context: Regulations like OSHA's Respirable Crystalline Silica standard (1926.1153) apply to stone drilling and mandate employers to limit worker exposure.

- Guidance: Prioritize wet drilling as it is a primary engineering control. If

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский