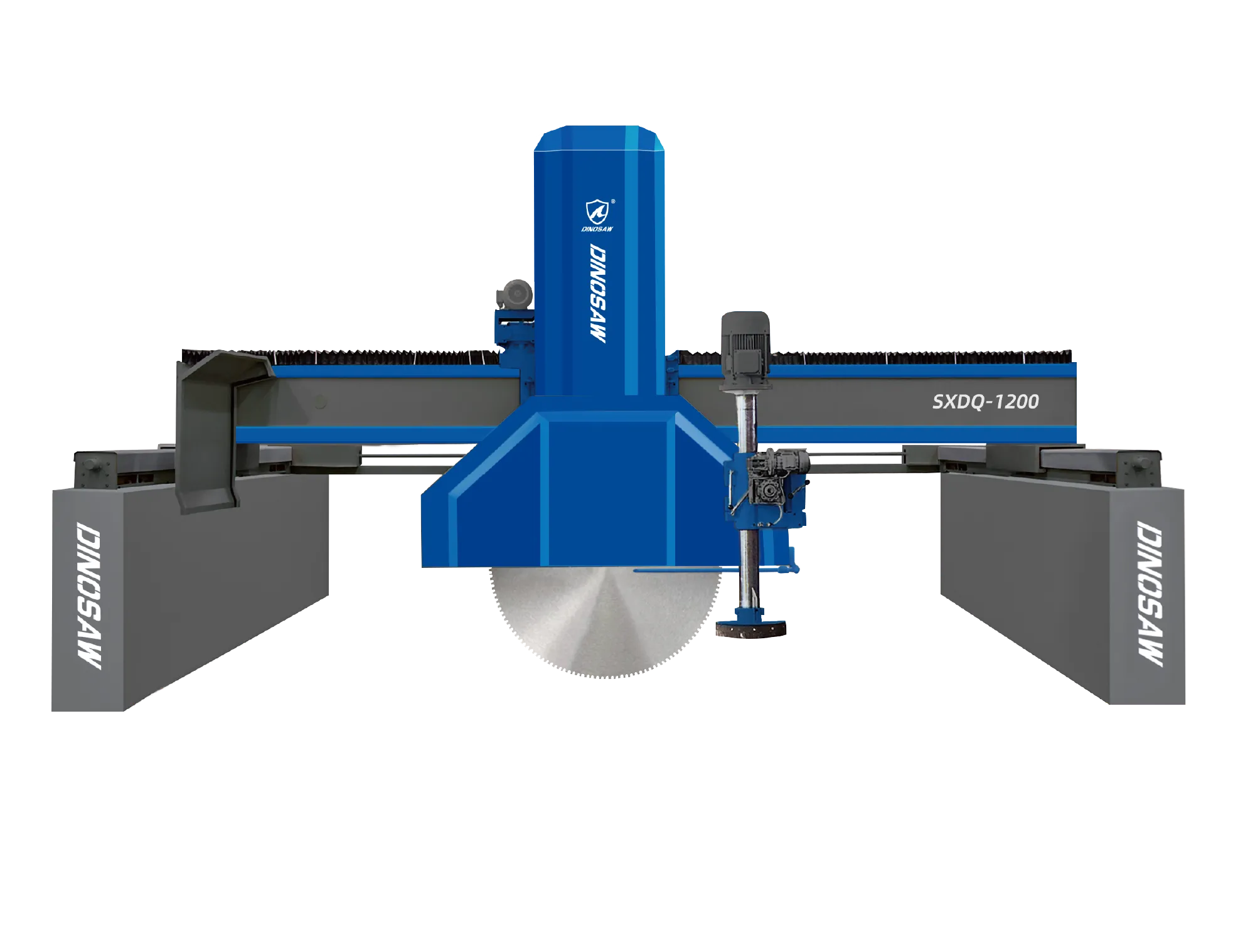

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

This guide covers the investment points, a 90-day qualitative pilot plan, and a decision matrix for adopting a dual-blade stone cutter for granite slab and kerb stone production.

TL;DR: The Business Case

- Core Value Proposition: Transitions your workshop from a slow, labor-intensive, stop-and-go process to a continuous, automated, and high-throughput production line.

- Primary Use Case: Ideal for factories focused on high-volume, standardized products like slabs, panels, and kerb stones, where it removes the primary production bottleneck.

- Decision Framework: This Stone Block Cutter with Horizontal Blade Machine is a strategic investment in efficiency and scalability. It's chosen when maximizing output and reducing labor dependency outweighs the need for universal flexibility.

Executive Summary: The Strategic Advantage

Executive Summary: The Strategic Advantage

Decision Matrix: Key Performance Indicators (Qualitative)

Factor | Dual-Blade Block Cutter | CNC Bridge Saw | Manual/Single-Blade Saw |

|---|---|---|---|

High Throughput | Excellent | Fair | Poor |

High Precision | Excellent | Excellent | Poor |

Automation | High | High | Low |

Safety | Excellent | Good | Poor |

Footprint | Large | Medium | Small |

90-Day Qualitative Pilot Program

Go/No-Go Checklist (Qualitative)

- Safety & Compliance: Have all safety protocols been successfully implemented and consistently followed by the team?

- Operational Readiness: Can operators run the machine independently without frequent supervision or unplanned downtime?

- Quality Evidence: Does the machine consistently produce slabs and blocks that meet our quality standards for finish and dimensional accuracy?

- Integration & Scheduling: Does the output of the block cutter feed smoothly into the next stage of production (e.g., bridge saw) without creating new bottlenecks?

- Stakeholder Sign-Off: Do the production manager, safety officer, and lead operator all agree that the machine is a valuable and effective addition to the workflow?

Your Next Step: A Complete Resource Hub

Executive FAQ: Key Investment Questions

What’s the key difference between a dual-blade block cutter and a single-blade saw?

- Context: A single-blade saw requires the operator to cut, stop, flip the entire heavy block, and then cut again to separate a slab. This is slow, labor-intensive, and hazardous.

- Procedure: The dual-blade machine automates this. Its synchronized vertical and horizontal blades cut and separate the slab in a single, continuous pass. The block never needs to be flipped.

- Next Step: Review the comparison table in the Buyer's Guide to see a direct feature-by-feature breakdown.

Can the same machine handle both granite and marble consistently?

- Context: Granite is extremely hard and requires high motor power and a blade with a softer bond to expose new diamonds. Marble is softer but more fragile, requiring a smoother cutting action to prevent fractures.

- Procedure: The high-power motor and rigid frame provide the stability for granite. For marble, the operator adjusts the feed rate and blade speed via the PLC to ensure a less aggressive, smoother cut. Blade segments must be swapped for optimal performance.

- Next Step: Consult the Technical Principles guide for details on material-specific parameter settings.

How does water recycling impact operating costs and compliance?

- Context: A block cutter can use a large volume of water (e.g., 20 m³/h) for cooling and dust suppression. Discharging this slurry-filled water is often regulated and costly.

- Procedure: A recycling system filters the stone particles (slurry) out of the water, allowing the clean water to be pumped back to the machine. The collected slurry can be disposed of as a semi-solid waste, which is often easier and cheaper to manage.

- Next Step: Before purchasing, investigate local environmental regulations for water discharge and slurry disposal. Request information on integrating a water recycling system with the machine.

What are the footprint and power requirements for a large dual-blade block cutter?

- Context: Space, foundation, and electrical capacity determine installation viability.

- Procedure: Verify site dimensions, prepare a level reinforced concrete foundation, confirm three-phase power and adequate water supply for wet cutting.

- Next Step: Request a site readiness checklist and a pre-install survey from the vendor.

Can the block cutter share production data with our ERP/MES?

- Context: Cycle status, alarms, and job parameters improve scheduling and OEE tracking.

- Procedure: Enable OPC UA/Modbus TCP on the PLC, map tags for cycle times and statuses, test connectivity with your MES sandbox.

- Next Step: Ask for a data points list and integration guide before purchase.

What does operator training and onboarding involve?

- Context: Consistency and safety depend on formal training, not informal shadowing.

- Procedure: Conduct classroom safety (CE/OSHA), hands-on PLC presets, blade change practice, daily/weekly checklists; run pilot batches with a trainer present.

- Next Step: Schedule a training calendar and keep signed attendance and competency records.

How is this block cutter different from other types without a horizontal blade?

- Context: Standard block saws or bridge saws make the vertical cut, but the slab remains attached at the bottom. This requires a time-consuming and often hazardous manual process to flip the heavy block for a separating cut, creating a major production bottleneck.

- Procedure: This machine uses synchronized blades. The large vertical blade cuts down, and the smaller horizontal blade immediately follows, cutting along the bottom to cleanly separate the slab in a single, continuous pass. This is ideal for producing strips, kerb stones, and slabs efficiently.

- Next Step: Review the technical diagram in the Core Technology guide to visualize how the synchronized blades create a continuous workflow.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский