Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Use an If-Then decision map to select the right sandstone cutting machine. Review key specs, comparisons, and procurement topics.

TL;DR: The Decision Framework

- Start Here: Verify your project against the five fundamental requirements: material hardness, cutting depth, geometry needs, power, and site conditions.

- Use the If-Then Tree: Match your specific scenario (e.g., high-volume sandstone vs. softer limestone) to the recommended operational approach and be aware of the risks.

- Compare Technologies: Understand when this quarry cutting machine is superior (speed and precision in medium-hard stone) and when a wire saw is better (granite, non-linear cuts).

What Are the Must-Have Prerequisites?

- Material Type: Is your primary material a medium-hard stone like sandstone, limestone, or laterite?

- Cutting Depth: Do you need to cut blocks with a thickness of 500 mm (≈19.7 in) or less in a single pass?

- Geometry Needs: Is achieving high right-angle consistency a primary goal for minimizing waste?

- Power Supply: Can you provide a stable power source of at least 150 kW (a 180 kW generator is recommended)?

- Site Conditions: Is the quarry floor stable enough for a 100m track system, or can it be prepared to be level?

How Do I Configure the Machine for My Scenario?

If: High-volume sandstone blocks

If: Softer limestone or travertine

If: Perfect right angles are critical

If: Power supply is limited

How Does This Machine Compare to Alternatives?

- vs. Drilling & Splitting: This traditional method has low initial cost but poor predictability and low material yield. The dual-saw machine replaces uncontrolled fractures with deterministic cuts, ensuring accuracy and boosting usable material.

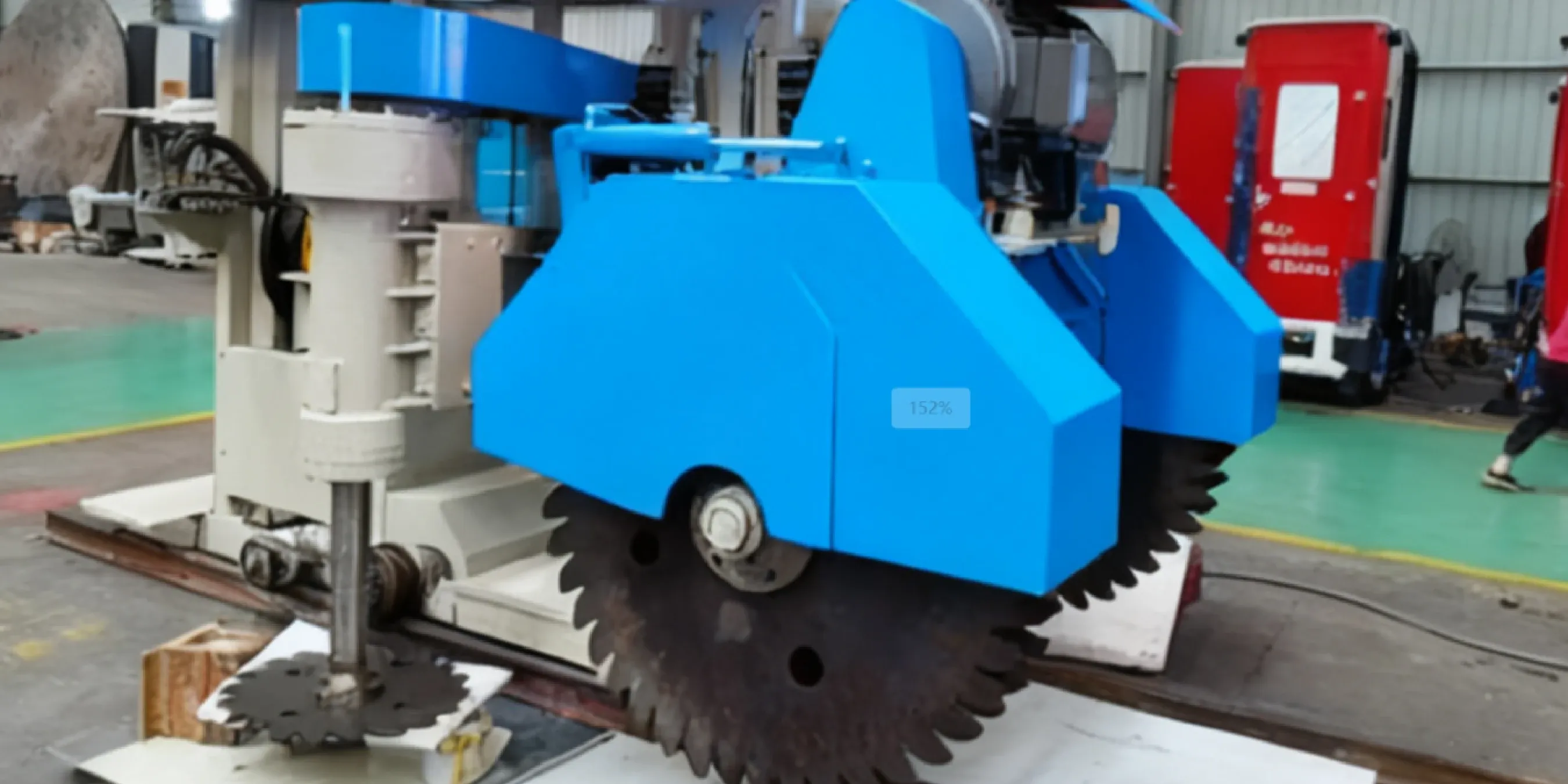

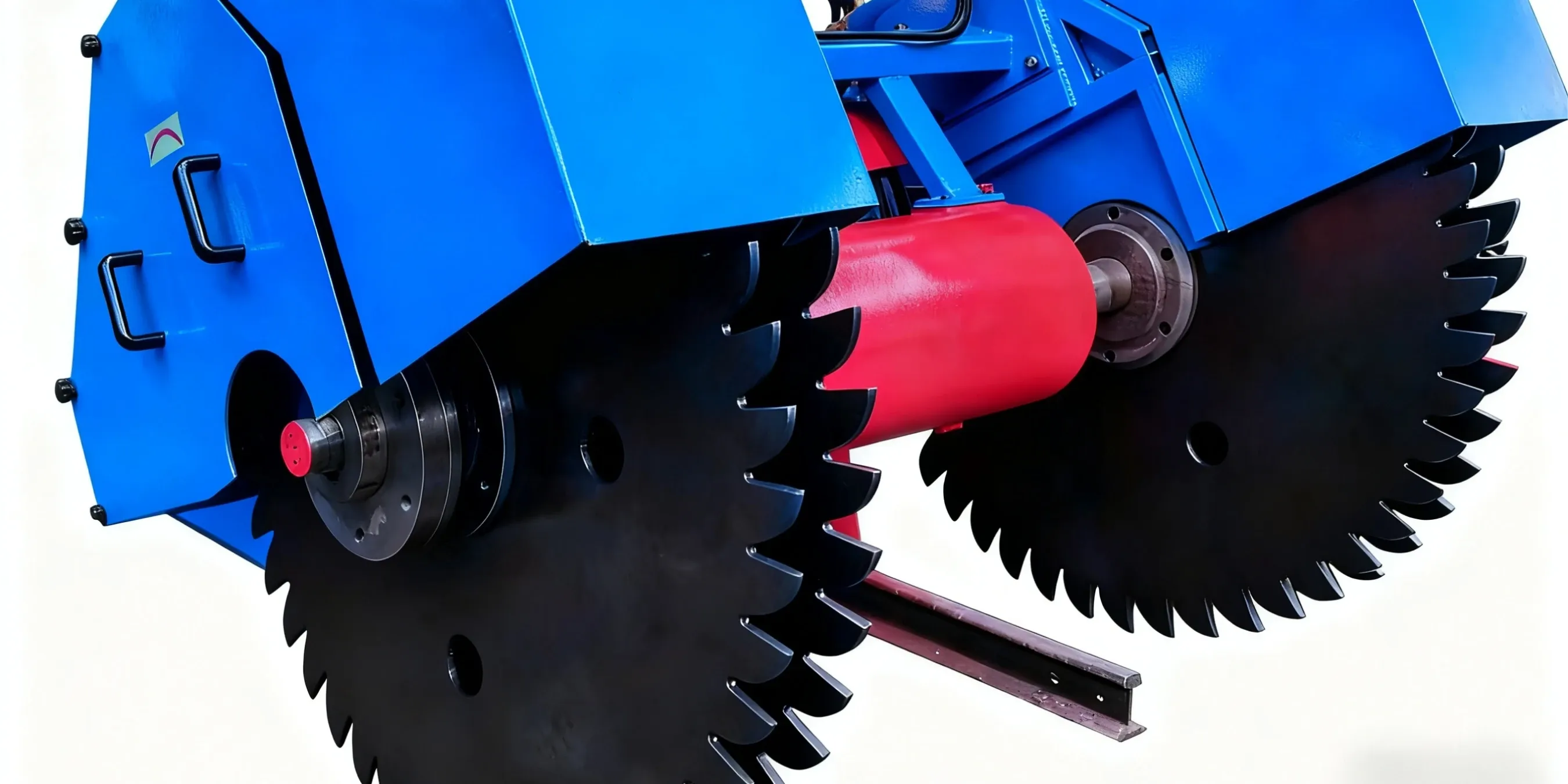

- vs. Single-Blade Saws: A single-blade machine requires two separate passes to form a corner, creating a risk of misalignment. The SSQJ-1400's integrated dual-saw head cuts both simultaneously, guaranteeing a perfect right angle.

- vs. Diamond Wire Saws: A wire saw is superior for cutting extremely hard rock (like granite) or very large, deep blocks. For straight-line, standard-sized blocks (up to 500 mm deep) in medium-hard stone, the dual-saw machine is faster and more cost-effective.

What Is on the Standard Supply List?

- Vertical Saw Blade (Ø1330 mm): 6 pcs

- Horizontal Saw Blade (Ø600 mm): 6 pcs

- Track System: 100 meters

- Dedicated Power Cable: 150 meters

- Cutter Segments: 6000 pcs

- Generator Set: 180 kW (1 set)

Frequently Asked Questions (FAQ)

Why prefer a quarry cutting machine over drilling/splitting?

It uses saws for precise cuts, unlike the uncontrolled fractures of drilling and splitting.

- Context : It is preferred when material yield and geometric accuracy are key business drivers, as it can minimize waste by up to 35% (manufacturer-reported).

- Boundaries: The initial CAPEX is higher, but this is often offset by reduced waste and less need for secondary processing.

- Next Steps: Evaluate your current material waste costs to build a business case and review the Sandstone cutting machine for quarrying page.

How do thickness and geometry needs affect my choice?

- Context & Parameters: The 500 mm maximum cutting depth is a hard limit. The dual-saw architecture guarantees right-angle consistency.

- Boundaries: If your blocks are thicker, or if slight variations are acceptable, other methods like wire saws might be considered.

- Next Steps: Check your customer's dimensional specifications to confirm if this level of precision is a "must-have."

Is a single-blade quarry cutter enough if I don’t need perfect right angles?

- Context : It requires two separate passes to form a corner, which doubles the cycle time and introduces a higher risk of misalignment.

- Boundaries: A dual-saw system's single-pass operation eliminates misalignment risk and maximizes throughput, making it better for high-volume production.

- Next Steps: Compare the value of higher throughput against the lower initial cost of a single-blade machine.

Which specification matters most when starting my selection?

- Context : Once confirmed, evaluate productivity drivers like blade diameters (Ø1330/Ø600 mm) and travel speed (10-45 m/min).

- Boundaries: If you need to cut deeper or process granite, this machine is not the right choice.

- Next Steps: Once these are confirmed, explore the full specifications on the product page to forecast output.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский