Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A complete guide for managers on CNC diamond wire saws. Covers evaluation, implementation, ROI, risks, and how to get started with a pilot program.

The 30-Second Briefing

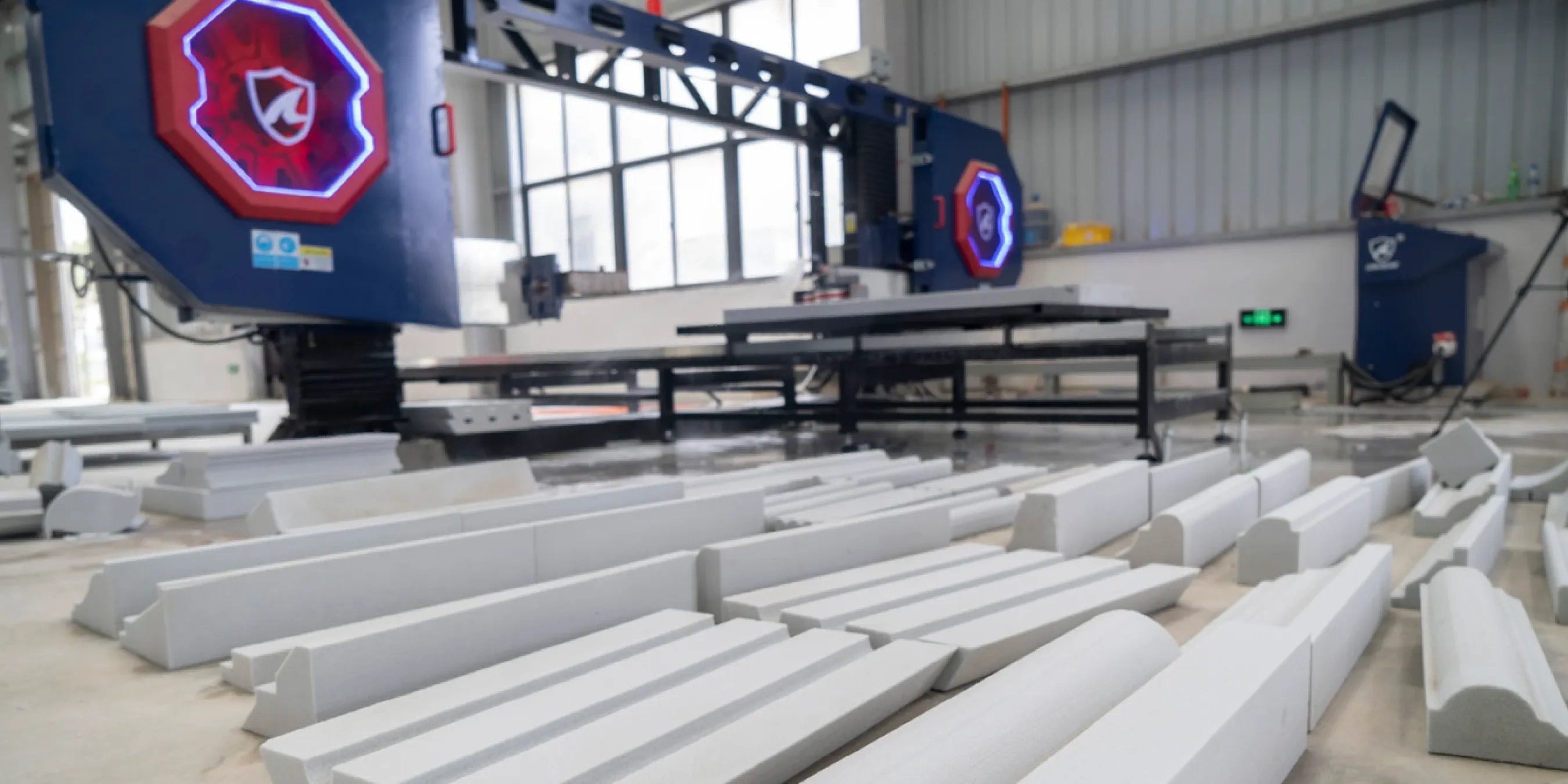

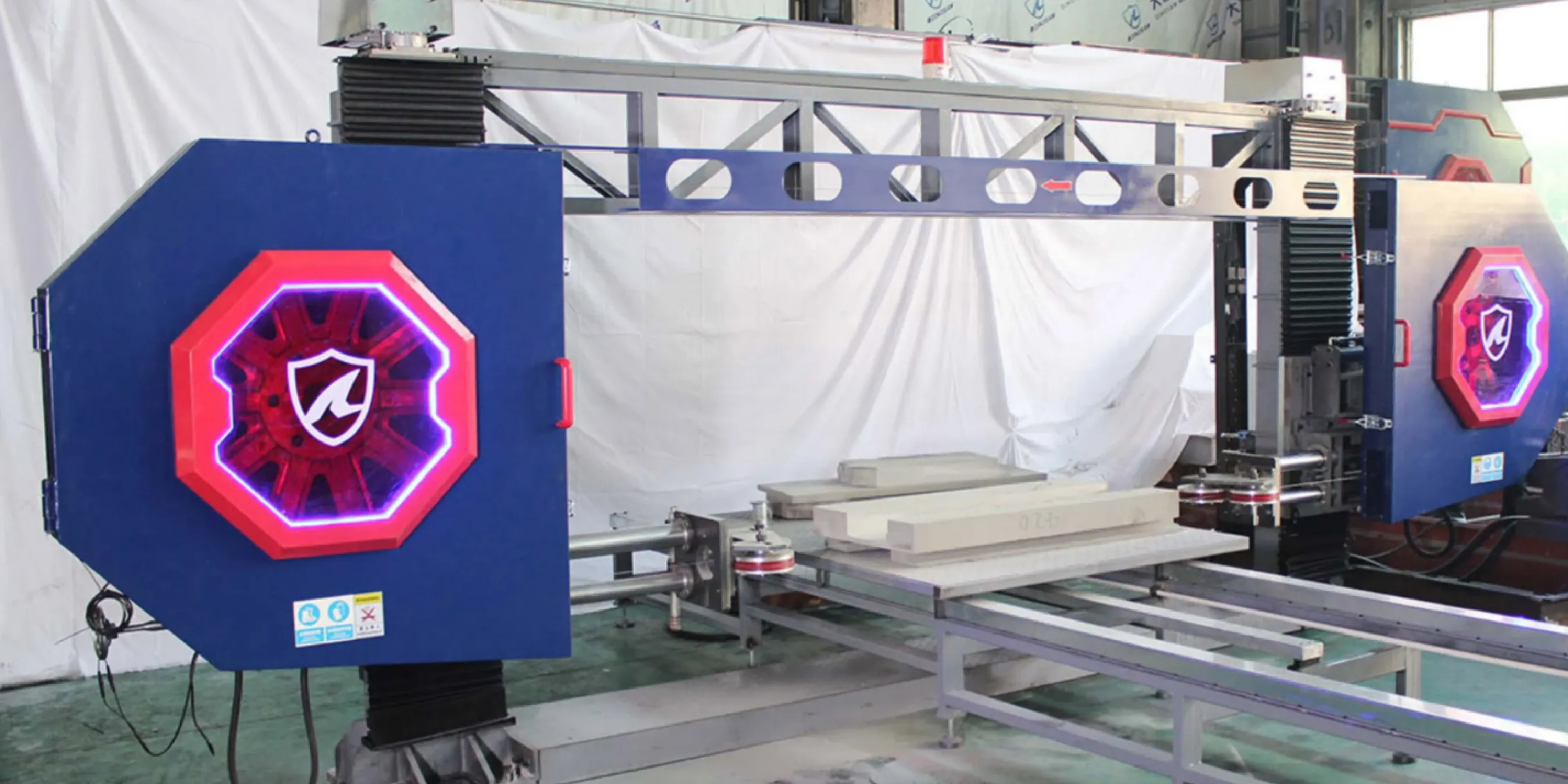

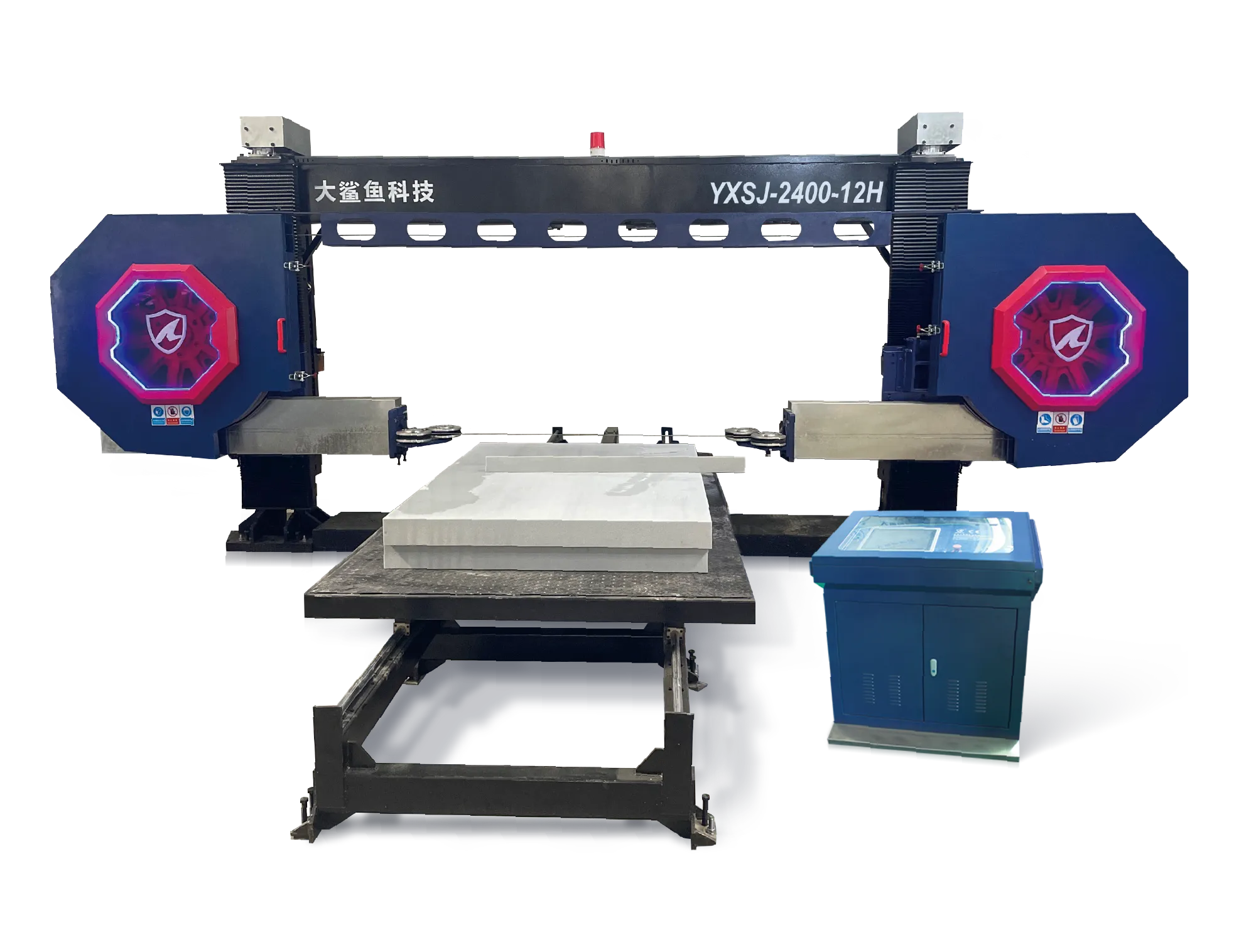

- What it is: An cnc diamond wire saw cutting machine for high-precision, low-waste cutting of fragile materials like foamed ceramics.

- Why you need it: To unlock new design possibilities, reduce material waste, and improve production efficiency.

- Where it fits: Ideal for complex geometries, prototyping, and high-value material processing where traditional methods fail.

- How to proceed: Review the evaluation checklist in this guide and contact our team for a technical assessment and TCO analysis.

Quick Q&A: Procurement for CNC Diamond Wire Saw Cutting Machine Foamed Ceramics

Stage 1: Awareness & Evaluation

- Q: What business problem does this solve?It solves three core problems: high material waste from inefficient cutting (improving yield), inability to produce complex designs (unlocking new revenue streams), and poor quality from material damage (reducing scrap rates and rework costs).

- Q: What is the typical ROI?For shops processing high-value ceramics, ROI can be achieved in 12-24 months. This is driven by direct savings from reduced kerf loss (up to 15% better material yield) and labor savings from automation, plus the added margin from producing high-value, complex parts.

Stage 2: Comparison & Approval

- Q: How does the TCO compare to a waterjet?While the initial purchase price might be comparable or lower, the TCO analysis for a wire saw is significantly more favorable. It avoids the high operational costs of waterjets, such as expensive high-pressure pump maintenance, garnet abrasive consumption, and complex water treatment systems, leading to lower long-term expenses.

- Q: What are the key decision gates we need to pass?Approval typically requires a technical sign-off (validating performance via a pilot), a commercial sign-off (approving the TCO and ROI analysis), a safety/compliance review, and final executive approval based on the strategic business case.

Stage 3: Implementation & After-Sales

- Q: What resources are needed to implement this technology?Implementation requires adequate facility space with a stable foundation, sufficient power, a mandatory dust collection system, and trained personnel. We provide comprehensive training for operators and maintenance staff to ensure a smooth transition and rapid ramp-up.

- Q: What does long-term support look like?Our support model includes defined Service Level Agreements (SLAs) covering remote diagnostics, on-site service response times, and guaranteed availability of critical spare parts. This ensures maximum uptime and protects your investment for its entire lifecycle.

Requirements Checklist for Ceramic Cutting Machine (porous ceramic blocks)

Requirement Area | Checkable Condition | Example Range / Target |

|---|---|---|

Materials | Primary materials to be cut? | e.g., Alumina foam, SiC foam, Porous Zirconia |

Geometry | Are complex curves or 3D shapes required? | e.g., Yes, require 5-axis capability. |

Precision | What is the required dimensional tolerance? | e.g., +/- 0.5mm |

Cycle Time | What is the target throughput? | e.g., 20 parts per 8-hour shift. |

Interfaces | Does it need to integrate with CAD/CAM or ERP systems? | e.g., Yes, must accept DXF files and provide production data. |

Space | What is the available machine footprint? | e.g., 6m x 4m x 3m (L x W x H) |

Safety & Compliance | Is a dedicated dust extraction system in place? | e.g., Yes, must connect to central HEPA system. |

Decision Gates: ROI/TCO Approval for CNC Stone Cutting Machine Foamed Ceramics

Technical Sign-off

- Confirm performance via a pilot project or test cut on your material.

- Verify maintenance requirements with your facilities team.

Commercial Sign-off

- Present a detailed TCO and ROI analysis.

- Secure budget approval from the finance department.

Legal & Compliance Sign-off

Legal & Compliance Sign-off

- Review warranty, SLA, and contract terms.

- Confirm machine meets all local safety and environmental regulations.

Executive Sign-off

- Submit the final business case, highlighting strategic benefits.

- Gain final approval from C-level leadership.

Contract & Delivery for CNC Diamond Wire Saw

- Final Quotation: Ensure it includes the machine, all optional accessories, shipping, installation, and training costs.

- Payment Terms: Clarify the payment schedule (e.g., 50% on order, 40% on delivery, 10% on commissioning).

- Delivery & Installation Timeline: Get a firm schedule for ex-factory date, shipping time, and on-site installation.

- Training Plan: Define the scope, duration, and location of operator and maintenance training.

- Safety Compliance Documentation: Confirm that the machine will be delivered with all necessary compliance certificates, particularly regarding electrical safety and adherence to the OSHA silica standard.

- Service Level Agreement (SLA): The SLA should be an appendix to the contract, detailing support response times and spare parts availability, referencing best practices from sources like the NIOSH guidelines for engineering controls.

- Acceptance Criteria: Define the objective criteria (e.g., successful cutting of a specific test part) that must be met for final sign-off and payment.

Selection Speed-Read: Wire Saw vs Waterjet

Selection Speed-Read: Wire Saw vs Waterjet

- vs. Blade Saws: The wire saw wins on precision and material savings. Its ultra-low kerf cutting minimizes expensive material waste, and the low-stress abrasive process prevents the micro-cracks and chipping common with high-impact blades, resulting in higher quality parts.

- vs. Waterjets: The wire saw wins on operational cost and reduced water ingress. It avoids the high TCO of waterjets (pumps, abrasives). While wire saws typically use water cooling, the controlled flow is less aggressive than a high-pressure jet, reducing the risk of deep water absorption into porous ceramics which can compromise the final part's structural properties.

Pilot Program: Validate CNC Diamond Wire Saw for Foamed Ceramics

- Define Success Criteria: Set clear, measurable goals (e.g., "achieve a dimensional tolerance of +/- 0.5mm on three consecutive parts").

- Provide Material & Designs: Send us samples of your most challenging foamed ceramic and the CAD files for the parts you need to cut.

- Receive Test Parts & Report: We will cut your parts and provide a detailed report on the parameters used, cycle times achieved, and final part quality for your internal evaluation.

Installation, Training & After-Sales: Complete Guide

- Installation & Commissioning: A certified technician will manage the complete on-site installation, including mechanical assembly, electrical hookup, final calibration, and executing a site acceptance test (SAT) to verify performance.

- Operator & Maintenance Training: We provide two distinct training tracks—one for operators focusing on machine operation and CAD/CAM workflow, and another for maintenance staff covering preventative tasks and basic troubleshooting.

- Documentation & Resources: You will receive a complete documentation package, including operation manuals, maintenance schedules, and access to our online portal for parameter libraries and software updates.

- Warranty & Service Level Agreements (SLA): Standard warranty covers parts and labor, with optional premium SLAs available for guaranteed faster response times and extended support hours.

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)

How long does installation and commissioning take?

- Context: Duration depends on machine size, power hookup, and site preparation.

- Procedure: Technician performs mechanical setup, electrical connections, calibration, and SAT.

- Next Step: Confirm site readiness checklist before scheduling to avoid delays.

What training modules are included and how long?

- Context: Two tracks ensure both production and upkeep competency.

- Procedure: Classroom + hands-on sessions with your parts; remote refreshers available.

- Next Step: Define trainee list and preferred schedule when booking installation.

Can training be delivered on-site and remotely?

- Context: On-site delivers hands-on confidence; remote supports continuity.

- Procedure: Use video sessions and shared parameter libraries for remote.

- Next Step: Ask your coordinator to add a remote follow-up to the service plan.

What is included in standard vs premium SLA?

- Context: SLA tiers balance cost and uptime needs.

- Procedure: Choose response windows (e.g., next business day vs same-day) and spare parts kits.

- Next Step: Align SLA tier with production criticality and budget.

How are spare parts stocked and shipped?

- Context: Minimizes downtime for pulleys, wires, sensors, and belts.

- Procedure: Maintain an on-site kit for consumables; reorder via portal or service desk.

- Next Step: Build a min/max parts plan with our team.

What is the escalation path for critical downtime?

- Context: Ensures rapid resolution for production-stopping issues.

- Procedure: Provide error codes, logs, photos/video to speed diagnostics.

- Next Step: Add escalation contacts to your SOP and maintain a current service contract.

Do you provide wastewater/slurry treatment solutions?

- Context: Wire saws typically use water cooling producing slurry.

- Procedure: We can propose screens/settling/filter systems sized to your throughput.

- Next Step: Request a facilities consultation if needed.

How are software updates and parameter libraries delivered?

- Context: Keeps CNC and presets current for new materials.

- Procedure: Follow release notes; perform backups before applying updates.

- Next Step: Schedule quarterly checks to keep configurations current.

Further Reading: CNC Stone Cutting Automation & Guides

- See what it does:See Practical Applications & Case Studies

- Learn how it works:Dive into the Core Technology

- Weigh your options:Compare it with Other Machines

- Plan for uptime:Review the Maintenance & Troubleshooting Guide

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский