Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

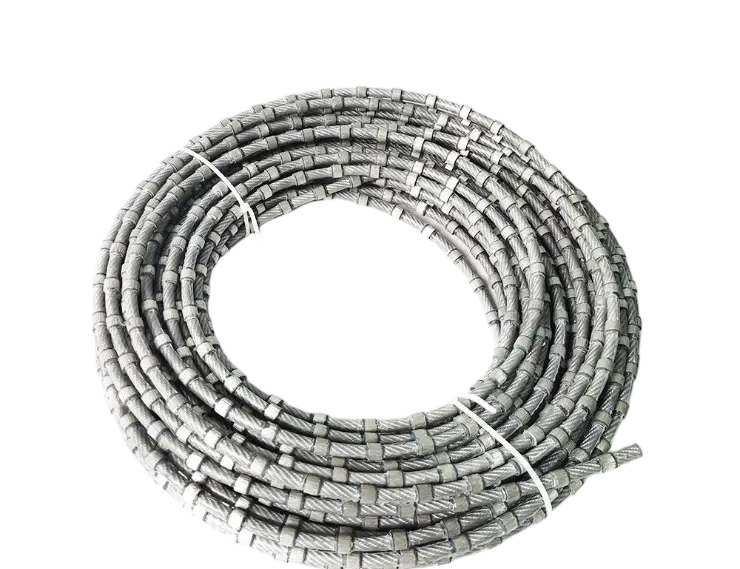

Explore how a diamond wire saw handles tough materials. See case studies for concrete cutting wire, granite cutting wire, and underwater wire cutting.

TL;DR: Your Guide to Diamond Wire Saw Applications

- A diamond wire saw is not just for stone; it precisely cuts reinforced concrete, metal, and other challenging materials.

- It excels where blade saws fail, offering lower noise, minimal dust, and the ability to perform complex or underwater cuts.

- This article provides real-world case studies showing how to leverage this technology for demolition, quarrying, and industrial projects.

Tired of Slow, Imprecise, and Hazardous Cutting Methods?

What Can This Tool Do for Your Project?

Using Diamond Wire for Concrete & Wire Saw for Demolition

Diamond Wire for Granite and Marble Blocks (Quarries)

Precision Slicing for Refractories Cutting

Cold Cutting Steel & Metal Structures

Specialized Underwater Wire Cutting Operations

Material & Processing Compatibility Matrix

Material | Recommended Wire Type | Primary Application |

|---|---|---|

Reinforced Concrete | Brazed Diamond Wire (Rubber Connection) | Demolition, infrastructure modification |

Hard Granite (Quarrying) | Sintered Diamond Wire (Spring Connection) | Block extraction from quarry |

Marble (Slab/Shape Cutting) | Electroplated or Sintered Wire | Countertop fabrication, architectural shapes |

Steel & Metal Alloys | Brazed Diamond Wire | Decommissioning, industrial cold cutting |

What Are the Processing Boundaries? (Can vs. Cannot)

✅ You Can

- Cut extremely hard or abrasive materials.

- Make cuts at any angle or in tight spaces.

- Process materials underwater or in hazardous zones.

- Achieve fine finishes with minimal kerf (cutting loss).

❌ You Cannot

- Effectively cut soft, gummy, or elastic materials.

- Achieve zero kerf loss; some material is always removed.

- Operate without sufficient water cooling (in most cases).

- Use it without proper operator training and safety protocols.

How Do You Actually Use the Diamond Wire? (Brief SOP)

- Pre-Use Inspection: Before installation, inspect the wire for any damage to the beads, connectors, or steel core.

- Threading Route & Protection: Thread the wire through pre-drilled holes or around the object. Ensure the path is clear of obstructions and the wire is correctly seated in the machine's pulley system.

- Tensioning & Coolant: Apply the correct tension to the wire using a calibrated gauge, as per specifications. Verify the coolant system is active and water is flowing directly onto the kerf.

- Initiate the Cut: Begin the cut at the appropriate wire speed for the material. Allow the wire to establish a groove before applying full feed pressure.

- Rotate Wire Periodically: To ensure even bead wear and maximize lifespan, rotate the wire by twisting it at the joint during maintenance intervals.

- Post-Use Cleaning and Storage: After use, clean slurry and debris from the wire, inspect it for damage, and store it coiled loosely in a dry place.

3 Mini-Cases: From Problem to Solution

- Problem: Slow, high-risk removal of a reinforced concrete bridge section using traditional methods.

- Solution: A hydraulic wire saw with brazed diamond wire for concrete was deployed for controlled, precise cutting.

- Result: Achieved a 60% time saving and 85% less dust compared to jackhammers. The process is now replicable for similar civil projects.

- Problem: High material waste and micro-cracks from traditional block extraction methods like blasting.

- Solution: Implemented a quarry wire saw machine with a sintered wire designed for abrasive stone.

- Result: Increased the yield of marketable, crack-free blocks by 35%. This outcome is repeatable with a proper maintenance schedule.

- Problem: Using hazardous thermal cutting (torches) to remove steel platform legs in an explosive subsea environment.

- Solution: A remote-operated brazed diamond wire was used for spark-free cold cutting, adhering to IMCA safety standards.

- Result: Project completed with a 40% time reduction and a significant improvement in operational safety, eliminating fire risk.

Key Risks & Prerequisites

- Operator Training: Ensure all operators are certified and understand the specific machine's safety features and emergency procedures.

- Personal Protective Equipment (PPE): Always use appropriate PPE, including safety glasses, hard hats, steel-toed boots, and waterproof gear.

- Dust Control: According to OSHA's fact sheet on respirable crystalline silica, wet cutting is essential to suppress dust. Manage slurry according to local environmental regulations.

- Structural Assessment: Before cutting structural elements, have a qualified engineer approve the plan to prevent unintended collapses.

Summary & Next Steps

Frequently Asked Questions (FAQs)

Can a diamond wire saw be used for steel cutting?

- Context:Brazed diamond bead wires are specifically designed for this. Unlike thermal torches, they don't create sparks, making them the preferred choice for oil and gas decommissioning or nuclear facilities where fire hazards are a major concern.

- Next Step:To understand the safety protocols for such environments, review the IMCA Guidance Register.

How fast can a diamond wire saw cut granite?

- Context:The speed is influenced by the granite's hardness, the machine's power (kW), and the specific granite cutting wire used. Softer materials like concrete or marble can be cut at significantly higher speeds.

What is the main advantage of a wire saw over a large blade saw for stone slabs?

- Context:A large blade saw is limited by its radius and can only make straight, shallow cuts. A wire saw can perform complex shapes like circles or curves and produces less noise and vibration, making it superior for intricate work.

How much water is needed for dust control (silica)?

- Context:Sufficient water flow is critical for two reasons: it cools the wire to prevent diamond degradation and flushes debris from the cut (slurry management). This is a key safety measure for controlling silica dust.

What is the difference between a wire saw for quarrying and one for concrete?

- Context:Quarrying wires often use sintered beads with spring connections for high tension, while concrete wires use brazed beads with rubber/plastic to handle rebar and protect the steel core.

Is a diamond wire saw safe for demolition in urban areas?

- Context:It performs a "cold cut" without high-impact percussion, so it doesn't transfer stress to adjacent structures. This makes it ideal for controlled demolition in populated and noise-sensitive areas.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский