Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

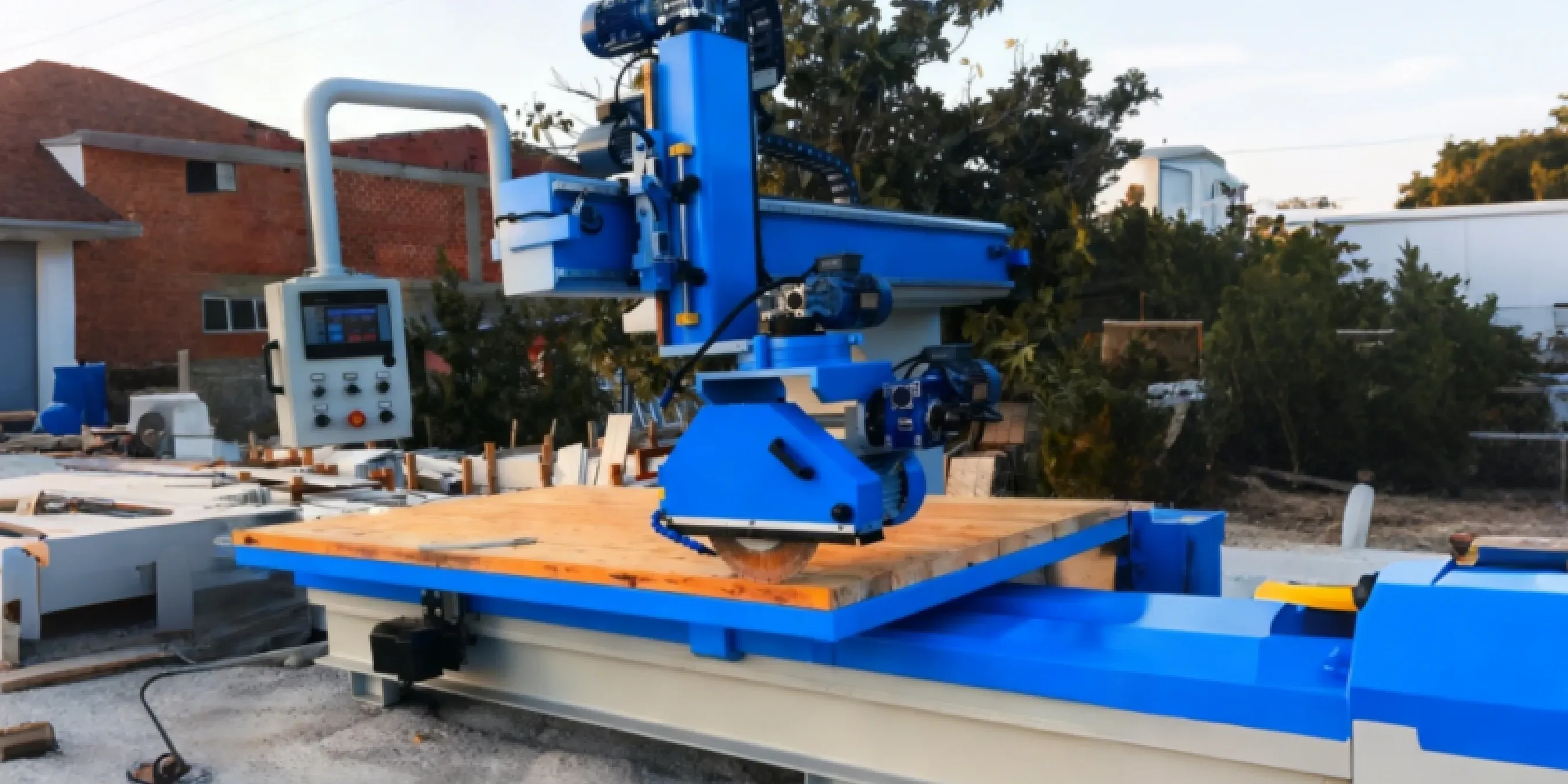

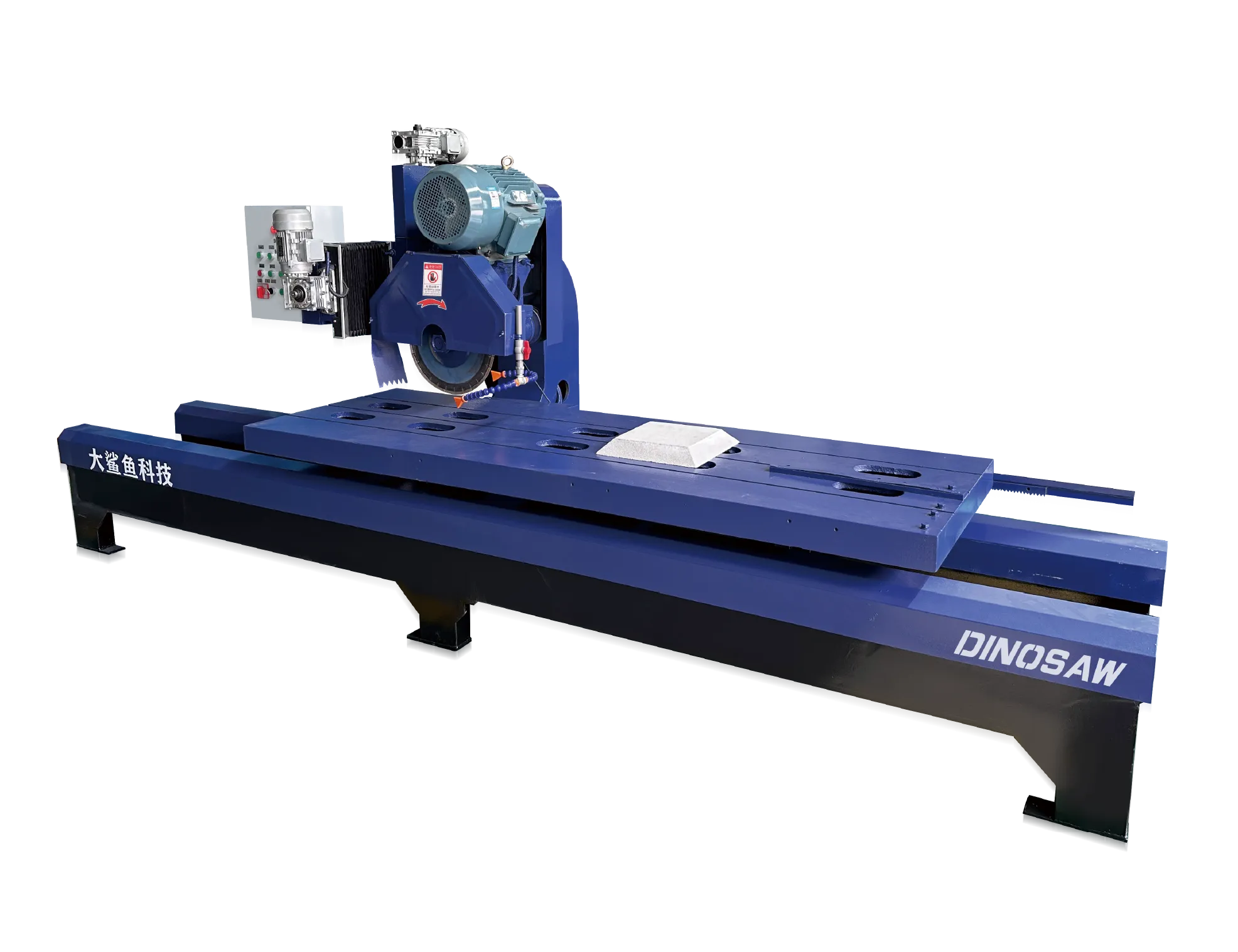

Compare manual stone cutting machine SYQJ‑600 and CNC for straight cuts and 45° chamfer.

TL;DR: 30-Second Selection Rules

- Manual Wins on Speed & Cost for Standard Jobs:For small-batch straight cuts and 45° chamfering, a manual industrial stone cutting machine is faster to deploy and has a lower Total Cost of Ownership (TCO).

- CNC Wins on Complexity & Volume:For intricate curves, high-volume production, and perfect repeatability, a CNC machine is the superior investment.

- Decision Hinges on Job Mix:Your choice depends on your primary work: geometry complexity (straight vs. curved), batch size, budget, and required precision.

- Key Machine Specs:The SYQJ-600 series offers a large cutting capacity (up to 3000×1200×180 mm or 118×47×7 in) and supports blades from Φ350–Φ600 mm, powered by a robust main motor up to 18.5 kW (manufacturer-reported).

Opening POV: Manual Stone Cutters vs. Automatic Bridge Saws (CNC/PLC)

Your Purchase Decision Guide: Key Factors to Evaluate Manual Stone Cutters

- Geometry Complexity:Are your jobs primarily straight cuts and 45° bevels, or do they involve complex curves and custom shapes? The former favors a manual cutter; the latter demands a CNC.

- Batch Size & Volume:Manual machines are ideal for small batches and one-off jobs. High-volume, repetitive tasks benefit from the automation and nesting capabilities of CNC systems.

- Budget & Total Cost of Ownership (TCO):Manual cutters have a lower initial price and simpler maintenance, resulting in a lower TCO. CNC machines require a larger upfront investment and have more complex maintenance needs.

- Training & Maintenance Window:An operator can become proficient on a manual machine in about a day. CNC systems require more extensive training. The maintenance window for a manual machine is shorter due to fewer electronic and software components.

- Space & Electrical Requirements: A manual machine typically has a smaller footprint. Both require industrial three-phase power, which is configurable per region (e.g., 380V/440V), but CNC systems may have additional power and cooling needs.A manual machine typically has a smaller footprint. Both require industrial three-phase power (380V/440V), but CNC systems may have additional power and cooling needs.

- Certifications & Compliance:Ensure any machine you consider is CE / ISO 9001:2015 compliant and supports safety features like dust-proof covers and water cooling (2–3 m³/h) to help meet local regulations.

Neutral Comparison: manual stone edge cutter vs automatic bridge saw

Technology | When to Choose | When Not to Choose |

|---|---|---|

Manual Stone Edge Cutter (This Product) | Small-to-medium batches of straight cuts & 45° chamfers. Wins on speed, cost, and flexibility for simple jobs. | High-volume automation, complex curves, or multi-axis patterns where CNC is superior. |

Automatic Bridge Saw (CNC/PLC) | High-volume production, intricate designs, perfect repeatability, and nesting to maximize slab yield. | Quick, one-off straight cuts where programming time and higher operating costs are not justified. |

Waterjet Cutter | Extremely intricate, custom shapes and cutting materials that are sensitive to heat. No heat-affected zone. | Standard straight edges and chamfers, where it is significantly slower and more expensive to operate. |

Cutting thick blocks or creating large-radius curves and complex 3D shapes that saws cannot produce. | High-speed, thin-slab processing for standard countertop work. |

If-Then Selection Tree: From Scenario to Solution

- If you primarily do standard straight cuts and 45° chamfers on flat slabs → Choose a Manual Industrial Stone Cutting Machine for fastest deployment and lowest TCO.

- If you fabricate countertops with sink cut‑outs or complex edge profiles → Choose a CNC bridge saw (or waterjet) for complex geometry and repeatability.

- If your factory space is limited → A manual stone edge cutter (worktable 2700×800 / 3000×800) has a smaller footprint than most CNC systems.

- If your power supply is not three‑phase industrial → You cannot operate a manual cutter or large CNC reliably; the required voltage (configurable per region, e.g., 380V/440V) must be available. → You cannot operate a manual cutter or large CNC reliably; upgrade infrastructure first.

- If your budget is the primary constraint → Manual cutter has the lowest initial cost; when volume/complexity grows, an entry‑level CNC is the next step.

- If you process thin slabs (backsplashes/panels) → Use thin‑kerf blade, gentle feed, full support; manual cutter is recommended.

- If you chamfer thick, hard stone (granite/quartzite) → Use blade Φ600 mm, slow feed, multiple shallow passes; manual cutter with 15–18.5 kW motor excels.

Key Procurement Topics for Your Checklist

- Total Cost of Ownership (TCO):Includes initial price, installation, training, energy consumption, consumables (blades), spare parts, and maintenance costs. A manual cutter's TCO is typically lower.

- Spare Parts & Consumables:Verify the availability and lead time for critical spares like motors, belts, and bearings. Understand blade compatibility and sourcing.

- Maintenance Window:A manual cutter's mechanical simplicity allows for a shorter maintenance schedule, often handled in-house. Clarify what daily, weekly, and monthly tasks are required.

- Training & Support:Confirm if on-site or remote training is included. Operator training time for a manual machine is typically just one day.

- Warranty & Certifications:Check the warranty period for parts and labor. Ensure the machine carries necessary certifications like CE and is manufactured under a quality management system like ISO 9001:2015.

- Delivery Time & Service Level Agreement (SLA):Confirm the delivery lead time and understand the terms of the post-sales support SLA, including response times for technical issues.

Frequently Asked Questions (FAQ)

When should I choose a manual stone edge cutter over a CNC?

- Context:Manual cutters excel in flexibility for one-off jobs and have near-zero setup time for simple tasks, making them ideal for workshops that don't need high-volume automation.

- Boundary:If more than 50% of your work involves complex curves or requires nesting for material optimization, a CNC is the better long-term investment.

- Next Step:Analyze your last 50 jobs. If they are mostly straight-edged countertops and panels, explore the Manual Industrial Stone Cutting Machine.

What's the difference in process for thin vs. thick slabs?

- Context:For thin slabs (<20 mm), use a fine-grit blade and a slow feed. For thick slabs (>80 mm), use a larger diameter blade (e.g., Φ600 mm) and cut in multiple, progressively deeper passes.

- Boundary:Never try to cut through a thick slab in a single pass, as it can damage the blade and motor. Always ensure thin slabs are fully supported and clamped to avoid vibration and cracking.

- Next Step:Contact DINOSAW for blade and parameter recommendations based on your material thickness.

What cutting capacity and worktable size should I plan for?

- Context:These dimensions are designed to handle standard slab sizes common in countertop and panel fabrication, giving you flexibility for a wide range of projects.

- Boundary:Ensure your typical workpiece dimensions fit within this envelope. For exceptionally oversized slabs, a different machine category may be needed.

- Next Step:Measure your largest typical slabs and compare them with the detailed specifications on the product page.

How do electrical requirements affect selection?

- Context:This is a heavy-duty industrial machine, not suitable for residential or light commercial power supplies. Proper voltage and phasing are critical for motor performance and safety.

- Boundary:If your facility lacks three-phase power, you cannot operate this machine. An electrical infrastructure upgrade would be a prerequisite.

- Next Step:Consult a qualified electrician to assess your workshop’s power supply before making a purchase decision.

What bevel control advantages does the manual cutter offer vs. an automatic bridge saw?

- Context:An automatic saw requires programming and more complex setup, which is inefficient for one-off straight cuts. A manual cutter's direct, mechanical angle lock is immediate.

- Benefits:This leads to higher throughput on simple jobs, lower operator training requirements, and a better TCO for workshops focused on core fabrication.

- Next Step:Analyze your job mix. If it's dominated by standard cuts, the manual machine is your most profitable choice.

What is the typical operator training time?

- Context:The intuitive control panel and mechanical nature make it easy to learn. Training focuses on safety, blade selection, angle calibration, and feed rate control, supported by our online, remote, and on-site service options.

- Boundary:While basic proficiency is rapid, mastery in fine-tuning for different materials to achieve a perfect finish comes with hands-on experience.

How demanding is the maintenance schedule?

- Context:The main tasks are daily water system checks, weekly cleaning and lubrication of the oil-immersed guide rails, and monthly inspection of belts and blades.

- Boundary:While simpler than a CNC, neglecting maintenance will lead to reduced accuracy and premature wear.

- Next Step: Request the official maintenance checklist for a detailed breakdown of the required schedule.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский