Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Is investing in premium core bits worth it? This guide covers ROI, TCO, decision gates, and implementation steps for managers to boost productivity and safety.

TL;DR: The Business Case for Diamond Core Bits

- The Goal is Lower Cost-Per-Hole:The objective isn’t buying the cheapest bit; it’s achieving the lowest total cost of ownership (TCO) by maximizing tool life and reducing labor time per hole.

- It’s a System Investment:Success requires matching the bit, the drill rig, and operator training to your specific materials. It’s a process upgrade, not just a tool purchase.

- Safety & Compliance Drive Value:Proper adoption (especially wet drilling) is a direct path to OSHA silica dust compliance, reducing liability and protecting your workforce.

- Pilot Program is Key:Start with a small, measurable pilot project on your most common material to validate performance and calculate a reliable ROI before scaling up.

Quick Q&A for Decision-Makers

Evaluation Stage

- What is the real ROI?It’s lower labor cost-per-hole + reduced material waste + faster throughput.

- What problem are we solving?High rework rates, production bottlenecks, and workplace safety risks (silica dust).

Implementation Stage

- What resources are needed?A project lead, operator training time, and a budget for initial bit stock and potentially upgraded drill rigs.

- How do we ensure adoption?Through a formal SOP, hands-on training, and clear communication of the benefits (e.g., less dust, faster work).

Measurement Stage

Measurement Stage

- What are the KPIs?Cost-per-hole, holes-per-bit, rework rate (%), and average drilling time.

- How long until payback?A pilot program will give a precise answer. For high-volume shops, it can be a matter of months.

Risk Management

- What if it doesn't work?A pilot program minimizes this risk. A reputable supplier will provide technical support to troubleshoot issues.

- What are the compliance risks?The biggest risk is non-compliance with silica dust regulations. Proper wet drilling or vacuum systems are non-negotiable.

Selection Quick-View: Diamond Core Bits vs. Traditional Tools

Business Metric | Diamond Core Bit | Traditional (Carbide/Hammer Drill) |

|---|---|---|

Quality & Rework | Clean, chip-free holes. Drastically reduces rework rates, protecting valuable materials. | High risk of chipping, cracking, and "blowout." Often requires secondary finishing, increasing labor time. |

Productivity | Significantly faster cutting speeds in hard materials. A premium industrial bit can increase throughput by enabling faster cycle times. | Very slow in hard stone. The tool dulls quickly, requiring frequent replacement and causing operator downtime. |

Safety & Compliance | Wet drilling is a primary engineering control for silica dust, simplifying compliance with OSHA standards. | Generates high levels of hazardous dust, requiring extensive and costly secondary control measures and strict PPE protocols. High compliance burden. |

Structuring a Pilot Program for Dimensional Stone Drilling

Navigating the Decision Gates

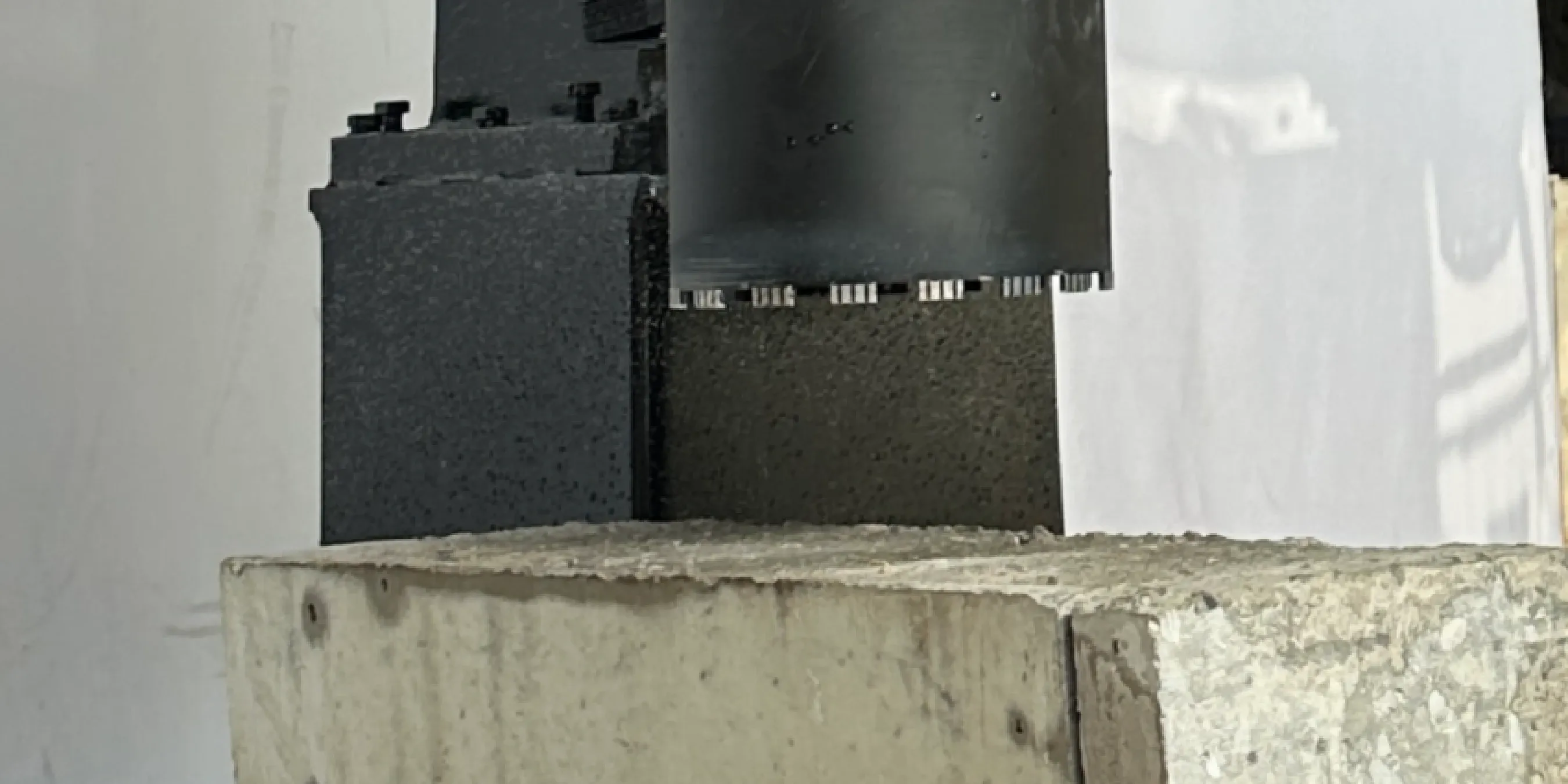

- Technical Gate (Engineering/Operations):Does the tool meet performance specs? Is it compatible with our existing Automatic Drilling Machines ? Will the supplier provide adequate technical support?

- Business Gate (Finance/Procurement):Does the ROI from the pilot program justify the investment? What is the TCO compared to our current solution? Are the payment and delivery terms favorable?

- Compliance Gate (Safety/HR):Does this solution help us meet NIOSH guidelines and OSHA standards for silica dust? Is the required training documented?

- Executive Gate (Management):Does this investment align with our strategic goals (e.g., improving efficiency, enhancing worker safety, increasing profitability)? Is the business case sound?

Contract, Delivery, and Post-Sales Support

- Implementation & Training:The supplier should provide clear SOPs and be available to support initial operator training. This ensures the tools are used correctly from day one for optimal performance.

- Post-Sales & SLA:Clarify the Service Level Agreement (SLA). What is the response time for technical support? How are warranty claims handled? Reliable post-sales support for your Stone Dry/Wet Core Bit is crucial for minimizing downtime.

- Spare Parts & Retipping:Confirm the availability and lead time for replacement Diamond Segments . A cost-effective retipping program can significantly extend the life of your bit barrels and lower long-term TCO.

Your Path to Optimized Drilling with CNC Granite Core Bits

Frequently Asked Questions (FAQ)

How do we justify the ROI for premium diamond core bits?

- Context:A lower upfront cost often hides higher long-term expenses from frequent replacements, slower labor, and material waste due to rework. A premium bit's value is in its longevity and performance.

- Guidance:The primary ROI drivers are a lower cost-per-hole (due to more holes per bit), reduced labor costs from faster drilling cycles, and significant savings from eliminating rework and material waste.

- Next Step:Initiate a pilot program on a high-volume task to quantify these metrics. This will provide hard data for a compelling business case.

Should our policy default to wet drilling for silica compliance?

- Context:Regulations like the OSHA 1926.1153 standard for respirable crystalline silica identify wet methods as a primary engineering control. It is far simpler to manage than airborne dust.

- Guidance:Mandating wet drilling for all feasible operations reduces liability, simplifies PPE requirements, and protects employee health. It also improves tool life and finish quality, creating a dual benefit.

- Next Step:Update your company's safety SOP to make wet drilling the default procedure for stone. Reserve dry drilling only for specific, documented exceptions where water is infeasible.

What KPIs should our team track in a pilot program?

- Context:The goal of a pilot is to replace assumptions with hard data. Tracking these KPIs will provide a clear before-and-after picture of the tool's impact.

- Guidance:Track these four KPIs: 1)Cost-per-hole(Total Bit Cost / Total Holes Drilled), 2)Holes-per-bit(Total lifespan), 3)Rework Rate (%)due to chipping/damage, and 4)Average Drilling Timeper hole.

- Next Step:Create a simple tracking sheet for the pilot team to log these data points for both the old and new bits under identical working conditions.

For our CNC granite core bits, should we deploy thin-wall or standard bits?

- Context:CNC machines provide the stability and consistent parameters needed to leverage the main advantage of thin-wall bits: faster cutting due to removing less material. Standard bits are more robust but slower.

- Guidance:Deploy thin-wall bits on your CNC machines to reduce cycle times. Reserve standard, thicker-walled bits for any manual or less stable drilling operations where durability is more critical than speed.

- Next Step:Run a comparative test on a single CNC machine with both bit types to quantify the cycle time reduction and confirm that finish quality remains within your standards.

How do we structure training and SOP adoption across teams?

- Context:Successful adoption requires operators to unlearn old habits and understand the 'why' behind the new procedures. Our Operation & Maintenance SOP provides the technical foundation.

- Guidance:Designate a "champion" from your operations team to lead the training. Conduct a brief classroom session to review the SOP, followed by a hands-on demonstration. Emphasize the benefits to them: less effort, faster work, and a safer environment.

- Next Step:Formalize the new SOP, make it easily accessible (e.g., laminated copies at each workstation), and have supervisors periodically review its implementation during the first month.

How do we manage post-sales support and SLAs to reduce downtime?

- Context:Downtime is more expensive than the tool itself. An effective support structure ensures that technical issues or stock shortages are resolved before they halt production.

- Guidance:Before purchasing, clarify the supplier's SLA for technical support response time. Establish a primary contact for troubleshooting. Discuss lead times for standard and custom orders to plan your inventory levels accordingly.

- Next Step:Designate a person responsible for inventory management and reordering. Keep the supplier's contact information and the product details for your specific Stone Dry/Wet Core Bit readily available.

How do we standardize bit diameters for faucet/sink operations to cut TCO?

- Context:Most plumbing fixtures adhere to industry-standard dimensions. For countertops, this often means a few key sizes handle the vast majority of jobs. Common sizes include 1-3/8" (≈35 mm) for faucets, and 2" (≈50 mm) or 3" (≈76 mm) for accessories.

- Guidance:Holding inventory for every possible size is inefficient and costly. By focusing on the 2-3 diameters that cover 80% of your work, you can reduce stock holding costs, simplify procurement, and potentially secure better pricing on bulk orders.

- Next Step:Analyze your last 50-100 countertop jobs to identify the most frequently drilled diameters. Consolidate your inventory to these core sizes and establish a clear process for one-off orders of unusual sizes.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский