Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

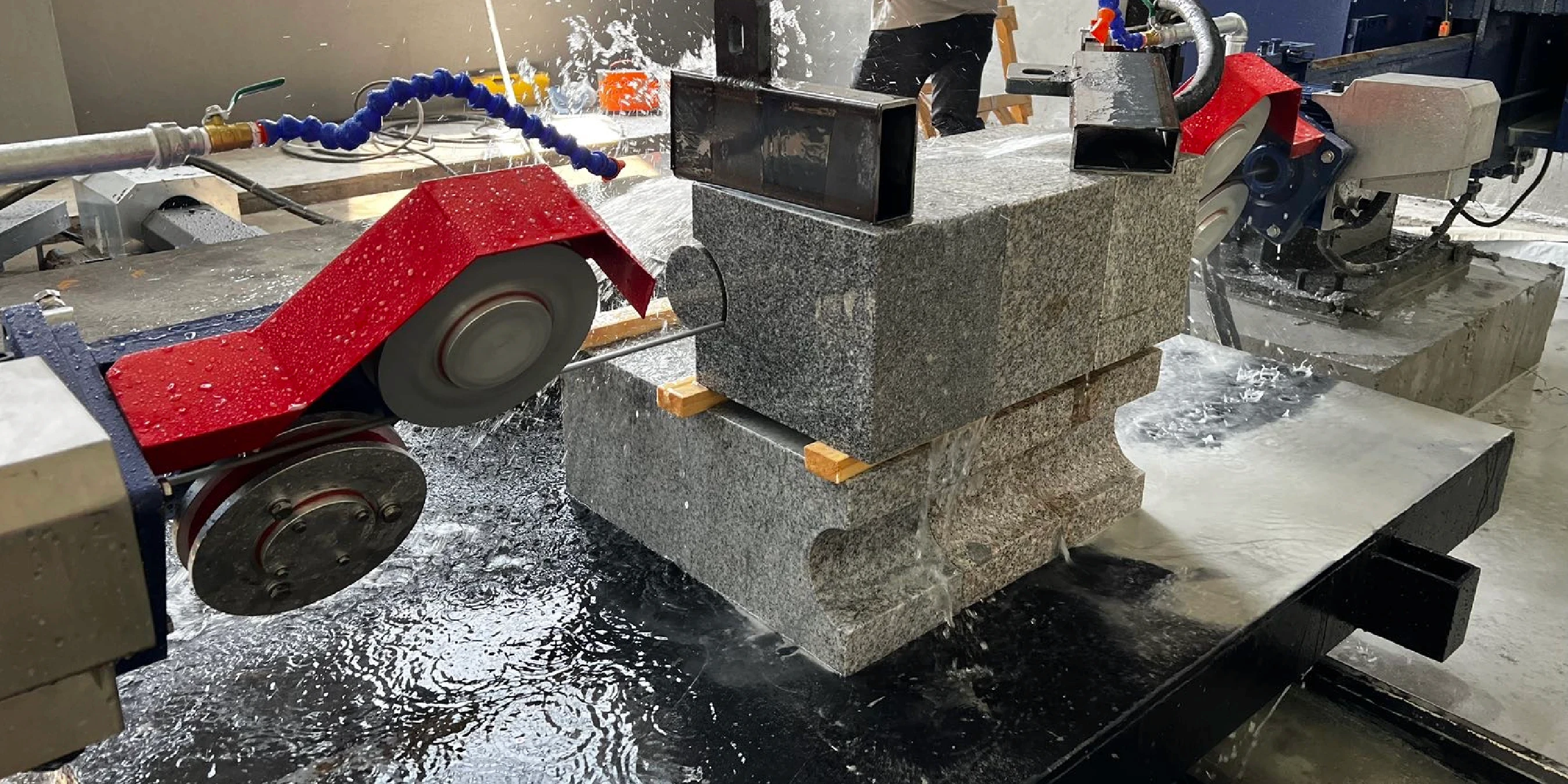

Keep your CNC wire saw running smoothly. This guide covers daily preventive maintenance, troubleshooting top issues, and safety compliance tips from industry pros.

What keeps CNC Wire Saw uptime high?

SOPs and daily checks prevent most alarms and wire breaks.

Guide wheel alignment, correct tension, and clean coolant stop defects.

Use the troubleshooting table + monthly calibration to stay within spec.

Ask for the O&M checklist adapted to your shop. See the full User Manual for CNC Wire Saw Machine .

Need a spare part or technical support? Contact our service team now for immediate assistance.

Standard Operating Procedures for CNC Wire Saw Operation

Consistency in your CNC wire saw operation is the foundation of safety and quality. Follow these SOPs for key daily tasks.

Startup Checklist: Before powering on, perform a visual inspection. Check for loose parts, ensure the work area is clear, verify coolant levels, and confirm the E-stop button is disengaged.

How to Replace Diamond Wire: Power down and follow Lockout/Tagout procedures. Release tension, carefully remove the old wire, and inspect guide wheels for debris or wear. Thread the new wire following the path specified in the manual, ensuring it is not twisted. Reengage the tensioning system and perform a slow test run.

Daily Calibration Checks: While a full calibration is periodic, quickly check the wire's home position and guide wheel alignment before the first cut of the day to ensure accuracy. Minor adjustments can prevent major errors.

Shutdown Procedure: Clean the machine of slurry and debris. Wipe down guide wheels and protective covers. Power down the controller and main electrical supply.

For first-time setup, a detailed guide on how to install a CNC wire saw machine is available for a step-by-step walkthrough.

Top 10 Issues: A Troubleshooting Flowchart

When issues arise, a systematic approach to CNC wire saw troubleshooting saves time and prevents further damage. Here are common symptoms and solutions.

Symptom | Potential Cause | Solution |

|---|---|---|

Frequent Wire Breakage | Incorrect tension, worn guide wheels, excessive feed rate. | Calibrate tension to spec. Inspect/replace wheels. Reduce cutting speed. |

Uneven Cuts / Poor Surface | Wire vibration, incorrect feed rate, worn wire. | Check tension. Adjust speed. Replace the diamond wire. |

"Tension Fault" Alarm | Hydraulic/pneumatic pressure loss, faulty sensor. | Check air/fluid lines and pressure. Test sensor. Reset alarm. |

Guide Wheel Not Rotating | Bearing failure, debris buildup in the groove. | Clean wheel grooves daily. Replace bearings if seized. See our guide on jammed wheels guide wheel jammed does not rotate solution for cnc wire saw. |

Excessive Vibration | Unstable workpiece, machine not level, worn motor bearings. | Securely clamp workpiece. Verify machine is level. Check motor for noise/play. |

Wire Slips on Flywheel | Flywheel/drive wheel contaminated with slurry; low wire tension; worn wheel lining. | Clean and dry the flywheel; increase tension within spec; replace or reline drive wheel. |

Wire Overheating / Discoloration | Insufficient coolant flow; excessive feed rate; clogged coolant nozzles. | Check pump and hoses; unclog/realign nozzles; reduce feed rate; verify coolant mix per manufacturer. |

Poor Coolant Flow / Pump Cavitation | Low coolant level; blocked filter; air leak on suction side; worn pump impeller. | Top up coolant; clean/replace filter; tighten fittings; service or replace pump. |

Axis Servo Following Error | Loose couplings; binding on linear guides; incorrect acceleration/jerk settings; encoder fault. | Inspect and tighten couplings; clean/lubricate guides; lower accel/jerk; run encoder diagnostics and replace if faulty. |

Door Interlock Open / Safety Trip | Interlock switch misaligned or failed; door not fully closed; wiring fault. | Realign or replace interlock switch; verify door closure; inspect wiring; clear alarm and test safety chain. |

A Preventive Maintenance Schedule

A proactive preventive maintenance schedule is the most effective way to ensure reliability. Adapt this checklist to your machine's manual and usage intensity.

Daily Checks

Clean slurry and debris from work area.

Inspect guide wheels for wear or damage.

Check coolant level and flow.

Wipe down all protective covers and sensors.

Weekly Checks

Check and top up CNC wire saw lubrication points.

Inspect diamond wire for even wear.

Verify tensioning system pressure.

Test all emergency stop buttons.

Monthly Checks

Perform guide wheels calibration. Follow our guide here Positioning Box Guide Wheel Calibration for CNC Wire Saw Machine.

Clean electrical cabinet filters.

Inspect all hydraulic hoses and electrical cables for wear.

Quarterly/Annually

Replace hydraulic fluid and filters.

Check motor bearings for noise or play.

Schedule a professional service and full machine geometry check.

Safety and Compliance: A Non-Negotiable Priority

Adhering to wire saw safety precautions and ensuring full safety compliance is critical. Failure to do so can result in serious injury or machine damage.

Machine Guarding: All moving parts, especially the wire path and drive system, must be fully enclosed. Interlock switches on access doors are mandatory. As per OSHA 1910.212, guarding must protect operators from hazards. The UK's HSE PUWER regulations enforce similar rules for safe work equipment.

Lockout/Tagout (LOTO): Before any maintenance, including changing a wire, the machine MUST be fully de-energized and locked out to prevent accidental startup.

Personal Protective Equipment (PPE): Safety glasses with side shields, steel-toed boots, and appropriate gloves are mandatory for all personnel in the machine area.

Coolant & Slurry Handling: Coolant can cause skin irritation. Slurry (the mixture of coolant and cutting debris) may contain sharp particles and must be handled and disposed of according to local environmental regulations.

Frequently Asked Questions for CNC Wire Saw O&M

How often should we replace the diamond wire?

The lifespan of a diamond wire is not fixed; it depends heavily on the material's hardness, the wire's grit and bond, and your operational parameters like tension and feed rate. A typical wire's life can range from a few hundred to over a thousand cutting meters.

Proactive replacement is key to preventing unexpected breakage. Monitor key performance indicators such as cutting speed, surface finish quality, and motor amperage draw. If you notice a significant drop in speed, a degradation in finish, or a consistent rise in current, it is time to replace the wire.

What alarm categories are most common and how should we respond?

The three most common alarm categories are wire tension faults, axis servo following errors, and safety circuit trips (like a door interlock being open). Each requires a different diagnostic approach.

For tension faults, immediately check the hydraulic or pneumatic pressure and inspect the sensor feedback. For servo errors, examine the mechanical system for any binding on linear guides and check motor couplings for looseness. For safety trips, the most common cause is a door not being fully closed or an interlock switch being misaligned.

It is good practice to keep the controller’s alarm list accessible and to log all incidents. This helps maintenance technicians spot recurring patterns that may indicate an underlying issue.

How do we diagnose and prevent sudden wire breakage?

udden wire breakage is almost always preventable and typically points to an issue with either parameters or machine condition. Start your diagnosis by verifying the wire tension is within the specified range for the job. Additionally, reduce the feed rate when cutting through particularly hard sections of material.

Next, inspect the condition of the guide wheels for wear and ensure the workpiece is securely clamped to minimize vibration. An unlevel machine can also introduce harmonic vibrations that stress the wire. Finally, clean the flywheel to prevent any slippage, which can cause sudden tension spikes.

The best prevention is proactive maintenance, including replacing aged wires before they reach their absolute end-of-life.

What daily startup and end-of-shift checks matter most for uptime?

A consistent daily routine is the simplest way to maximize uptime. At startup, the operator should perform a quick visual inspection for any loose fasteners, clear the work area of obstructions, verify coolant levels and flow, and confirm all E-stops are functional and accessible. Running a brief dry cycle can also help validate axis motion and sensor status before a live cut.

At the end of a shift, the focus should be on cleaning and handover. The operator should thoroughly clean slurry and debris from the machine, wipe down the guide wheels and protective covers, and properly power down the controller and main electrical supply.

Crucially, any issues or unusual behavior observed during the shift should be recorded in a logbook for a clear and effective handover to the next shift or to the maintenance team.

English

English 中文

中文 Italian

Italian Türkçe

Türkçe Português

Português Español

Español Deutsch

Deutsch العربية

العربية Tiếng Việt

Tiếng Việt Français

Français Русский

Русский