Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An executive guide to CNC bridge saw procurement. Learn to define operational requirements, evaluate suppliers, manage delivery and acceptance, and secure post-sales support with a clear SLA.

TL;DR: Executive Summary

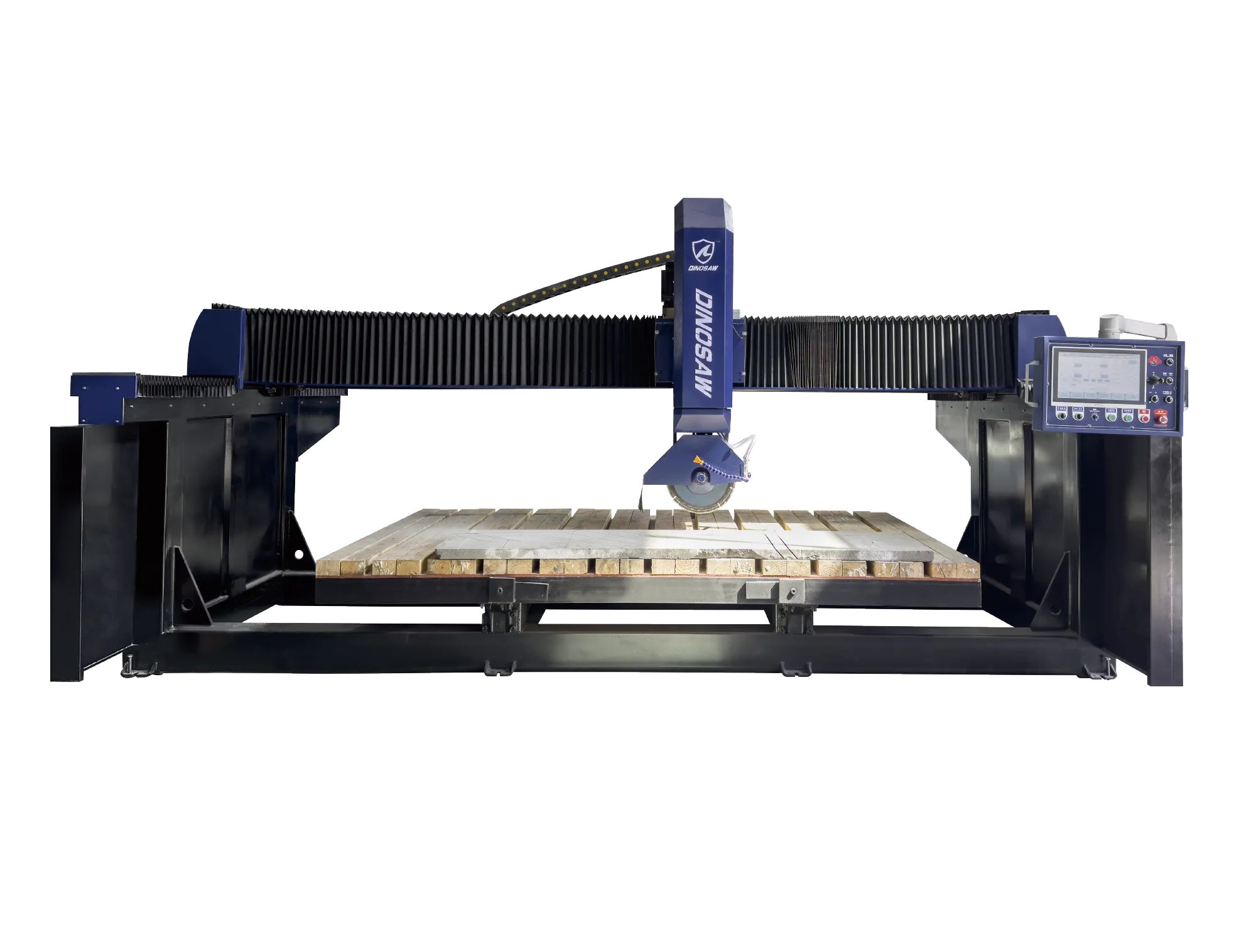

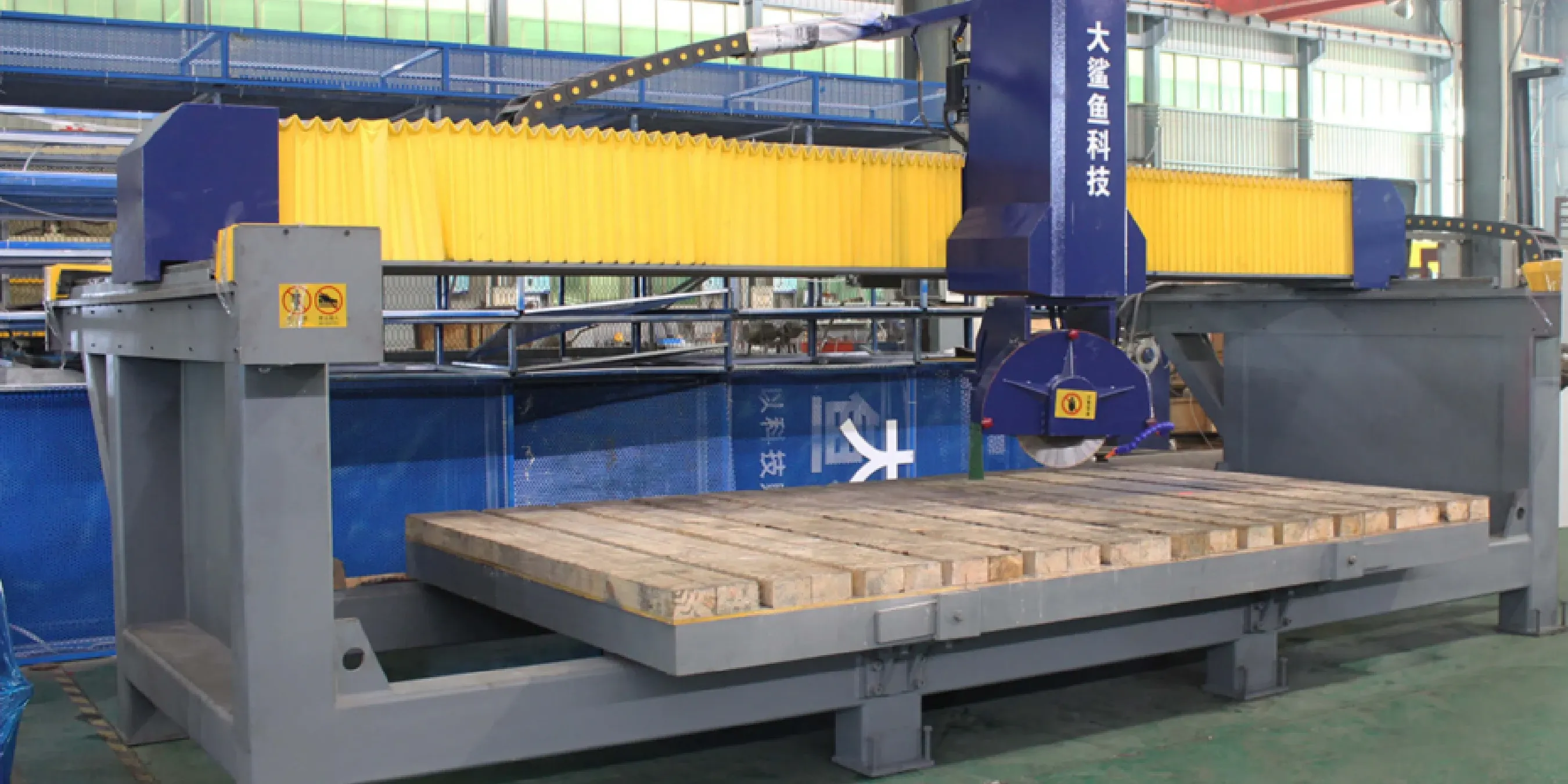

- A CNC bridge saw is a strategic acquisition for improving productivity. Focus on operational fit: a monoblock design simplifies installation and offers layout flexibility.

- The right supplier is as important as the machine. Prioritize partners who offer robust post-sales support, comprehensive training, and a clear Service-Level Agreement (SLA).

- This guide covers key procurement stages: defining requirements, evaluating suppliers, managing delivery, site readiness, and securing post-sales support.

How to Define Your Operational Requirements (Not Just Technical Specs)

- Production Volume: How many slabs per week do you need to process? This determines the required level of automation and speed.

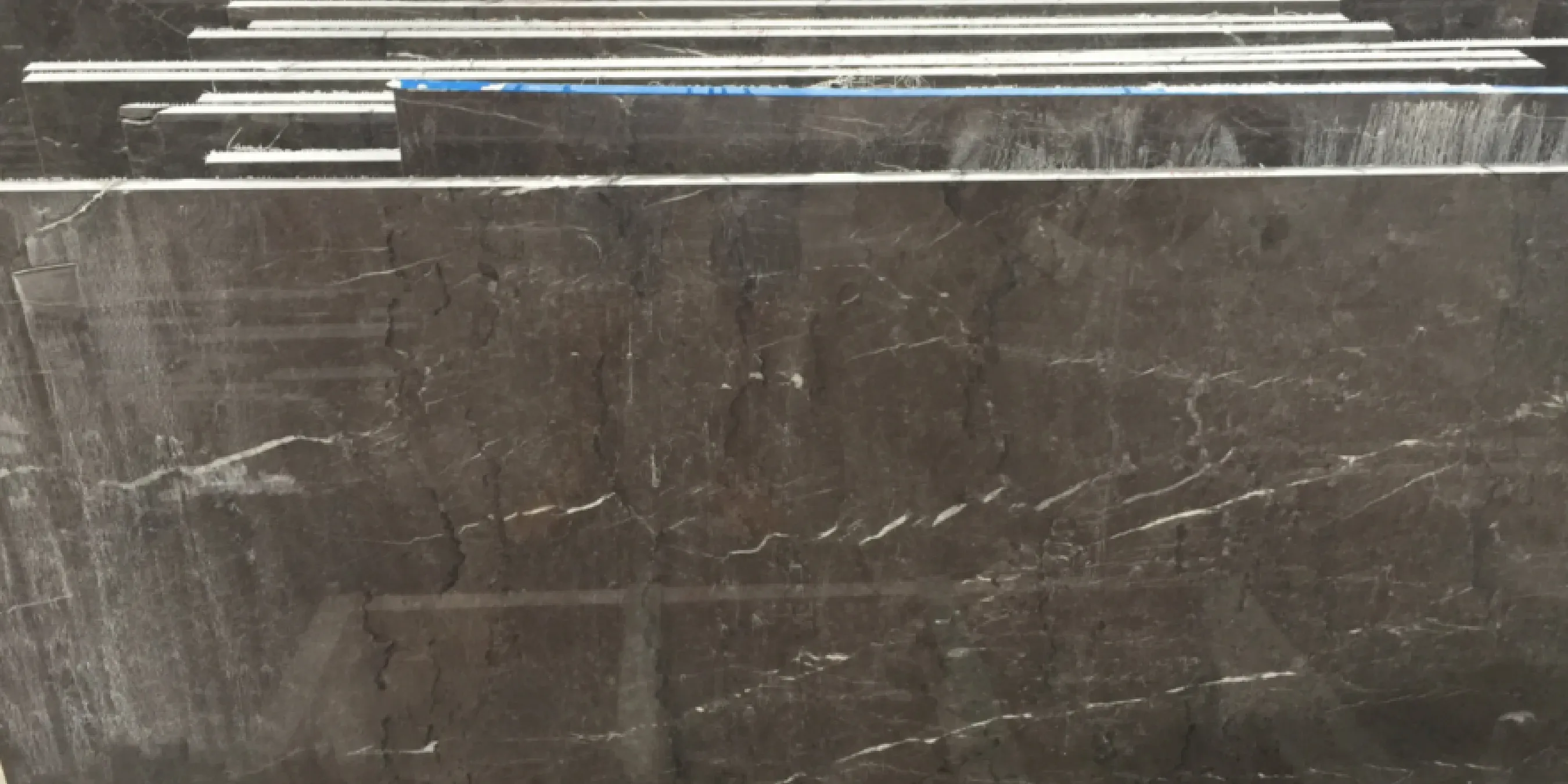

- Material & Job Complexity: Are you cutting standard granite countertops or complex architectural pieces from sintered stone? This dictates the need for features like miter cutting or advanced CNC capabilities.

- Labor & Skill Level: Will the machine be operated by seasoned professionals or newer staff? The user-friendliness of the HMI and the quality of vendor training are critical.

- Workshop Footprint: A monoblock design offers significant layout flexibility and avoids the construction associated with gantry saws. Measure your available space accurately.

A Framework for Supplier Evaluation

Evaluation Criteria | What to Look For |

|---|---|

Post-Sales Support & SLA | Guaranteed response times, availability of local technicians, and a clear Service-Level Agreement (SLA). |

Training & Implementation | On-site, hands-on training for both operators and maintenance staff. Clear documentation and checklists. |

Spare Parts Availability | Local or regional warehousing of critical spare parts to minimize downtime. |

Reputation & References | Speak to existing customers with similar operational profiles. |

Managing Delivery, Installation, and Acceptance

- Site Readiness Checklist: Before the machine arrives, ensure the floor is level, the correct power (e.g., 3-phase, specific amperage) is installed, and water/air lines are in place.

- Acceptance Testing: Define clear, measurable acceptance criteria in the contract. This should include test cuts on your specific materials to verify the machine meets the promised accuracy and performance specifications.

- Final Payment Trigger: Link the final payment to the successful completion of acceptance testing, not to the delivery date.

Four-Link Summary

- Applications & High-Value Use Cases:Explores the practical applications of a monoblock bridge saw, from cutting granite countertops to fabricating complex sintered stone panels.

- Technical Principles & Core Components:Dives into the core technologies that enable high precision, including the monoblock architecture, CNC system, and servo motors.

- Selection & Comparison Guide:Provides a neutral comparison between monoblock and gantry saws, helping you choose the right machine based on footprint, cost, and production needs.

- Operation & Maintenance:Offers a practical guide for operators on daily SOPs, troubleshooting, preventive maintenance, and OSHA safety compliance.

Frequently Asked Questions (FAQ) for CNC Bridge Saw Procurement

What are the typical lead times from order to delivery?

- Context: Standard models are often in stock or have a consistent production schedule, while custom-configured machines require additional engineering and assembly time.

- Benefits: Planning your procurement around this lead time ensures your site is fully prepared, preventing costly delays upon the machine's arrival.

- Next Step: Contact our sales team early in your planning process to get a precise delivery timeline for your desired configuration.

What should be included in the Service-Level Agreement (SLA)?

- Context: The SLA should specify guaranteed response times for technical support, on-site service availability, and terms for warranty claims.

- Benefits: It provides a clear, legally binding framework that protects your investment and ensures you receive timely support when you need it most.

- Next Step: Review the vendor’s standard SLA and negotiate any amendments needed to meet your business's operational requirements before signing the contract.

What does the warranty cover for a CNC stone cutting machine?

- Context: This usually includes non-wear parts like motors, controllers, and structural components. Consumables like blades and belts are generally excluded.

- Benefits: The warranty protects you from premature failure of key components, providing peace of mind for your initial operational period.

- Next Step: Ask for a detailed list of what is and is not covered by the warranty. Also, inquire about options for an extended warranty.

What is involved in operator training?

- Context: A qualified technician should provide on-site, hands-on training that allows your operators to run actual jobs under supervision.

- Benefits: Proper training ensures you get the most out of your machine from day one, improves efficiency, reduces the risk of costly errors, and promotes a safer work environment.

- Next Step: Confirm that the cost of training is included in the purchase price and specify the number of training days in the contract.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский