Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

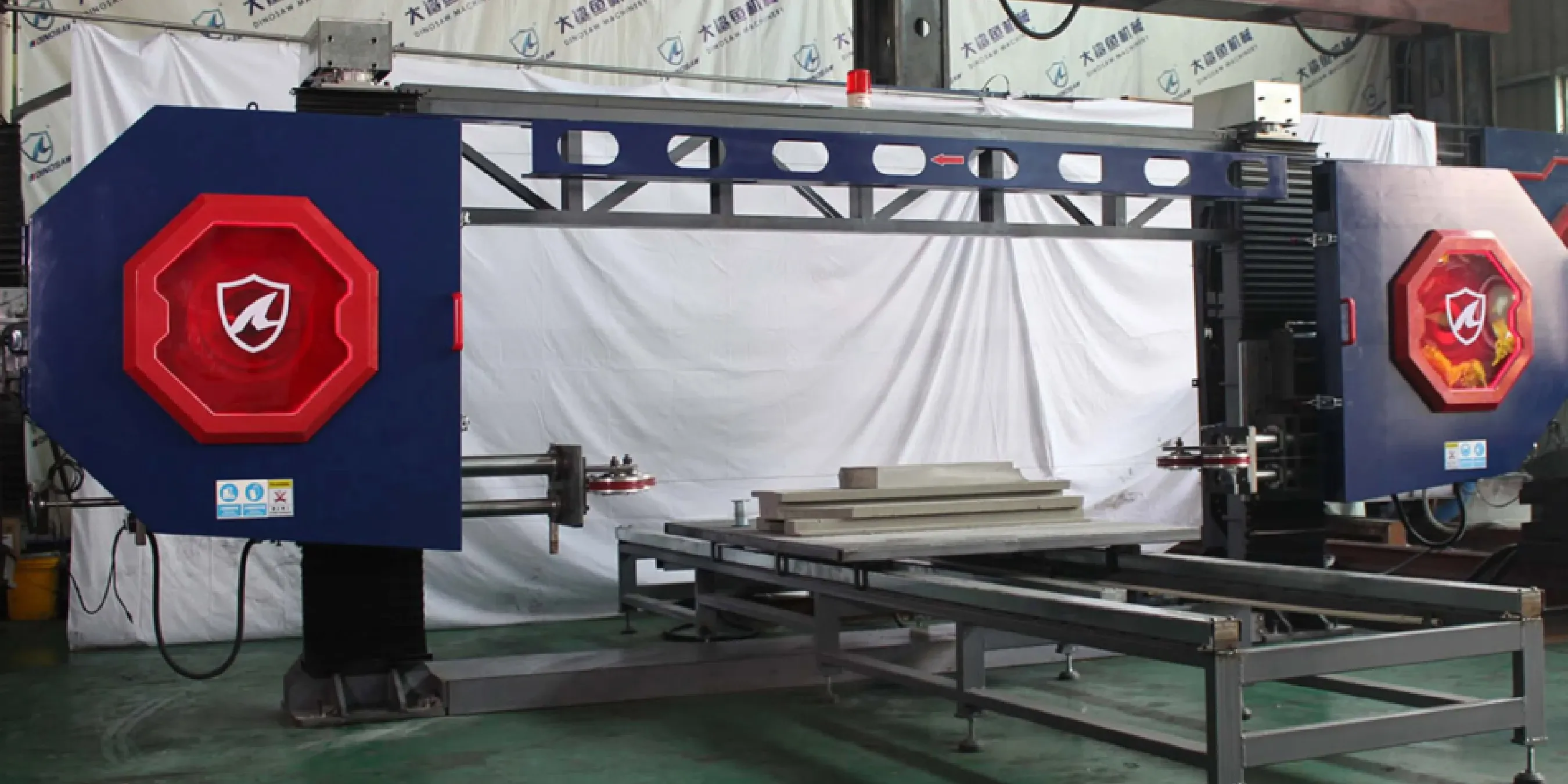

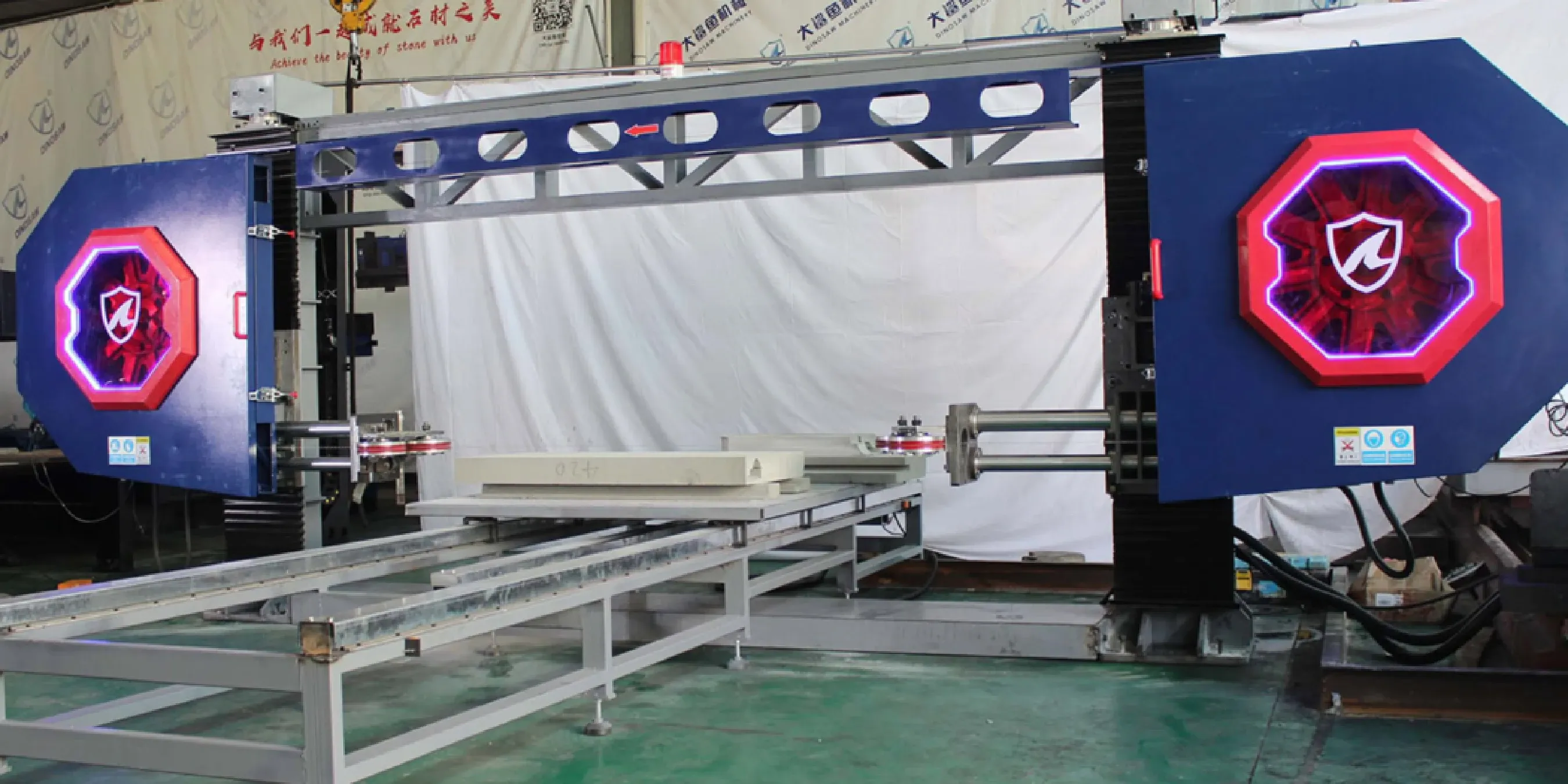

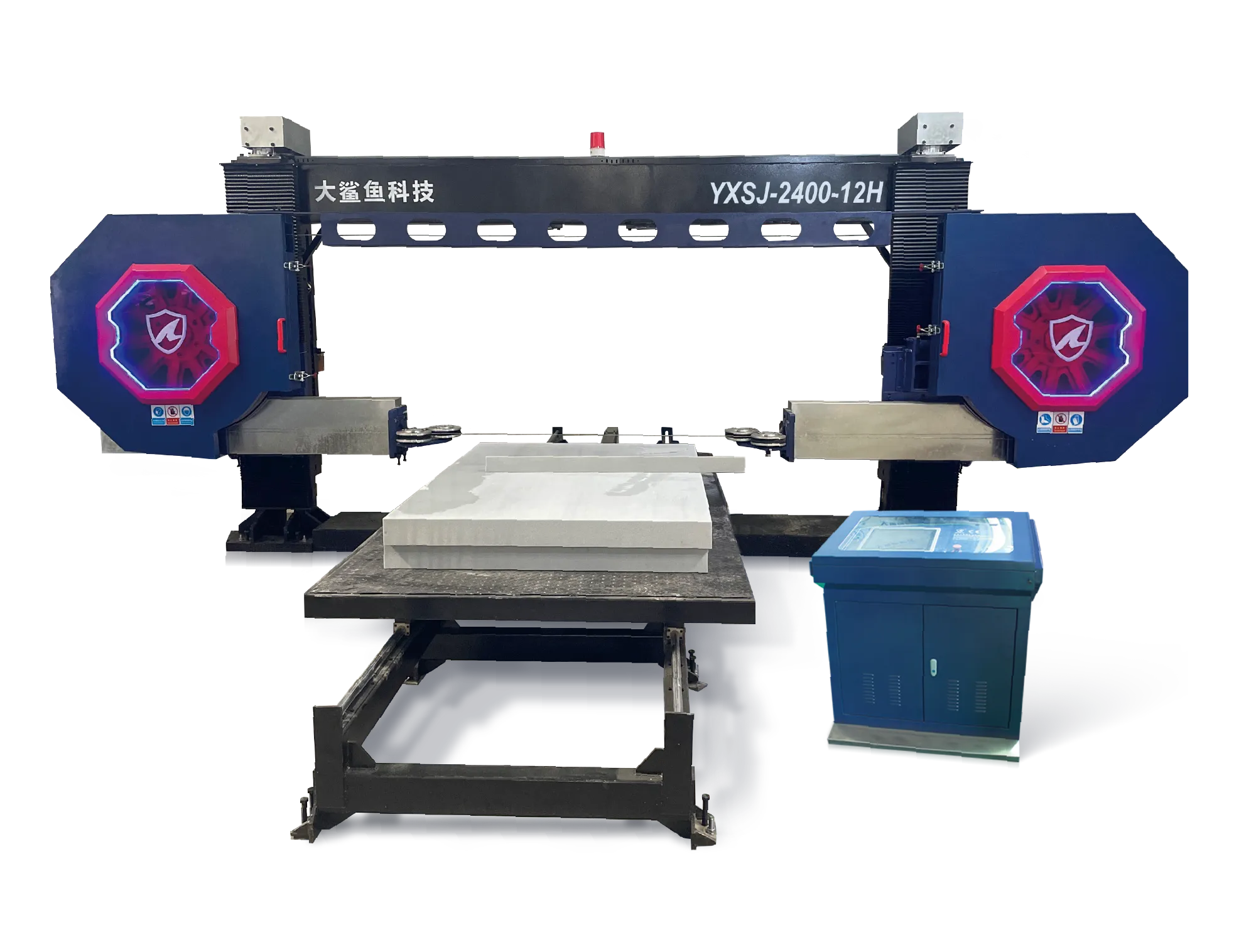

Explore the engineering principles of our CNC diamond wire saw. Learn about the architecture, core components, and technical advantages for cutting fragile materials.

TL;DR: Key Technical Advantages

- Low-Stress Abrasive Process: Unlike blades that apply high force, the Diamond Wire Saw Cutting Machine uses abrasion to slice material. This is the core diamond wire saw principle, preventing micro-cracks and subsurface damage in brittle ceramics.

- Sub-Millimeter Precision: The CNC system for cutting, combined with a stable machine architecture, allows for repeatable accuracy under 1mm, enabling complex designs.

- Automated & Efficient: Full CNC control over cutting parameters like wire speed, tension, and feed rate ensures optimal performance, minimal waste, and reduced need for constant operator supervision.

Precision Abrasion: The Core of CNC Diamond Wire Saw Technology

What Exactly is a CNC Diamond Wire Saw

System Principles & Architecture: How It All Works Together

System Principles & Architecture: How It All Works Together

System Architecture Overview

Module | Role | Connections | Notes |

|---|---|---|---|

CNC Controller | Central control, executes G-code and manages IO | Connects to Servo Motors (X/Y/Z/A/C), Wire Drive System, Automatic Tensioning Unit, Workpiece Table sensors | Provides closed-loop control and parameter management |

Servo Motors (X, Y, Z, A, C) | Positioning for multi-axis motion | Controlled by CNC; feedback via encoders to CNC | Enables complex 2D/3D paths |

Wire Drive System | Drives the diamond wire loop | Receives start/stop/speed commands from CNC; mechanical link to Guide Pulleys | Houses wire speed actuator |

Guide Pulleys | Guide and stabilize wire path | Mechanical interface with Wire Drive System; monitored by CNC via sensors | Co‑planarity critical to accuracy |

Automatic Tensioning Unit | Maintains constant wire tension | Receives target tension from CNC; feedback sensor to CNC | Prevents breakage and wandering |

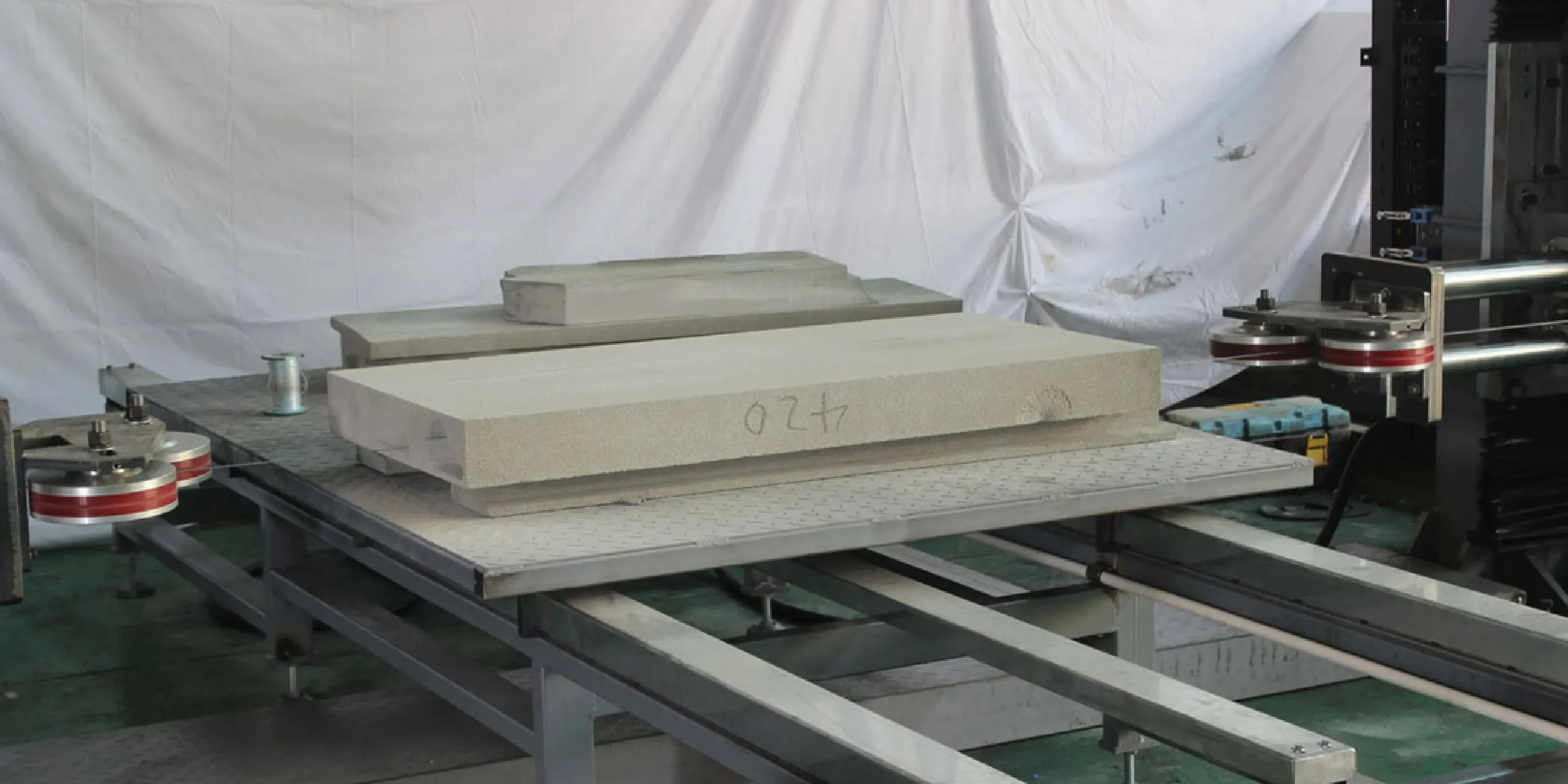

Workpiece Table | Secures workpiece fixturing | Receives clamp/interlock signals to CNC; may integrate probing sensors | Rigid, vibration‑damped foundation |

Cooling & Slurry Management | Water cooling and slurry capture | Interlocks to CNC for flow status; interfaces with sump/pump | Default water‑cooling; manage slurry flow |

Safety & Interlocks | E‑stops, guards, limit switches | Hardwired to CNC safety IO | Must be active for motion enable |

Power & Drives | Power distribution and motor drives | Supplies servo amplifiers and auxiliary systems | Sized to machine envelope |

CNC Diamond Wire Sawing Core Technical Advantages: Low Kerf Cutting & No Micro-Cracks

- Precision & Automation: The closed-loop control between the servo motors and the CNC system allows for real-time position correction, achieving sub-millimeter accuracy. Once a program is loaded, the machine can run with minimal intervention, ensuring consistency across hundreds of parts. This is a key advantage of modern CNC stone cutting automation.

- Low Kerf & Minimal Waste: Kerf, or the width of the cut, is directly related to the diameter of the cutting tool. With a diamond wire diameter often under 2mm, the kerf loss is significantly less than that of a 5mm or thicker blade saw. For expensive materials like zirconia foam, this reduction in waste translates directly to cost savings.

- Minimal Micro-Cracks: The primary advantage for foamed ceramic properties is the avoidance of subsurface damage. Studies, such as those on diamond wire sawing of sapphire and silicon, confirm that the abrasive mechanism generates far less mechanical stress than impact-based cutting. This prevents the formation of microcracks that compromise the material's strength, a critical factor in technical ceramics. For example, research published in Engineering Fracture Mechanics highlights how subsurface damage is a key indicator of cutting quality.

5 Key Components & Parameters

5 Key Components & Parameters

1. Diamond Wire

- Types: Electroplated (for softer materials), Sintered (for hard, abrasive ceramics).

- Diameter: 0.55mm to 2.5mm. Thinner wire for finer cuts, thicker for durability.

- Diameter: typically 3–4 mm for foamed ceramic line cutting; specialty finer or thicker wires may be used for specific materials and geometries.

2. Guide Pulleys

- Material: Hardened steel or ceramic-lined for wear resistance.

- Alignment: Must be perfectly co-planar to prevent wire twisting.

3. Automatic Tensioning System

- Mechanism: Typically pneumatic, hydraulic, or spring-loaded systems that compensate for wire stretch.

4. CNC Control System

- Compatibility: Supports standard G-code and DXF files from CAD/CAM software like AutoCAD, SolidWorks, or Rhino.

5. Cooling and Dust Control

- Cooling Options: Water cooling is standard. It effectively manages heat and flushes out slurry. However, for highly porous materials, the process must account for potential water absorption and subsequent drying steps. In special cases, air blow or minimal mist may be used. A vacuum shroud for dust/slurry extraction is mandatory for compliance with OSHA standards.

Common Failure Modes & Mitigation in CNC Diamond Wire Sawing

Common Failure Modes & Mitigation in CNC Diamond Wire Sawing

Failure Mode | Likely Cause | Mitigation Strategy |

|---|---|---|

Frequent Wire Breakage | Incorrect wire tension (too high/low); excessive feed rate; worn guide pulleys. | Calibrate tensioning system; reduce feed rate; inspect and replace pulleys. |

Poor Surface Finish | Wire vibration; incorrect wire speed; wrong diamond grit for the material. | Check pulley alignment; adjust wire speed; use a finer grit wire. |

Dimensional Inaccuracy | CNC calibration drift; loose workpiece clamping; mechanical backlash. | Run CNC calibration routine; ensure workpiece is secure; check machine for mechanical wear. |

Compatibility: PLC/OPC UA/Profinet for CNC Stone Cutting Automation

Recommended Starting Parameters for Foamed Ceramic Cutting

Material | Wire Speed | Feed Rate | Tension |

|---|---|---|---|

Alumina Foam | typically 12–20 m/s | commonly 300–800 mm/min | around 160–220 N |

Silicon Carbide (SiC) Foam | typically 10–18 m/s | commonly 200–600 mm/min | around 180–240 N |

Porous Zirconia | typically 10–16 m/s | commonly 180–500 mm/min | around 190–250 N |

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)

How is wire tension measured and controlled?

- Context: Consistent tension is vital for cut accuracy and preventing wire breakage. The system applies a constant force to a pulley on a movable slide, compensating for any wire stretch during operation.

- Procedure: An electronic sensor provides real-time feedback to the CNC controller, which adjusts the tensioner to maintain the programmed value (e.g., 200N) throughout the entire cut.

- Next Step: Ensure the tension value in the cutting parameters is set according to the wire manufacturer's specification for the material you are cutting.

What is the difference between an electroplated and a sintered diamond wire?

- Context: Electroplated wires have a single layer of diamonds bonded to the core. They are less expensive but have a shorter lifespan. Sintered wires have diamonds mixed into a metal matrix that is fused to the core, exposing new diamonds as the wire wears.

- Procedure: Use electroplated wires for softer, less abrasive materials or for short-run jobs where cost is a primary concern. Use more durable sintered wires for hard, abrasive ceramics like SiC or for long production runs.

- Next Step: Consult our materials compatibility guide or speak with a technician to select the most cost-effective wire for your specific application.

How critical is the cooling system for cutting foamed ceramics?

- Context: Water cooling is typical for both foamed ceramics and stone. It effectively removes heat from the wire and workpiece, prolongs wire life, and suppresses hazardous dust by creating a manageable slurry.

- Procedure: Ensure a consistent flow of water is directed at the cutting point. The system should capture the resulting slurry for proper filtration and disposal, preventing environmental contamination and maintaining a clean work area.

- Next Step: For highly porous materials, factor in a post-cutting drying stage into your workflow. If water absorption is a critical issue, discuss alternative cooling options like specialized coolants with the manufacturer.

Can the machine’s axes be upgraded later?

- Context: Some models are designed with a modular framework that allows for the future addition of a rotational axis (A/C axis) or a tilting head. Others have a fixed architecture where such an upgrade is not feasible.

- Procedure: An axis upgrade is a significant modification that involves both new hardware and software integration. It is not a simple bolt-on addition.

- Next Step: If you anticipate needing more axes in the future, it is critical to discuss this during the initial purchase consultation to ensure you select a machine with an upgrade path.

What does ‘subsurface damage’ mean in the context of cutting ceramics?

- Context: SSD is caused by the mechanical and thermal stress of the cutting process. In technical ceramics, this damage can compromise the finished part's mechanical strength and long-term reliability, even if it's not visible.

- Procedure: Low-stress methods like diamond wire sawing are used to minimize SSD. The abrasive action grinds away material gently, unlike the high-impact force of a blade, which is why it is the superior method for cutting critical ceramic components.

- Next Step: When evaluating cutting technologies, consider not just the surface finish but also the impact on subsurface integrity, as detailed in academic papers like this one from MDPI.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский