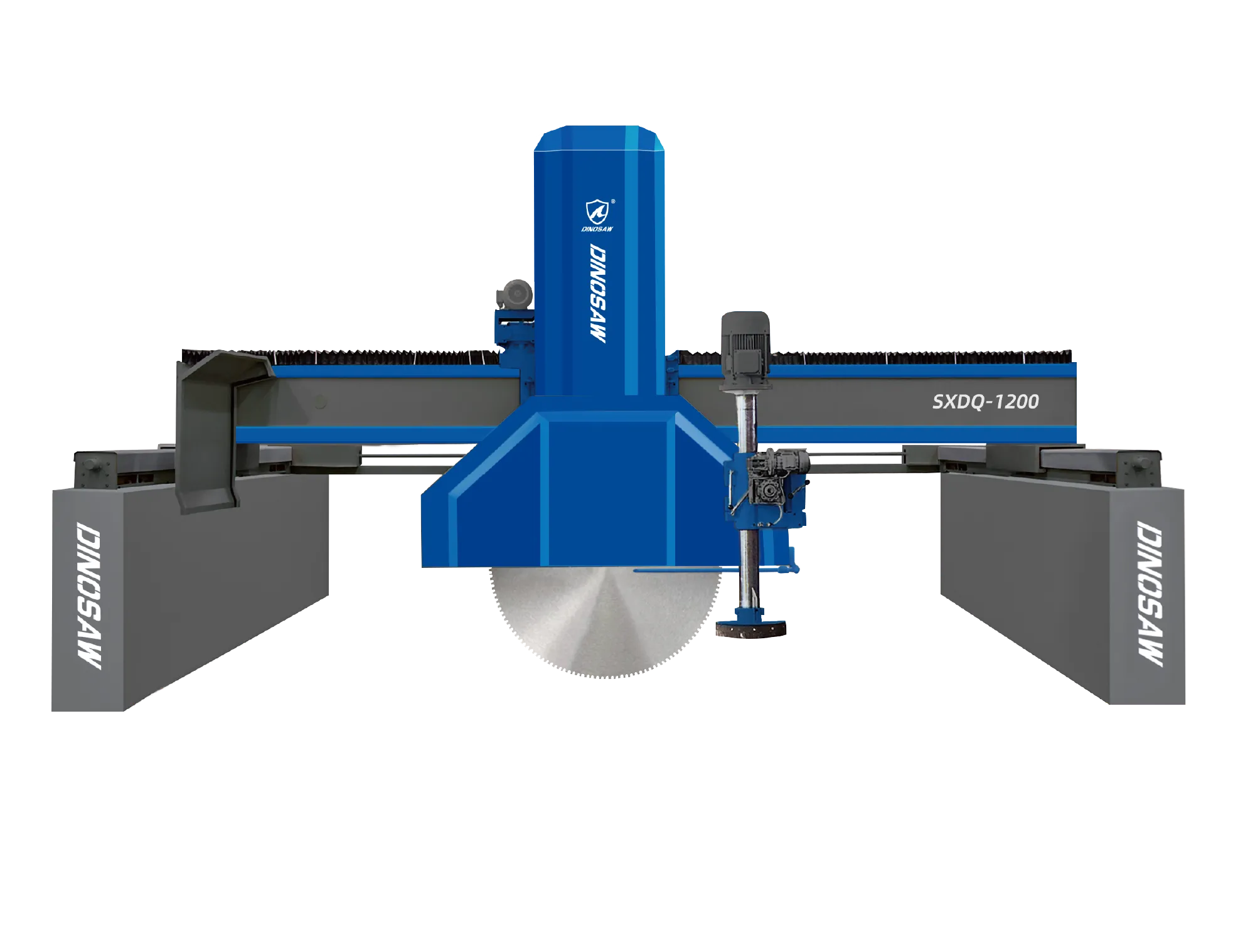

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Buyer's guide to choosing a block saw machine. Compare a dual-blade stone cutter vs. bridge saw and wire saw for granite, marble, and kerb stone applications.

TL;DR: The Decision Framework

- Choose For Stone Block Cutter with Machine :High-volume, repetitive cutting of rectangular slabs (e.g., kerb stones, standard panels, monument bases) where throughput and automation are the top priorities.

- Consider Alternatives If:Your primary need is complex, custom shapes (use a 5-axis bridge saw) or processing extremely large, irregular blocks (use a wire saw).

- Key Trade-off:You are trading the versatility of a CNC bridge saw for the specialized, high-speed efficiency of a dedicated block cutter.

Key Decision Factors for Your Purchase

Production Capacity

Material & Thickness

Tolerance

Automation Level

Footprint

Neutral Comparison: Stone Block Cutter vs. Other Machines

Machine Type | Best For | Pros | Cons |

|---|---|---|---|

Stone Block Cutter with Horizontal Blade | High-volume, repetitive cutting of rectangular slabs. | Highest throughput, fully automated, excellent safety, low labor per unit. | Not versatile; cannot do curves or angled cuts. Requires large footprint. |

CNC Bridge Saw | Custom jobs: countertops, sink cutouts, mitering, complex shapes. | Extremely versatile (5-axis), high precision, can do almost any cut. | Much slower for bulk slab production. Higher cost per cut for simple jobs. |

Diamond Wire Saw | Quarrying or processing very large, irregular, or extremely hard blocks. | Can cut blocks of almost any size. Low noise and vibration. | Slower cutting speed than blades. Wire requires frequent replacement. Less precise surface finish. |

Single-Blade Block Cutter | Lower volume slab production where automation is less critical. | Lower initial investment. Simpler mechanics. | Requires flipping the block to separate slabs, creating a bottleneck and safety risk. Lower throughput. |

If-Then Selection Tree: Making the Right Choice

- If you primarily produce high-volume, standardized rectangular products(e.g., kerb stones, monument bases) → Your best choice is a dual-blade stone block cutter for maximum throughput and automation.

- If you fabricate custom countertops with sink cut-outs and complex edges→ A 5-axis CNC bridge saw is superior for its versatility in handling both 2D and 3D contours.

- If you are processing extremely large, thick, or misshapen blocks from a quarry→ A diamond wire saw is more suitable for initial block trimming before it goes to a block cutter.

- If your factory space or power supply is limited→ A single-blade block cutter has a smaller footprint and lower power draw, but at a high cost to throughput and safety.

- If your budget is the primary constraintand your volume is low → A single-blade cutter has the lowest initial cost but the highest long-term labor cost and safety risk.

- If you need to process both hard granite and fragile marble→ The large dual-blade stone cutter is a robust choice, offering the power for granite and the stability needed to prevent cracks in marble.

Procurement & Compliance Checklist

- Total Cost of Ownership (TCO):Factor in energy consumption, water usage, diamond segment replacement costs, and spare parts availability. An efficient machine may have a higher initial price but lower long-term operating costs.

- Warranty and Support:Confirm the warranty period (typically 12 months) and the availability of technical support for remote diagnostics and on-site service.

- Compliance and Certification:Ensure the machine complies with international standards. Look for CE marking, which indicates compliance with directives like the Machinery Directive 2006/42/EC for safety. Also, verify if the manufacturer operates under a quality management system like ISO 9001:2015.

- Operator Training:A comprehensive training program covering PLC operation, routine maintenance, and safety protocols is essential. This ensures you can maximize machine uptime and performance from day one.

Technical FAQ for Buyers

Is a dual-blade stone cutter a better investment than two separate single-blade saws?

- Context:You're weighing the output, labor, and space requirements of one automated machine versus two less-automated ones.

- Benefits:A dual-blade cutter automates the cut-and-separate process, eliminating the bottleneck and safety risk of flipping blocks. One operator can manage the output of what might require two or more operators and a forklift with single-blade saws.

- Next Step:Calculate your required throughput per shift and compare it to the specifications on the block saw machine product page.

What are the hidden costs when buying a sandstone panel cutter?

- Context:Buyers often focus on the machine's price tag, but Total Cost of Ownership (TCO) is a more accurate financial measure.

- Benefits:Planning for these "hidden" costs avoids budget overruns. Also, consider the cost of a water recycling system, which can significantly reduce long-term operational expenses and help comply with environmental regulations.

- Next Step:Request a detailed quote that includes a breakdown of all associated costs, from shipping to commissioning.

Why choose a PLC-controlled stone cutter over a manually operated one?

- Context:Manual machines rely entirely on operator skill, which can vary, leading to inconsistent quality and speed.

- Benefits:A PLC executes the exact same cutting sequence every time, ensuring every slab has the same dimensions. It automates safety checks and optimizes motor loads, reducing the chance of operator error and machine damage.

- Next Step:Read the Technical Principles guide to understand how closed-loop control works.

Can a single automated stone cutting machine handle both granite and marble?

- Context:Granite is much harder and more abrasive than marble. Using the same setup for both is inefficient and can damage the material or the blade.

- Benefits:You use a blade with a softer bond for granite (to expose new diamonds) and a harder bond for marble (to resist abrasion). The PLC allows you to save pre-sets for each material, so changing from cutting a granite block to a marble block is as simple as selecting a different program.

How important are the safety certifications like CE for a monument stone cutter?

- Context:Industrial machinery poses significant safety risks if not properly designed and built. Regulations exist to protect operators.

- Benefits:A CE mark certifies that the machine meets the EU's essential health and safety requirements, covering everything from electrical safety to emergency stops and guarding. It is a legal requirement for machinery sold in the EU and a globally recognized benchmark for quality. Similarly,OSHA standard 1926.1153 compliance for dust control is vital for worker health.

- Next Step:Always request the Declaration of Conformity from the manufacturer as proof of CE certification before purchase.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский