Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Is a manual stone cutter right for you? This implementation guide covers requirements, pilot planning, decision gates, and improving quarry productivity.

TL;DR: Key Takeaways for Decision-Makers

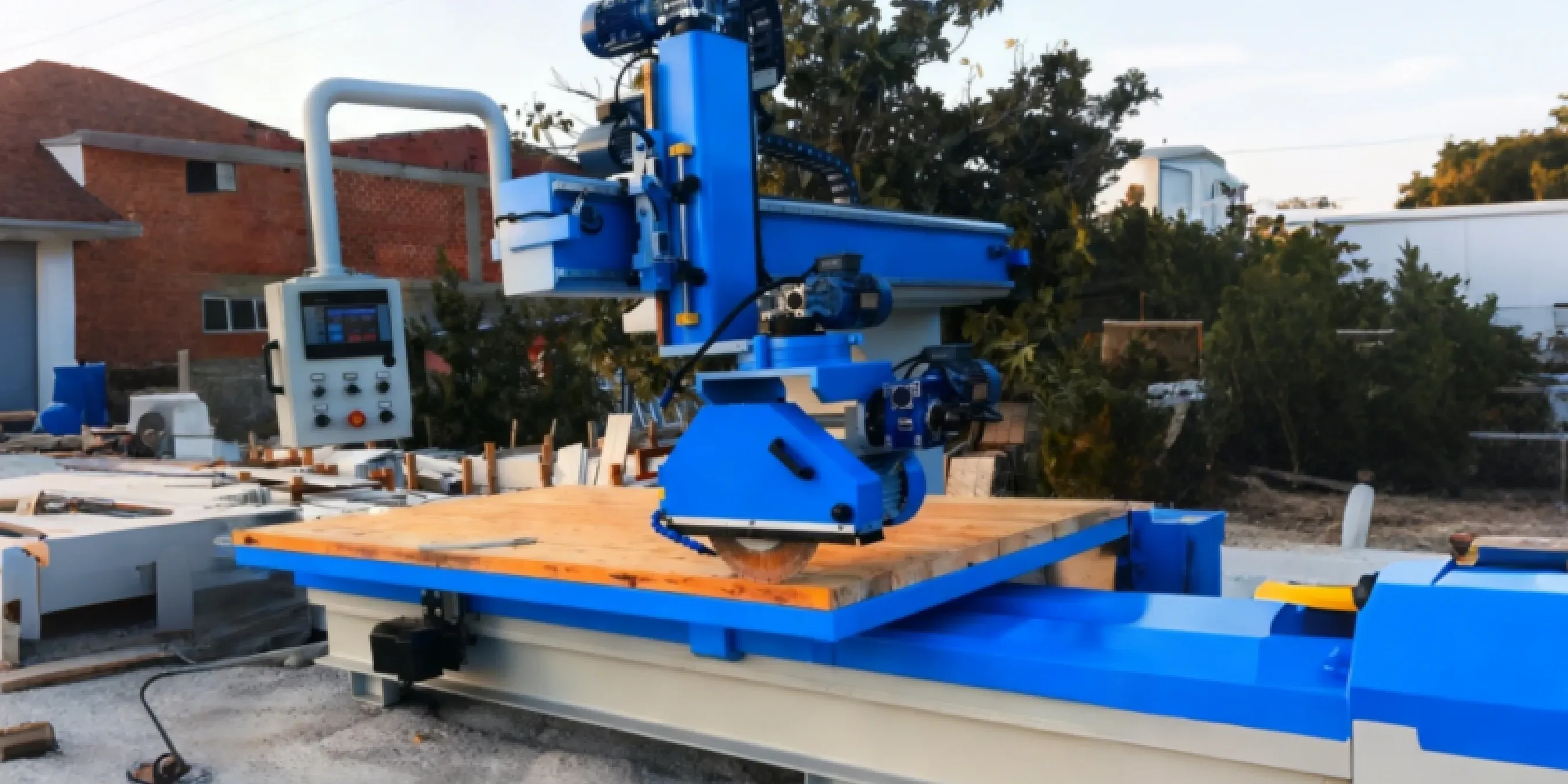

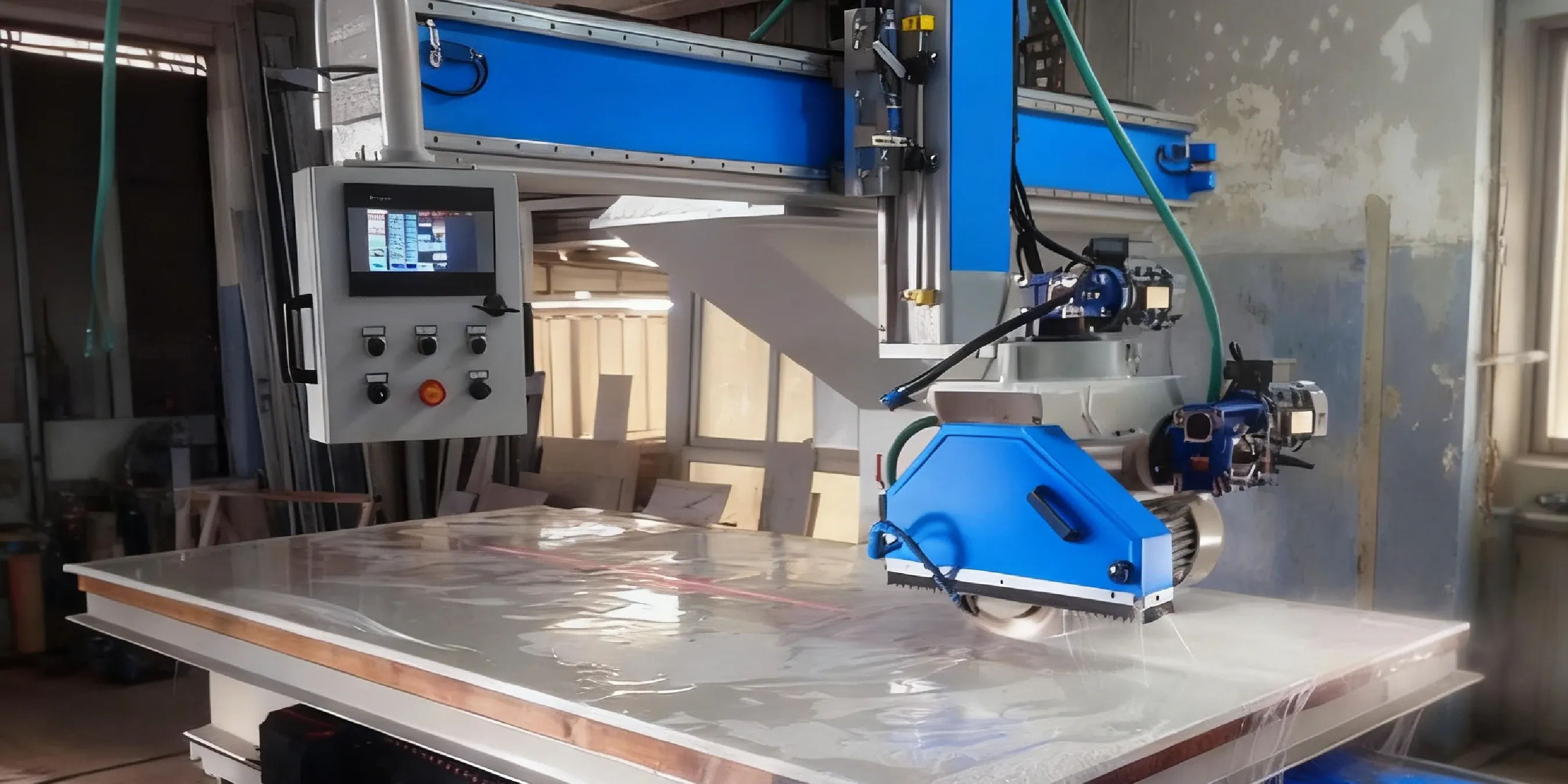

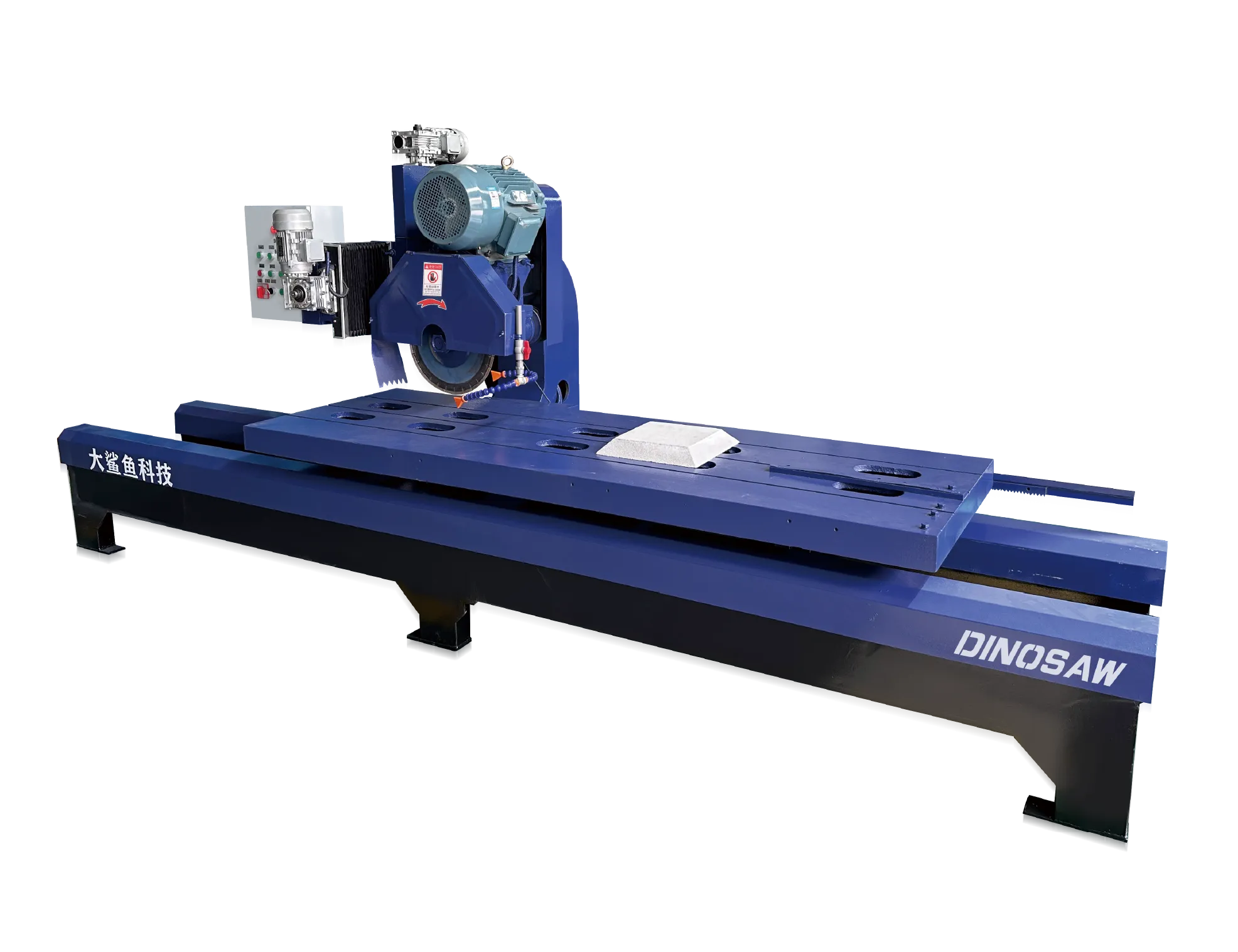

- What It Is:A manual industrial stone cutting machine designed for high-precision straight cuts and 45° chamfers on stone slabs.

- Value Proposition: Delivers a lower Total Cost of Ownership (TCO), rapid deployment, and repeatable edge quality for core products like kitchen countertops, vanities, and panels.

- Fit vs. Not a Fit:It is the ideal fit for small-batch, standard geometries. It is not designed for complex curves or 3D shapes, which are better suited for an Automatic Bridge Saw (CNC/PLC). For very thick blocks or large radius curves, a wire saw machine is the specialized tool.

- Next Step: Confirm your needs with the requirements checklist, then run a structured 2-week pilot with measurable acceptance metrics to validate performance and ROI.

Your Requirements Checklist: manual industrial stone cutting machine specs

- Materials & Geometry :

- Primary materials: Granite, Marble, Quartz, Slate.

- Core operations: Straight edge cutting, 45° chamfering.

- Slab types: Thin slabs (e.g., backsplashes) and thick slabs (e.g., countertops).

- Max Cutting Size: Up to 3000×1200×180 mm (approx. 118×47×7 in).

- Blade Diameter: Supports Φ350–Φ600 mm.

- Precision & Finish :

- Edge quality: Minimal to no chipping.

- Angle consistency: ≤0.5° deviation on chamfers.

- Dimensional tolerance: ≤±1 mm on length/width.

- Cycle Time & Batch Size :

- Batch profile: Primarily one-off jobs and small batches.

- Target improvement: Increase cycle time efficiency by 20–30% on standard cuts.

- Interfaces & Space :

- Worktable Size: 2700×800 mm or 3000×800 mm.

- Electrical: Industrial three-phase power (380V/440V) available.

- Fixturing: Requires mechanical clamps and positioning jigs.

- Data: Basic status monitoring via workshop PLC is possible where applicable.

- Safety & Compliance :

- Dust suppression: Water cooling system must provide 2–3 m³/h.

- PPE: Operators must use N95/FFP2 respirators, safety glasses, hearing protection, and steel-toed boots.

- Regulatory: Must support compliance with OSHA 1926.1153 and NIOSH REL of 0.05 mg/m³ for silica.

- Quality standard: Manufactured under ISO 9001:2015 certified processes.

Selection Quick View: manual stone edge cutter vs automatic bridge saw

- Manual Stone Edge Cutter: Wins on speed and cost for straight cuts and 45° chamfers. Its simplicity means rapid deployment and low TCO. The main limitation is its unsuitability for complex curves.

- Automatic Bridge Saw (CNC/PLC): Wins on complex geometry, high-volume production, and repeatability. It's the go-to for nested cutting and intricate designs. The trade-off is higher deployment and maintenance costs. Wins on complex geometry, high-volume production, and repeatability. It's the go-to for nested cutting and intricate designs. The trade-off is higher deployment and maintenance costs.

- Waterjet Cutter: Wins on intricate shapes and multi-material cutting without a heat-affected zone. It is significantly slower and more expensive for standard straight cuts and bevels.

- Wire Saw Machine: Wins on cutting thick blocks, large-radius curves, and 3D contours that saws cannot handle. It is not optimized for high-speed processing of thin slabs.

Your 5-Step Pilot Plan

- Scenario Definition: Select three representative jobs: a marble countertop edge, a quartz backsplash panel, and a granite curb stone. Define the material, dimensions, and required finish for each.

- Data Collection: For each job, baseline and then measure key metrics: dimensional tolerance, angle deviation, edge chipping rate, and total cycle time (setup to completion).

- Success Thresholds: Define clear, measurable acceptance criteria. Examples: dimensional accuracy within ±1mm, angle deviation ≤0.5°, a significant reduction in chipping, and a 20–30% improvement in cycle time for standard tasks.

- Two-Week Timeline:

- Week 1: Parameter tuning and SOP finalization. Work with operators to find optimal feed rates and blade choices for each scenario.

- Week 2: Batch validation and review. Run small batches for each scenario to confirm repeatability and collect final data.

- Cross-Functional Review: Convene stakeholders from engineering, quality, safety, and purchasing to review the pilot data. Formulate a "production-ready" conclusion and identify any remaining action items.

Navigating the Decision Gates

Technical Gate

- Capability confirmed (max cutting size, blade diameter Φ350–Φ600, power).

- Fixturing and clamping plan is viable.

- Quality inspection process and standards are defined.

Commercial Gate

- TCO model is approved (including consumables, maintenance, energy).

- Delivery timeline and Service Level Agreement (SLA) meet requirements.

- Spare parts list and availability are confirmed.

Legal & Compliance Gate

- OSHA/NIOSH dust control measures are documented.

- CE/ISO 9001:2015 certifications are verified.

- Safety training records plan is in place.

Executive Approval Gate

- ROI analysis and risk assessment are approved.

- The investment aligns with the company's long-term capacity planning.

Contract & Delivery Checklist

- Scope and Specifications: Explicitly list the machine model (e.g., SYQJ-600ZB), included components (main motor, worktable size), and all optional features.

- Delivery Timeline: Define the Ex-Works/FOB date and estimated arrival, including any penalties for delays.

- Installation and Training: Specify the scope of on-site or remote installation support and the duration of operator training.

- Warranty Terms: Detail the warranty period for both parts and labor.

- Service Level Agreement (SLA): Document response times for support requests and escalation paths for critical issues.

- Spare Parts and Consumables: Attach a recommended spare parts list and confirm the supply process for consumables like blades.

- Compliance Documentation: Ensure the delivery includes all necessary compliance certificates (CE, ISO 9001) and safety manuals. According to OSHA 29 CFR 1926.1153, employers must maintain records of exposure control methods.

- Data and Reporting: Define requirements for logging maintenance, uptime, and pilot results. It's crucial to track metrics related to the NIOSH REL for respirable crystalline silica of 0.05 mg/m³. All processes should align with ISO 9001:2015 Quality management systems for continuous improvement.

Implementation & Training

- Site Prep: Ensure the floor is level and the three-phase 380V/440V electrical connection is installed by a qualified professional.

- Systems Check: Commission the water cooling circuit (2–3 m³/h) and inspect all safety guards and emergency stops.

- Core SOP Training: Train operators on guide rail lubrication, the 45° calibration procedure, and safety protocols, including PPE usage and lockout/tagout.

- Parameter Starting Points (To Be Validated in Trial Cuts):

- Soft Stone (Marble): Use a fine-tooth blade, a gentle feed rate, and 2–3 m³/h water flow.

- Hard Stone (Granite): Use a medium-to-coarse grit blade, a slow feed rate, and multiple shallow passes.

- Thin Slabs: Use a thin-kerf blade, ensure full slab support with clamps, and perform a strict 45° calibration.

Post-Sales & Service Level Agreement (SLA)

- Support Channels: Access to technical support via email, phone, and on-site visits as defined in your SLA.

- Response Times: SLAs typically define response windows, such as a 4-8 hour remote response for critical failures.

- Escalation Path: A clear procedure for escalating unresolved issues to senior engineers or management.

- Annual Maintenance Package: Optional packages for comprehensive annual inspections to maintain peak performance.

- Spare Parts Availability: Guaranteed turnaround times for critical spare parts to minimize downtime. For detailed specifications and support options, visit the product page for the Manual Industrial Stone Cutting Machine.

Four-Link Summary

- Applications & Case Studies: See real-world examples of how the machine handles granite countertop edges, marble chamfers, and quartz panels.

- Technical Principles: Understand the engineering behind its precision, including its cast iron frame, oil-immersed guide rails, and 45° chamfer control.

- Selection & Comparison: Use our decision tree to compare the manual cutter against CNC, infrared, and waterjet systems for your specific job mix.

- Operation & Maintenance: Access detailed SOPs, troubleshooting flows, and preventive maintenance schedules to maximize uptime and safety.

Frequently Asked Questions (FAQ)

Is this Manual Industrial Stone Cutting Machine the right fit for our product mix?

- Context: The SYQJ-600 is optimized for speed and low TCO on high-volume, low-complexity tasks. It excels where CNC programming time is not justified.

- Benefits: You gain rapid deployment, operational flexibility for one-off jobs, and a reliable machine with a simple maintenance schedule.

- Next Step: Analyze your job history and see if this machine aligns with your core business. Contact us for a suitability assessment.

What key requirements should we define before selection?

- Context: This data ensures the machine's technical specifications, from its worktable size to its power, match your operational reality.

- Benefits: A clear requirements list prevents purchasing an under- or over-specified machine and serves as the basis for your pilot plan's success metrics.

- Next Step: Use the requirements checklist in this guide to prepare your specification sheet, then request a technical consultation.

How do we design a pilot and set acceptance criteria?

- Context: A successful pilot proves the machine's value with hard data, making the final purchasing decision easy for all stakeholders.

- Benefits: It de-risks the investment by confirming the machine meets your quality and efficiency standards before a full-scale rollout.

What decision gates should our team set before purchasing?

- Context: These gates ensure that engineering, purchasing, legal, and management all approve the key aspects of the acquisition, from TCO to safety compliance.

- Benefits: This structured process prevents oversights and ensures all departments are aligned, leading to a smoother implementation.

- Next Step: Use our decision gates checklist to structure your internal review meetings and review the machine specifications.

Which contract and delivery terms matter most?

- Context: These terms protect your investment by defining exactly what you will receive, when you will receive it, and what level of support you are entitled to.

- Benefits: A well-defined contract minimizes ambiguity and provides clear recourse if issues arise with delivery or performance.

- Next Step: Contact DINOSAW to discuss post-sales support options and tailor SLA terms to review with your legal and purchasing teams.

How do we ensure our manual stone cutter operation is compliant and safe?

- Context: Compliance with standards like OSHA and NIOSH for silica dust is non-negotiable. The machine's design aids compliance, but operational discipline is essential.

- Benefits: A strong safety culture protects your team, reduces liability, and ensures uninterrupted operations.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский