Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

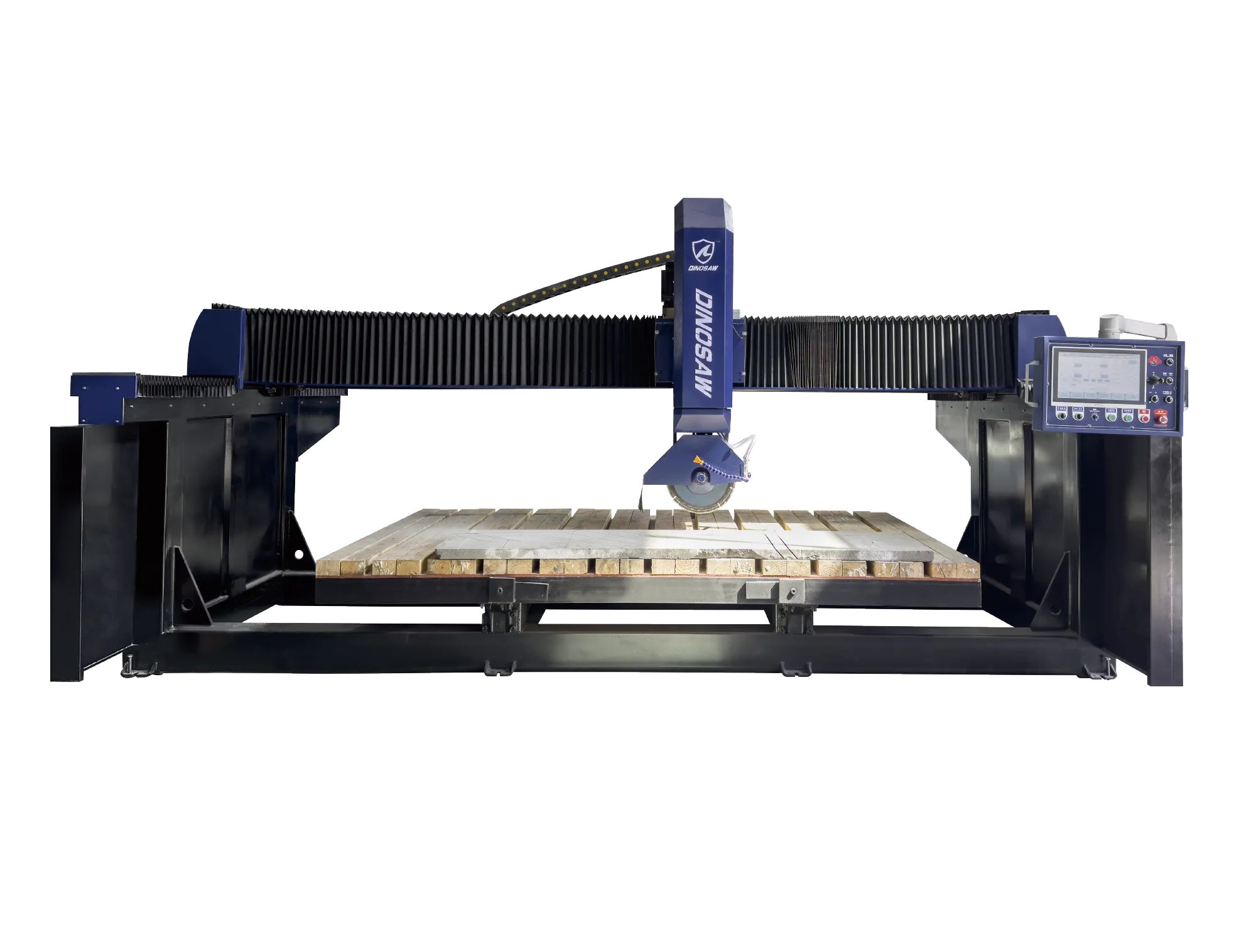

A technical guide to the monoblock bridge saw. Explore the CNC control, servo motors, and rigid design of our stone fabrication equipment that deliver ±0.5mm cutting accuracy for stone fabricators.

TL;DR: The Engineer's Briefing

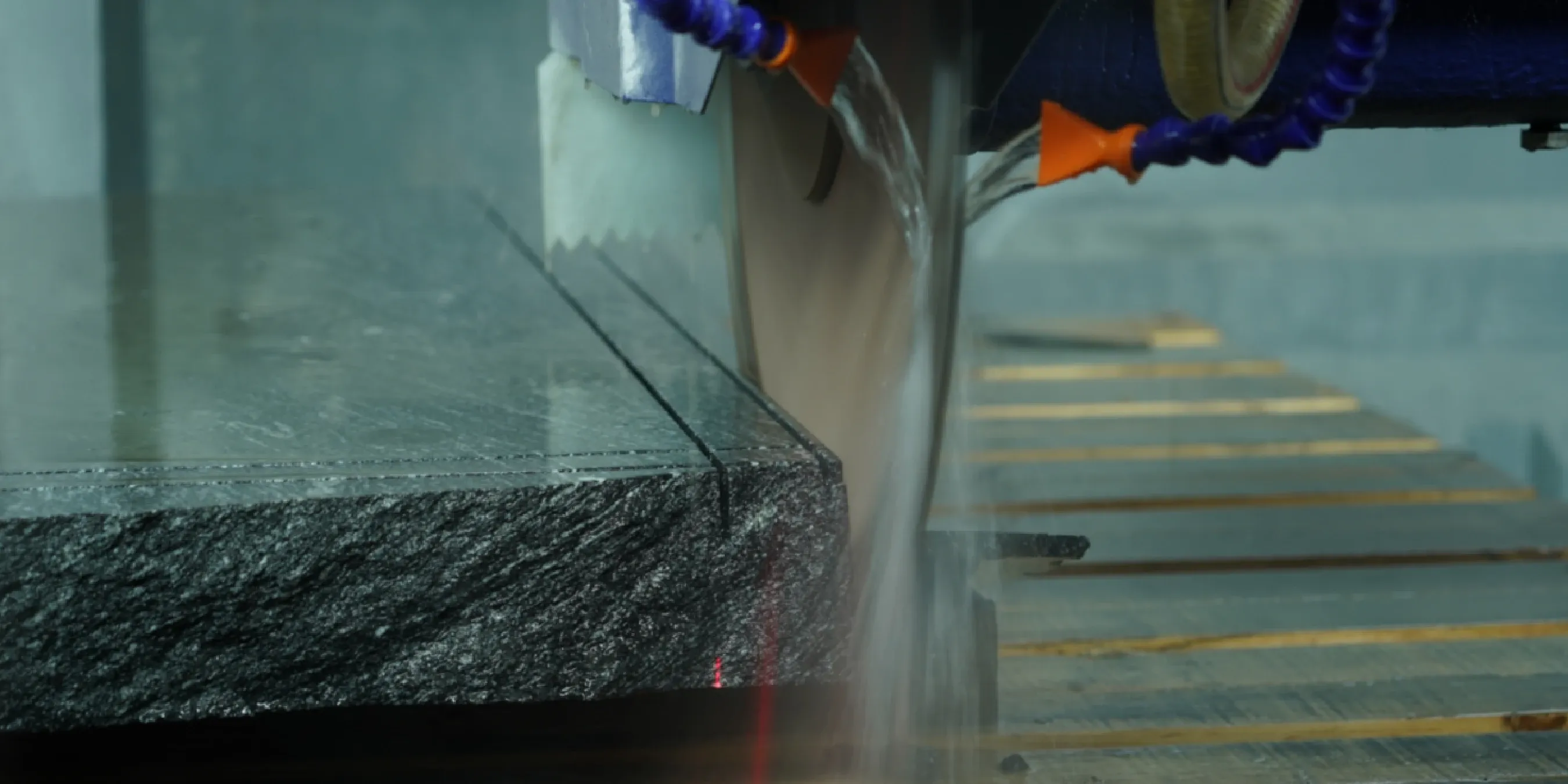

- The machine's precision comes from a combination of a rigid monoblock frame that minimizes vibration, a closed-loop CNC system, and high-precision encoders on all servo-driven axes.

- Key components include the 18.5kW main motor with variable speed control, servo-driven axes for rapid and precise positioning, and a user-friendly touchscreen HMI for programming.

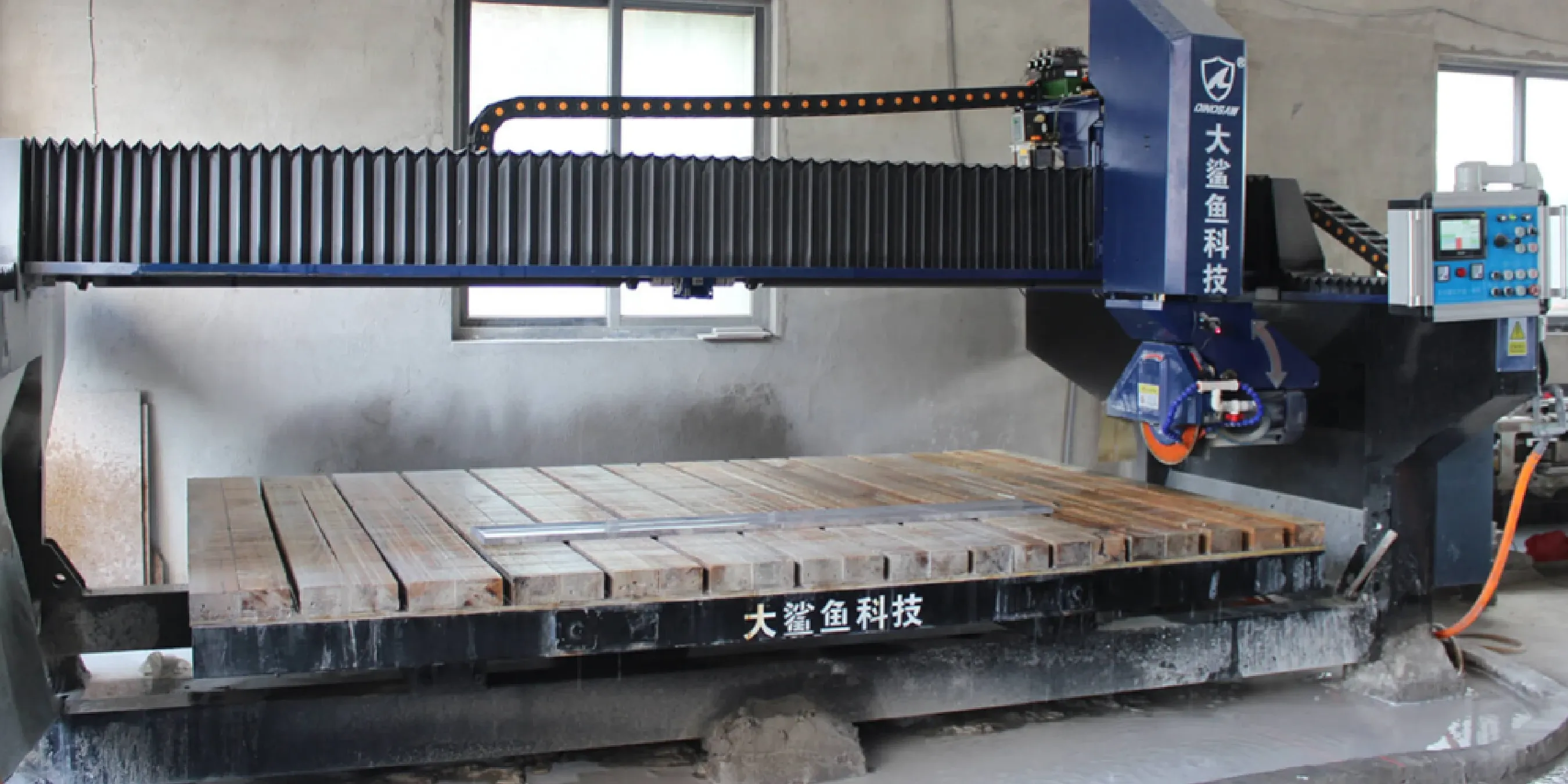

- Unlike traditional saws that require permanent concrete foundations, the monoblock bridge saw design is a self-contained unit, dramatically simplifying installation and allowing for future relocation.

How Does a Monoblock Bridge Saw Achieve High Precision?

How Does Its Architecture Provide an Advantage?

What Are the Core Technical Advantages?

CNC System for Automated Control

Servo Motors & Encoders for Precision

Cutting Motions & Options: Travel, Tilt, Rotation

- X-Axis: Bridge movement along the length of the worktable.

- Y-Axis: Cutting head movement across the bridge.

- Z-Axis: Vertical movement of the blade for depth control.

- A-Axis (Optional): Tilting of the cutting head, typically from 0° to 45°, for creating mitered edges.

- C-Axis (Optional): Rotation of the worktable, enabling cuts at any angle without repositioning the slab.

Anatomy of the YTQJ-600: Key Components of this CNC Stone Cutting Machine

Component | Specification | Function |

|---|---|---|

Main Motor | 18.5 kW, variable speed | Provides the power to cut through dense materials like granite and quartz. Variable speed allows for optimizing the cut based on material hardness. |

Control System | 12" touchscreen HMI, multi-language support | The operator's interface for programming jobs, running calibration routines, and monitoring machine status. |

Worktable | 3200x2000mm, with 0-85° hydraulic tilting | Supports the slab and allows for easy loading via the hydraulic tilt function. Optional C-axis rotation simplifies multi-angle cutting. |

Cutting Head | Accommodates 350-600mm blades, 0-45° tilting | Houses the main motor and blade assembly. The optional A-axis tilt is essential for creating precise mitered edges for waterfall countertops. |

Guidance System | Linear slide guides | High-precision linear guides on the X, Y, and Z axes ensure smooth, low-friction movement, which is critical for cut quality and accuracy. |

System Compatibility & Interfaces

Frequently Asked Questions (FAQ) on Bridge Saw Technology

What are the main advantages of advanced cutting options?

- Context:A saw with a tilting head and rotating table can perform straight cuts, angled cuts, and miter cuts, as well as complex shapes and curves.

- Benefits:This reduces material handling time, increases efficiency, and expands the range of jobs you can complete, from simple countertops to intricate architectural pieces.

- Next Step:Evaluate your current and future job mix to determine if the added capability for complex cuts will open up new revenue streams.

How does the CNC control system improve operation?

- Context:It allows the machine to execute complex designs directly from a digital file, reducing reliance on manual operator skill.

- Benefits:This automation minimizes human error, reduces material waste, and ensures every piece is cut with high precision (e.g., ±0.5mm).

- Next Step:Assess your current CAD/CAM workflow to see how seamlessly a CNC machine can be integrated for a "design-to-cut" process.

What does "monoblock design" mean for my workshop?

- Context:The machine is a single, self-contained unit that does not require the construction of special concrete foundations.

- Benefits:This saves weeks of construction time and significant budget. It also provides flexibility, as the machine can be moved in the future if your workshop layout changes.

- Next Step:Confirm your concrete floor is solid and level, as this is the only major site requirement for a monoblock machine.

What is the power of the main motor and why is it important for a granite cutting machine?

- Context:Hard, dense materials like quartzite and granite require significant power to cut through cleanly and efficiently.

- Benefits:A high-power motor prevents the machine from slowing down or stalling, ensuring a smooth cut, preventing damage to the blade, and maintaining high throughput.

- Next Step:Compare the motor power (in kW or HP) when evaluating different machines, as this is a key indicator of its cutting capability.

What bridge saw maintenance does the CNC system require?

- Context:Maintenance typically involves keeping the electrical cabinet clean and dry, checking connections, and ensuring software is updated if applicable.

- Benefits:This simplifies the overall maintenance burden, as operators can focus on the mechanical aspects like lubricating guide rails and checking motors.

- Next Step:Request a detailed preventive maintenance schedule from the supplier to understand the weekly and monthly tasks required.

Can I upgrade a machine with more features later?

- Context:Adding these capabilities requires a different cutting head, additional servo motors, and a more advanced CNC controller and software.

- Benefits:Investing in a machine with the right configuration from the outset is more practical and ensures you have the capability when needed, avoiding significant future downtime and expense.

- Next Step:Carefully consider your 2-3 year business plan to decide if the demand for complex cuts justifies the upfront investment in an advanced configuration.

How does the closed-loop system work?

- Context:An encoder on each motor provides constant positional feedback to the CNC controller, which compares the motor's actual position to the target position.

- Benefits:If there's a discrepancy, the controller instantly adjusts power to the motor to correct the error, ensuring much higher accuracy than open-loop systems which have no feedback.

- Next Step:When comparing machines, always confirm that the axes are driven by servo motors in a closed-loop system, not simpler stepper motors.

What are linear slide guides and why are they important?

- Context:These guides and their bearing blocks constrain the movement of the bridge and cutting head, providing smooth, low-friction travel.

- Benefits:This prevents vibration during cutting, which is essential for achieving a flawless, chip-free edge and maintaining the machine's long-term accuracy.

- Next Step:During a machine inspection, check that the linear guides are from a reputable brand and ask about the recommended lubrication schedule.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский