Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Is a DTH drilling machine right for your quarry? This executive guide covers requirements, pilot planning, decision gates, and boosting quarry productivity.

TL;DR: Executive Guide to DTH Drilling Investment

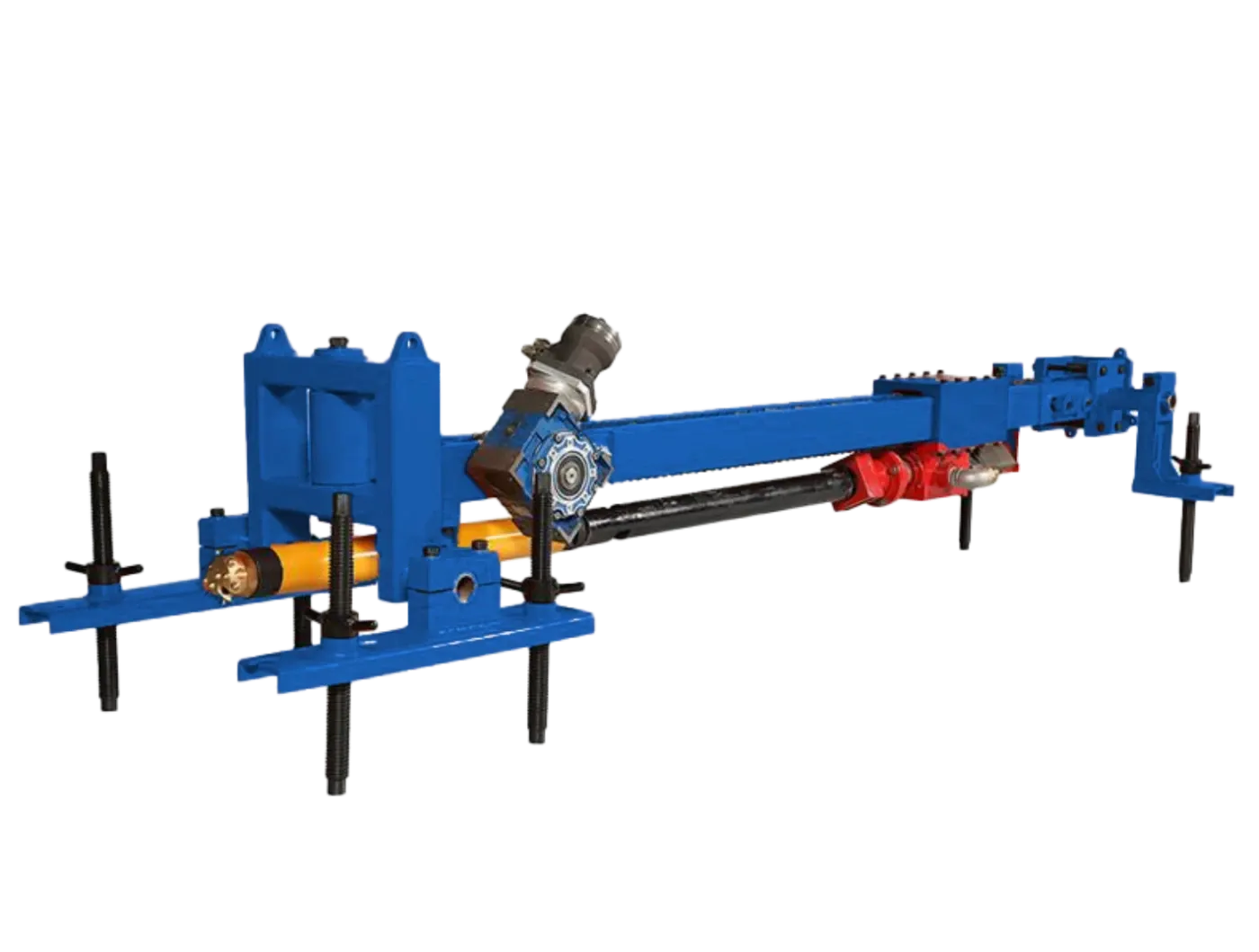

- What it is:A high-efficiency down-the-hole drilling system proven to boost quarry productivity in hard rock.

- What it does for you:Delivers faster drilling penetration rates, straighter holes, and ultimately, a lower cost per meter drilled.

- Where it fits best:High-volume operations in granite, basalt, or other hard formations. It is not a primary solution for soft materials or small-scale projects.

- Next Step:Start by defining your technical and operational needs with our Requirements Checklist in this guide.

Quick Q&A for Decision Makers

Awareness Stage: Is DTH even relevant to me?

What business problem does DTH solve?

- Context:Traditional methods lose impact energy over distance, making them slow and inaccurate in deep or hard formations. DTH maintains full power at the bit, ensuring consistent performance.

- Next Step:Review the top-hammer vs DTH comparison in our selection guide to quantify the performance gap for your geology.

Evaluation Stage: Is it a viable investment?

What are the non-negotiable prerequisites?

- Context:The DTH system's performance is directly tied to its air supply. An undersized high-pressure air compressor CFM is the number one cause of failure. Furthermore, the maintenance of the DTH hammeris critical for its longevity.

- Next Step:Use the Requirements Checklist below to audit your existing infrastructure and team readiness.

Sign-Off Stage: How do we justify the cost?

What is the core value proposition?

- Context:Straighter holes mean better blast fragmentation (less secondary breaking) and more stable walls. Faster drilling means more rock drilled per shift. These efficiencies directly impact your operational expenditures.

- Next Step:Use our pilot planning guide to define KPIs (e.g., meters drilled per hour, bit life) to build a concrete business case based on your own data.

Requirements Definition Checklist

- ☐Material:Our primary drilling is in ________ (e.g., Granite, Basalt, Limestone).

- ☐Geometry:Our typical drilling depth per pass needs to be around ________ meters, and our desired hole diameter is in the ________ mm range.

- ☐Precision:We require hole deviation control to be within an acceptable tolerance (e.g., under 2-3%) for effective blasting.

- ☐Throughput:We need a system capable of achieving a target penetration rate sufficient for our production goals in our specific rock type.

- ☐Interfaces:The rig should have capabilities for future data integration (OPC UA/Profinet integration).

- ☐Safety & Compliance:The system must include adequate dust suppression for drilling(e.g.,wet drilling kit) and support the use of all necessary PPE for quarry drilling.

Selection Snapshot: DTH vs. Legacy Methods

Navigating Internal Decision Gates

Technical Sign-Off

- Confirm infrastructure compatibility (especially air supply).

- Validate maintenance plan feasibility.

Business & Finance Sign-Off

- Approve ROI analysis based on pilot data.

- Confirm total cost of ownership aligns with budget.

Legal & Compliance Sign-Off

- Verify compliance with all safety and environmental regulations.

- Review contract terms, warranty, and SLA.

Executive Sign-Off

- Confirm strategic alignment with long-term productivity goals.

- Provide final budget approval.

Key Contract & Delivery Points

- Delivery Lead Time:Confirm a realistic delivery schedule.

- Acceptance Criteria:Ensure the KPIs from the pilot are written into the contract.

- Warranty Period:Define what is covered and for how long.

- Spare Parts Package:Negotiate an initial package of critical spares (e.g., bits, hoses, hammer service kit).

Implementation, Training, and Post-Sales Support (SLA)

FAQs for Executive Decision-Making

What is the primary business case for switching to DTH drilling?

- Context:It excels in hard rock by delivering higher penetration rates and superior hole straightness compared to other methods.

- Benefits:This leads to better blast fragmentation (reducing secondary breaking costs), higher throughput, and improved safety from more predictable blasts.

Is DTH always better than top-hammer drilling?

- Context:DTH provides unparalleled performance in medium-to-hard rock and for deep holes (>15 meters), where its energy efficiency shines. Top-hammer rigs can be more suitable for softer ground or shallower holes.

- Benefits:Choosing the correct technology based on geology and scale prevents over-investment and ensures optimal performance.

- Next Step:Review the top-hammer vs. DTH comparison in our selection guide to make an informed decision.

What is the single biggest mistake to avoid when purchasing a DTH system?

- Context:A DTH hammer's performance is directly dependent on receiving adequate air volume (CFM) at high pressure (bar/PSI). An undersized compressor will "starve" the hammer.

- Benefits:Procuring the rig and compressor as a matched system guarantees the hammer operates at its specified performance, preventing a drastic drop in drilling speed.

- Next Step:Consult the technical requirements for our high-pressure air compressors to ensure a proper system match.

How do I calculate the ROI for a DTH drilling machine investment?

- Context:The goal is to measure direct operational savings and increased output from using a DTH system.

- Benefits:Tracking metrics like meters drilled per hour, cost per meter, and reduction in secondary breaking costs provides tangible data for a robust business case.

- Next Step:We can help you set up a pilot project to track these KPIs. Contact our team to start planning.

What kind of training is required for my team?

- Context:Operators need to learn DTH-specific techniques (collaring, feed pressure), while maintenance needs training on lubrication, hammer service, and troubleshooting.

- Benefits:Proper training ensures the machine is operated efficiently and maintained correctly, maximizing its lifespan and preventing costly downtime.

- Next Step:Ask about our on-site training packages included with the commissioning of a new DTH drilling machine.

What does a typical after-sales support (SLA) package include?

- Context:An SLA should clearly define response times for service, guarantee availability of critical spare parts, and outline the process for accessing expert technical support.

- Benefits:This ensures that any issues are handled swiftly, minimizing downtime and giving you peace of mind that your machine will operate at peak efficiency.

Can I use my existing drill bits with a new DTH hammer?

- Context:Drill bits are designed to match the specific shank, splines, and performance characteristics of a particular hammer model. A bit for one hammer will not fit another.

- Benefits:Using the correct, specified bit ensures proper function, prevents severe damage to the hammer, and maintains drilling performance.

- Next Step:Always procure bits specified for your exact DTH hammer model to avoid compatibility issues.

How long does a DTH hammer last before it needs to be rebuilt?

- Context:A hammer's lifespan is influenced by rock abrasiveness, adherence to lubrication schedules, and correct operating procedures. A well-maintained hammer can last hundreds of hours.

- Benefits:Proactive maintenance and regular inspections are the key to maximizing service life and preventing premature, costly failures.

- Next Step:Implement the preventive maintenance schedule outlined in our operator's handbook to extend hammer life.

Further Reading

- Applications & Case Studies: See practical examples of DTH in granite and marble quarries.

- Selection Guide: A detailed comparison of DTH vs. top-hammer and an If-Then selection tree.

- Operation & Maintenance: Access checklists and troubleshooting tables to maximize uptime.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский