Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

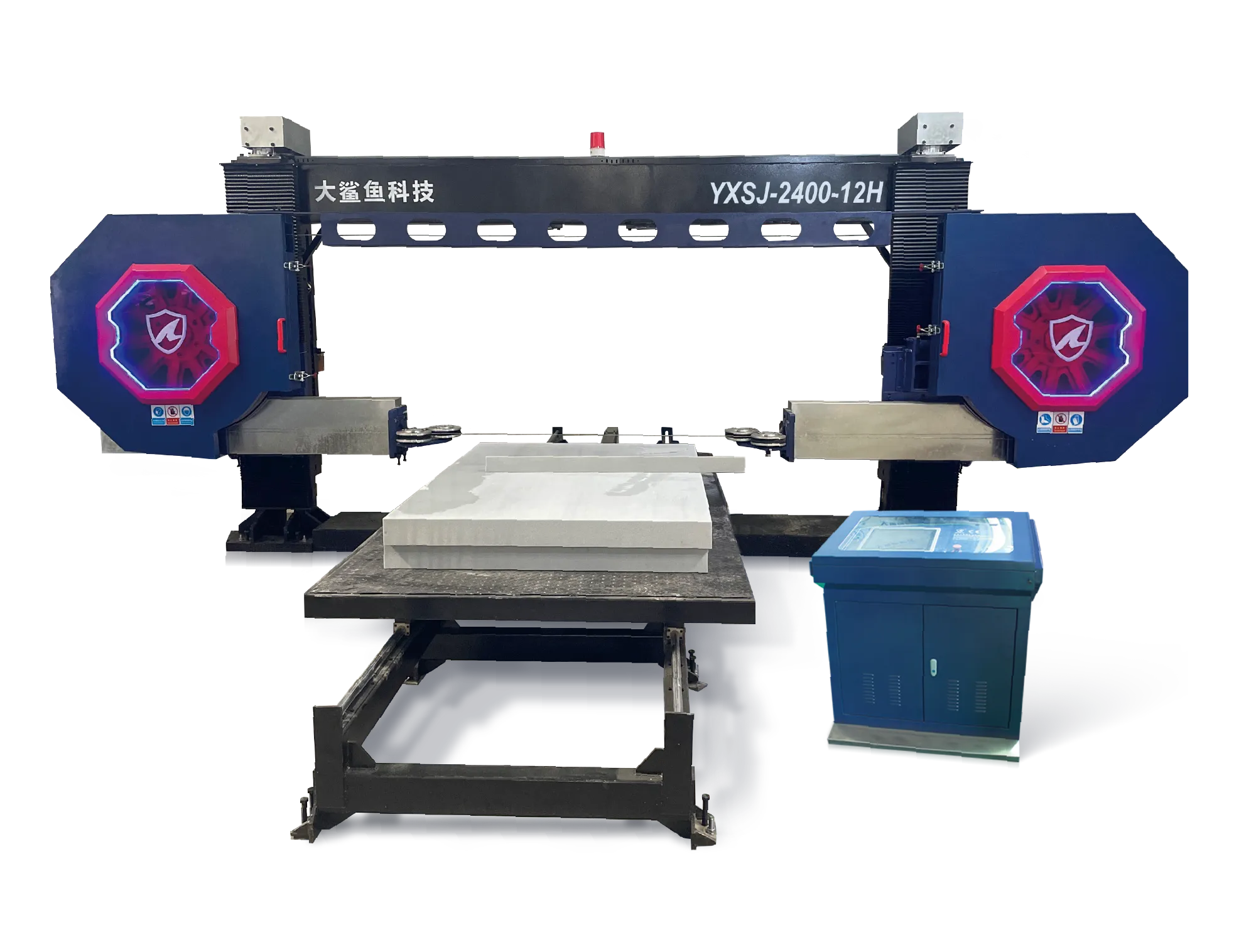

Discover how our CNC diamond wire saw precisely cuts foamed and porous ceramics. See real-world applications, material compatibility, and case studies for complex shapes.

TL;DR: Key Takeaways

- Precision Without Compromise: CNC diamond wire saws excel at cutting intricate, complex shapes in fragile foamed ceramics with minimal material loss (low kerf cutting) and no micro-cracks.

- Superior to Traditional Methods: Unlike blade saws or waterjets, diamond wire cutting is a low-stress abrasive process, preventing chipping, cracking, and water absorption issues in porous materials.

- Broad Application Spectrum: From aerospace insulation and architectural ceramics to industrial kiln furniture, the technology enables fabrication of high-value custom ceramic shapes.

Why a CNC Diamond Wire Saw Is Best for Foamed & Porous Ceramics

Why a CNC Diamond Wire Saw Is Best for Foamed & Porous Ceramics

What Can a CNC Diamond Wire Saw Do for Foamed Ceramics

- Create Complex Geometries: The multi-axis control allows for curves, contours, and intricate internal cutouts that are impossible with straight-blade saws. This unlocks new possibilities for architectural ceramics and custom components.

- Achieve Smooth Finishes: The gentle, abrasive action produces a fine, smooth surface that often requires no secondary polishing, saving time and labor.

- Minimize Material Loss: The ultra-thin diamond wire creates a very narrow kerf (cut width), maximizing the yield from each expensive block of foamed ceramic. This low kerf cutting is a significant cost-saving advantage.

Material & Processing Compatibility Matrix for Porous Ceramic Blocks

Material & Processing Compatibility Matrix for Porous Ceramic Blocks

Material Category | Examples | Processing Notes |

|---|---|---|

Foamed & Porous Ceramics | Silicon Carbide (SiC) foam, Alumina foam, Zirconia foam, Cellular Glass | Ideal for precision cutting. Adjust wire speed and feed rate for optimal finish. |

Ceramic Insulation | Refractory Ceramic Fiber (RCF) boards, Microporous insulation panels | Excellent for ceramic insulation cutting with complex shapes for thermal shielding. |

Lightweight Concrete & Composites | EPS/GRC blocks, Foamed Cement, Autoclaved Aerated Concrete (AAC) | Cuts smoothly without crumbling the material. |

Stone & Marble | Marble, Granite (for profiling), Sandstone |

Processing Boundaries for CNC stone cutting machine

- Extremely Large Blocks:This model cannot process ultra‑large workpieces due to its cutting envelope. For quarry‑scale or very large blocks, choose a DINOSAW large wire saw.

- Hard Metals:Designed for lightweight building materials (e.g., foamed ceramics, foamed cement). Cutting hard metals is difficult by design; choose a DINOSAW heavy‑duty wire saw for metal applications.

Quick Guide: How a CNC Diamond Wire Saw Cuts Foamed Ceramics

Quick Guide: How a CNC Diamond Wire Saw Cuts Foamed Ceramics

- CAD Design: Create your 2D or 3D design in any standard CAD software and export it as a compatible file (e.g., DXF, G-code).

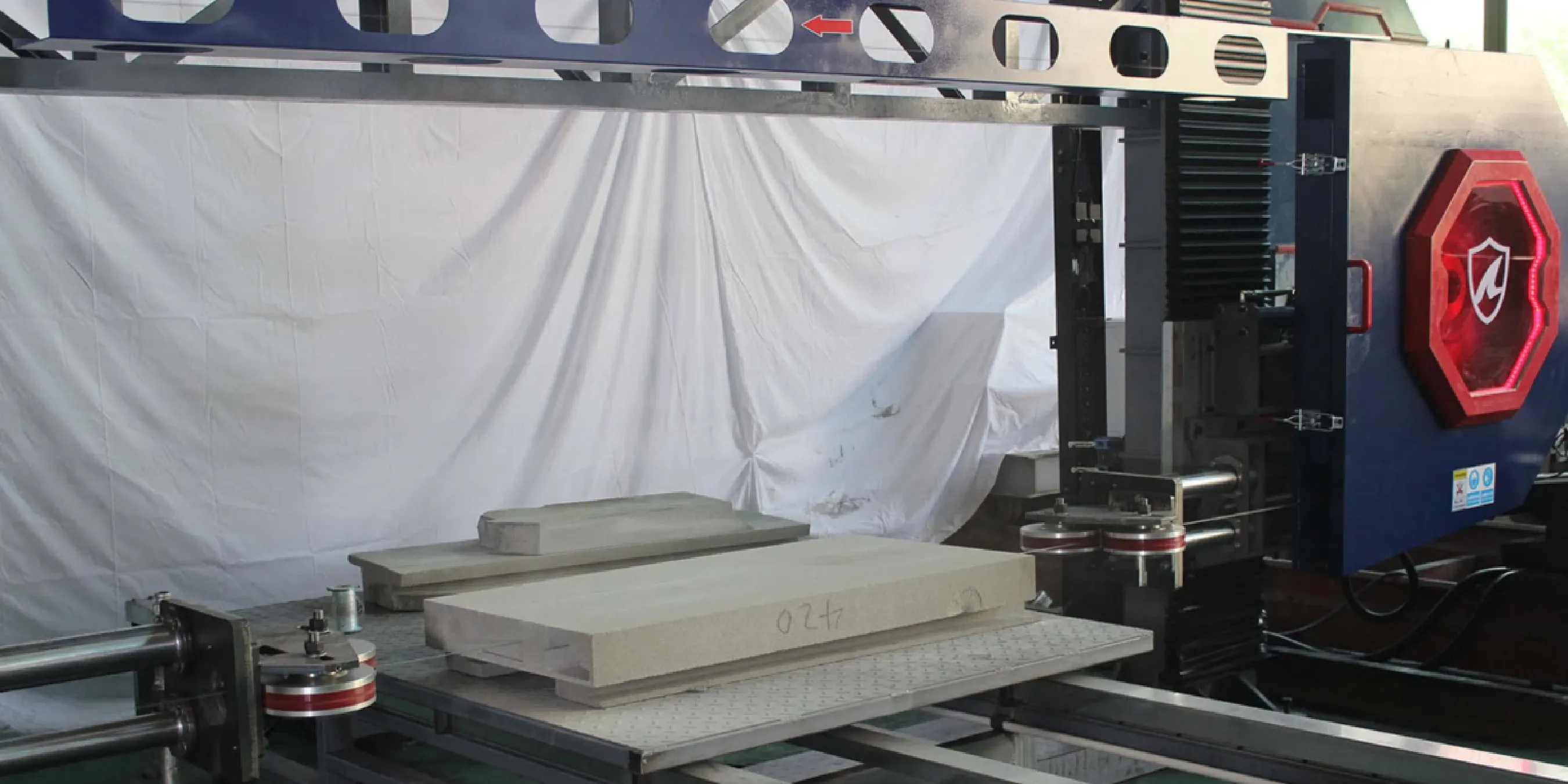

- Machine Setup: Load the program into the CNC controller, secure the foamed ceramic block on the worktable, and ensure the diamond wire tension is correct.

- Execution: Start the cutting cycle. The machine will automatically execute the programmed path with precise control over wire speed and feed rate.

- Completion: Remove the finished part, which should have a clean, smooth surface requiring minimal post-processing.

Wire Saw vs Waterjet vs Blade Saw: Scenario-Based Advantages

The primary issue with conventional cutting methods is the introduction of mechanical stress, which is a major cause of subsurface microcrack damage in brittle materials. Research confirms that diamond wire sawing significantly mitigates this.

Method | Disadvantage for Foamed Ceramics | Diamond Wire Saw Advantage |

|---|---|---|

Band Saws | High risk of chipping and edge fractures; blade wear is rapid due to abrasiveness. | Gentle abrasive cutting preserves edges and wire life is longer. |

Waterjets | Porous materials absorb water, which can cause structural weakness or require lengthy drying. The process is also messy. Many studies note limitations when cutting hard ceramics. | Wire saw employs controlled water cooling in most operations; compared to a waterjet’s high-pressure stream, the controlled coolant flow reduces water ingress risks. The choice of process should consider material porosity and post-drying needs. |

Blade Saws | High kerf loss, significant mechanical stress leading to micro-cracks, and loud operation. | Minimal stress, ultra-low kerf loss, and quieter operation. |

3 Mini Case Studies: CNC Diamond Wire Saw for Porous Ceramics

Case 1: Aerospace

- Problem: A manufacturer needed to cut lightweight SiC foam insulation panels with complex curved cutouts to fit around satellite components, a task impossible with traditional methods without causing fractures.

- Solution: The CNC diamond wire saw was programmed with the precise CAD file to execute the intricate cuts on the fragile SiC foam material.

- Result: The panels were cut with sub-millimeter precision and no fractures, passing all quality inspections and allowing the project to proceed on schedule.

Case 2: Architecture

Case 2: Architecture

- Problem: An architectural firm's ambitious design for a building facade required over 500 unique, custom decorative porous ceramic blocks, which was not feasible with traditional saws due to high costs and inability to create the shapes.

- Solution: The diamond wire saw was used to fabricate each unique block directly from the digital designs, handling the complexity and variety with ease.

- Result: The project was successfully realized, with all 500+ blocks produced accurately and cost-effectively, enabling the firm to complete its visionary design.

Case 3: Industrial

- Problem: A producer of high-temperature kiln furniture was experiencing significant material waste and high costs when slicing large zirconia foam blocks into thin plates using an old blade saw.

- Solution: They switched to a CNC diamond wire saw, taking advantage of its ultra-thin wire and minimal kerf to slice the blocks.

- Result: The wire saw's low kerf loss increased material yield by over 15% compared to their old saw, leading to immediate and significant annual cost savings.

Risks & Prerequisites for a CNC diamond wire saw Cutting Machine

- Facility Requirements: A stable, level foundation and consistent power supply are essential for maintaining precision.

- Safety and Dust Control: Cutting ceramics generates fine dust, which can contain respirable crystalline silica. A proper dust extraction system is mandatory to comply with standards like OSHA's Silica Standard and recommendations from NIOSH. Operators must be equipped with appropriate PPE.

- Operator Skills: While the CNC system automates the cutting, operators should be familiar with basic CNC controls, program loading, and routine machine checks.

Summary: Is a CNC Diamond Wire Saw the Right Stone Cutting Machine for You?

Summary: Is a CNC Diamond Wire Saw the Right Stone Cutting Machine for You?

Frequently Asked Questions (FAQ)

What is the maximum cutting speed for foamed ceramics?

- Context: Cutting speed is a trade-off between throughput and quality. Softer materials can be cut faster, while harder, denser ceramics like SiC foam require a slower feed rate to prevent wire wear and ensure a clean cut.

- Procedure: Start with a conservative speed (e.g., 400 mm/min) for a new material and perform a test cut. Gradually increase the feed rate while monitoring the surface finish and listening for any signs of machine strain.

- Next Step: Record the optimal parameters for each material type in your internal SOPs to ensure consistent results on future jobs.

How long does a diamond wire last when cutting porous ceramic blocks?

- Context: Wire life depends on factors like material abrasiveness, diamond wire tension, wire speed, and cutting complexity. Lifespan is often tracked in meters for line profiles. Aggressive parameters on hard materials will shorten the wire's lifespan significantly.

- Procedure: Use the manufacturer-recommended tension for your specific wire and material. Avoid excessive feed rates and ensure the guide pulleys are clean and rotate freely, as seized pulleys can cause rapid wear.

- Next Step: Implement a log to track the cutting hours for each wire. This helps predict replacement cycles and manage consumable inventory effectively.

Can this machine cut sharp internal corners?

- Context: The sharpest possible internal corner is dictated by the radius of the cutting tool itself. A wire is circular, so it will always leave a corner with a radius equal to its own.

- Procedure: For a 0.55mm diameter wire, the minimum achievable corner radius is approximately 0.28mm. The design file (CAD) must account for this physical limitation. For 90-degree internal corners, a different process like milling or EDM would be required.

- Next Step: During the design phase, specify a minimum corner radius that matches or exceeds your wire's radius to ensure manufacturability.

What kind of dust collection system is required?

- Context: This is crucial for capturing fine ceramic dust, which can contain respirable crystalline silica. Effective dust control is a mandatory safety requirement to protect operators and comply with occupational health standards.

- Procedure: The vacuum system should have sufficient airflow (CFM) for the size of the cutting envelope. It should be directly connected via flexible hosing to the machine's integrated dust port or shroud.

- Next Step: Consult local regulations and standards, such as those from OSHA, to ensure your chosen dust collection system meets all legal requirements for your facility.

Is it possible to test cut my material before purchasing?

- Context: We understand that investing in new equipment is a major decision, and validating its performance on your specific material is a critical part of the due diligence process.

- Procedure: You send us a sample of your material along with the cutting specifications or a design file. We will then process it on one of our machines.

- Next Step: Contact our sales team to initiate the process. We will return the finished part to you for your own quality inspection and evaluation.

How does the price compare to a waterjet machine?

- Context: While a waterjet offers broader material versatility, its operational costs are much higher due to the need for high-pressure pumps, garnet abrasive, and complex water recycling systems. A wire saw's costs are mainly limited to the wire and electricity.

- Procedure: When comparing, create a TCO model that includes purchase price, installation, consumables (wire vs. garnet/nozzles), energy, maintenance, and water treatment costs over a 3-5 year period.

- Next Step: Request a TCO worksheet from our team to help you build an accurate financial comparison based on your expected usage.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский